Hybrid FRP (Fiber Reinforced Plastics)-steel composite bar sea sand concrete beam

A technology of concrete beams and composite bars, applied in the directions of joists, girders, trusses, etc., can solve the problems affecting the bearing and service performance of FRP reinforced concrete members, restricting the promotion and application of FRP reinforced concrete members, excessive crack width and deflection, etc. problems, to achieve the effect of improving comprehensive mechanical properties, high elastic modulus, crack width and deflection mitigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

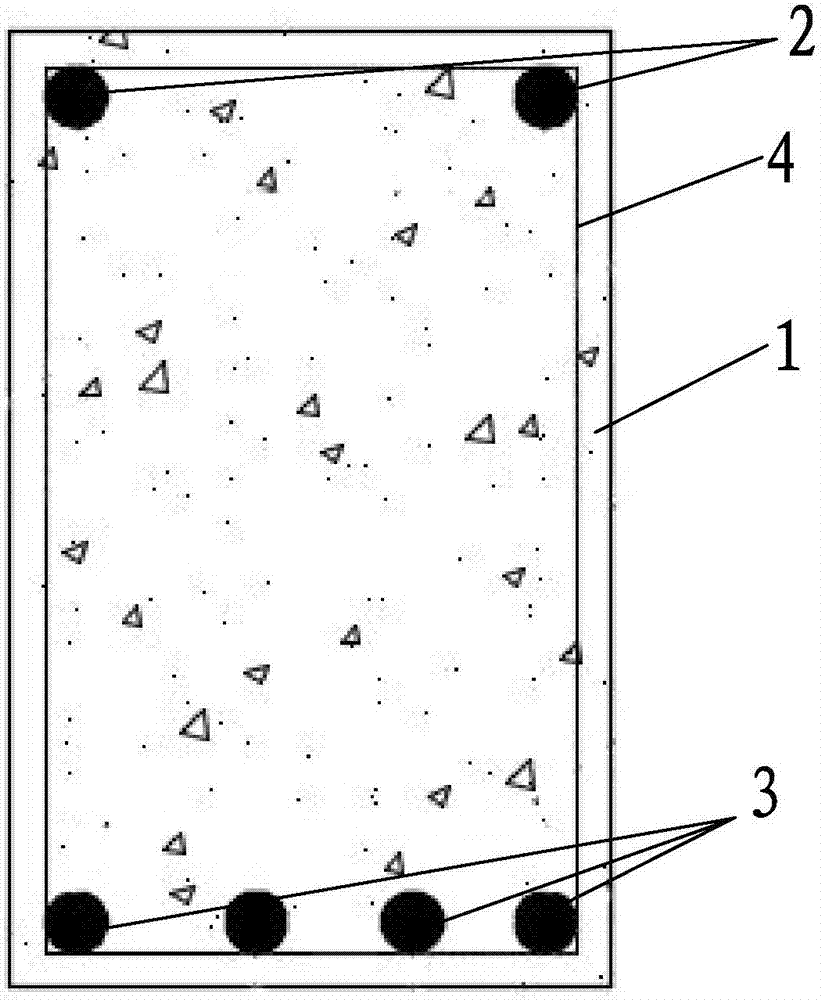

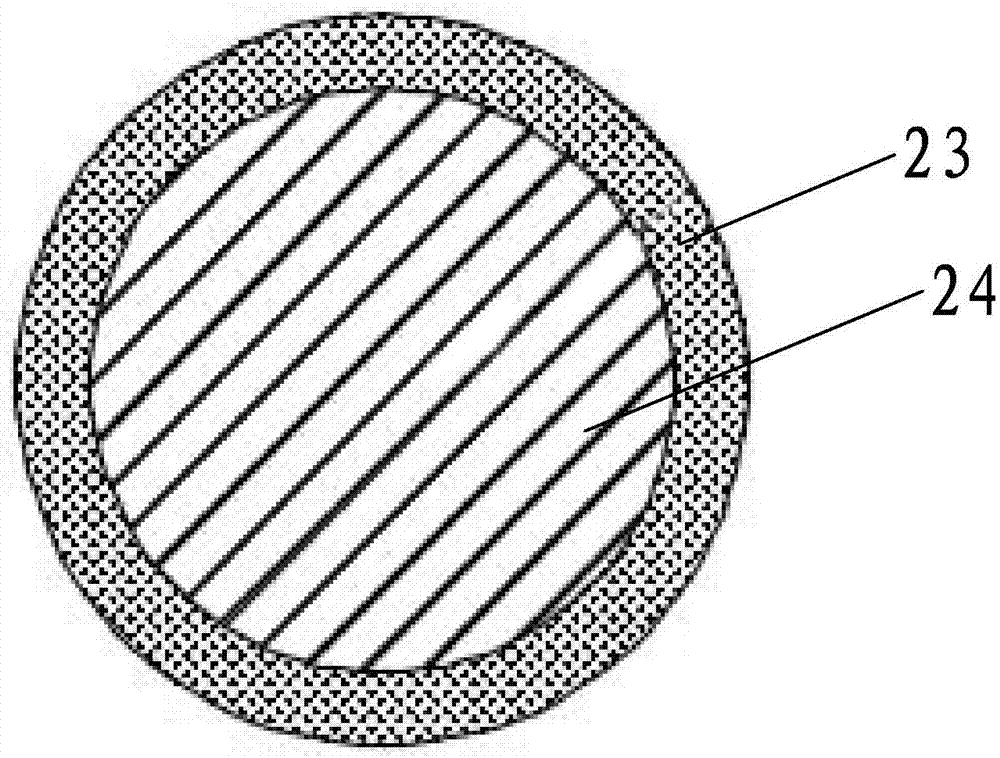

[0032] refer to figure 1 with image 3 , this embodiment relates to a sea-sand concrete beam, the cross-section of which can be rectangular, or T-shaped or box-shaped, which includes a sea-sand concrete 1 and an upper composite bar 2 and a lower composite bar 3 fixed in the sea-sand concrete 1 and stirrups 4, the stirrups 4 are set to a plurality, and are evenly fixed and bound on the outer surfaces of the upper composite ribs 2 and the lower composite ribs 3 along the length direction of the upper composite ribs 2 and the lower composite ribs 3; The upper composite reinforcement 2 and the lower composite reinforcement 3 are all set to a plurality, and are arranged on the upper end and the lower end of the sea-sand concrete 1 respectively; The FRP fiber cloth 23 on the outer surface of each upper composite rib 2 is the same material or different materials, and the FRP fiber cloth 23 of a plurality of lower composite ribs 3 adopts at least two kinds of materials, and the FRP ...

Embodiment 2

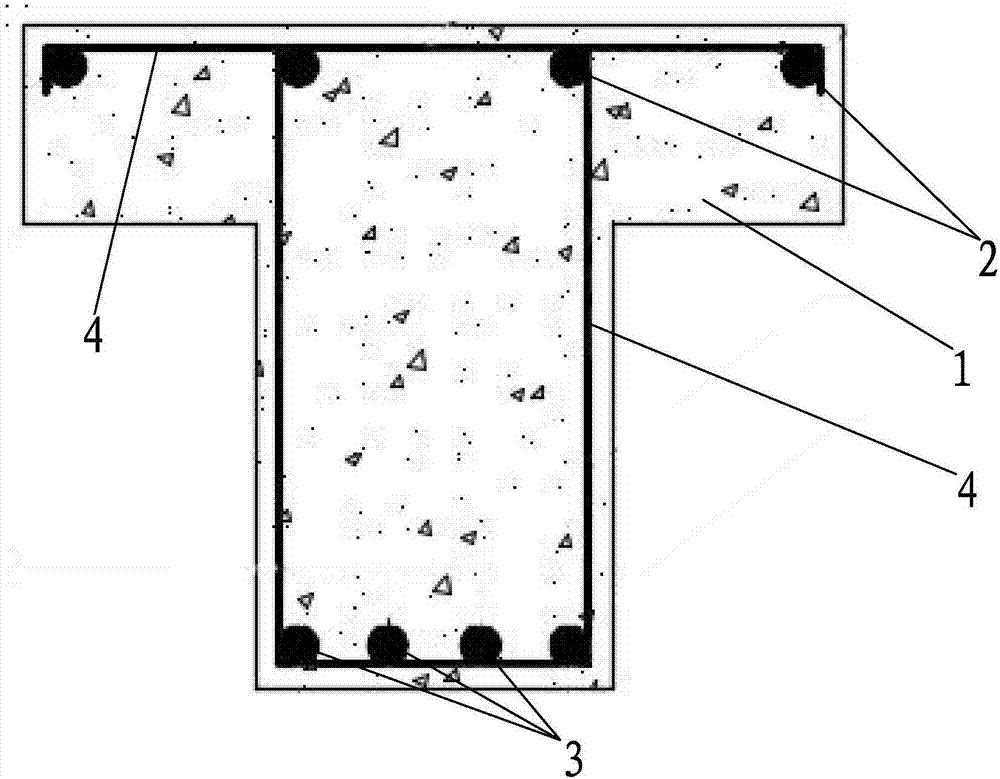

[0043] This embodiment is on the basis of Embodiment 1, as an improvement to the arrangement structure of the upper composite rib 2, as figure 2 As shown, the cross-section of the sea-sand concrete 1 is a T-shaped structure, and the upper composite bars 2 are set to be multiple, and evenly arranged on the top of the sea-sand concrete 1; the upper composite bars 2 are fixedly bound together by the stirrup 4, In addition, the upper compound bar 2 and the lower compound bar 3 are also fixedly connected together by the stirrup 4 . The upper composite bar 2 of this structure is bound alone through the stirrup 4 to form an integral bar structure, which greatly improves the ability of the upper composite bar 2 to withstand pressure.

Embodiment 3

[0045] This embodiment is on the basis of Embodiment 1, as an improvement to the arrangement structure of the lower composite rib 3, as Figure 4 As shown, the lower composite bars 3 are arranged in two rows, and the lower compound bars 3 are fixedly connected to the inner ring of the stirrup 4 . The structure adopts multiple rows of lower composite bars 3 as the supporting function, which greatly improves the tensile capacity of the concrete beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com