Liquid detergent throwing device

A technology for dispensing devices and detergents, which is applied to washing devices, other washing machines, textiles, and papermaking, etc. It can solve the problems of cumbersome operation, inaccurate dosing and measurement, and complex structure, and achieve low cost, simplified electrical circuits, and accurate dosing and measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

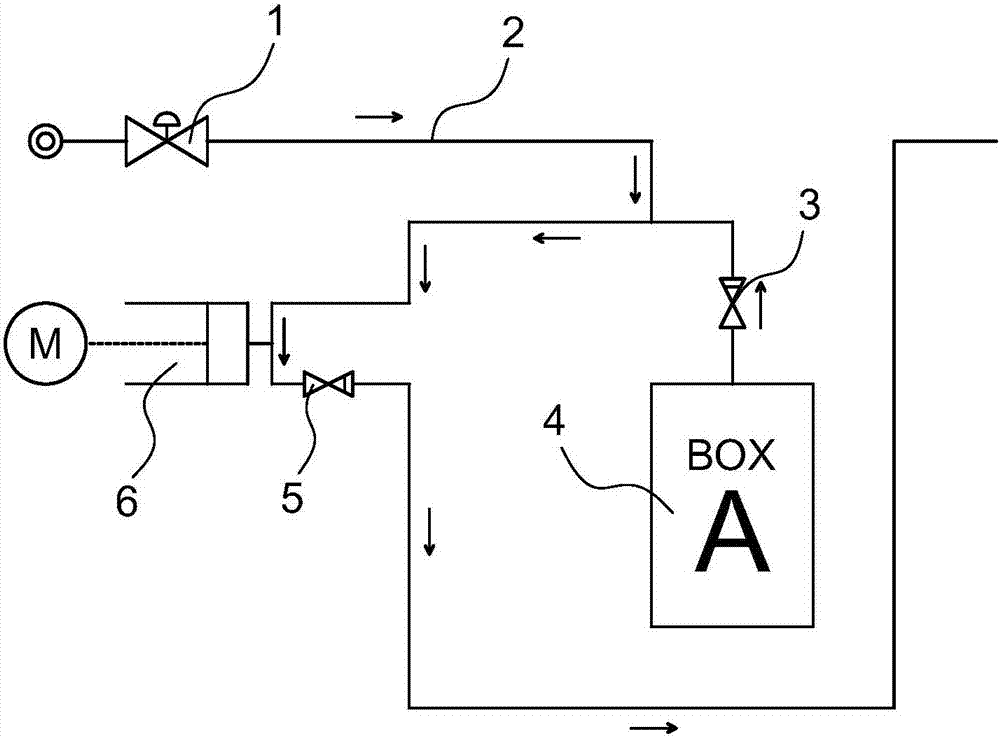

Embodiment 1

[0052] A liquid detergent delivery device, see figure 1 , the entrance of the main channel 2 is connected with a water inlet valve 1, the water inlet valve is preferably an electromagnetic water inlet valve, the outlet of the main channel 2 is connected to the water inlet of the washing bucket, and is provided with a piston 6, a valve A3, a valve B5 and a detergent A box 4, The piston 6 is connected to the main channel 1, the water inlet section of the main channel is formed between the piston inlet and the main channel inlet, the water outlet section of the main channel is formed between the piston outlet and the main channel outlet, the inlet of the valve A3 is connected with the detergent A box 4, and the valve The outlet of A3 bypasses the water inlet section of the main channel, the valve B5 is connected to the water outlet section of the main channel, and the inlet and outlet of the valve B5 correspond to the outlet of the piston 6 and the outlet of the main channel respe...

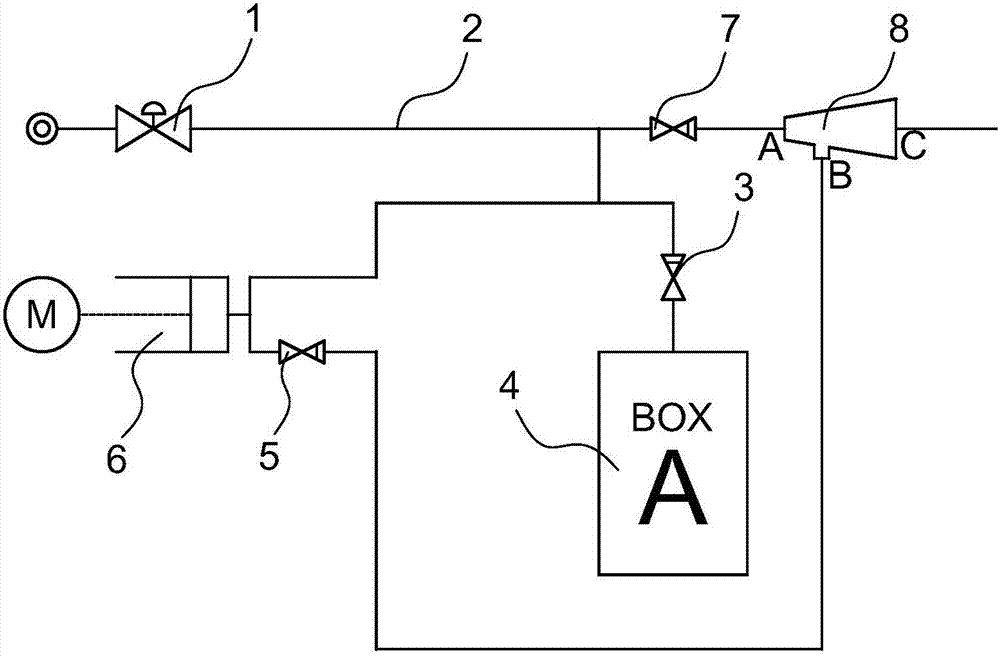

Embodiment 2

[0054] see figure 2 In this example, on the basis of Example 1, a Venturi negative pressure generator 8 is connected between the outlet of the main channel 2 and the water inlet of the detergent bucket. Connect the water inlet section of the main channel, the Venturi negative pressure generator 8 is connected to the water inlet of the washing bucket at port C as shown in the figure, and the negative pressure port of the Venturi negative pressure generator 8 is connected to the main channel 2 outlet at port B as shown in the figure .

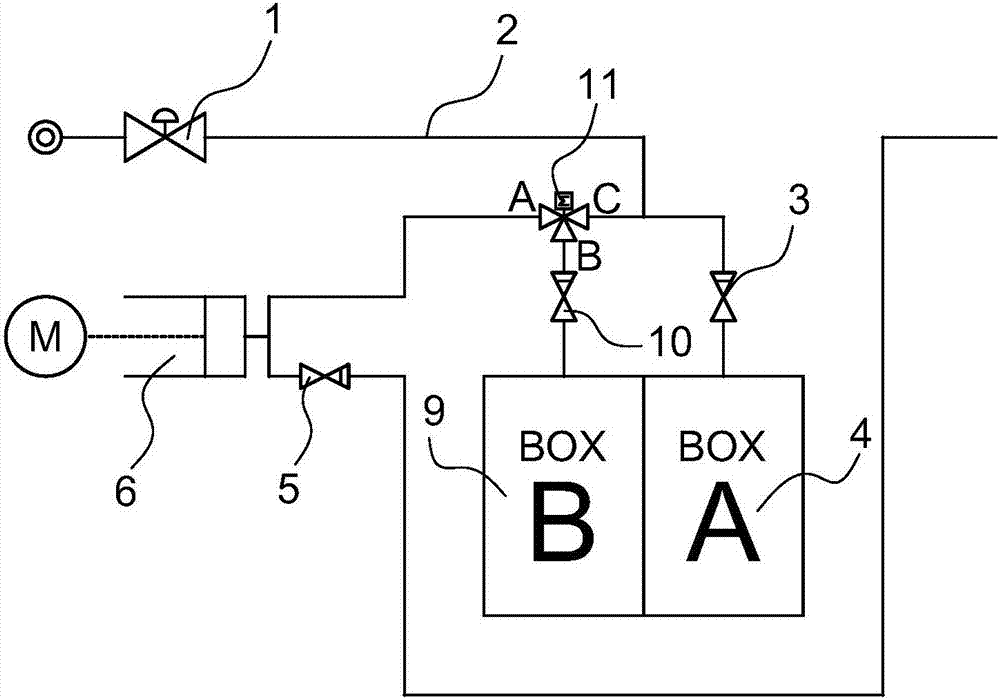

Embodiment 3

[0056] see image 3 , in this case at figure 1 Basically, a two-position three-way valve 11 is connected to the water inlet section of the main channel. The outlet of the valve A is described above, and the other inlet of the two-position three-way valve is connected to the detergent B box 9 after the B port in the figure is connected to the valve D.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com