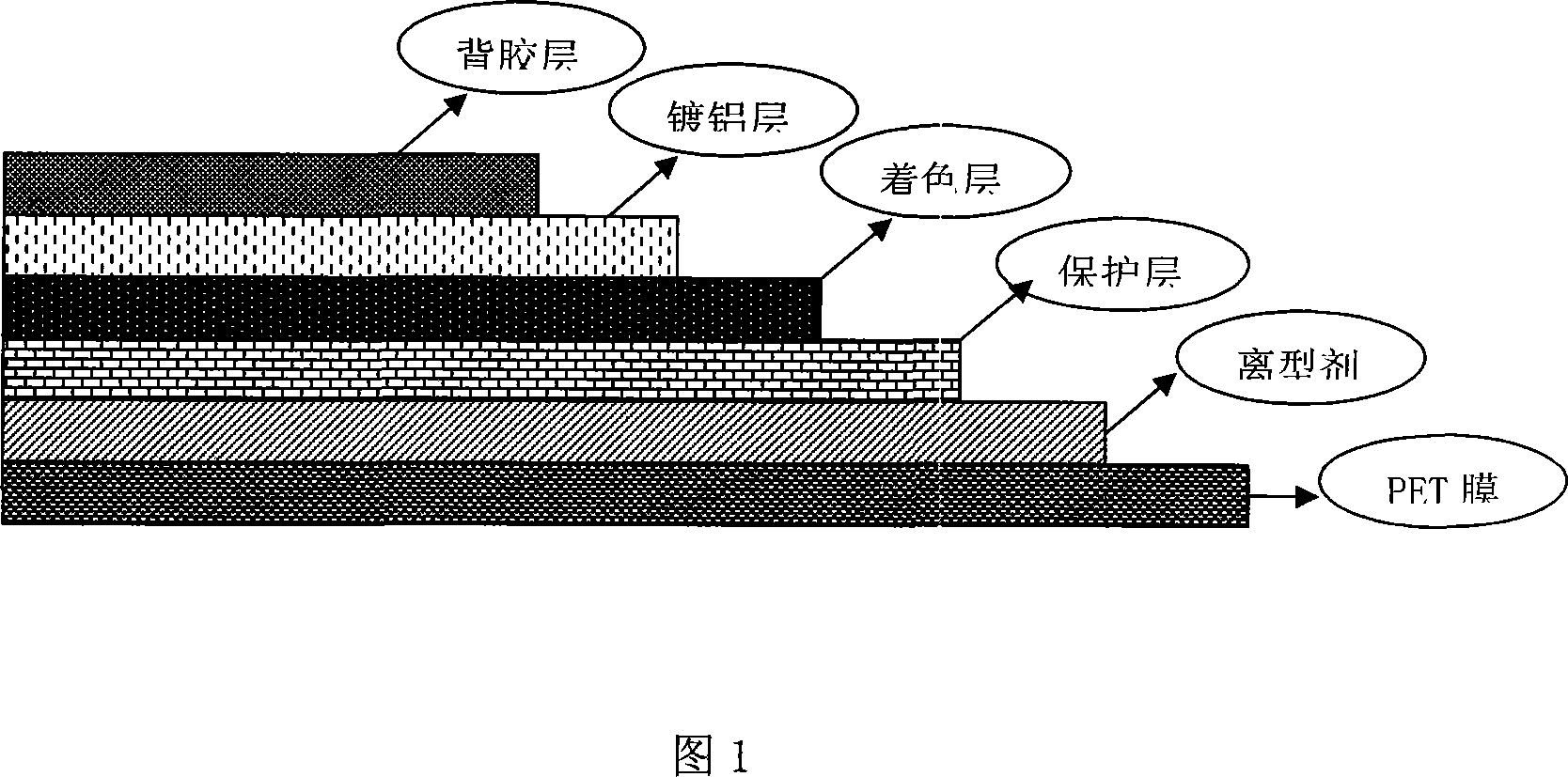

Coloring layer coating for leather full wiped film and preparation method thereof

A coloring layer and coating technology, which is applied in the field of coloring layer coatings and two-component polyurethane coatings, can solve the problems affecting the surface color effect of the full transfer film, affecting the surface effect of the transfer skin, separation of the aluminum layer and the coloring layer, etc., to achieve excellent durability Solvent corrosion resistance, excellent temperature resistance, excellent effect of solvent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Raw materials: main agent: hydroxy acrylic resin 221kg; curing agent: polyisocyanate resin 105kg; accelerator: nitrocellulose resin 326kg; yellow metal complex dye 32kg; coating additives: leveling agent 4kg, defoamer 3kg, Drier 6kg; butanone 350kg; butyl acetate 150kg.

[0036] preparation:

[0037] (1) add 221kg main agent hydroxy acrylic resin, 105kg curing agent and 326kg accelerator resin in stirring reactor;

[0038] (2) Then add 32kg yellow metal complex dye and 4kg leveling agent, 3kg defoamer, 6kg drier;

[0039] (3) Add 350kg butanone and 150kg butyl acetate solution at last, stir until the resin resin solution is fully dispersed;

[0040] (4) Stirring is stopped, and the material is discharged to obtain a coloring layer coating for leather full-transfer film, which is applied to the machine within 5 hours and coated.

[0041] In this way, a golden-yellow full-transfer film for leather is prepared, and then the prepared golden-yellow full-transfer film is b...

Embodiment 2

[0043] Raw materials: main agent: hydroxyacrylic resin 221kg; curing agent: polyisocyanate resin 105kg; accelerator: nitrocellulose resin 326kg; metal complex dye 0kg; coating additives: leveling agent 4kg, defoamer 3kg, catalyst Dry agent 6kg; butanone 350kg; butyl acetate 150kg.

[0044] preparation:

[0045] (1) add 221kg main agent hydroxy acrylic resin, 105kg curing agent and 326kg accelerator resin in stirring reactor;

[0046] (2) Then add 4kg leveling agent, 3kg defoamer, 6kg drier;

[0047] (3) Add 350kg butanone and 150kg butyl acetate solution at last, stir until the resin resin solution is fully dispersed;

[0048] (4) Stirring is stopped, and the material is discharged to obtain a coloring layer coating for leather full-transfer film, which is applied to the machine within 5 hours and coated.

[0049] In this embodiment, no metal complex dye is added to the colored layer paint, and a silver-white full transfer film is obtained. Then, the obtained silver full-t...

Embodiment 3

[0051] Raw materials: main agent: castor oil modified alkyd resin 400kg; curing agent: polyisocyanate resin 185kg; accelerator: nitrocellulose resin 365kg; dark brown metal complex dye 54kg; coating additives: leveling agent 6kg, 5kg of defoamer, 18kg of drier; 300kg of butanone; 150kg of butyl acetate.

[0052] preparation:

[0053] (1) add 400kg main agent castor oil modified alkyd resin, 185kg curing agent and 365kg accelerator resin in stirring reactor;

[0054] (2) Then add 54kg dark brown metal complex dye and 6kg leveling agent, 5kg defoamer, 18kg drier;

[0055](3) Add 300kg butanone and 150kg butyl acetate solution at last, stir until the resin resin solution is completely dispersed;

[0056] (4) Stirring is stopped, and the material is discharged to obtain a coloring layer coating for leather full-transfer film, which is applied to the machine within 6 hours and coated.

[0057] In this way, a full-transfer film for dark brown leather is prepared, and then the dar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com