Water inlet device capable of feeding detergents

A water inlet device and detergent technology, which is applied to washing devices, control devices of washing machines, other washing machines, etc., can solve the problems of low washing efficiency of detergents, cumbersome operation process, inaccurate dosage of detergents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

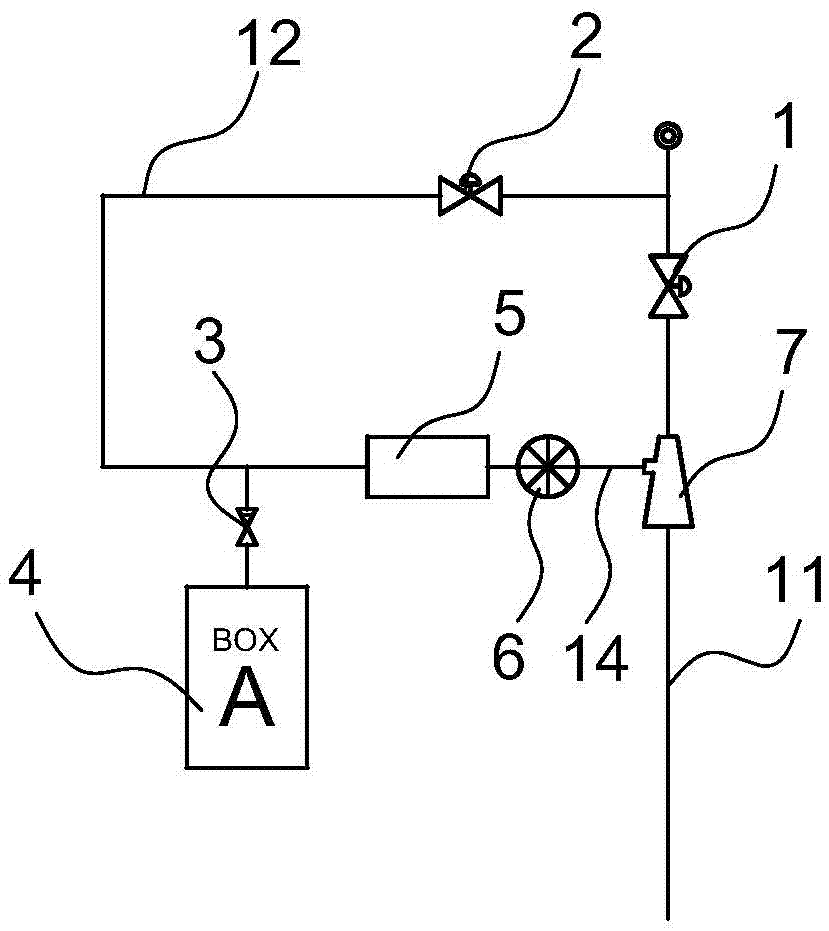

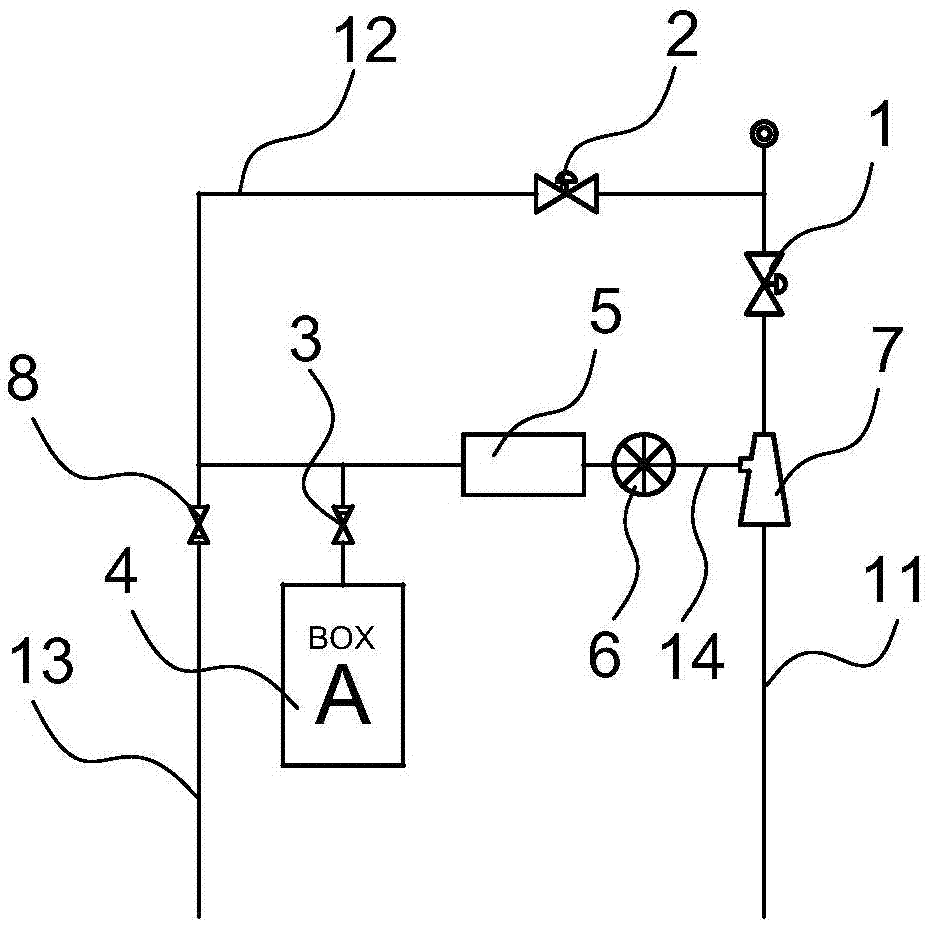

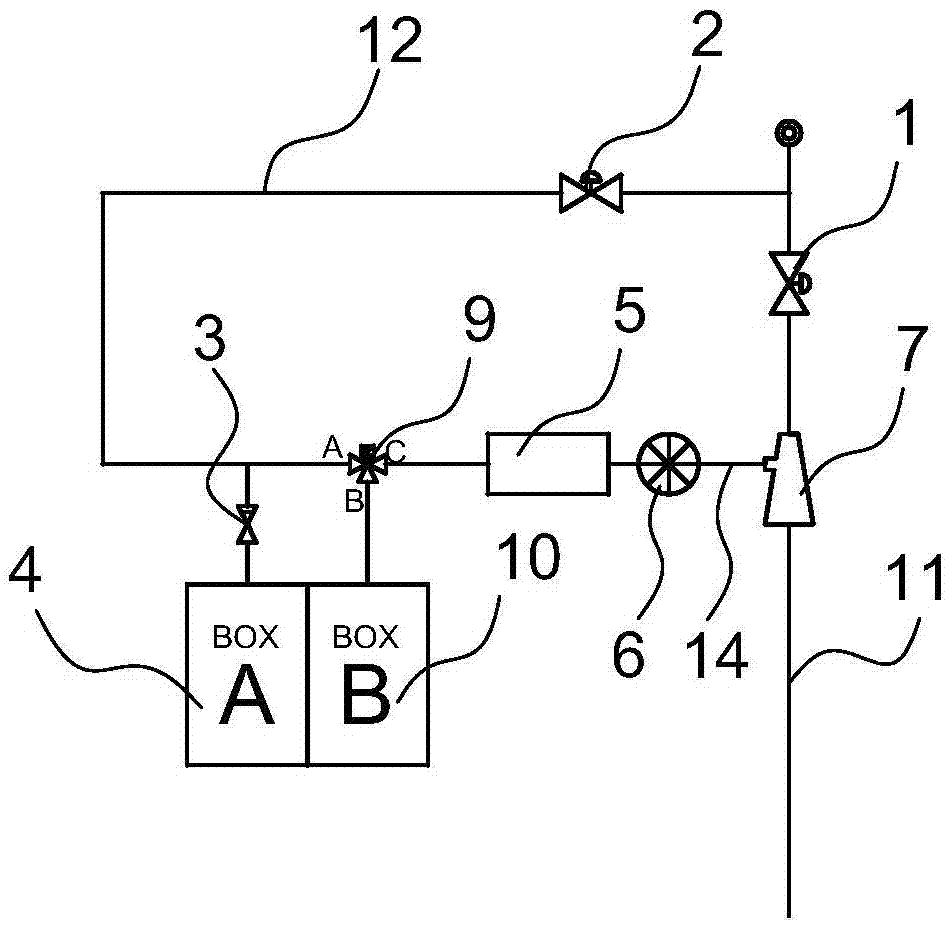

[0049] A kind of water inlet device that can drop detergent, see Figure 4 , Figure 5 , Figure 7 , Figure 10 , Figure 11 , the main channel 11 and the flushing and liquid inlet channel 12 are connected in parallel on the water inlet channel. The outlet direction of the water inlet valve is connected with a Venturi tube 7, the flushing and liquid inlet channel is connected with a liquid collection chamber 5 in the direction of the outlet of the flushing electromagnetic water inlet valve, and the flushing and liquid inlet channel is connected between the flushing electromagnetic water inlet valve and the liquid collection chamber. There is a two-position three-way electromagnetic switch valve 9, and the inlet B direction of the two-position three-way electromagnetic switch valve is connected with a detergent B box 10, and the flushing and liquid inlet channel is located between the flushing electromagnetic water inlet valve and the two-position three-way electromagnetic s...

Embodiment 2

[0064] A kind of water inlet device that can put detergent in this example is different from the above example in that the detergent box is a pull-out detergent box 24, see Figure 23 , Figure 24 A dual-channel transition joint 25 is installed at the detergent A outlet 2011 and the detergent B outlet of the box body 20, the outlet of the detergent A box and the outlet of the detergent B box correspond to one of the two inlets of the transition joint respectively, and the transition The two outlets of the connector communicate with the detergent A inlet 2103 and the detergent B inlet 2102 of the switching valve respectively. Other constructions are the same as the above example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com