Patents

Literature

35results about How to "Large radiating surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

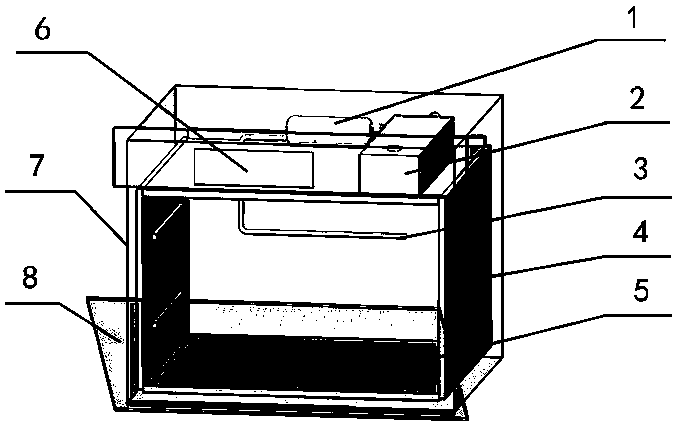

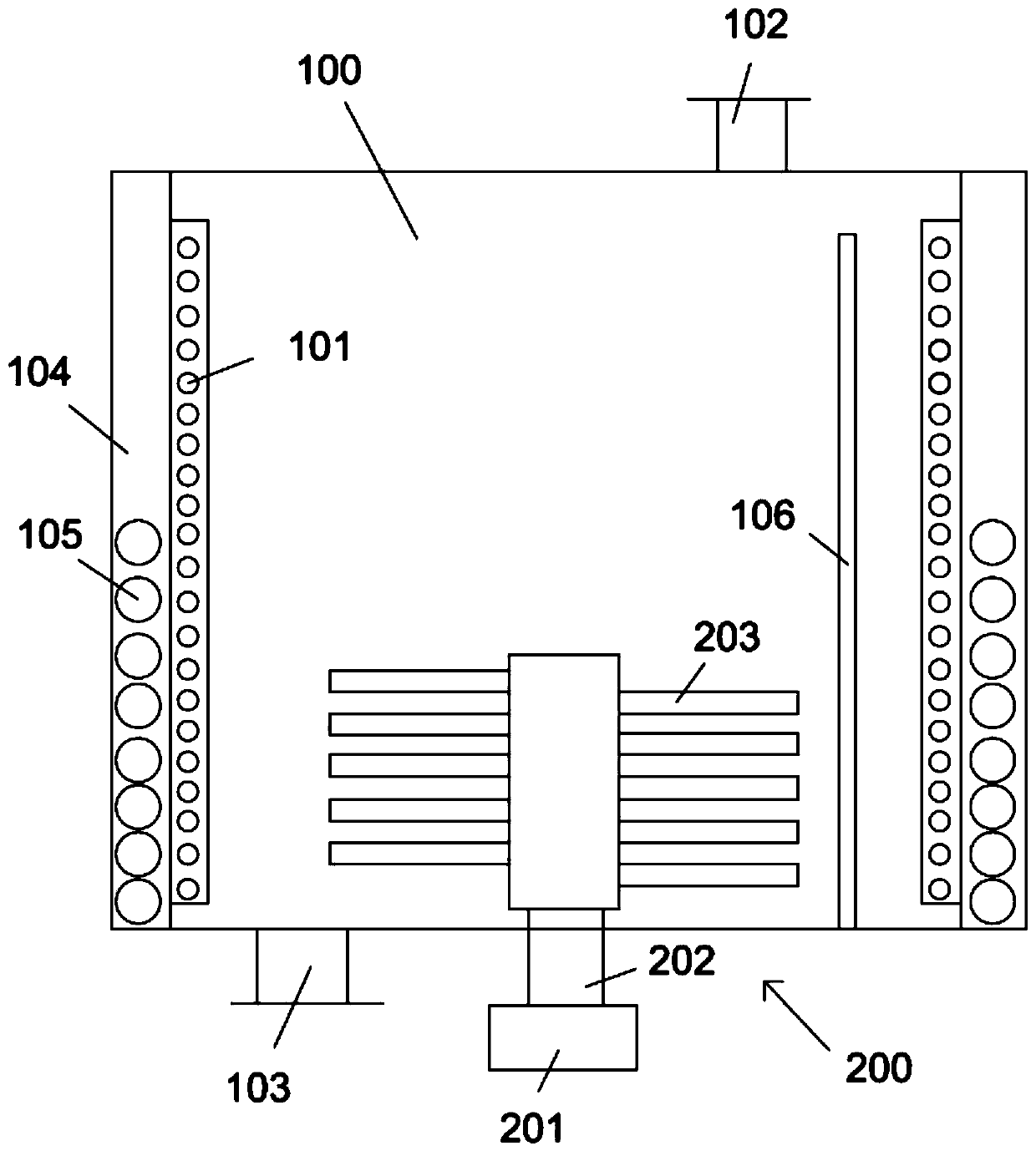

Multifunctional steam oven and control method thereof

InactiveCN108113502AEasy to control temperatureEasy to control humiditySteam cooking vesselsRoasters/grillsThermodynamicsEngineering

The invention relates to the technical field of kitchen appliances and especially relates to a domestic multifunctional steam oven and a control method thereof. The multifunctional steam oven disclosed by the invention is provided with an instant steam generator and an infrared radiation heating plate assembly, then can be combined with a single chip microcomputer and a temperature and humidity sensor to perform program control and can perform program control on a cooking mode and cooking time through automatic selection or manual selection; meanwhile, high temperature steam output by the instant steam generator is utilized to be matched with infrared radiation to roast food materials to cook varieties of delicious food, so that quickly cooking food is achieved, cooking time is reduced, and stability in roasting food is improved. Users can share experience (steaming and roasting programs set by mobile phone APP) in making meals through the steam oven and self-created recipes (steamingand roasting programs) to an APP user group to compare together and improve cooking skills.

Owner:深圳丰科力达电子有限公司

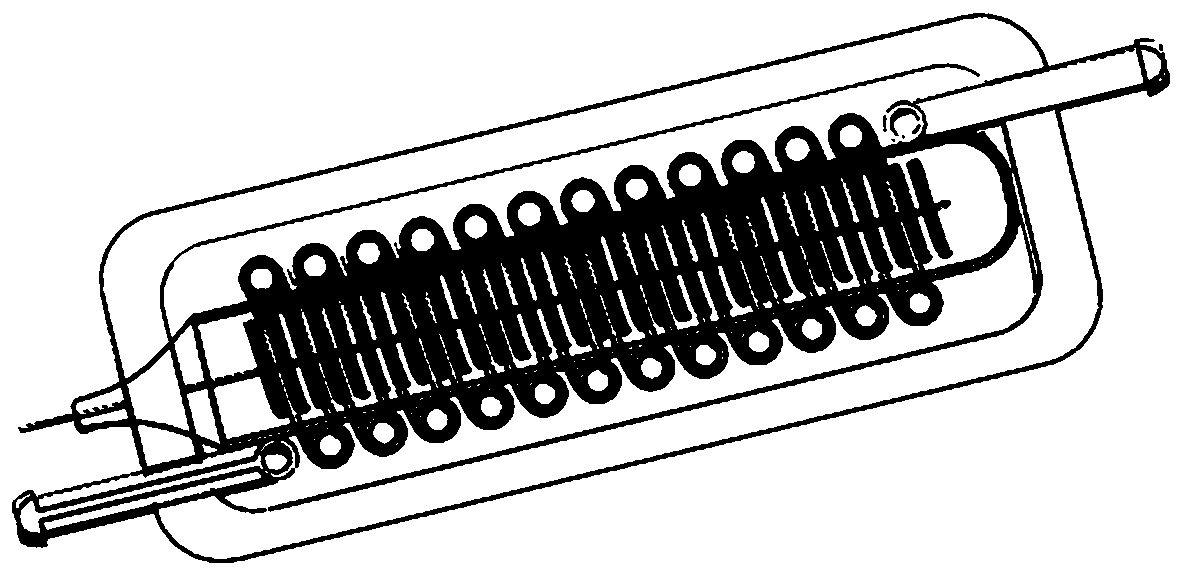

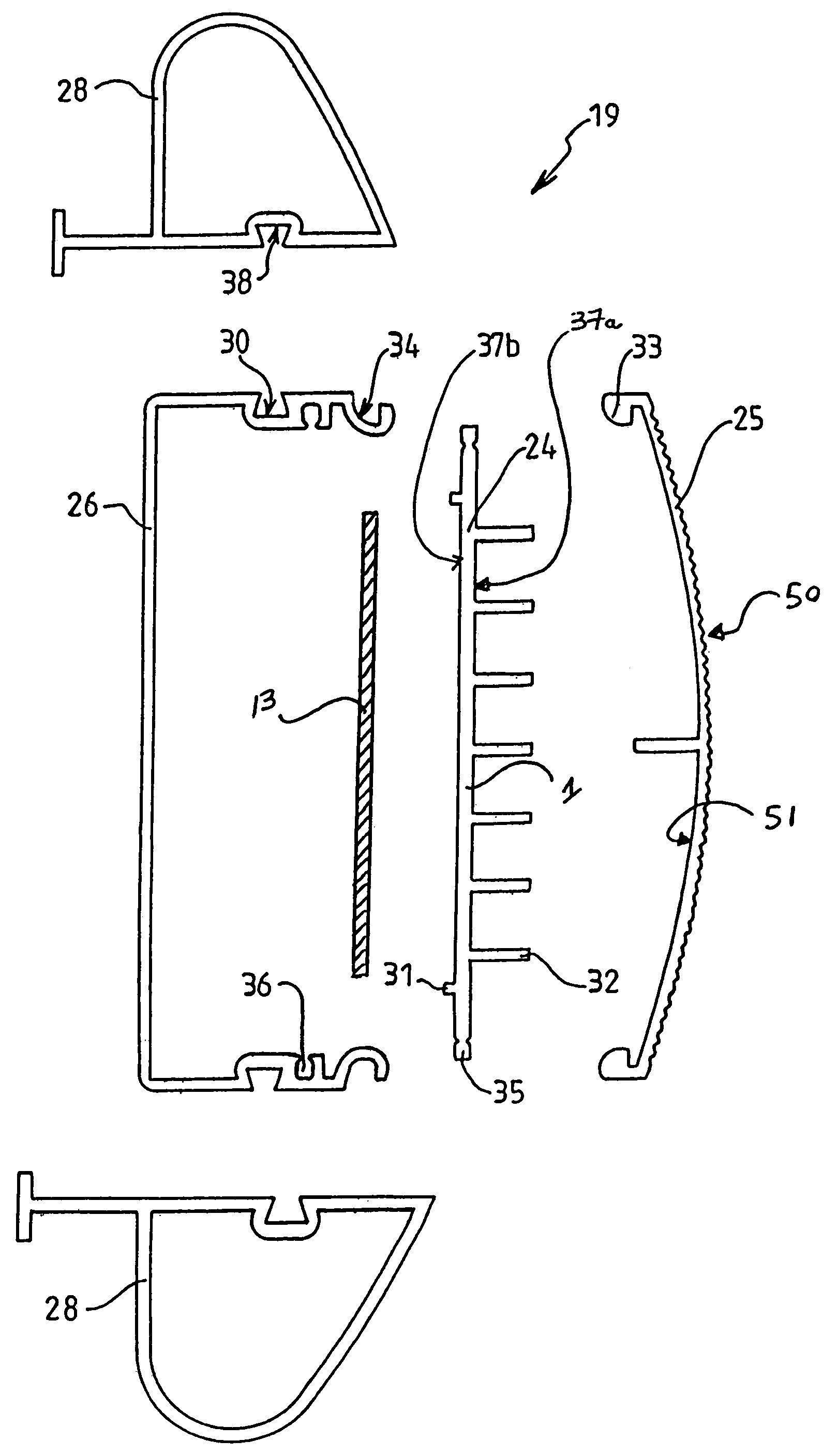

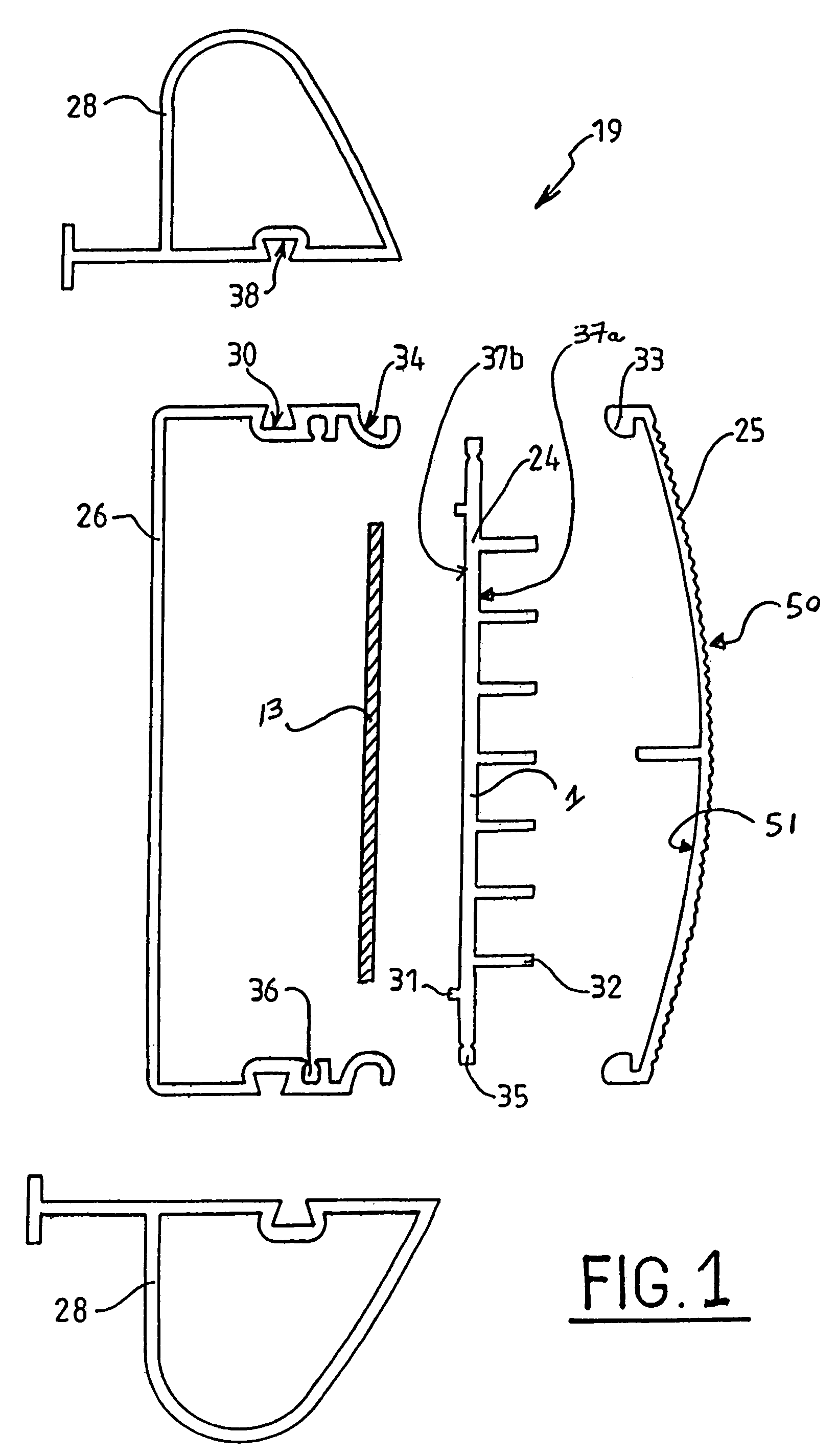

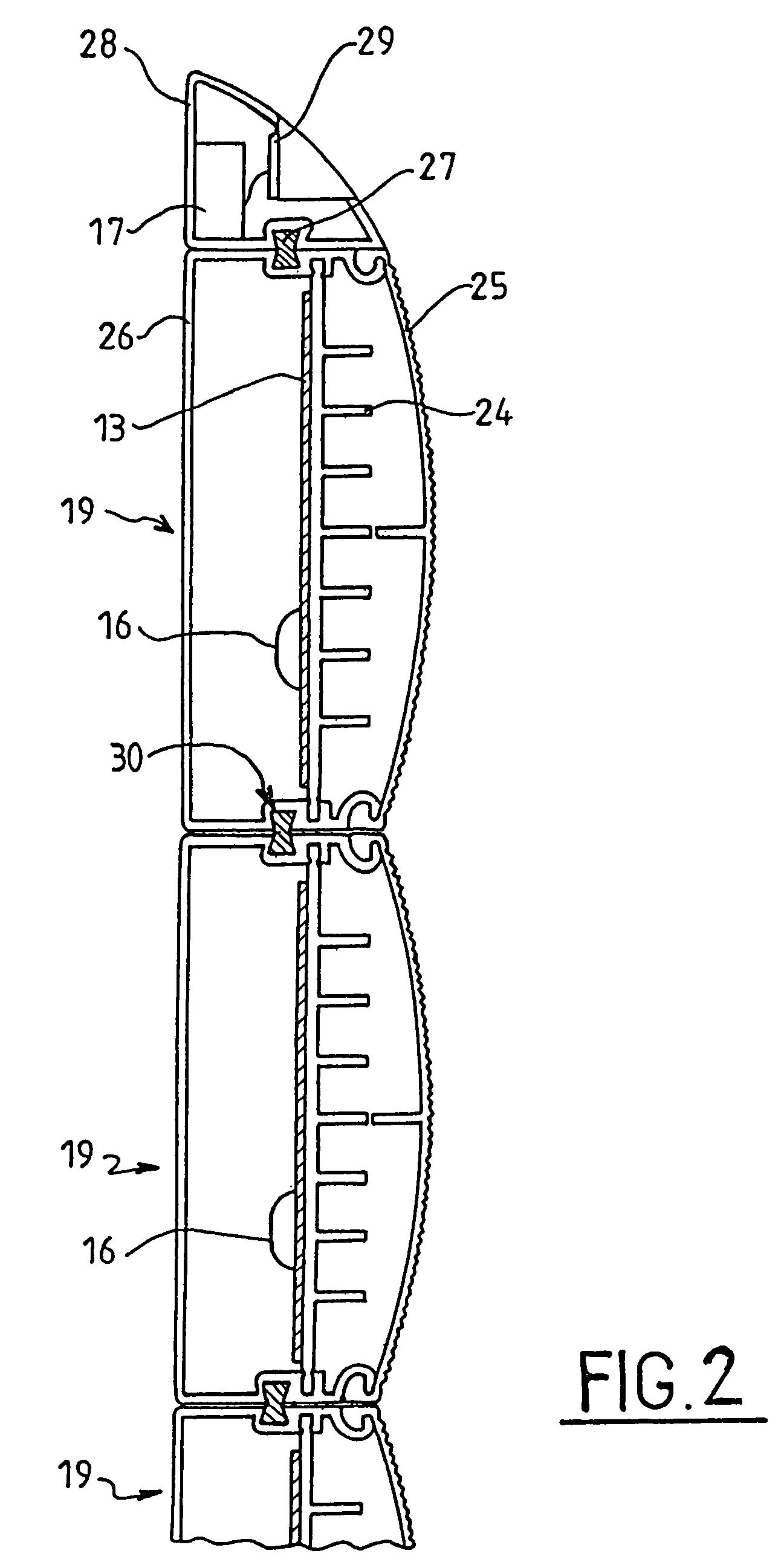

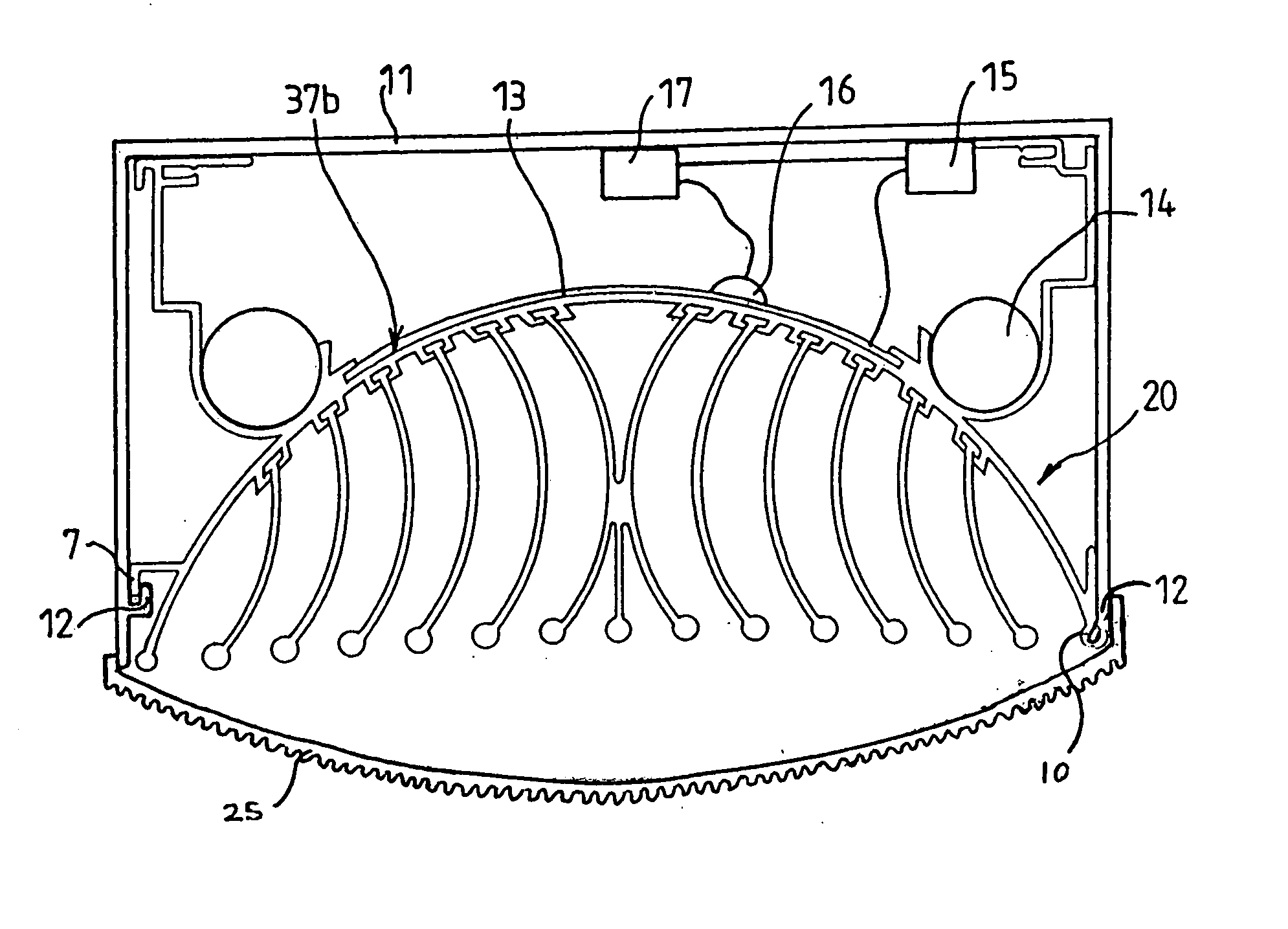

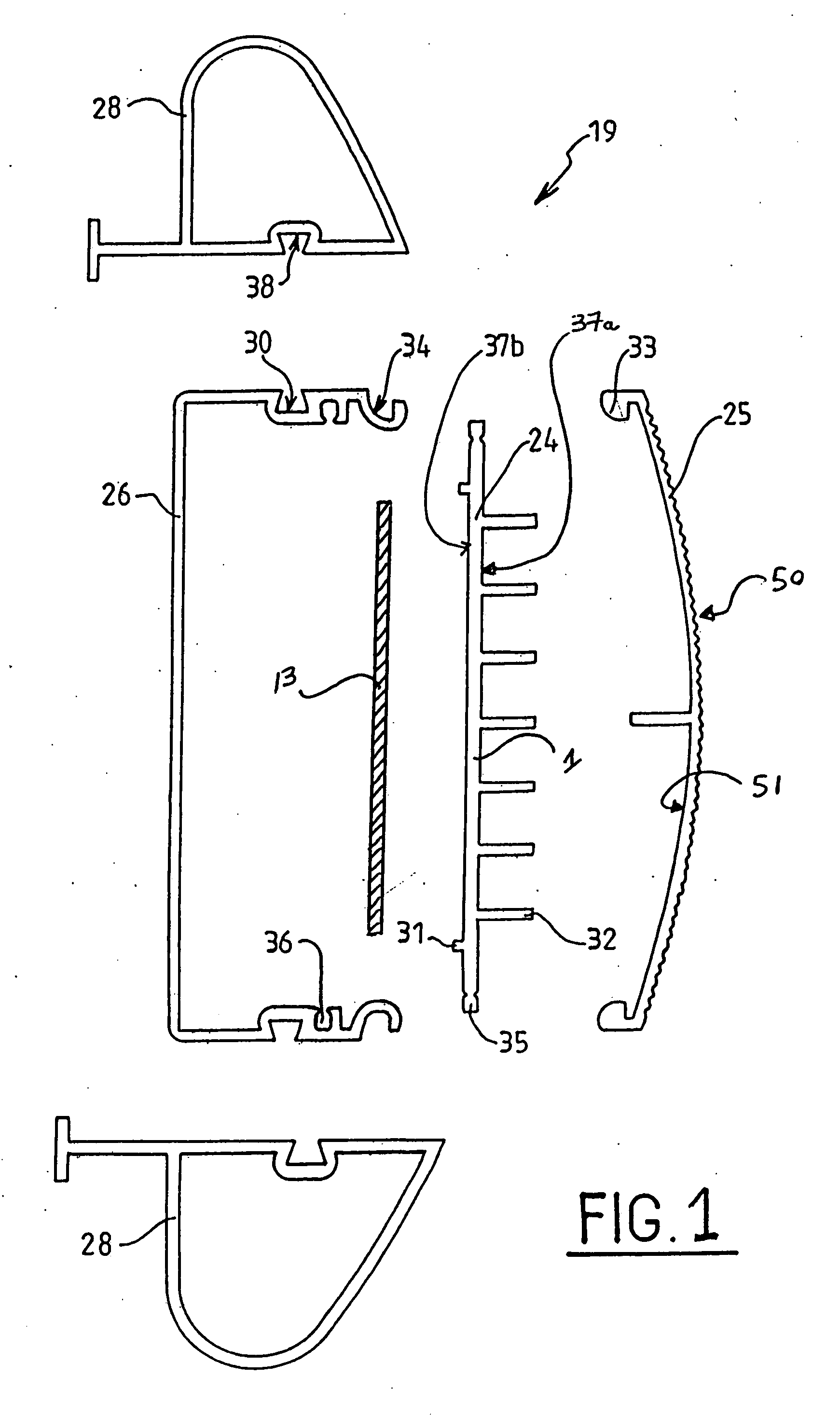

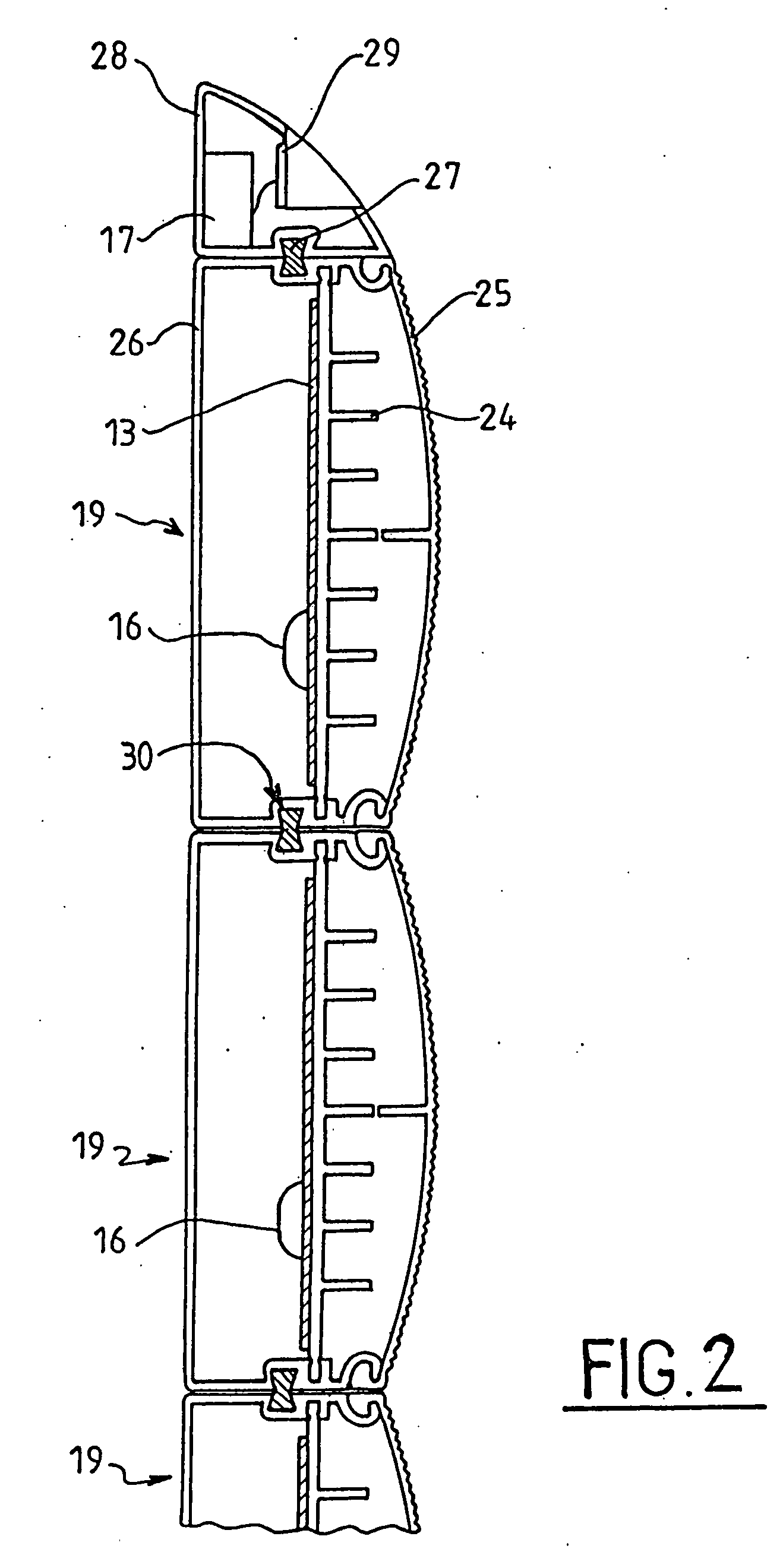

Temperature exchanging element made by extrusion and incorporating an infrared radiation diffuser

InactiveUS7725011B2Large radiating surfaceComplex shapeSolar heating energyDomestic stoves or rangesHeat conductingComputer module

The invention thus relates to a radiation module incorporating a support, at least one heating and / or heat conducting element and a temperature exchanging element made by extrusion and constituted by a single-piece base with an internal face incorporating at least one means to integrate the heating and / or heat conducting element and an external face incorporating radiation fins wherein the module incorporate a diffuser receiving infrared radiation from the temperature exchanging element, said diffuser enabling infrared radiation to be emitted of a wavelength that is less than that of the radiation received.

Owner:CALORIGEN USA CORP

Temperature exchanging element made by extrusion and incorporating an infrared radiation diffuser

InactiveUS20070235438A1Improve efficiencyIncrease the exchange areaSolar heating energyDomestic stoves or rangesHeat conductingEngineering

The invention thus relates to a radiation module incorporating a support, at least one heating and / or heat conducting element and a temperature exchanging element made by extrusion and constituted by a single-piece base with an internal face incorporating at least one means to integrate the heating and / or heat conducting element and an external face incorporating radiation fins wherein the module incorporate a diffuser receiving infrared radiation from the temperature exchanging element, said diffuser enabling infrared radiation to be emitted of a wavelength that is less than that of the radiation received.

Owner:CALORIGEN USA CORP

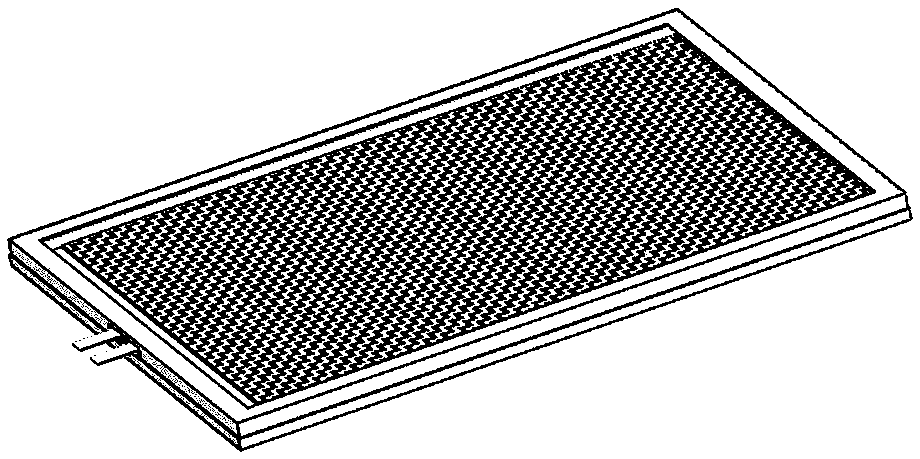

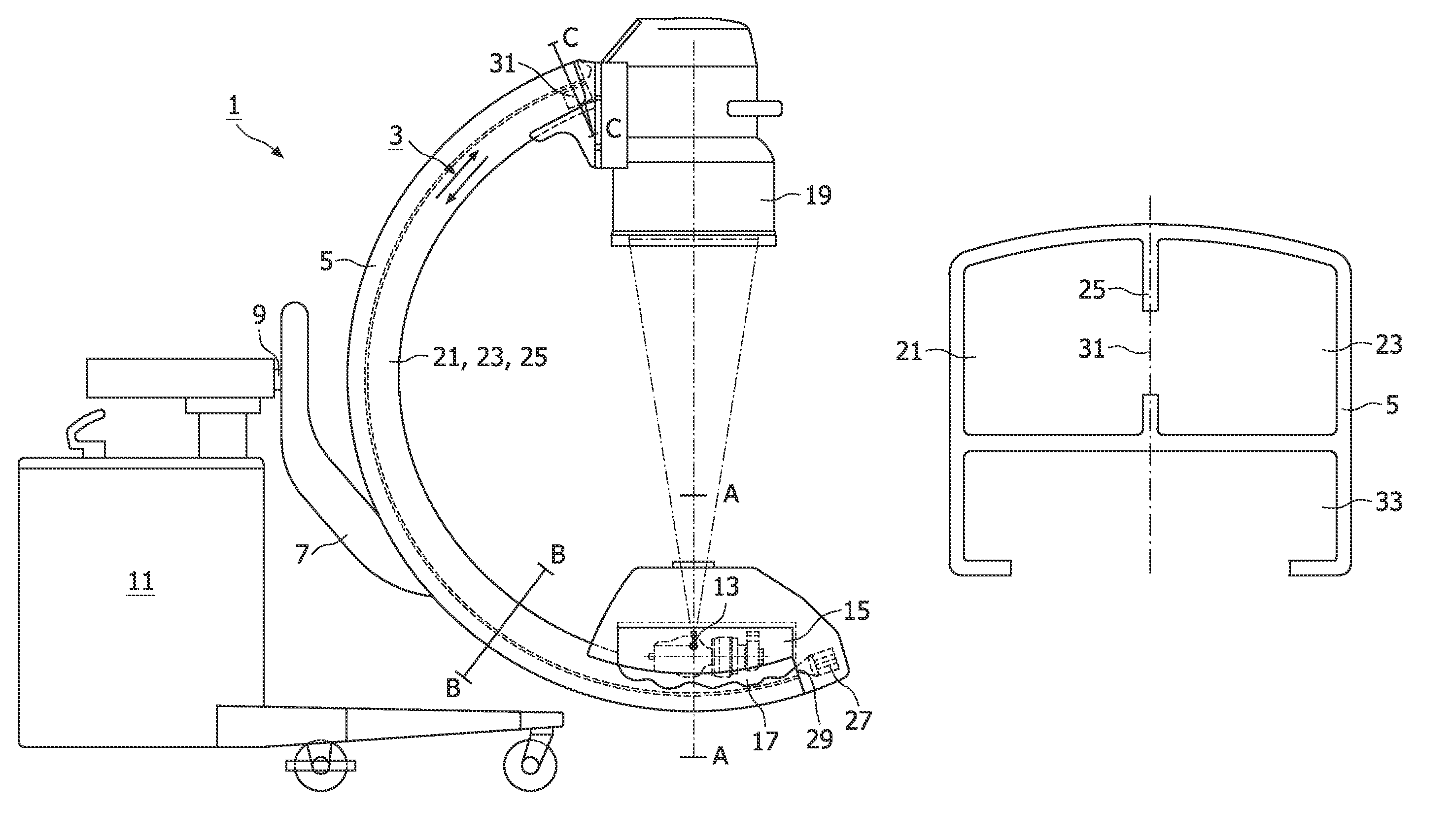

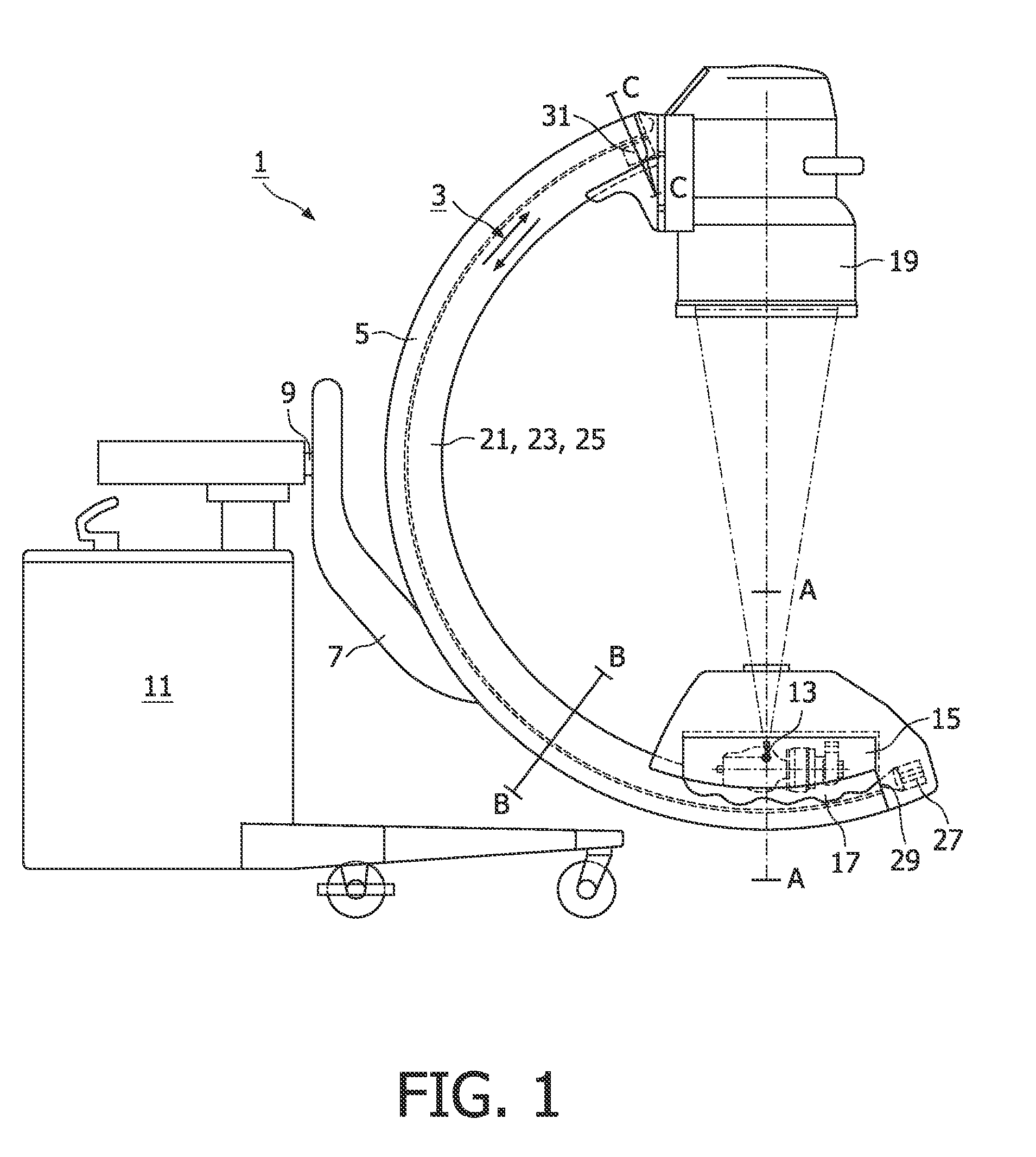

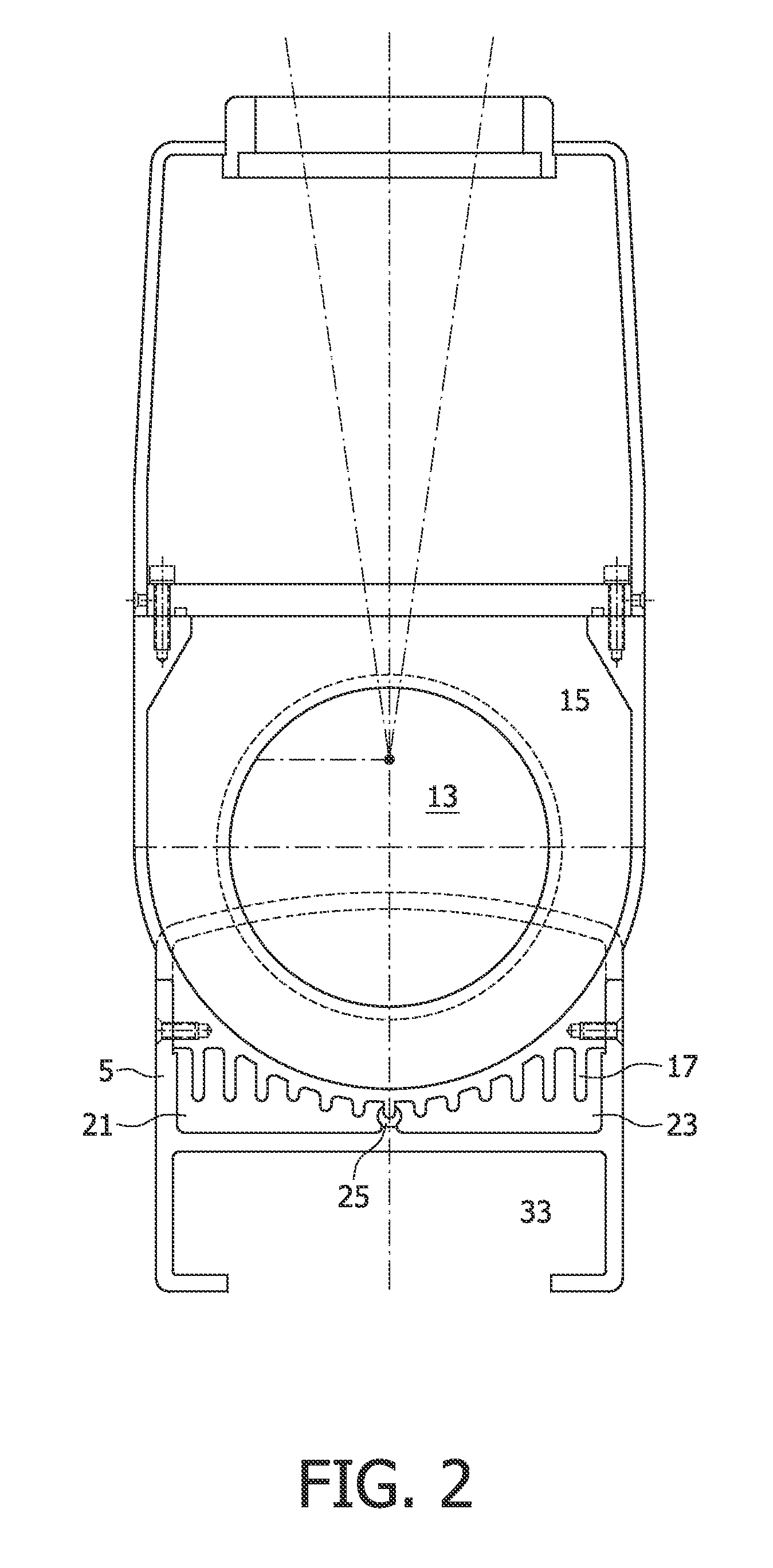

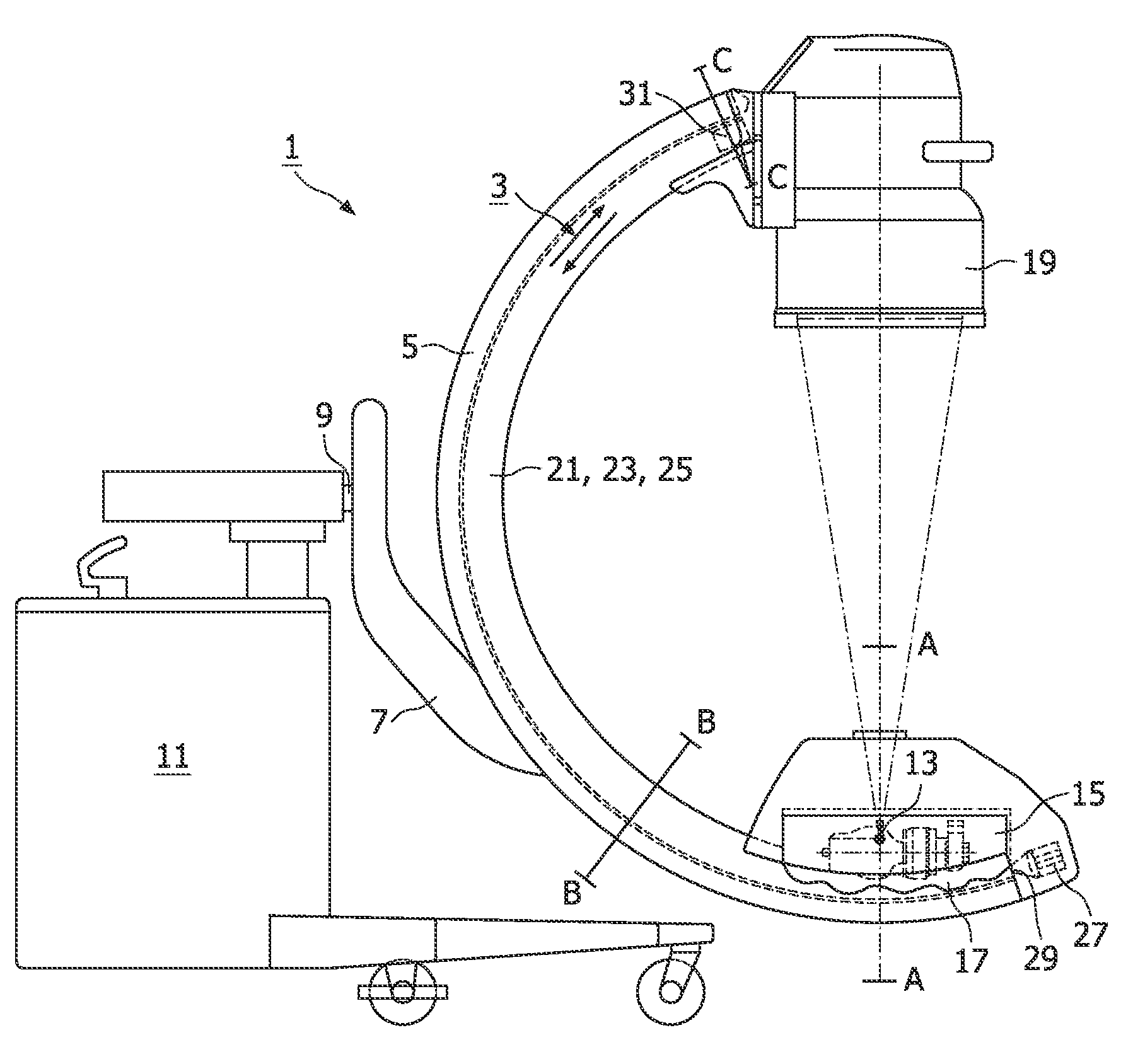

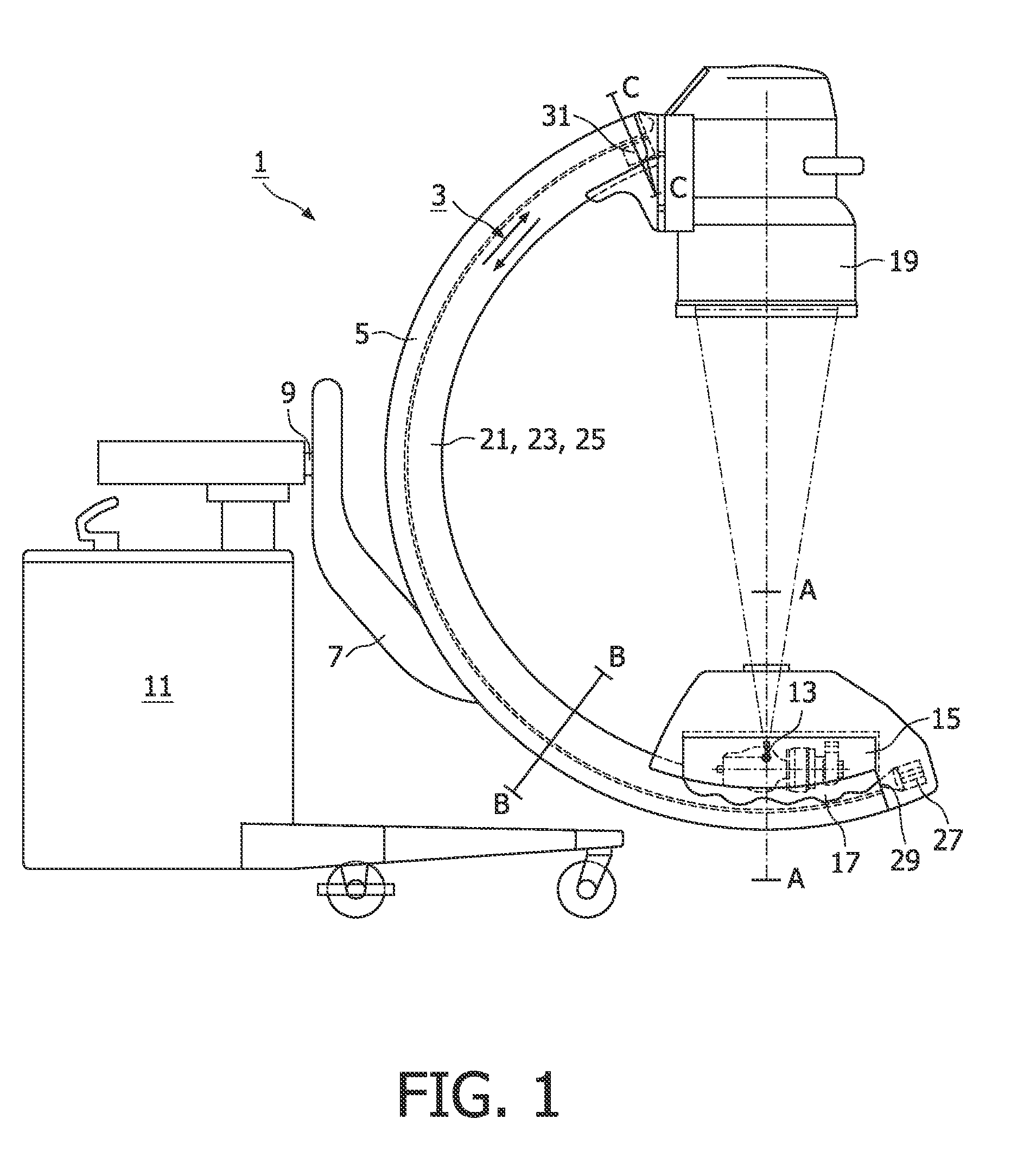

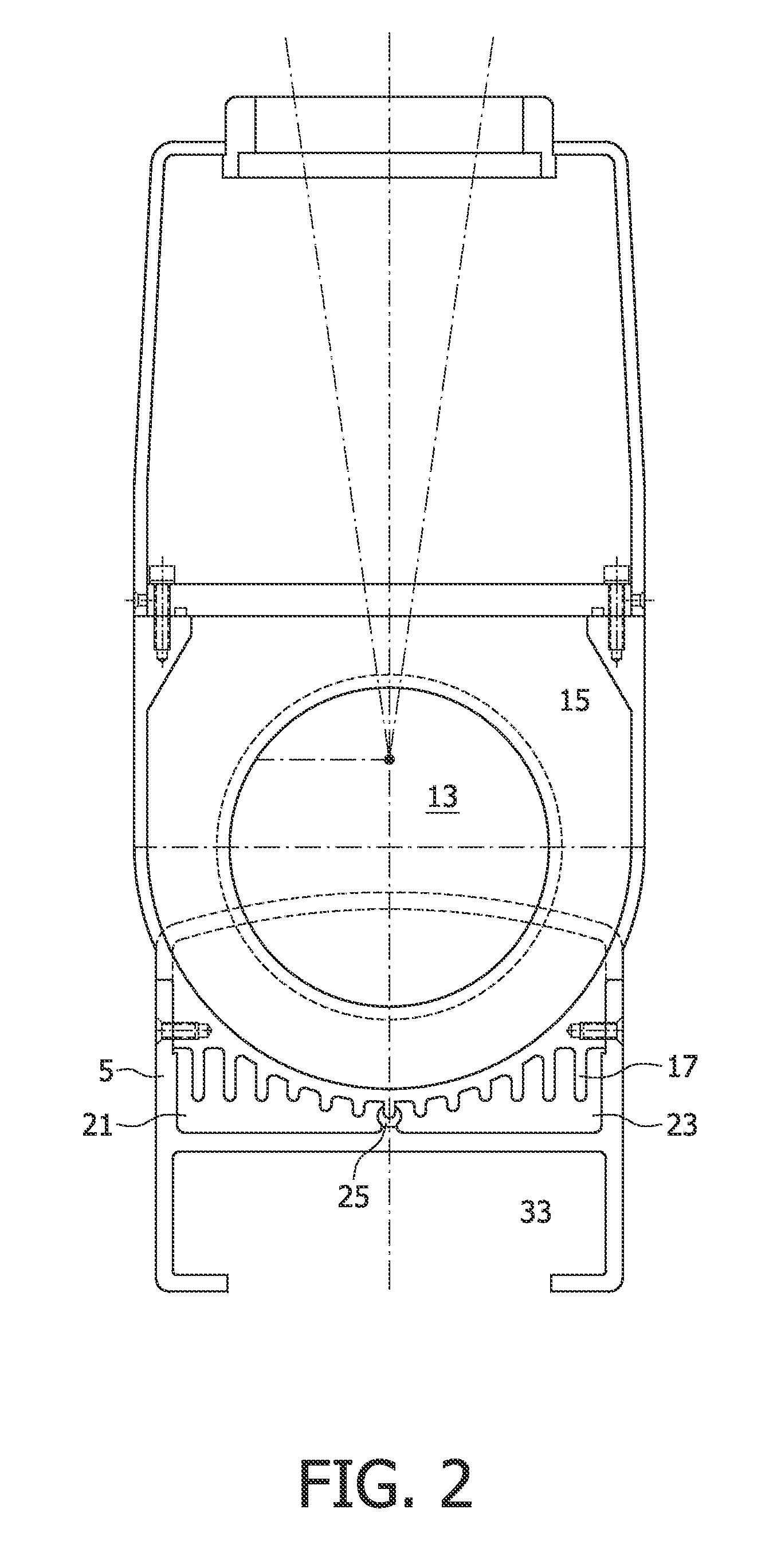

Medical diagnostic X-ray apparatus provided with a cooling device

ActiveUS7912181B2Large radiating surfaceImprove cooling effectX-ray tube electrodesX-ray apparatusSoft x rayX-ray

A medical diagnostic X-ray apparatus includes an X-ray source, a hollow carrier to which the X-ray source is connected, and a cooling device provided with a cooling device to cool the X-ray source during use of the X-ray apparatus. The cooling device is in direct thermal contact with the carrier, thus providing an efficient cooling mechanism for the X-ray source.

Owner:KONINK PHILIPS ELECTRONICS NV

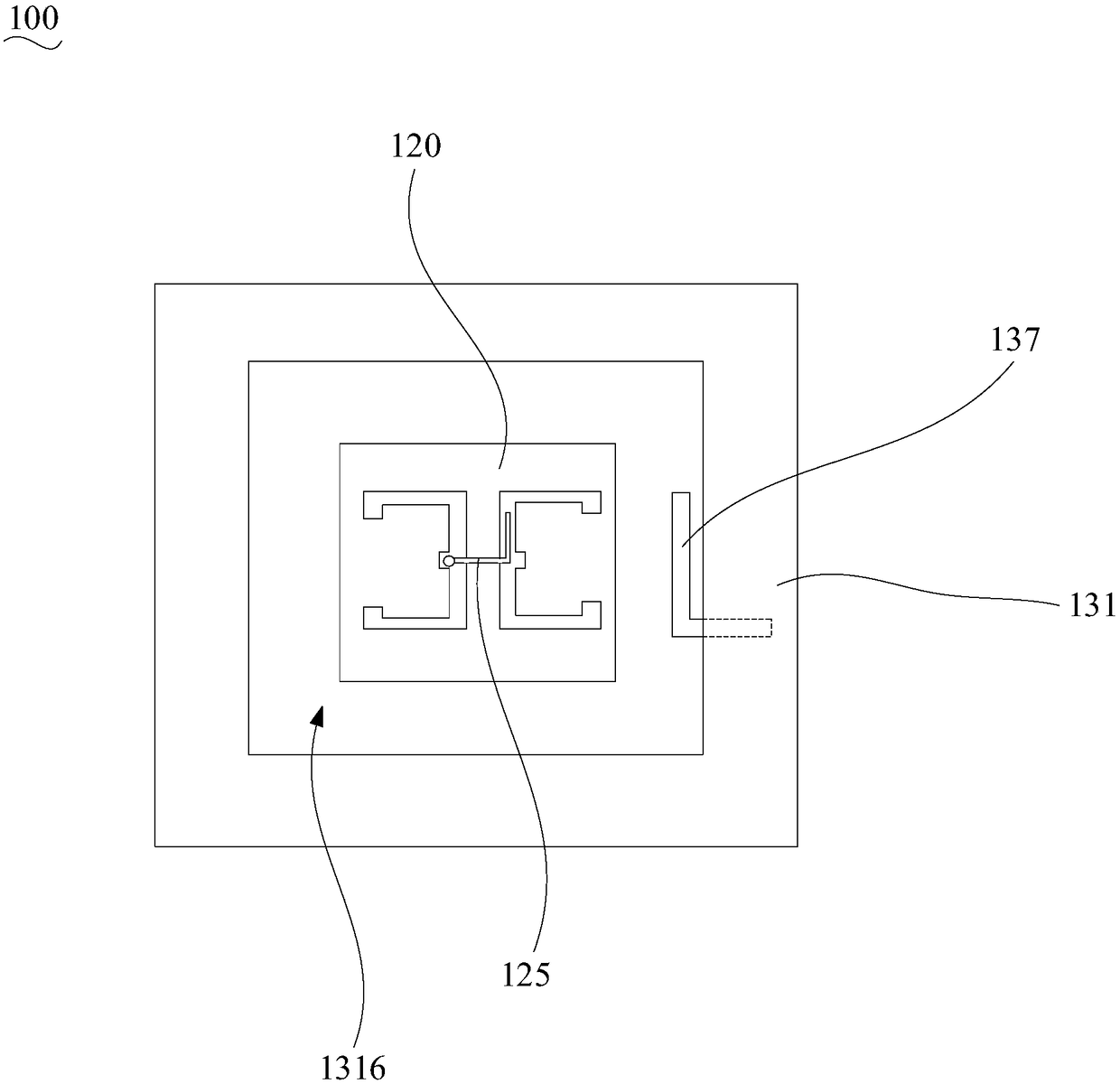

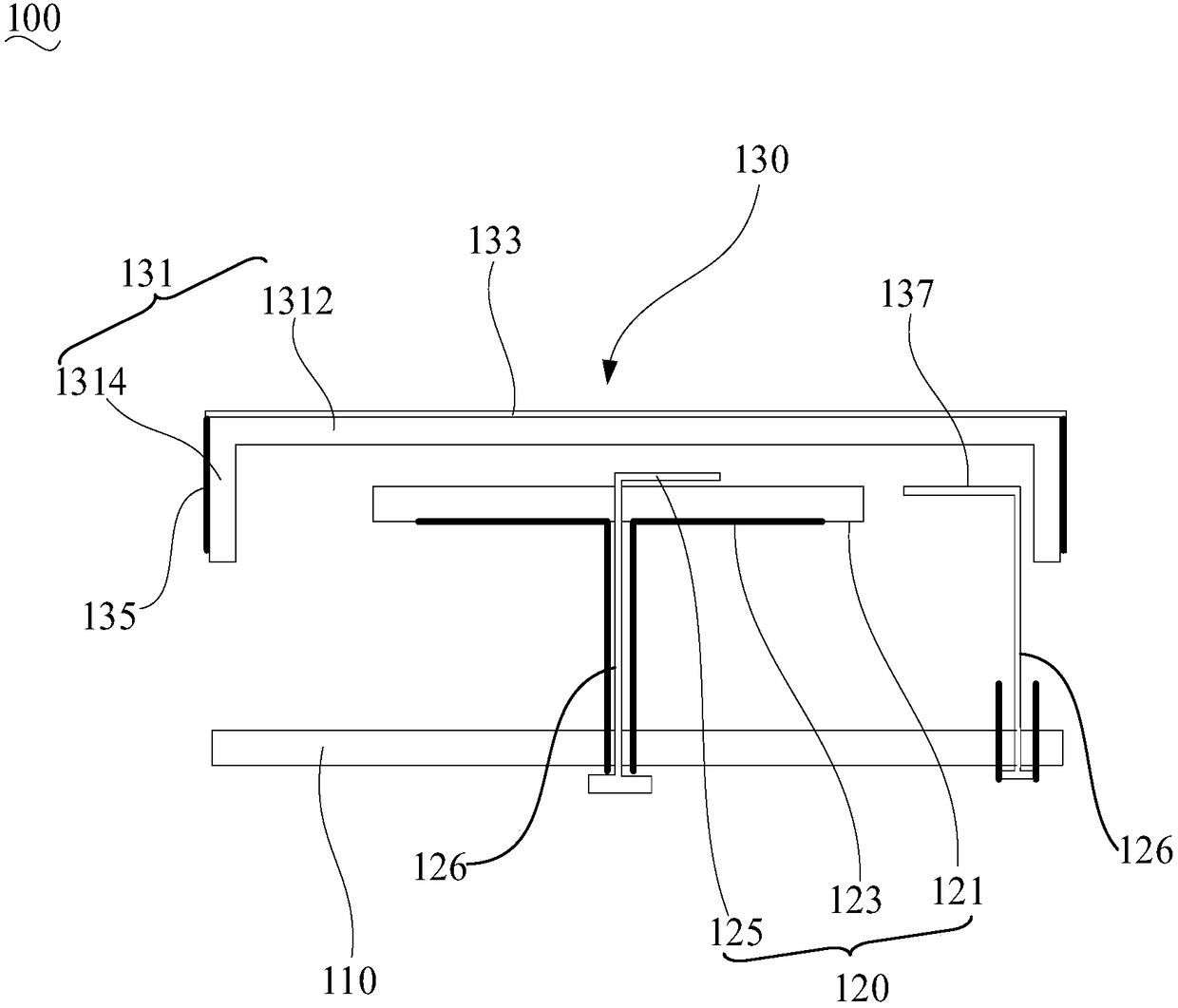

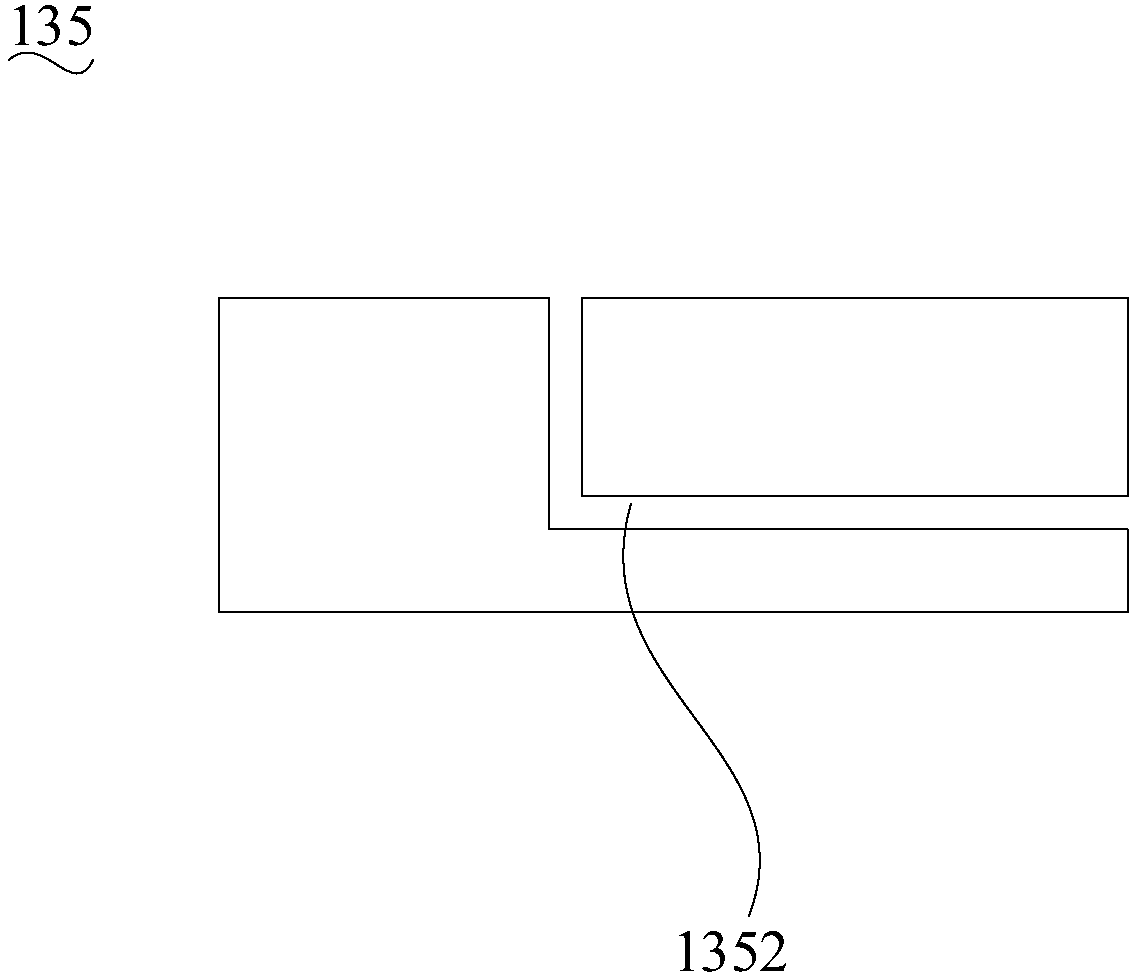

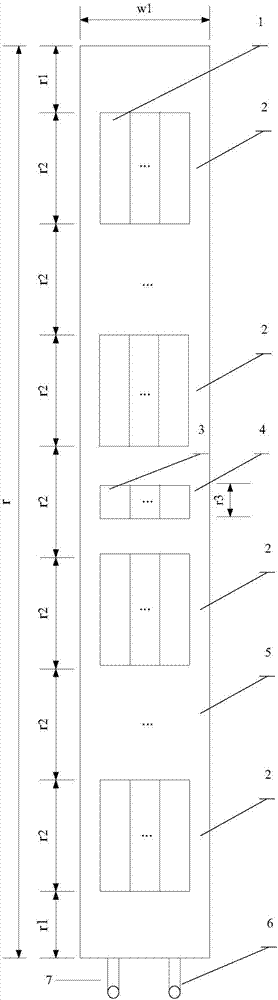

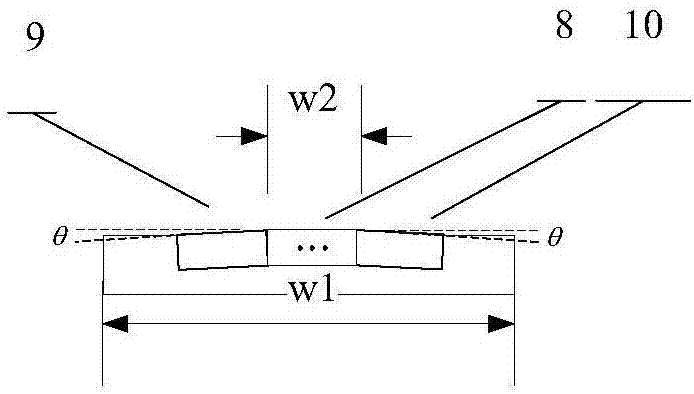

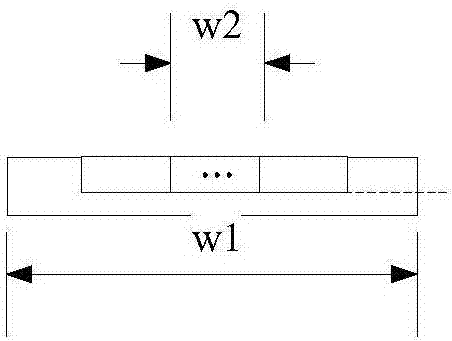

Miniaturized dual-frequency nested antenna

ActiveCN108258403ALarge radiating surfaceReduce horizontal sizeRadiating elements structural formsAntenna earthingsDual frequencyMiniaturization

The invention provides a miniaturized dual-frequency nested antenna. A through hole is formed in the middle part of a low-frequency dielectric substrate and thus a low-frequency antenna has an annularhollow structure and a high-frequency antenna is arranged in the annular structure, so that the positions of the low-frequency antenna and the high-frequency antenna are overlapped partially and thusthe horizontal dimension is reduced. Moreover, vertical side plates are arranged around the low-frequency dielectric substrate and the surface of the low-frequency dielectric substrate is covered bya horizontal radiation metal patch, so that the horizontal dimension of the low-frequency antenna is reduced and the radiation surface of the low-frequency antenna is increased. Furthermore, verticalradiation metal patches with L-shaped grooves are arranged at the peripheral directions of the side plates and the L-shaped grooves play a role of optimizing the bandwidth. Therefore, the wireless signal transceiving system and the miniaturized dual-frequency nested antenna have the following beneficial effects: the frequency band requirement is met and the size is reduced effectively.

Owner:GUANGDONG MIKWAVE COMM TECH

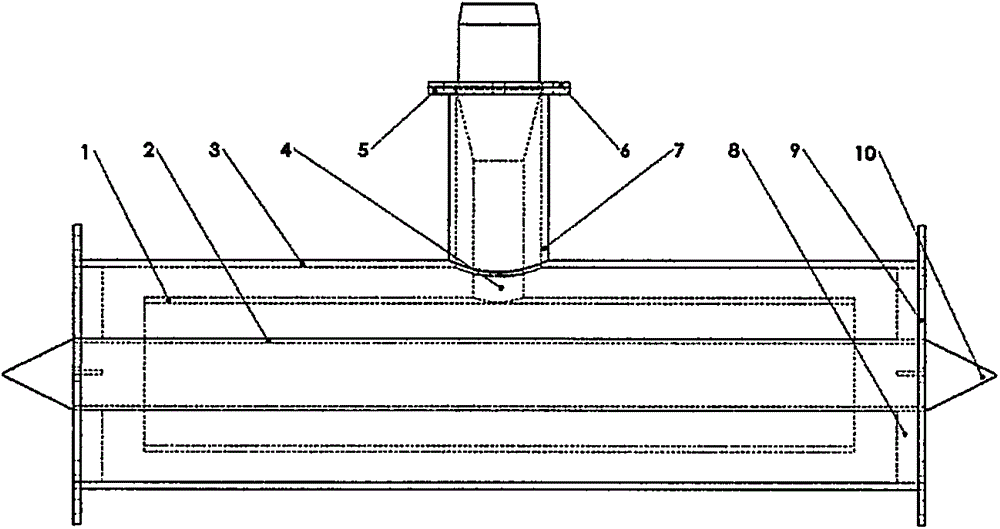

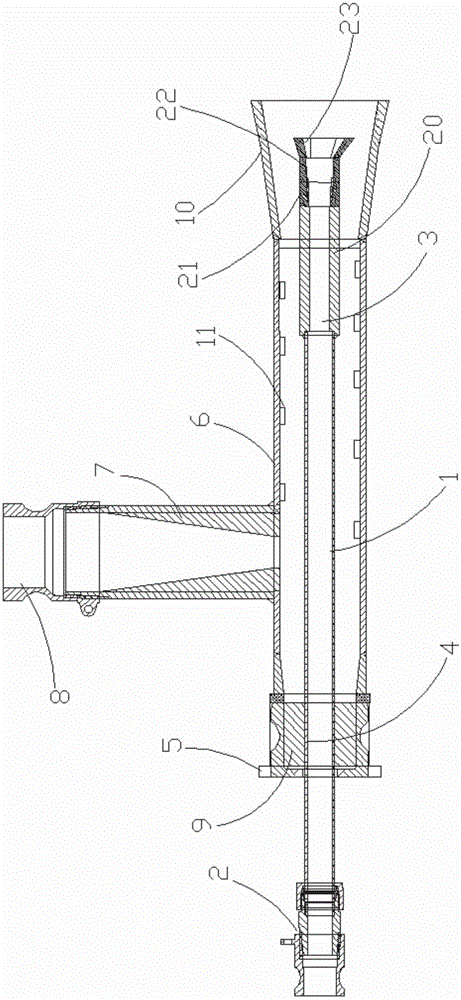

Near sound field ultrasonic reactor

ActiveCN104645916ALarge radiating surfaceUniform sound intensityEnergy based chemical/physical/physico-chemical processesEnvironmentally friendlyContinuous production

The invention relates to the technical field of generation and transfer of ultrasonic vibration and particularly relates to a near sound field ultrasonic reactor which efficiently uses ultrasonic energies. The near sound field ultrasonic reactor comprises an ultrasonic vibration tube, an ultrasonic internal reflection tube, an ultrasonic external reflection tube, an ultrasonic amplitude transformer, a flange connected with the ultrasonic amplitude transformer, an ultrasonic amplitude transformer flange, a fixed amplitude transformer sleeve, a fixed internal reflection tube rib, an internal reflection tube dividing conehead, an external reflection tube flange and the like. The ultrasonic reactor provided by the utility model is the near sound field ultrasonic reactor which is simple in structure, free from maintenance in operation, high in utilization ratio of ultrasonic energy, large in ultrasonic radiating area, uniform in ultrasonic sound intensity, low in power consumption and energy-saving and environmentally friendly and efficiently uses ultrasonic energies. The near sound field ultrasonic reactor provided by the utility model not only effectively utilizes radiating energies on the internal and external faces of the ultrasonic vibrating tube, but also effectively utilizes radiating energies reflected from inner and outer sides, so that the near sound field ultrasonic reactor is suitable for industrial flows in continuous production. A common plate type ultrasonic reactor is not as good as the near sound field ultrasonic reactor.

Owner:山东润蒙应急救援装备有限公司

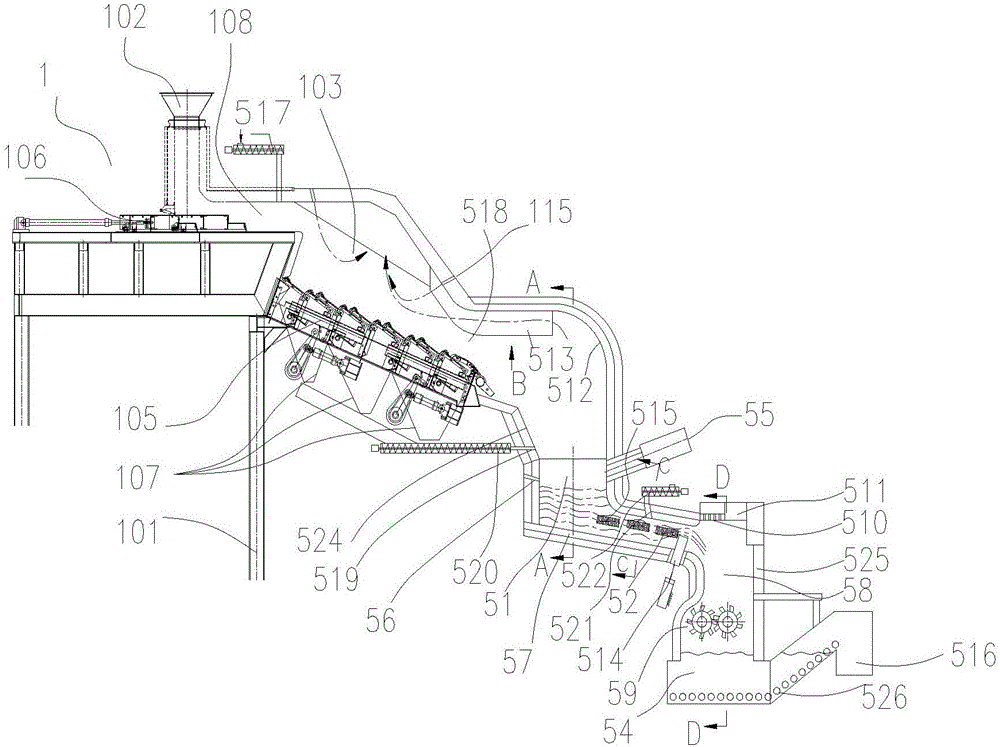

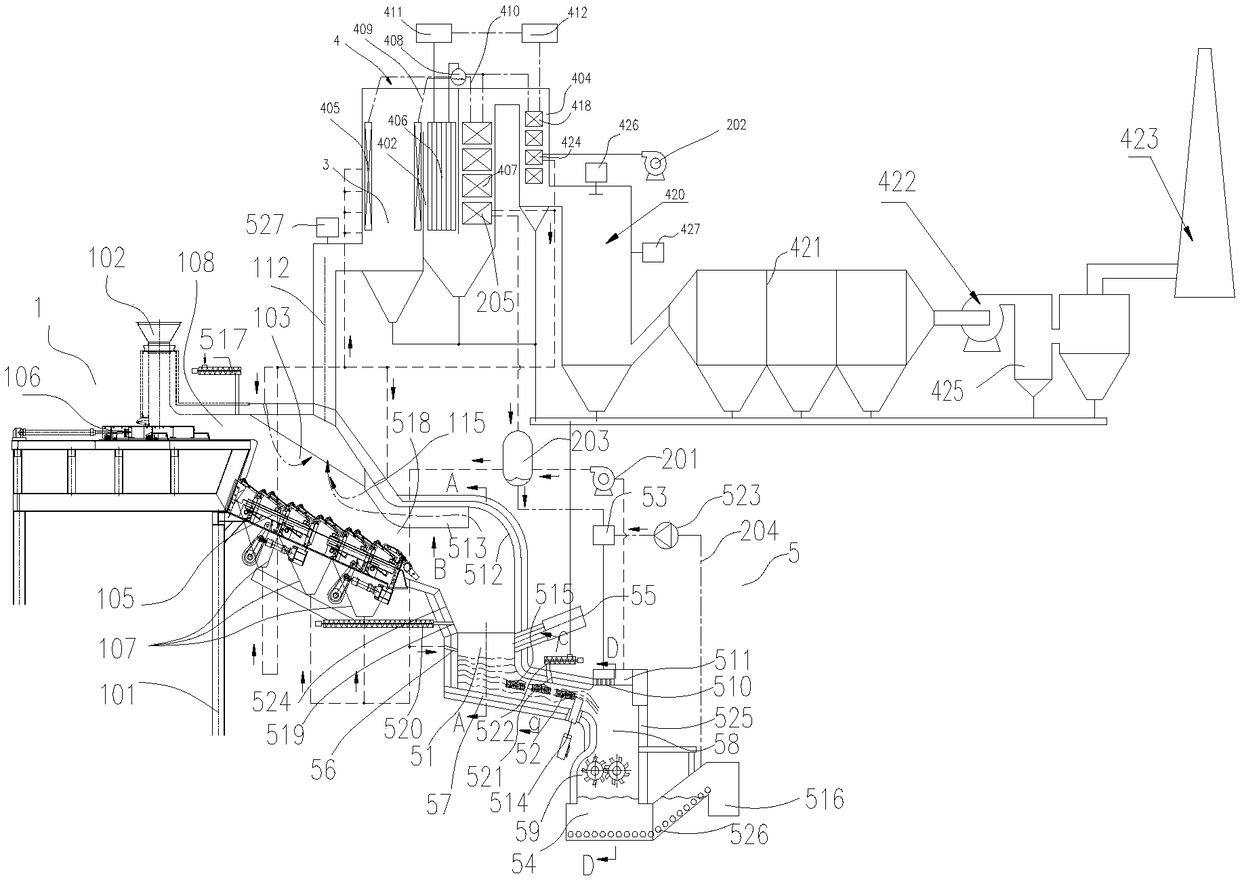

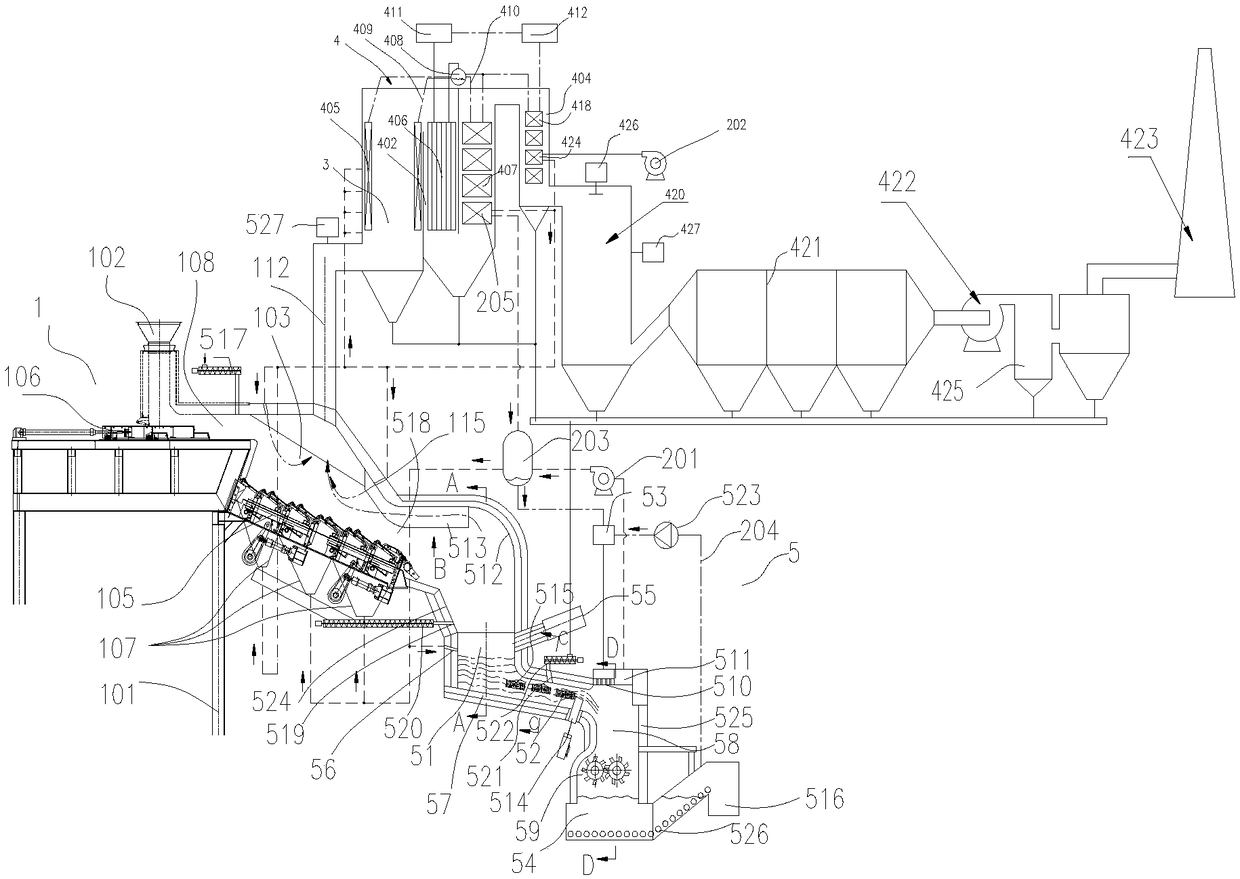

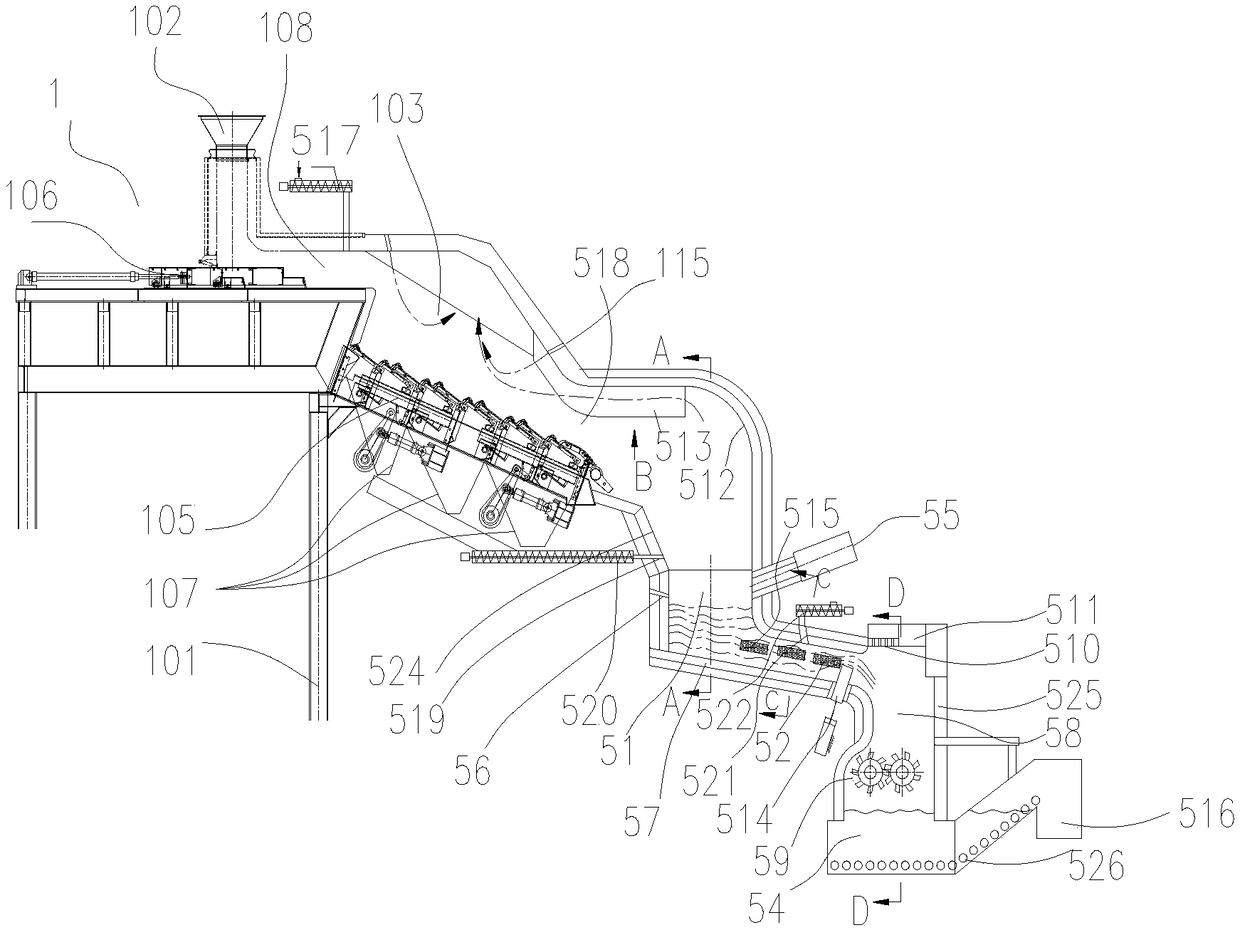

Waste fusing and curing treatment system and method

ActiveCN106524175ARealize continuous gasification and melting processingLarge amount of processingIncinerator apparatusCombustorSlag

The invention discloses a waste fusing and curing treatment system and method. When the waste fusing and curing treatment system and method are used for treating rubbish, the rubbish conveying capacity is higher, the rubbish treating capacity is larger, the thermal loss can be reduced, the heat exchanging efficiency can be improved, the recovery efficiency of heat is relatively high, and the emission load of pollutants can be effectively reduced. The waste fusing and curing treatment system comprises a fusion hearth, a laminar flow channel, a water-cooling breaking system and a water seal deslagging system all of which are sequentially arranged in the feeding direction. A high-temperature burner and a gasifying agent inlet are formed in the side wall of the fusion furnace. The water-cooling breaking system comprises a water-cooling system, a water-cooling cavity and a glass body pulverizer. The method comprises the first step of furnace starting and drying; the second step of enabling residues into the fusion hearth to be fused; the third step of fusing inorganic waste in the laminar flow channel; the fourth step of carrying out water cooling on fusion slag and curing the fusion slag into glass body dregs, and breaking and discharging the dregs; and the fifth step of turning off the waste fusing and curing treatment system after the waste fusion dregs are discharged completely.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

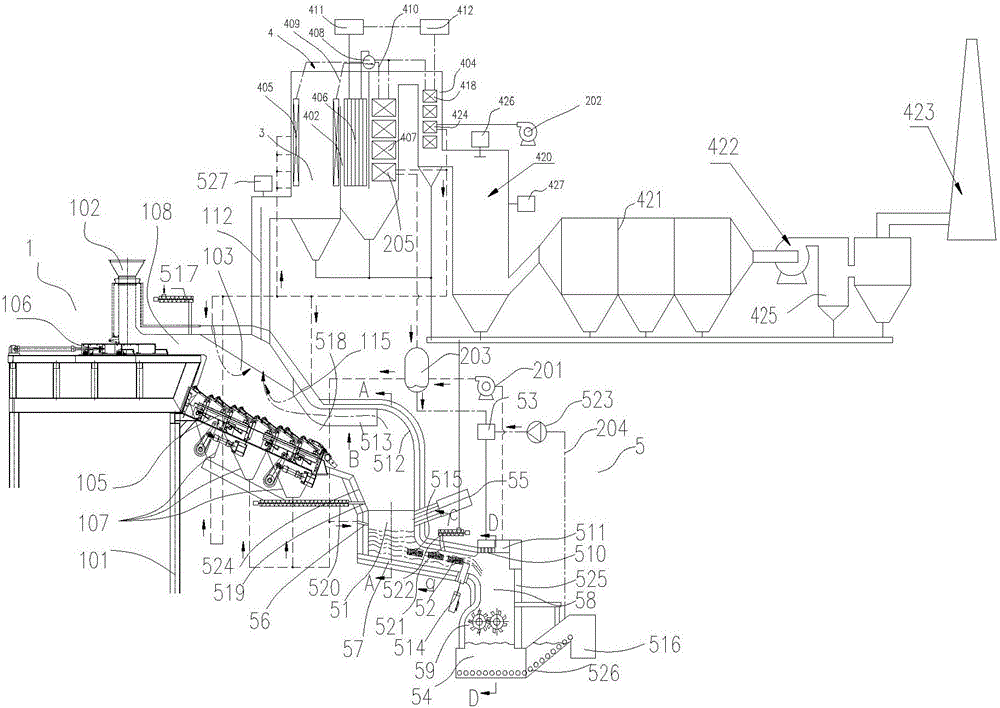

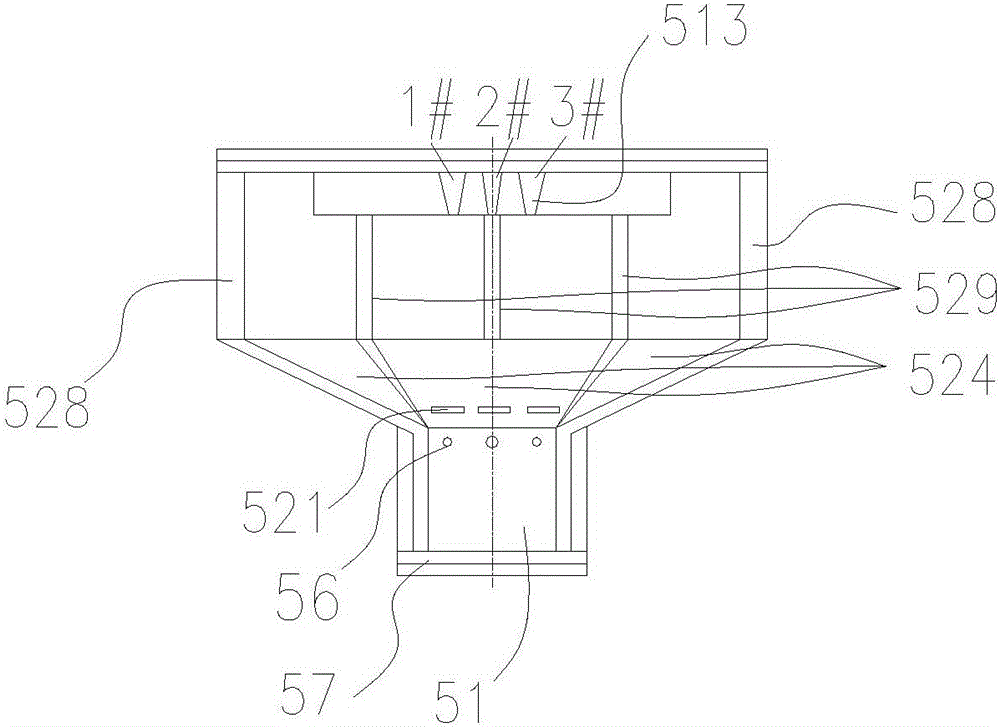

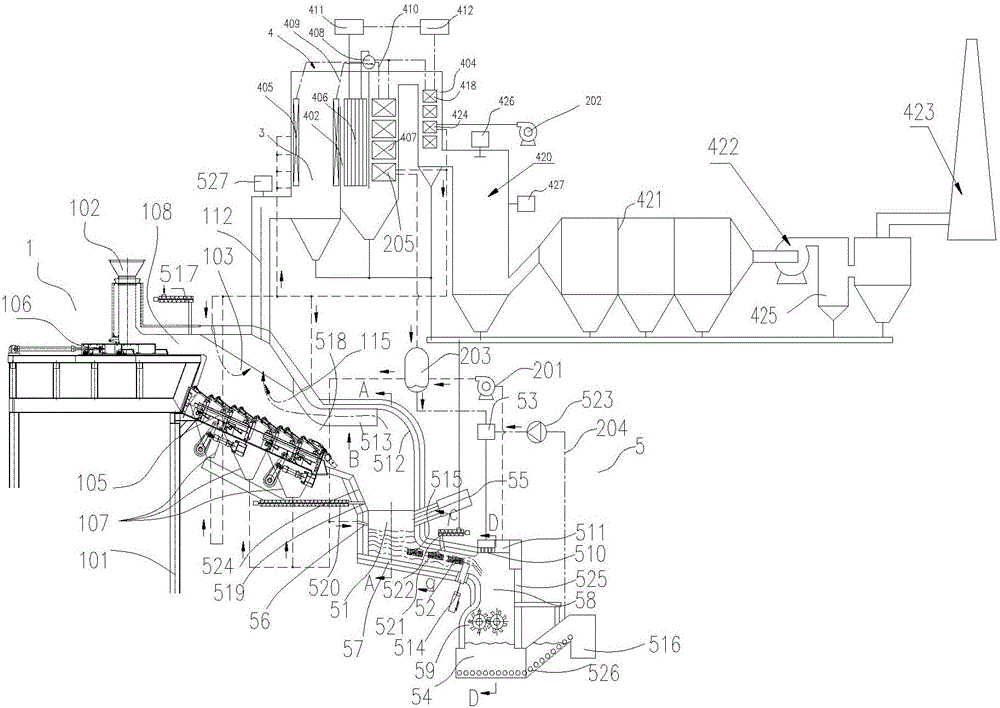

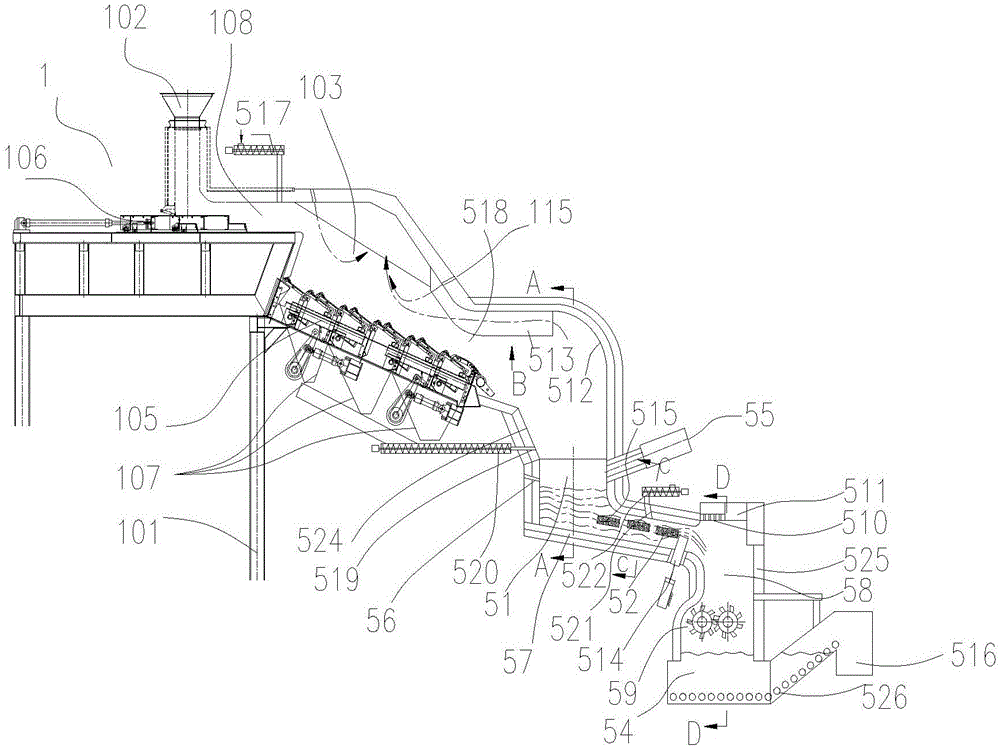

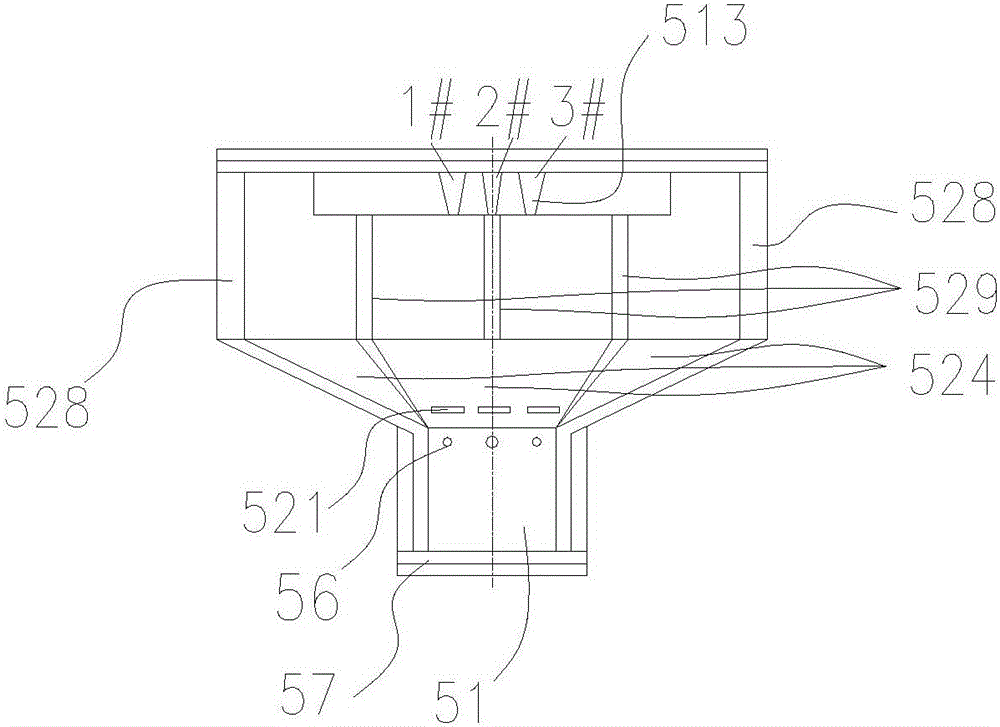

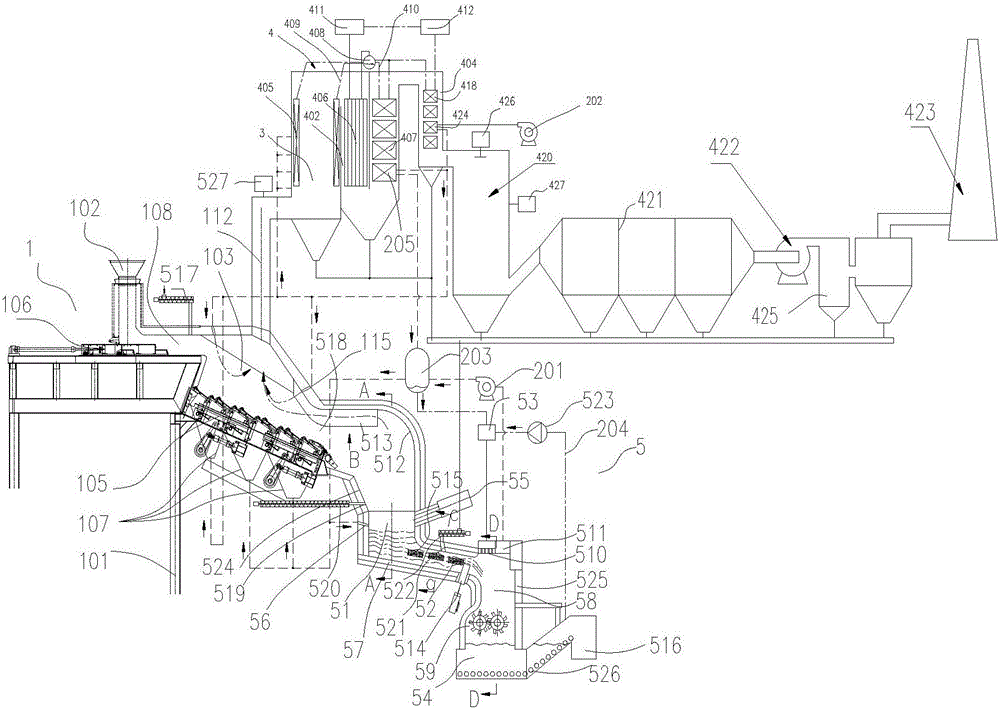

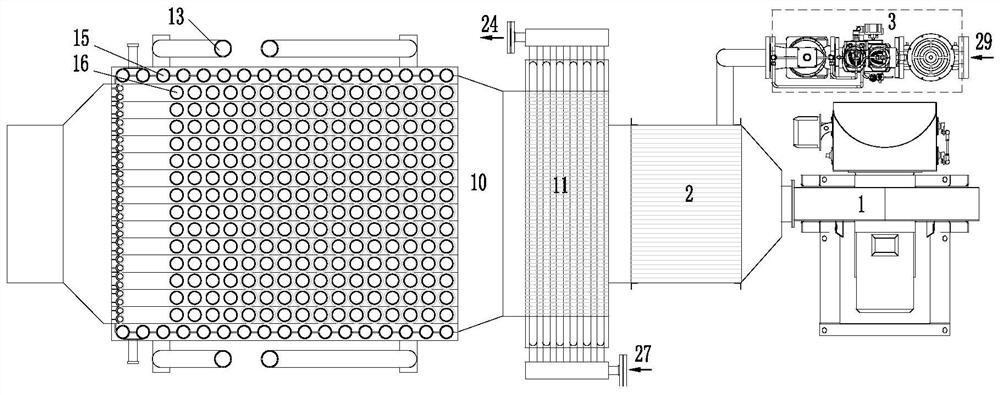

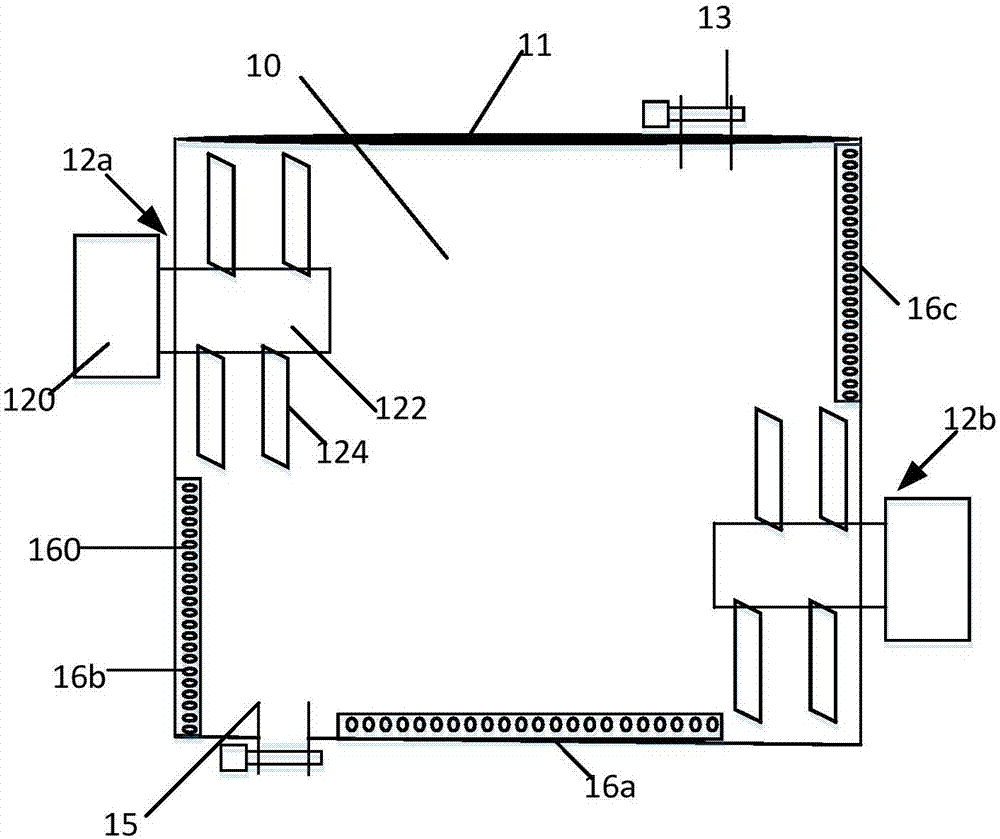

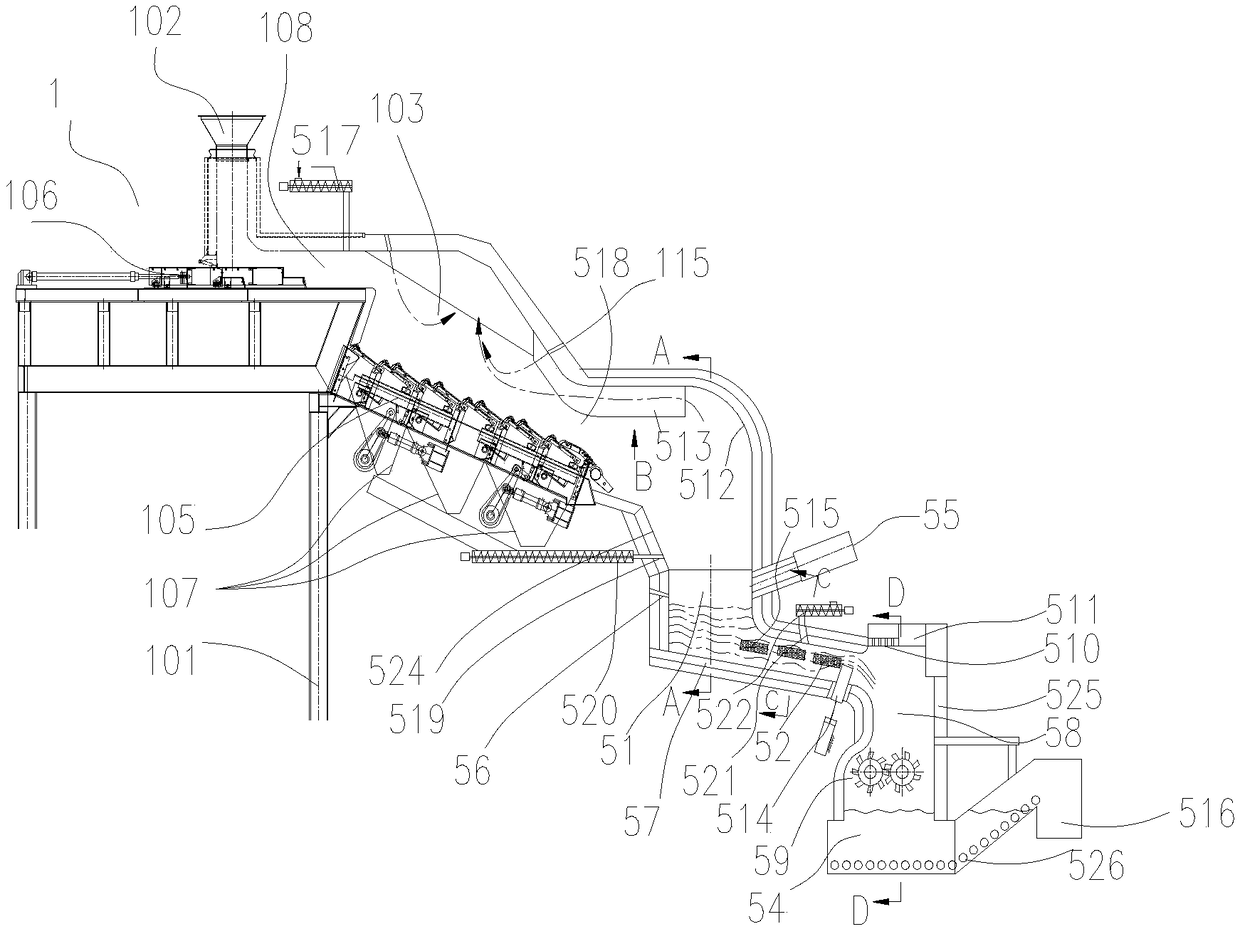

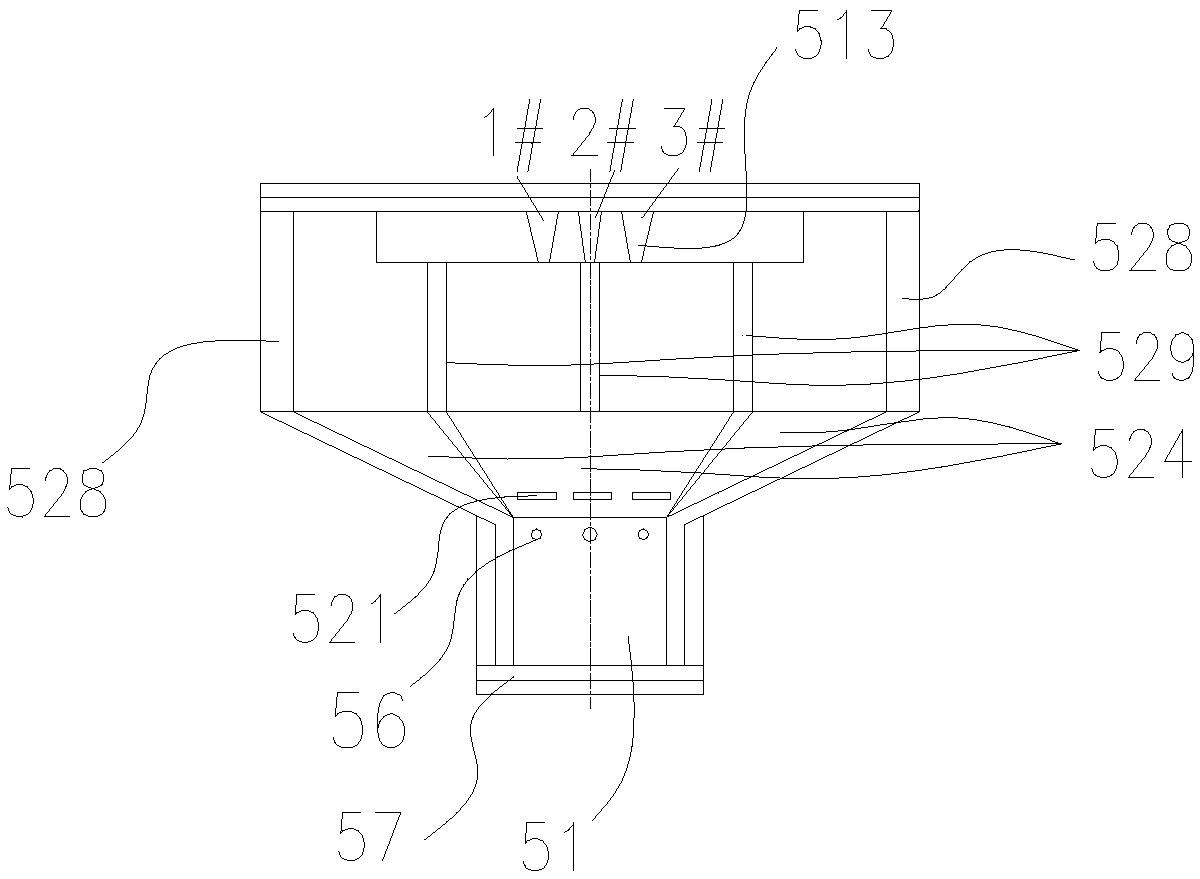

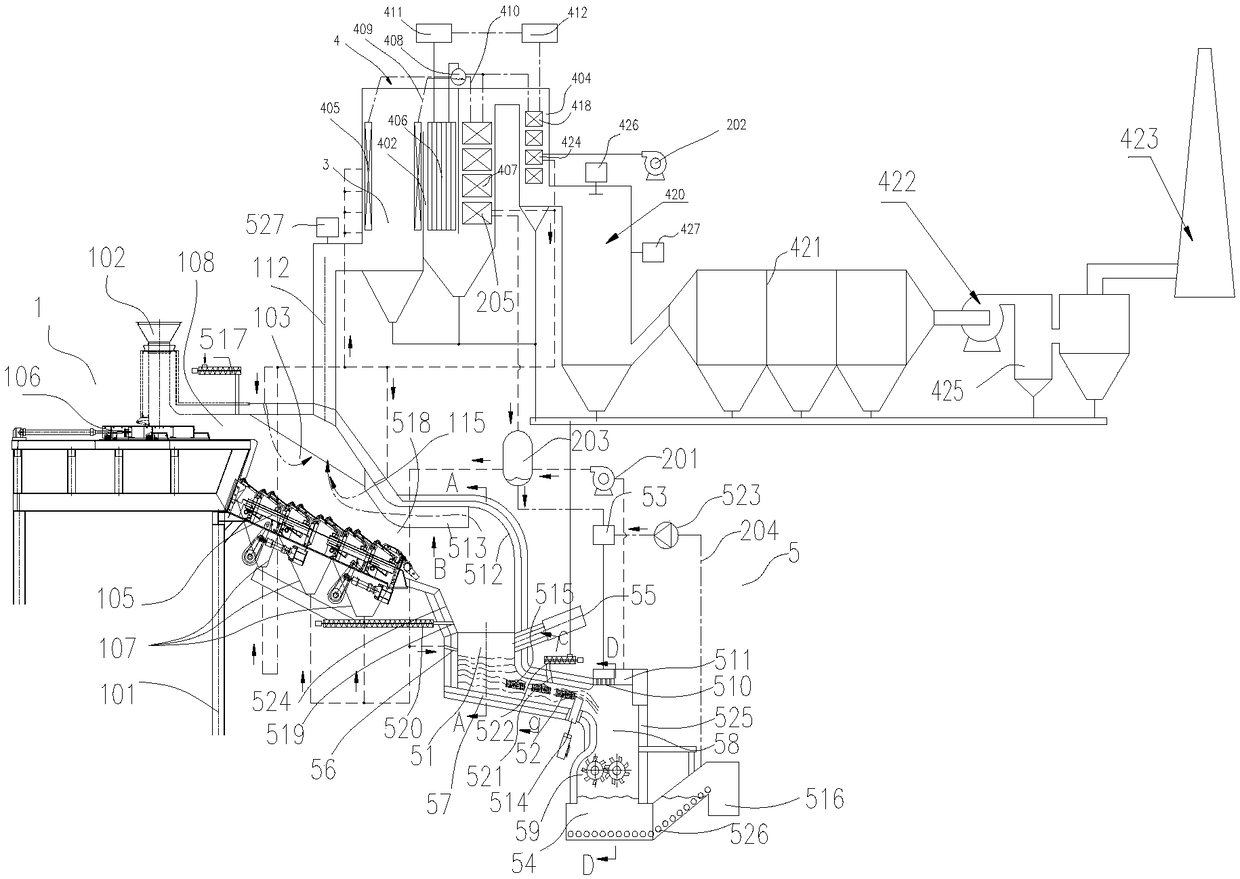

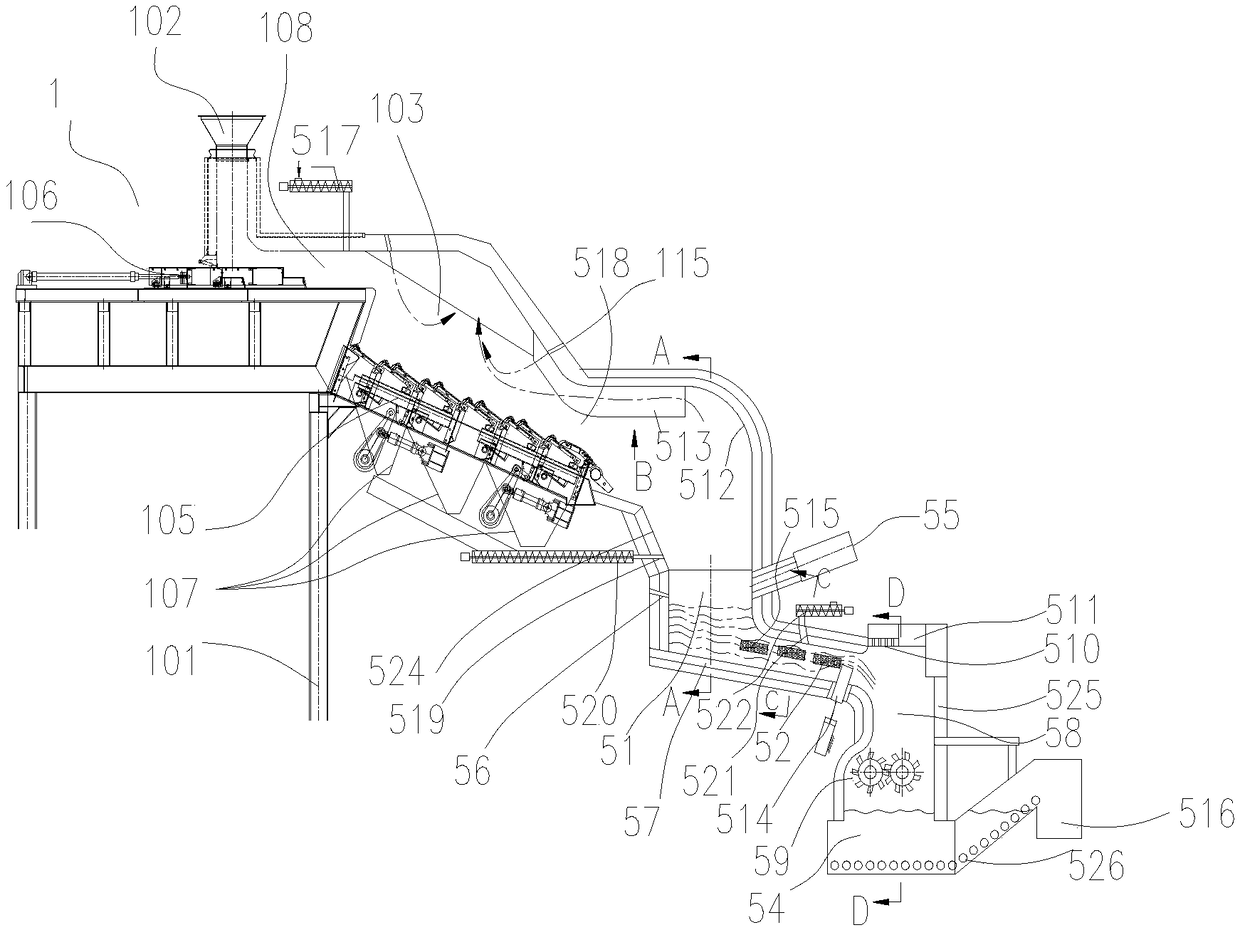

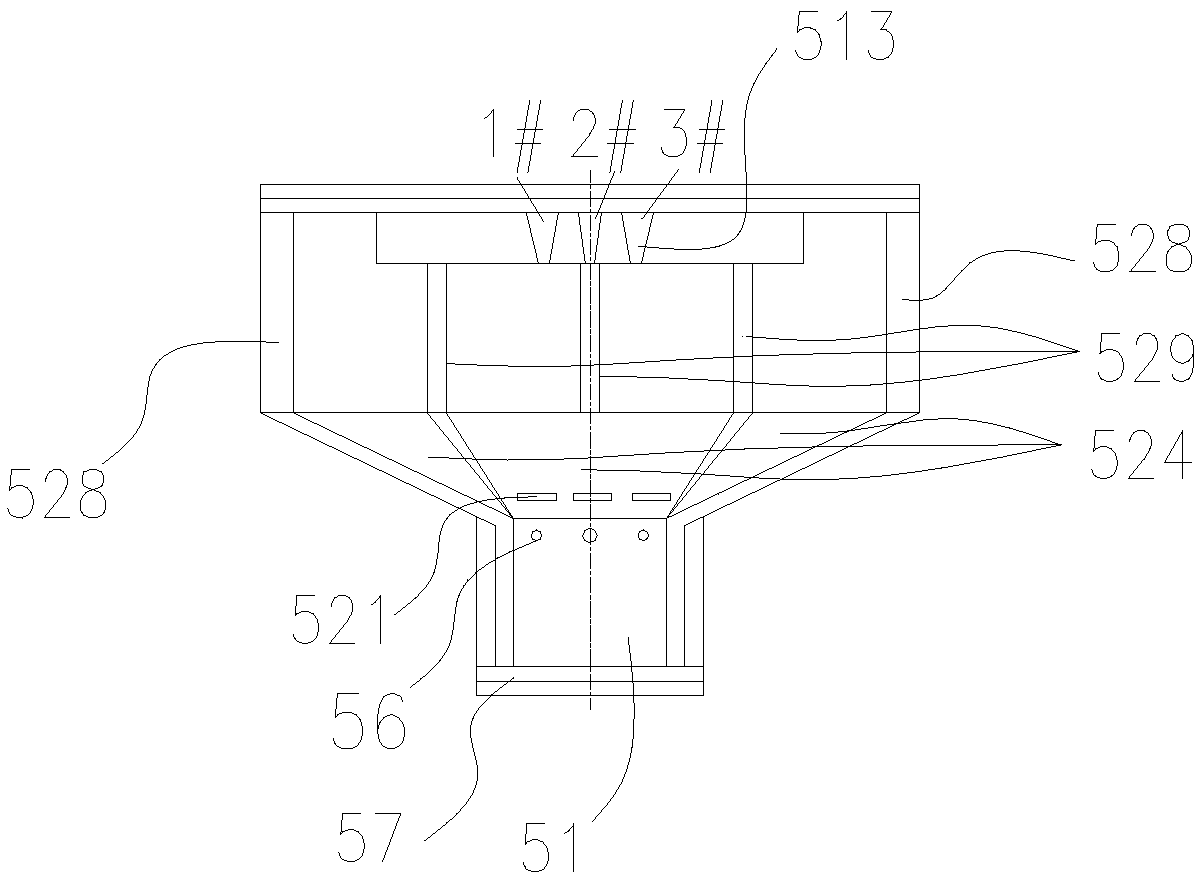

Waste gasification melting combustion system

ActiveCN106524176ARealize continuous gasification and melting processingLarge amount of processingIncinerator apparatusCombustion systemSlag

The invention discloses a waste gasification melting combustion system. The system is used for treating garbage, is higher in garbage conveying capacity, is higher in garbage treatment quantity, can reduce the heat loss and improve the heat exchange efficiency, is higher in heat recovery efficiency, and can effectively reduce the pollutant discharge. The waste gasification melting combustion system comprises a waste gasification melting furnace and a boiler system; the waste gasification melting furnace includes a furnace frame, and a feeding bin, a gasification furnace and a melting curing system arranged on the furnace frame in the feeding direction in sequence; the melting curing system includes a melting hearth, a laminar channel, a water cooling crushing system and a water seal deslagging system arranged in sequence in the feeding direction; a high-temperature combustor and a gasifying agent inlet are arranged on the side wall of the melting hearth; the water cooling crushing system includes a water cooling system, a water cooling cavity and a glass body crusher; and a discharge end of the water seal deslagging system is connected with a glass body slag discharge port.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Medical diagnostic x-ray apparatus provided with a cooling device

ActiveUS20100111259A1Improve cooling efficiencyFine surfaceX-ray tube electrodesX-ray apparatusX-rayThermal contact

The invention relates to a medical diagnostic X-rayapparatus (1) comprising an X-raysource (13), a hollow carrier (5) to which the X-raysource is connected, and a cooling mechanism (3) provided with a cooling means to cool the X-raysource (13) during use of the X-rayapparatus (1). The cooling means is in direct thermal contact with the carrier (5), thus providing an efficient cooling mechanism (3) for the X-raysource (13).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

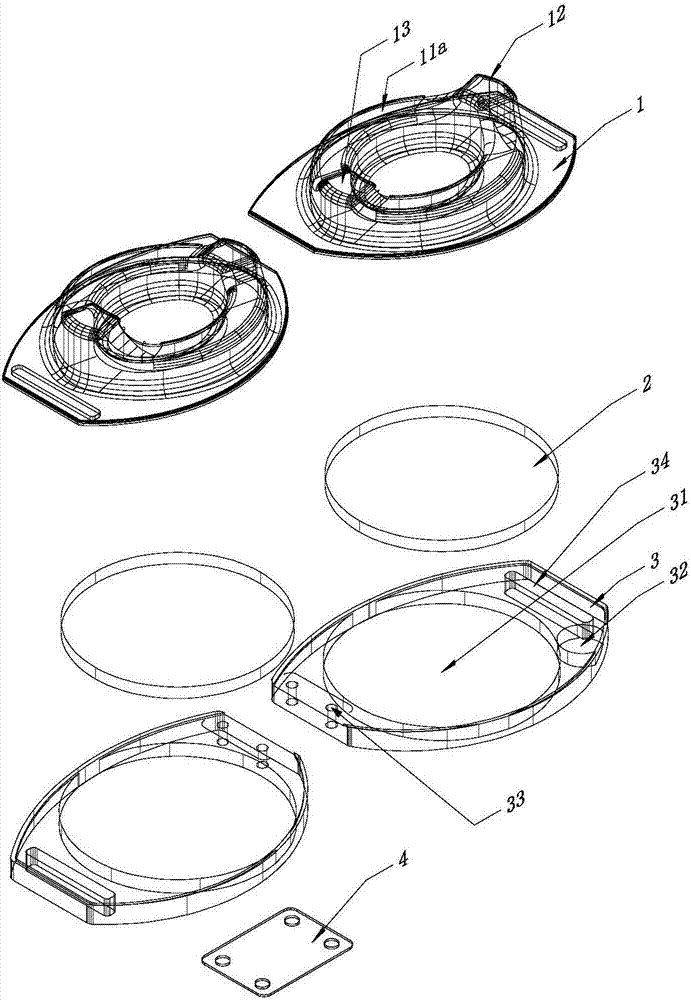

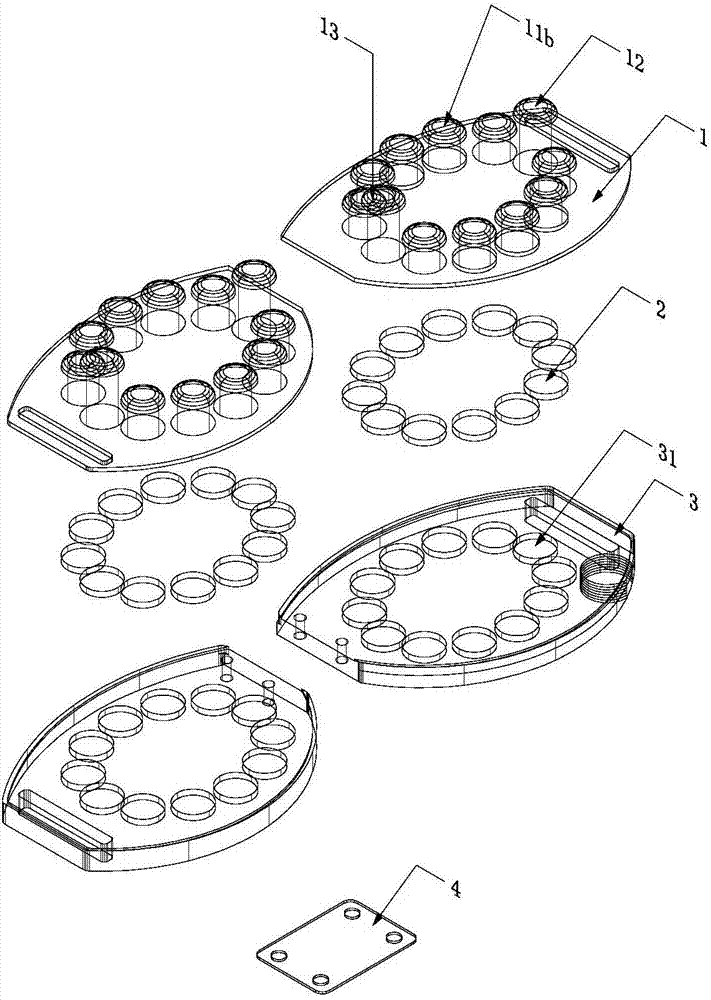

Ultrasonic treatment head configured to act on eyes

PendingCN107349532AWon't hurtNo personal restrictionsUltrasound therapyEye treatmentMedicineMechanical engineering

The invention provides an ultrasonic treatment head configured to act on eyes. The ultrasonic treatment head comprises two mutually connected ultrasonic transducers configured to act on a left eye and a right eye respectively, wherein the ultrasonic transducers are of a symmetrical structure. Each ultrasonic transducer comprises a coupling body tightly attached to the periphery of an eyeball, a backing matched with the coupling body, and a piezoelectric ceramic sheet. The front surface of the coupling body is provided with a continuous annular protrusion configured to be attached the eye socket of an eye up and down. The backing is provided with a groove for accommodating the piezoelectric ceramic sheet. The back surface of the coupling body and one side of the backing provided with the groove are attached together so as to package the piezoelectric ceramic sheet inside the groove. The electrodes of the piezoelectric ceramic sheets of the two ultrasonic transducers for left and right eyes are connected with each other or are separately led out. The annular protrusion can be a continuous ring, or connected or separate columns arranged in an annular form. According to the invention, the ultrasonic treatment head can be tightly attached to the eye sockets of eyes, while the eyeballs of the eyes are not pressed at all. Low-frequency ultrasonic waves can penetrate the eye sockets and soft tissues around the eye sockets to act on the muscle groups of the eyes. Therefore, the treatment on the muscle groups of the eyes can be realized.

Owner:南京亮易电子科技有限公司

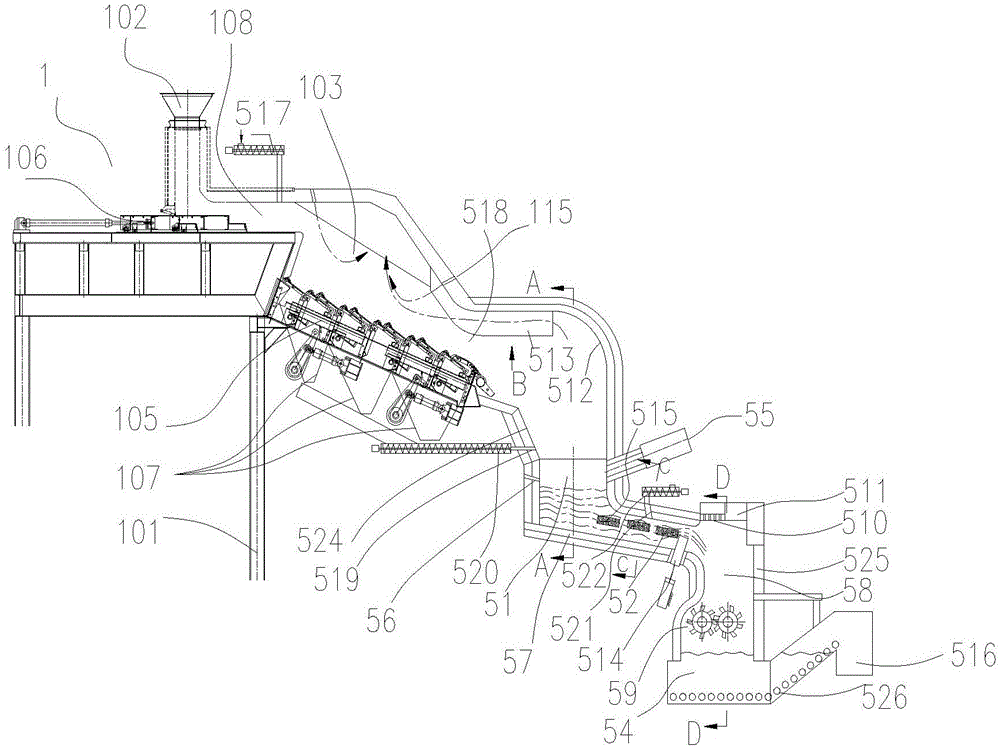

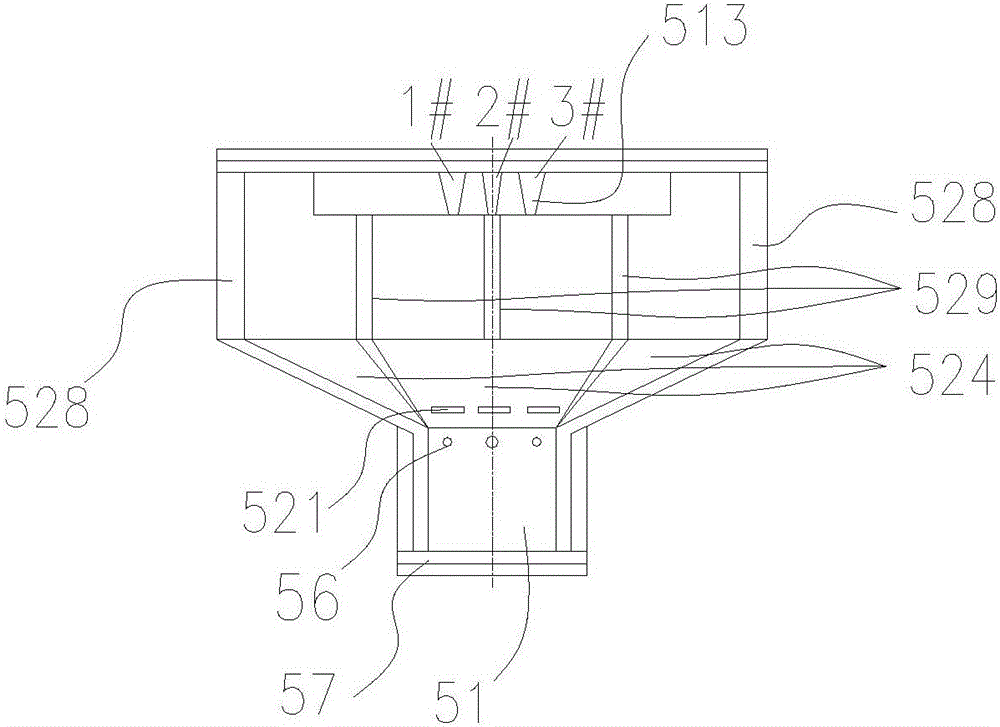

Waste gasification melting furnace

ActiveCN106642138ARealize continuous gasification and melting processingLarge amount of processingIncinerator apparatusCombustorHeat losses

The invention discloses a waste gasification melting furnace; and the waste gasification melting furnace is used for treating garbage, is higher in garbage conveying capacity, is higher in garbage treatment quantity, can reduce the heat loss and improve the heat exchange efficiency, is higher in heat recovery efficiency, and can effectively reduce the pollutant discharge. The waste gasification melting furnace comprises a furnace frame, and a feeding bin, a gasification furnace and a melting curing treatment system arranged on the furnace frame in sequence in a feeding direction; the melting curing treatment system includes a melting hearth, a laminar channel, a water cooling crushing system and a water seal deslagging system arranged in the feeding direction in sequence; a high-temperature combustor and a gasification agent inlet are arranged on a side wall of the melting hearth; the water cooling crushing system includes a water cooling system, a water cooling cavity and a glass body crusher; and a discharge end of the water seal deslagging system is connected with a glass body deslagging outlet.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

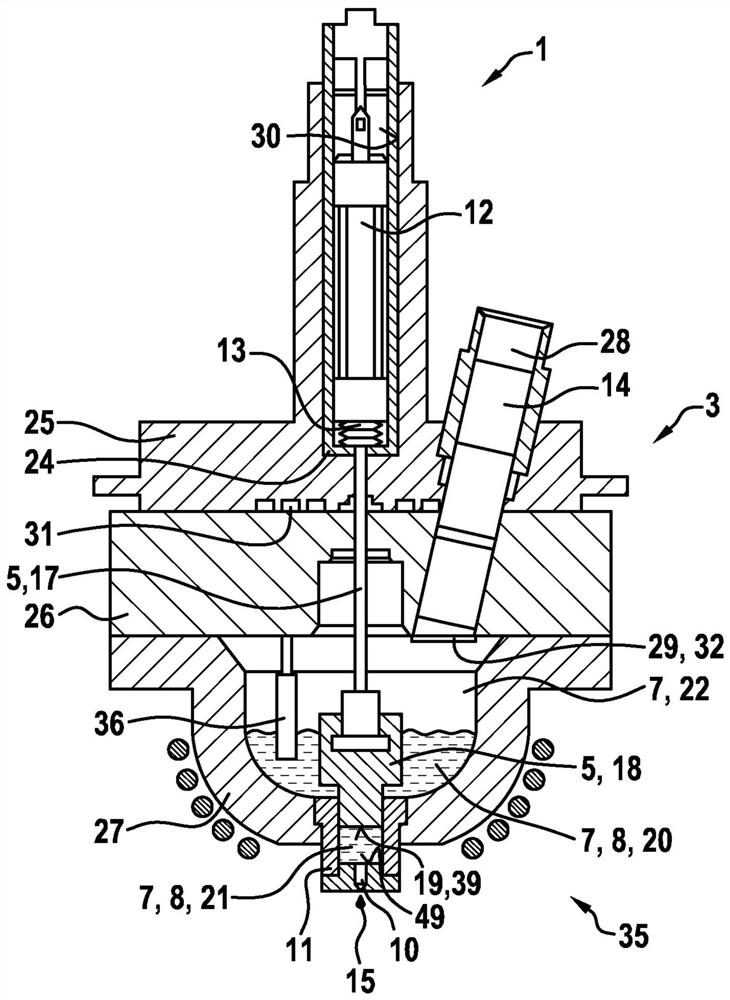

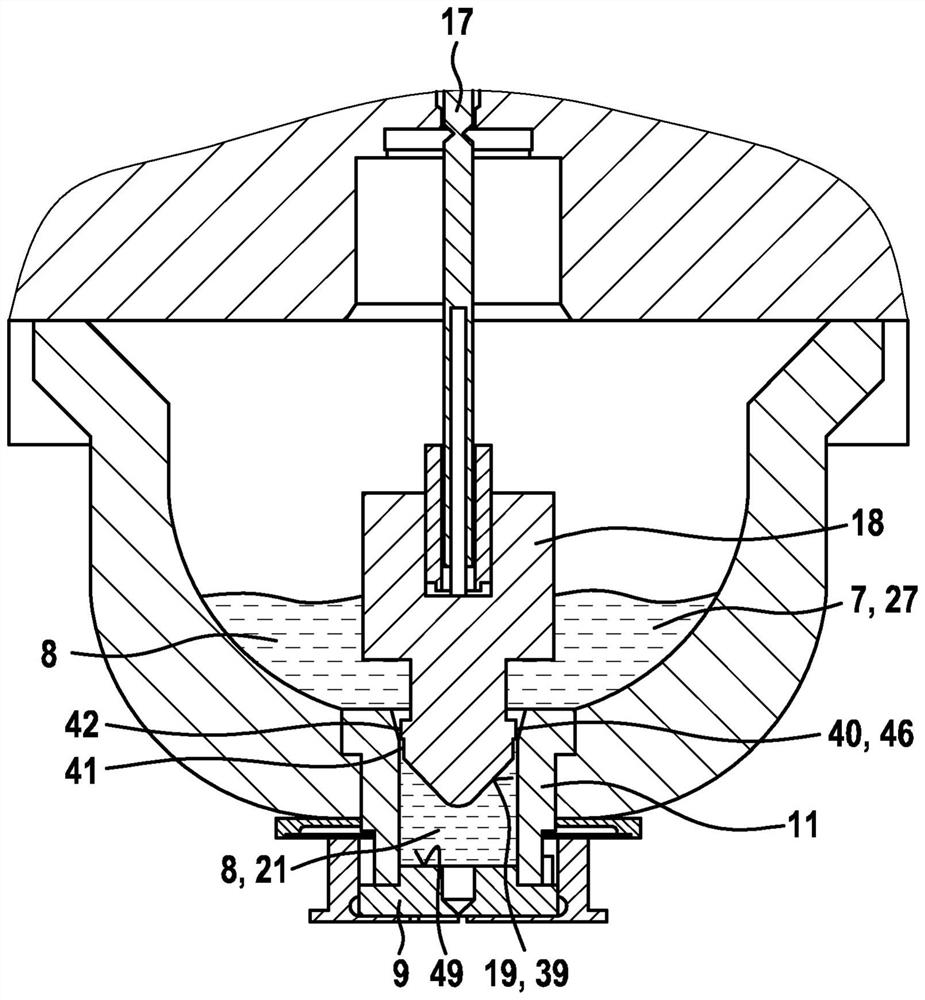

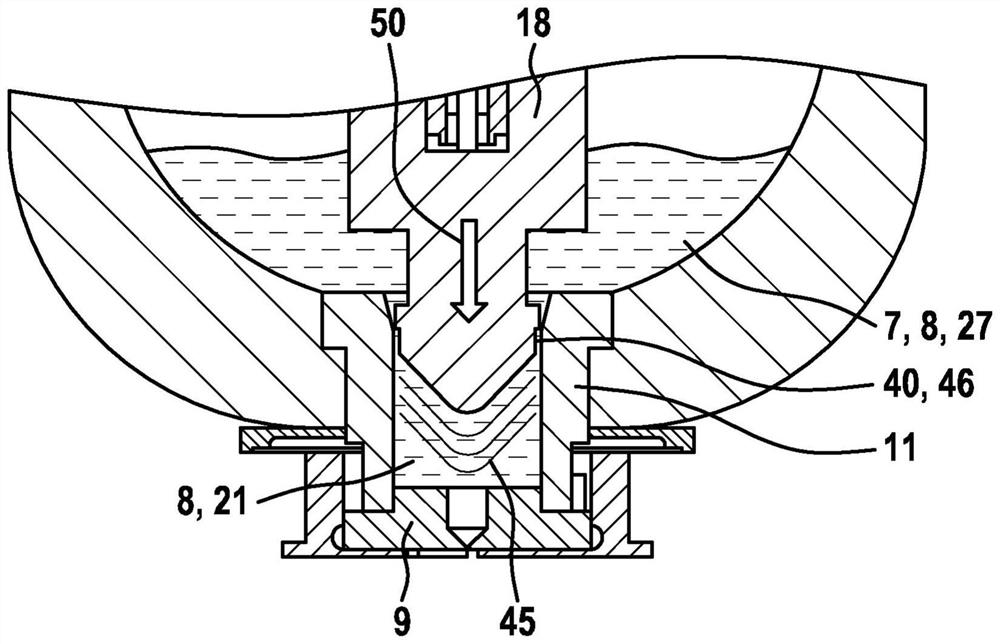

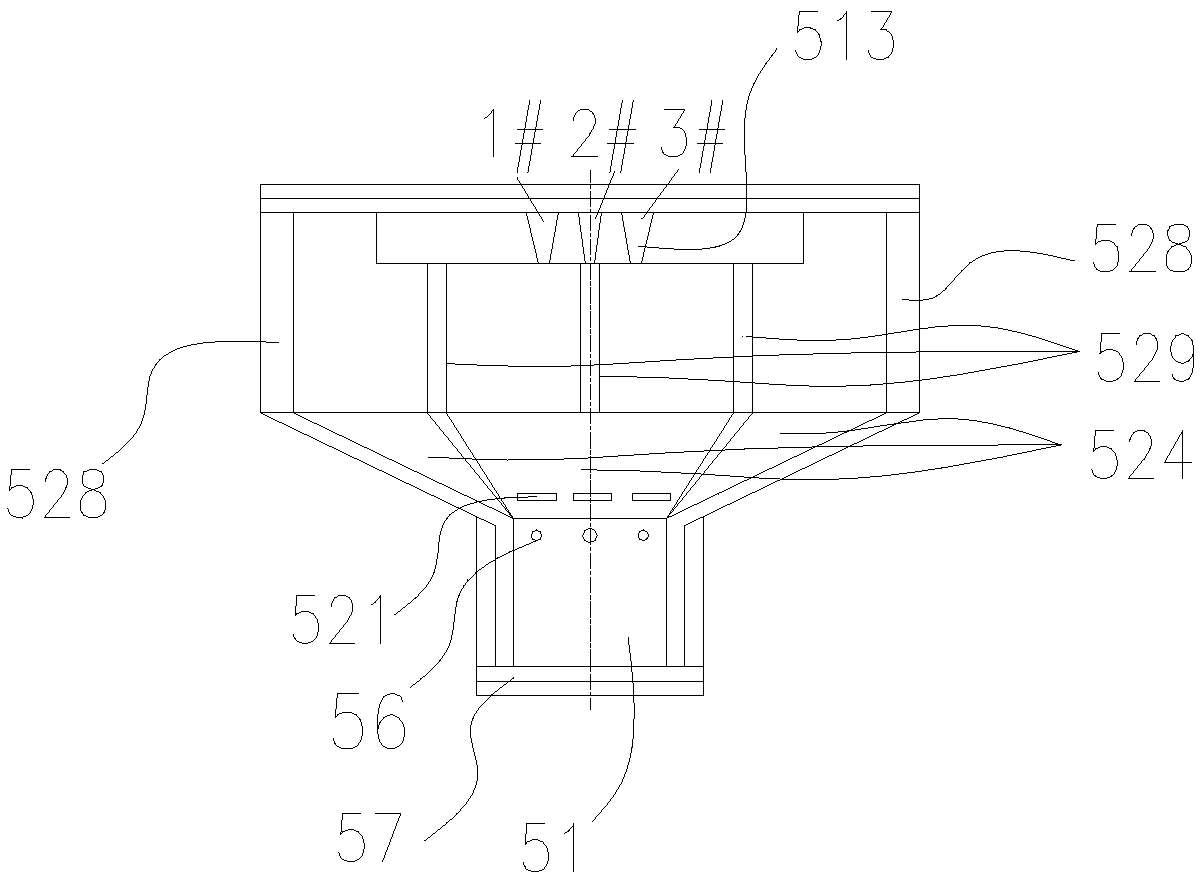

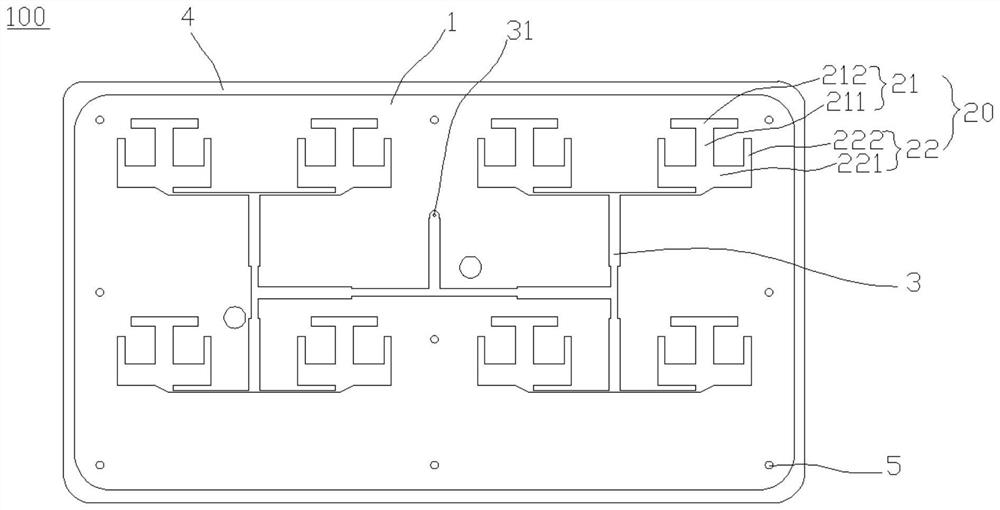

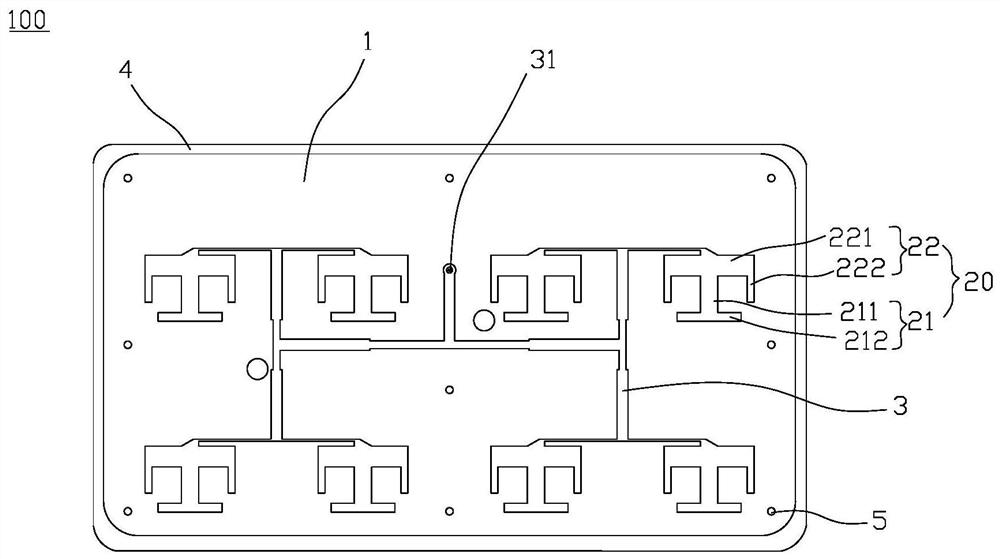

Piston for printhead of 3D printer and printhead for 3D printer

ActiveCN111655405ADetermine the qualityDetermine repeatabilityAdditive manufacturing apparatusInking apparatusComputer printingEngineering

The invention relates to a piston (5) for a printhead (1) of a 3D printer, particularly a metal printer, comprising a piston rod (17) and a ram (18), the ram (18) having a discharge side (19) that hasa convex or tapering surface (39). The invention also relates to a printhead (1) for a 3D printer, particularly a metal printer, comprising a housing (3), a device (28) for supplying a metal (14), areservoir (7, 27) for a liquid phase (8) of the metal (14), a nozzle device (2) comprising a guide sleeve (11) and a nozzle plate (9), and a piston (5) according to one of the preceding claims, the ram (18), the guide sleeve (11) and the nozzle plate (9) forming a displacement chamber (21), and the ram (18) and the guide sleeve (11) forming at least one area (40) for conducting the liquid phase (8) between the reservoir (27) and the displacement chamber (21).

Owner:ROBERT BOSCH GMBH

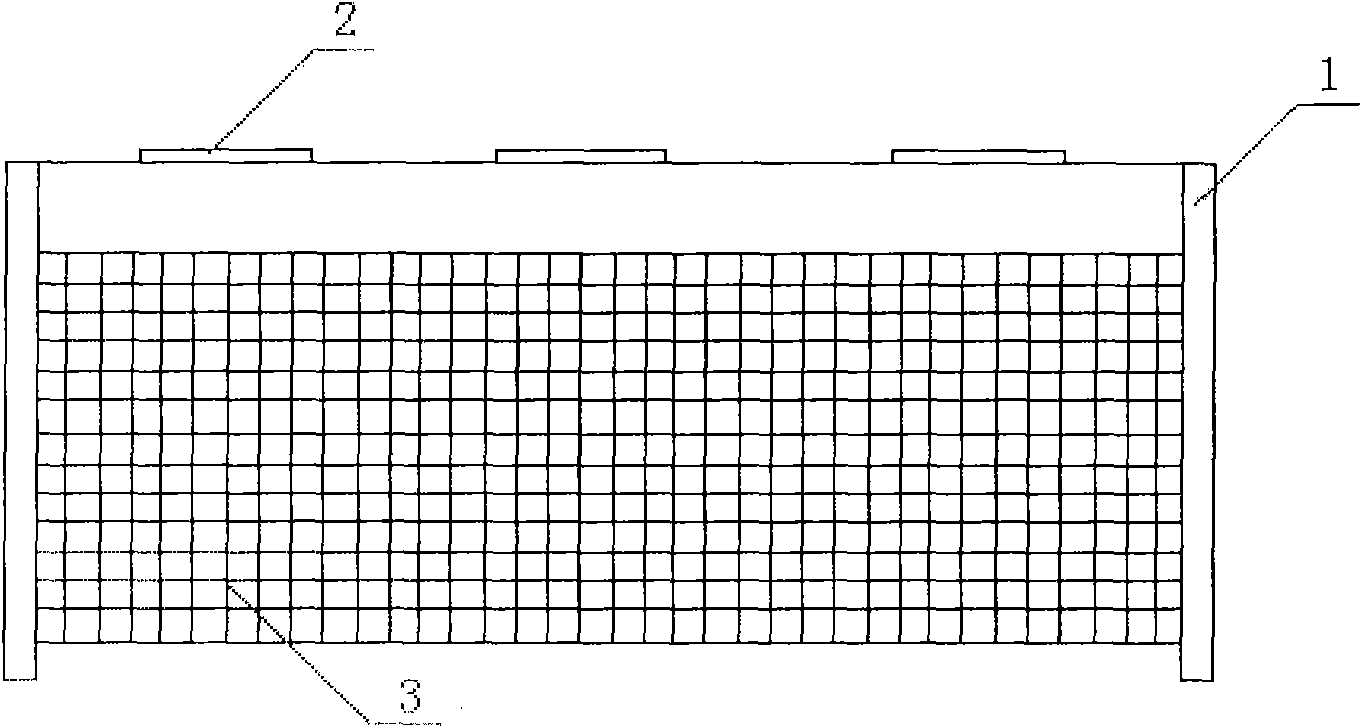

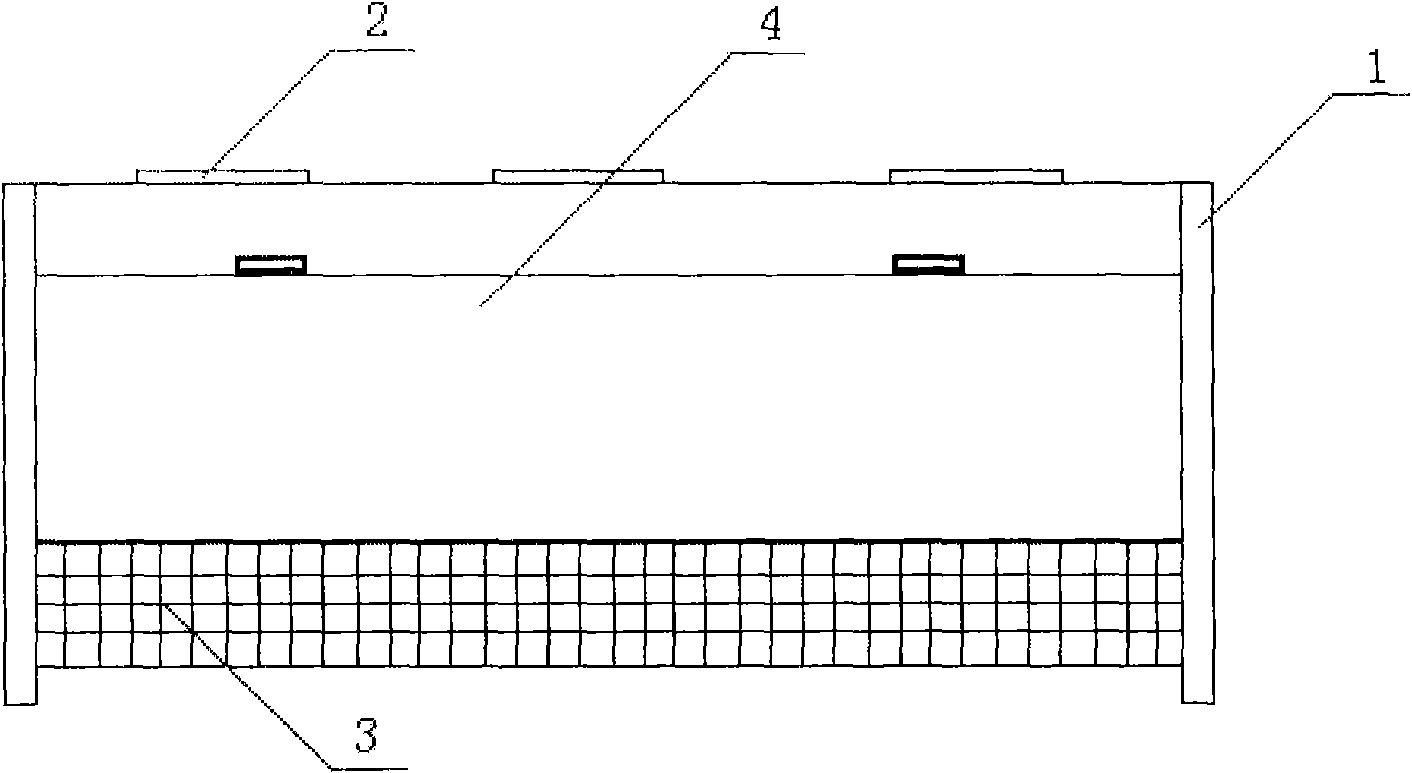

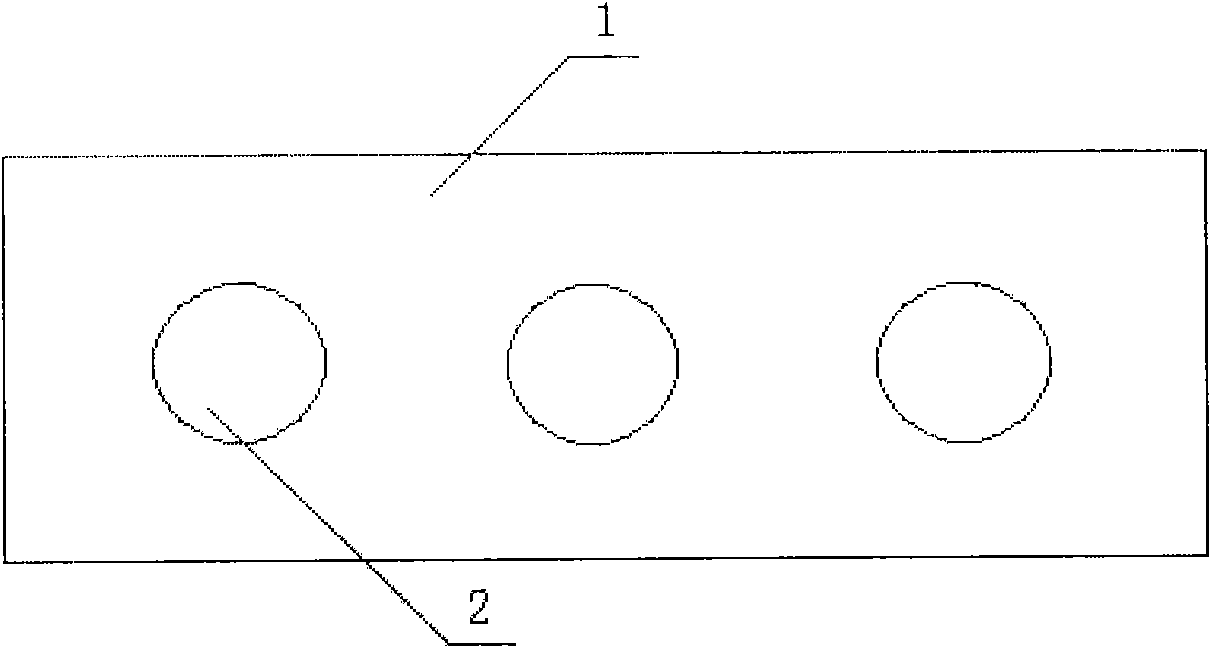

Multifunctional moxibustion instrument

InactiveCN101773448ALarge radiating surfaceSimple and fast operationDevices for heating/cooling reflex pointsEffective actionHeat losses

The invention discloses a multifunctional moxibustion instrument which comprises a shell, a steel wire net surface arranged in the shell, moxa holes arranged at the top of the shell, a heat deflector arranged at the rear part of the shell and a three-dimensional bracket connected with the moxibustion instrument. The steel wire net surface has 60-100 meshes and an external arc surface, the number of the moxa holes is from 1 to 8, the distances among the moxa holes range from 2cm to 8cm, the heat deflector and the shell top can be connected in a hinge mode, and the three-dimensional bracket is connected with the moxibustion instrument by a connecting shaft arranged at the rear side of the moxibustion instrument. The moxibustion instrument has great radiation area and simple and convenient operation, can effectively act on various parts of a body, is convenient to adjust the distance between the moxibustion instrument and the body and has less heat loss and wide application range.

Owner:王家芝

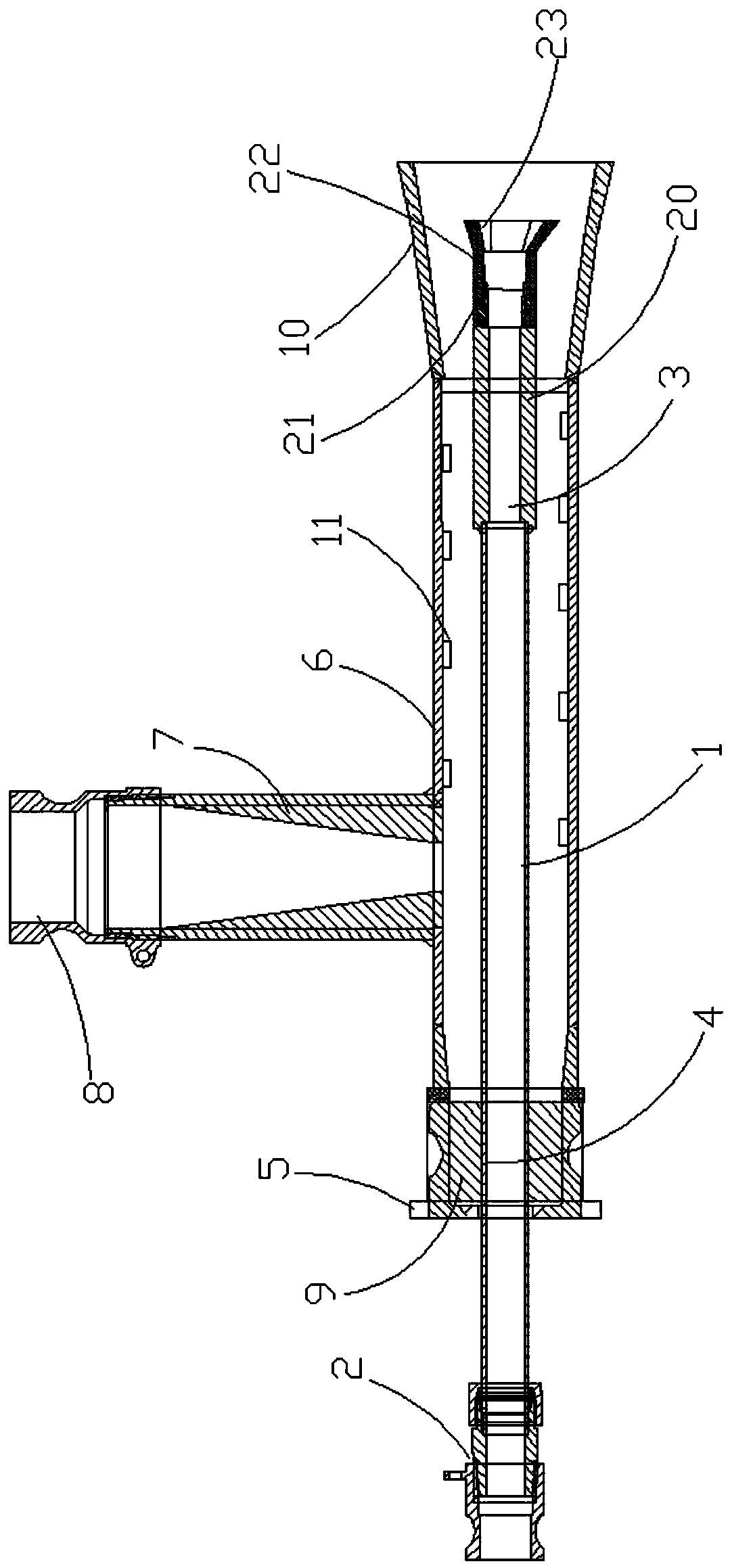

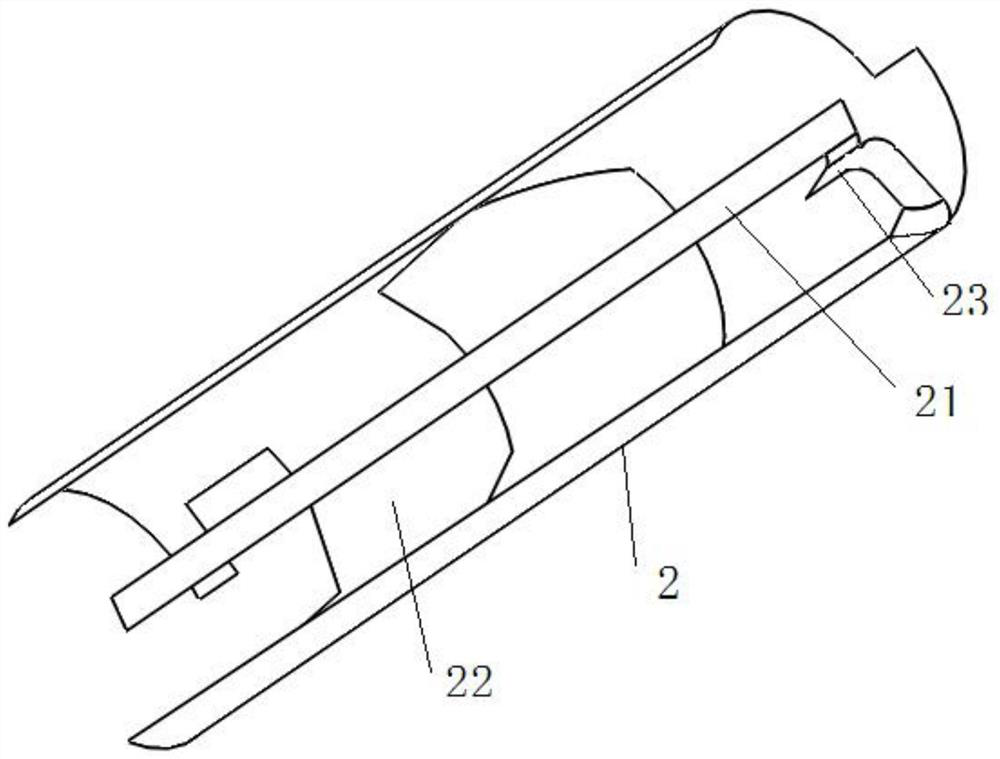

Improved-type desulfurization and denitrification spray gun

InactiveCN103990367AExtended service lifeReduce outputDispersed particle separationAgricultural engineeringCooling pipe

The invention discloses an improved-type desulfurization and denitrification spray gun. The improved-type desulfurization and denitrification spray gun comprises a spray gun inner pipe and a spry gun sleeve, wherein a joint is welded at one end of the spray gun inner pipe, and the other end of the spray gun inner pipe is welded with a spray gun head; the outer wall of the spray gun inner pipe forms a threaded region, and one side of the threaded region is provided with a stop ring; the spray gun sleeve is in threaded connection with the threaded region; the spray gun sleeve is provided with an inlet pipe; the inlet pipe is provided with a cooling pipe; an end socket is arranged between one end of the spray gun sleeve and the stop ring, and the other end of the spray gun sleeve is provided with a trumpet-shaped flaring; the inner wall of the spray gun sleeve is provided with 2-3 spirally arranged flow guide elements at intervals. According to the invention, the desulfurization and denitrification operation efficiency is improved, and meanwhile the service life is prolonged.

Owner:姜建勇

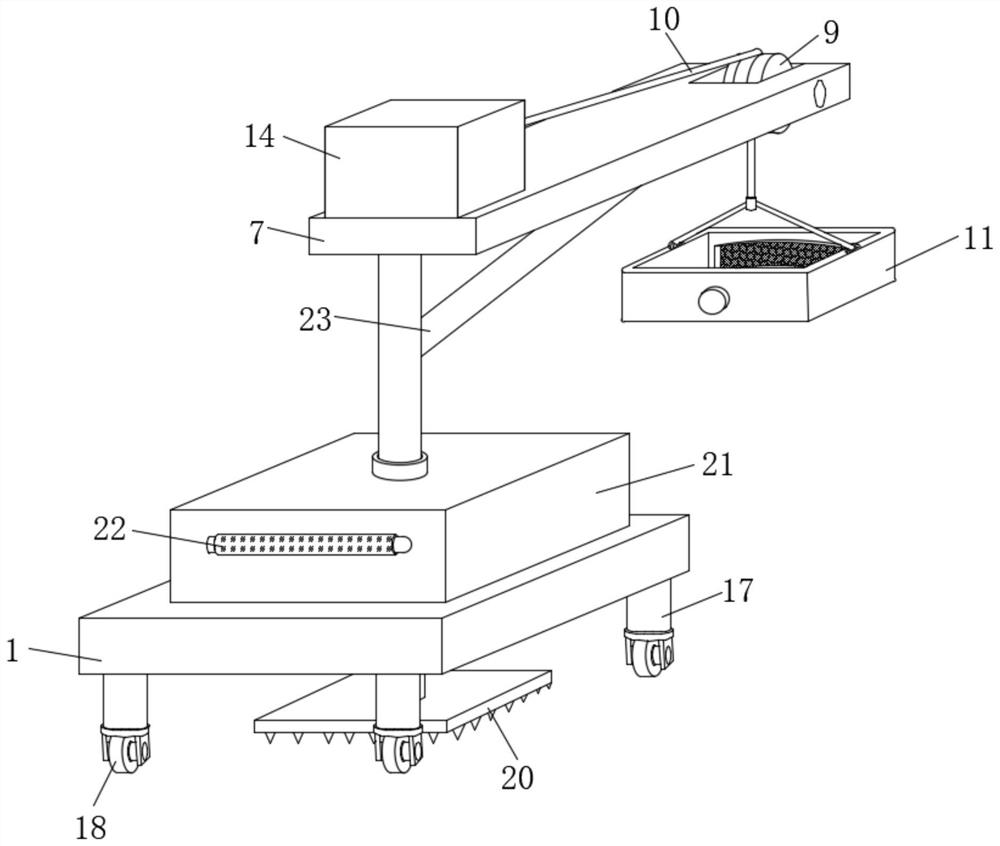

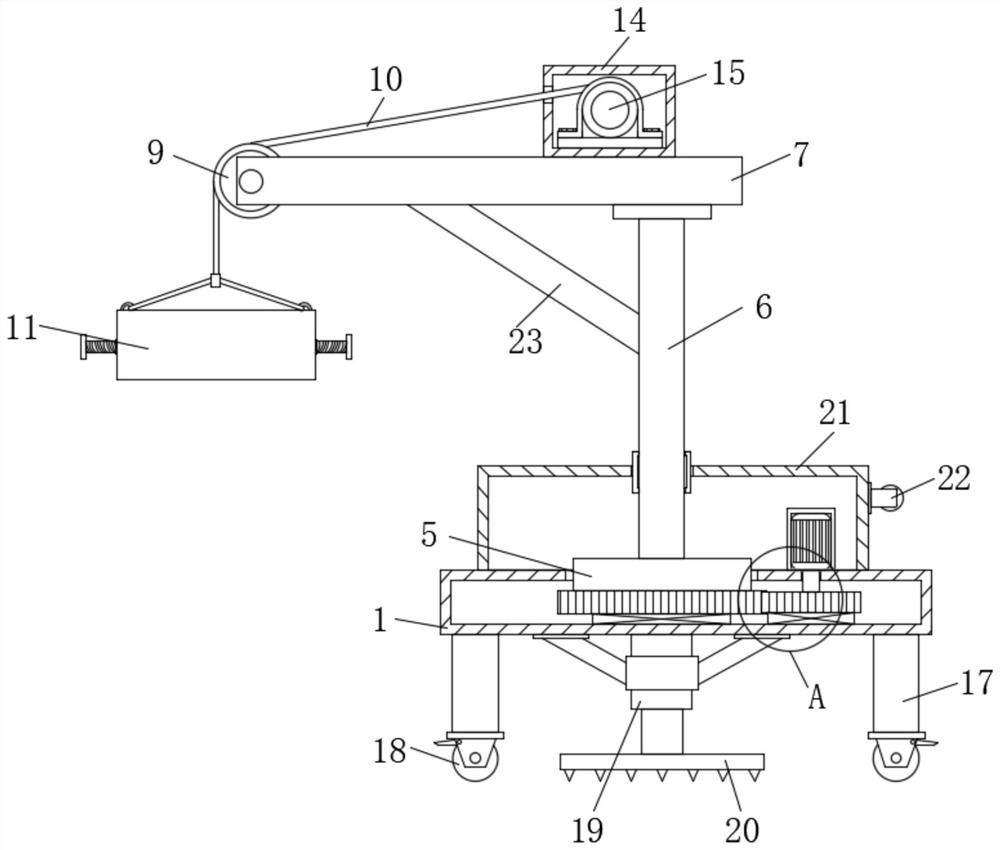

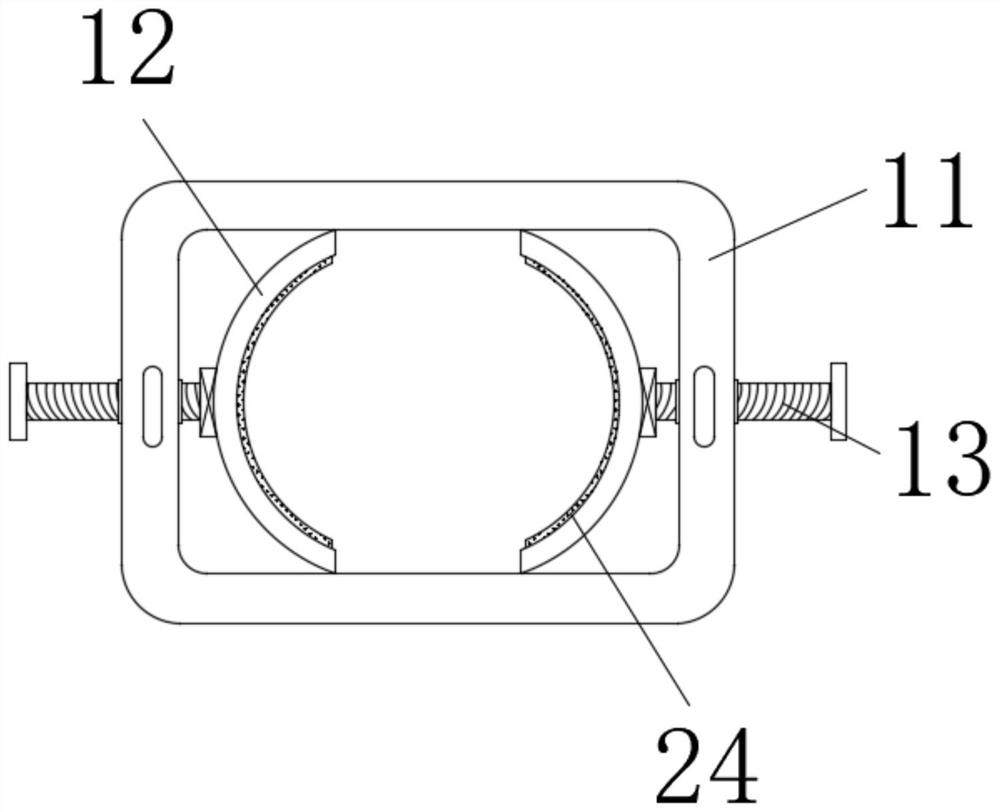

Tree lifting device for garden engineering

The invention relates to the technical field of garden engineering, and discloses a tree lifting device for garden engineering. The tree lifting device comprises a base, wherein a first gear is rotatably connected to the bottom of the inner wall of the base, one side of the first gear is meshed with a second gear, and a steering motor is in bolted connection to the right side of the top of the base; the output end of the steering motor is bolted with the top of the second gear; by designing the base, the first gear, the second gear, the steering motor and a supporting plate which are convenient to use, the lifting direction can be conveniently changed according to needs, traditional vertical lifting is avoided, the radiation surface of the lifting range is enlarged, and the use burden is greatly relieved; and by designing a winding mechanism, a pulley, a lifting rope, a fixing frame and arc-shaped clamping plates, which are convenient to use, materials can be conveniently fixed and lifted according to needs, loosening and falling caused by unfirm binding are avoided, the lifting safety is greatly improved, and the lifting device is worthy of popularization and application.

Owner:广东中煤地质环境工程有限公司

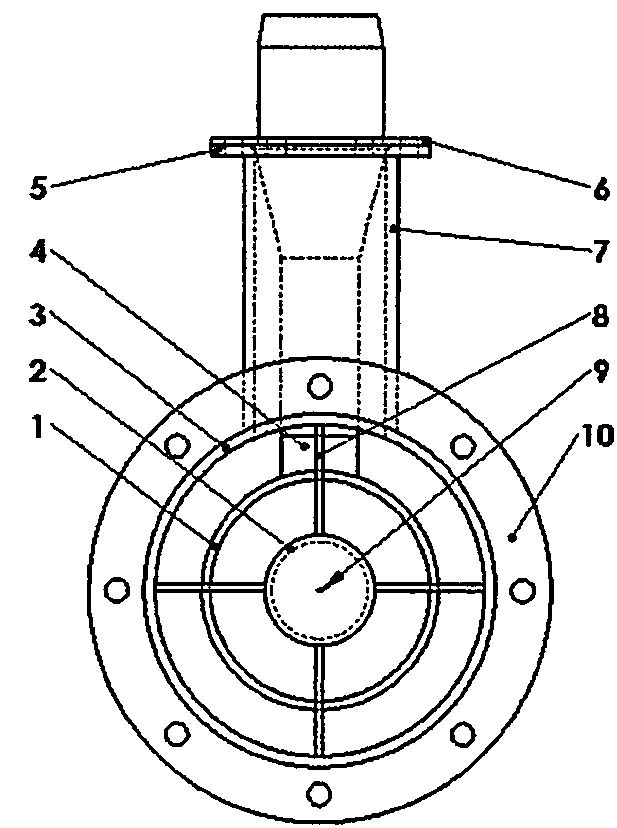

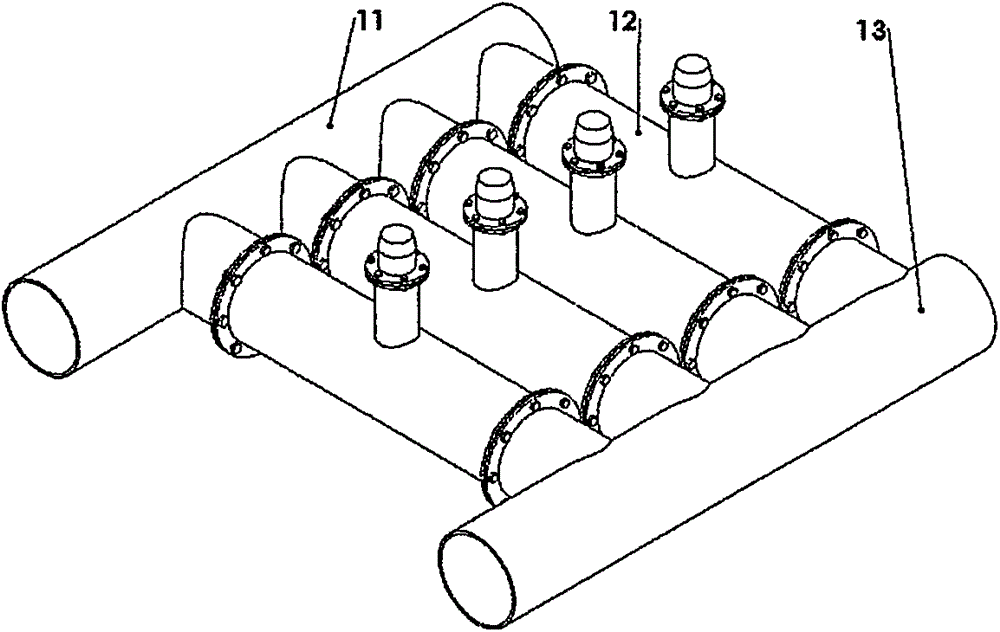

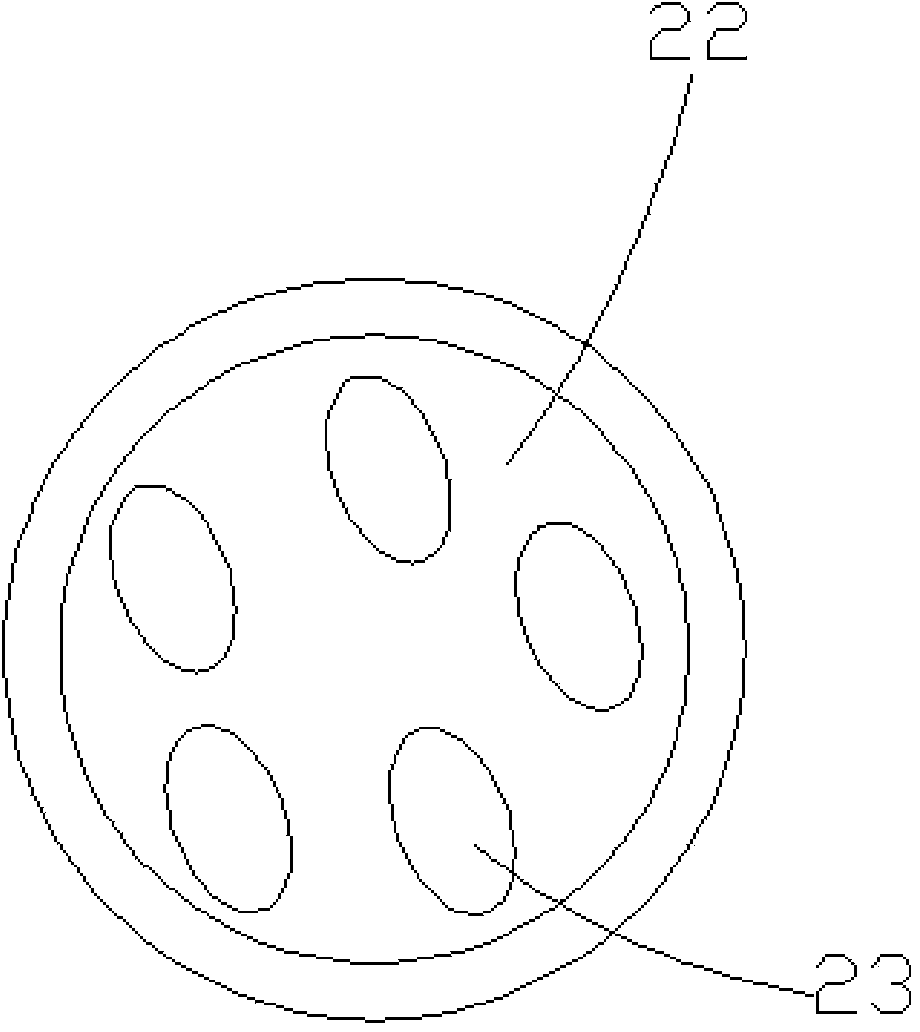

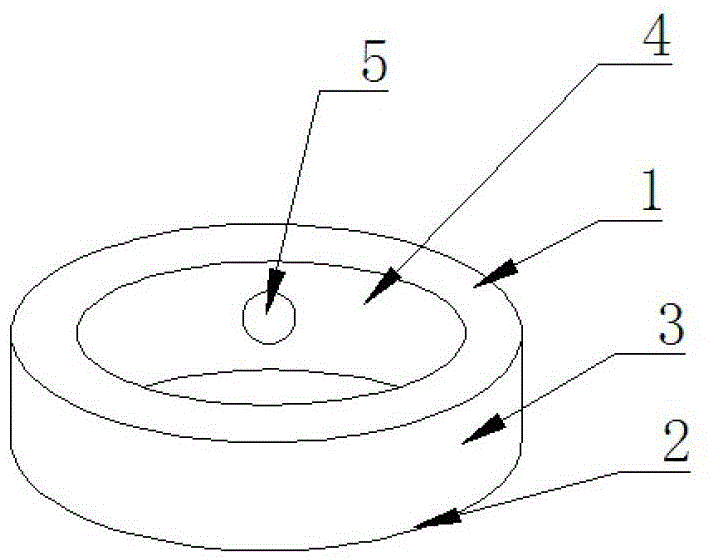

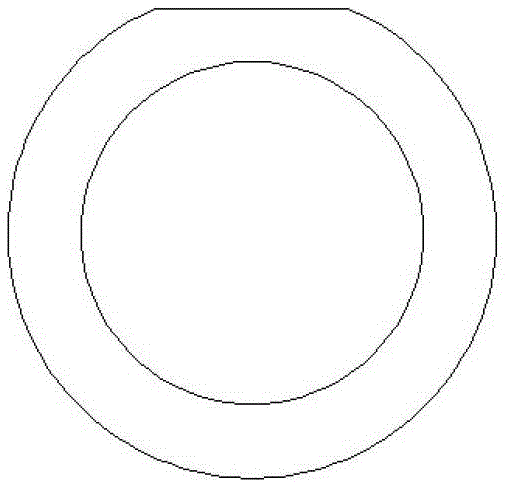

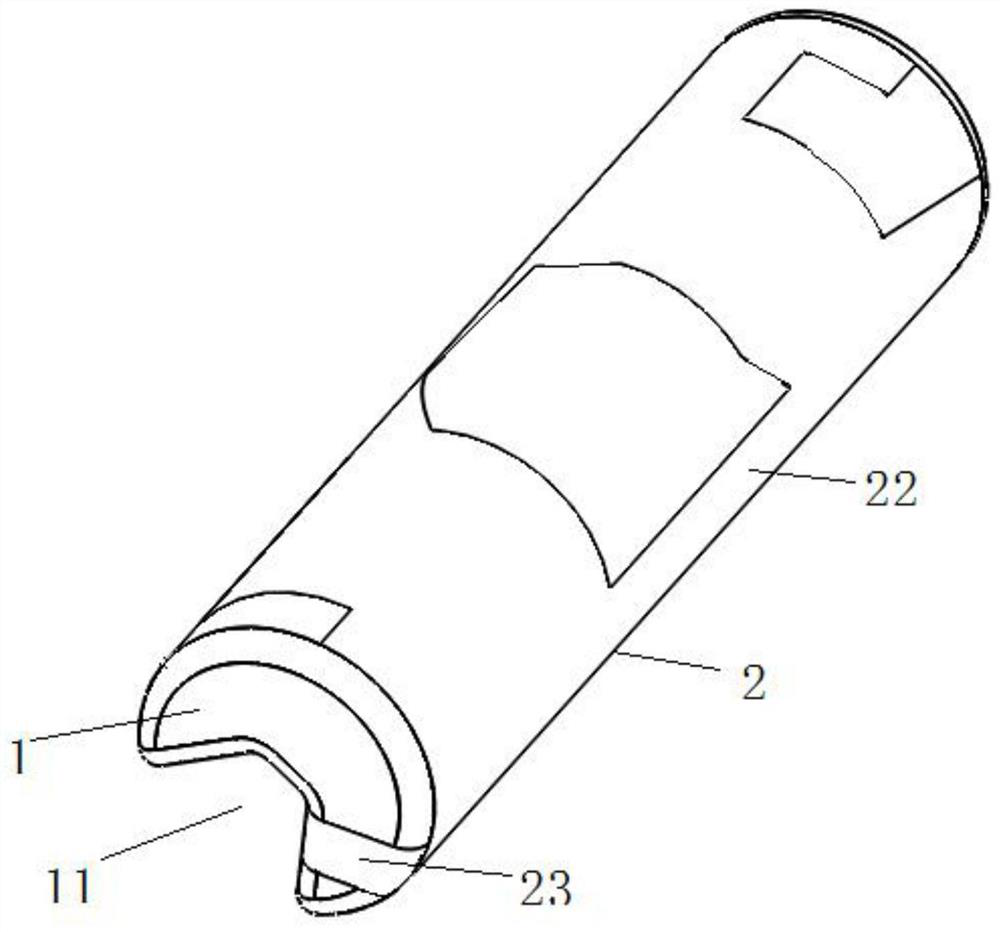

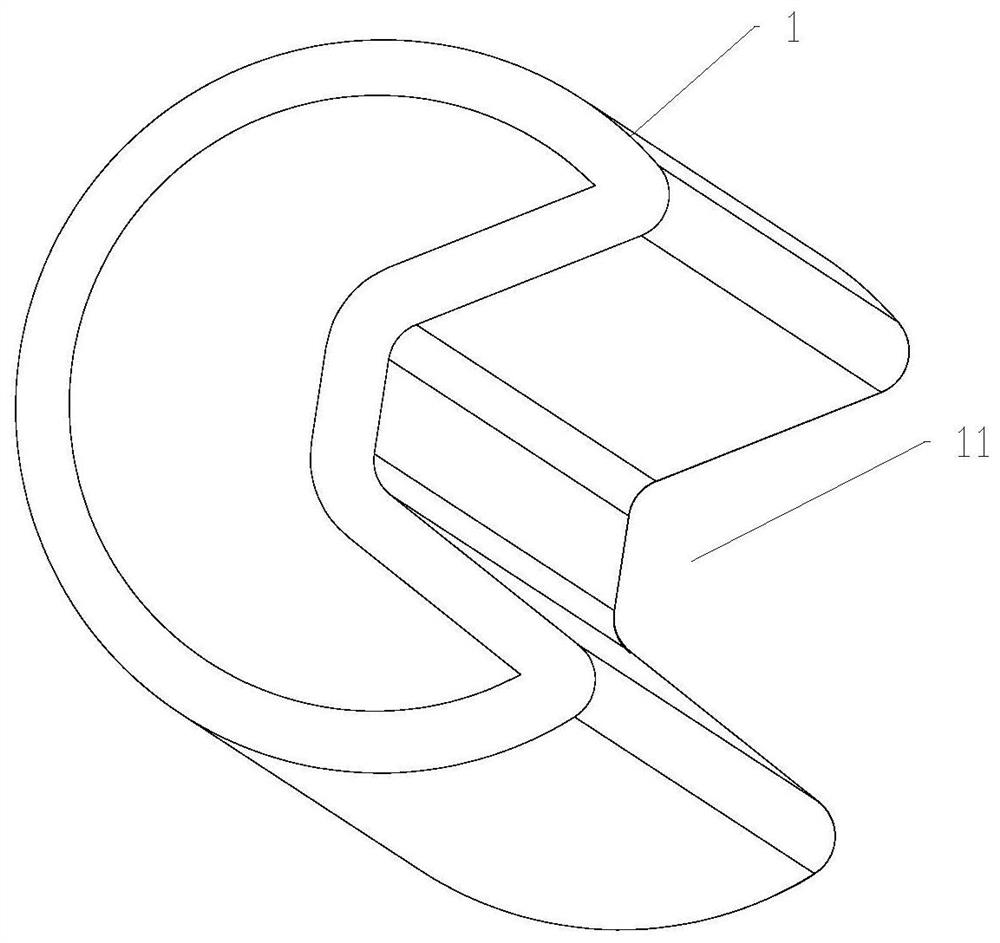

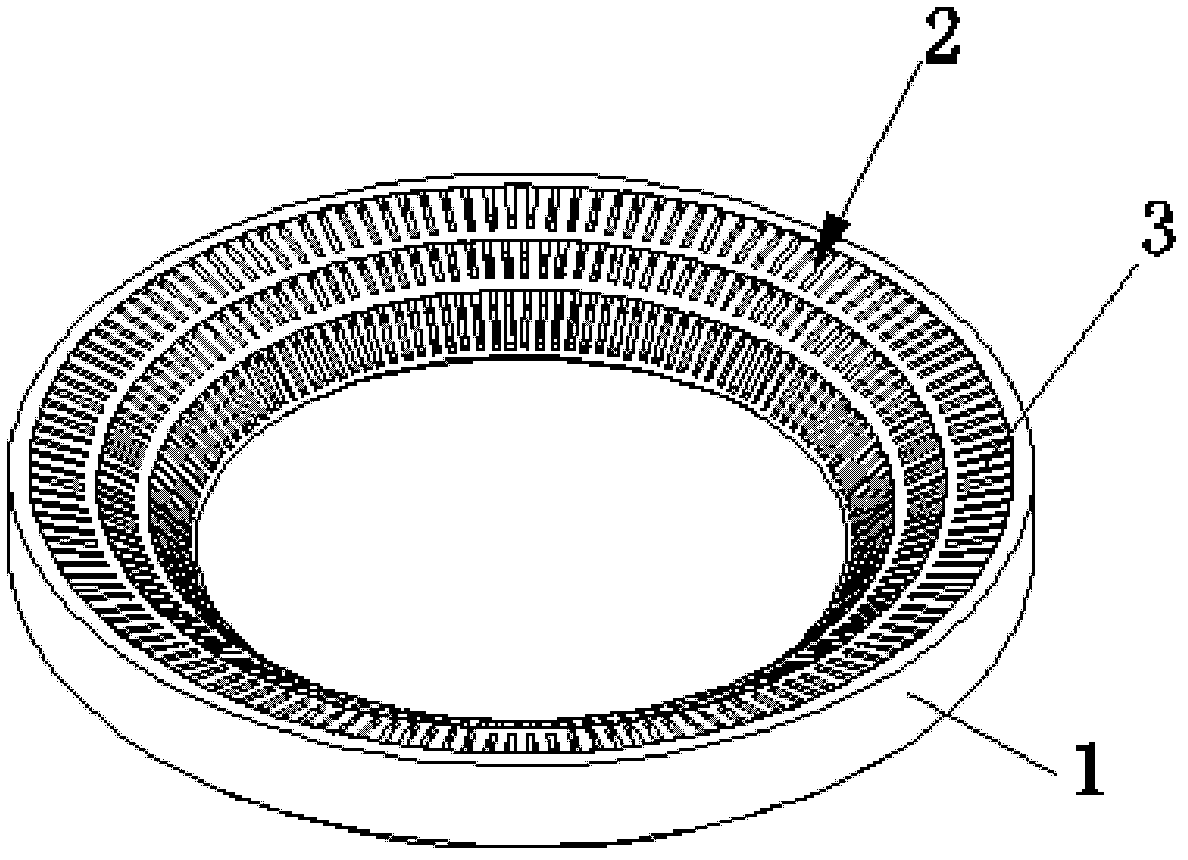

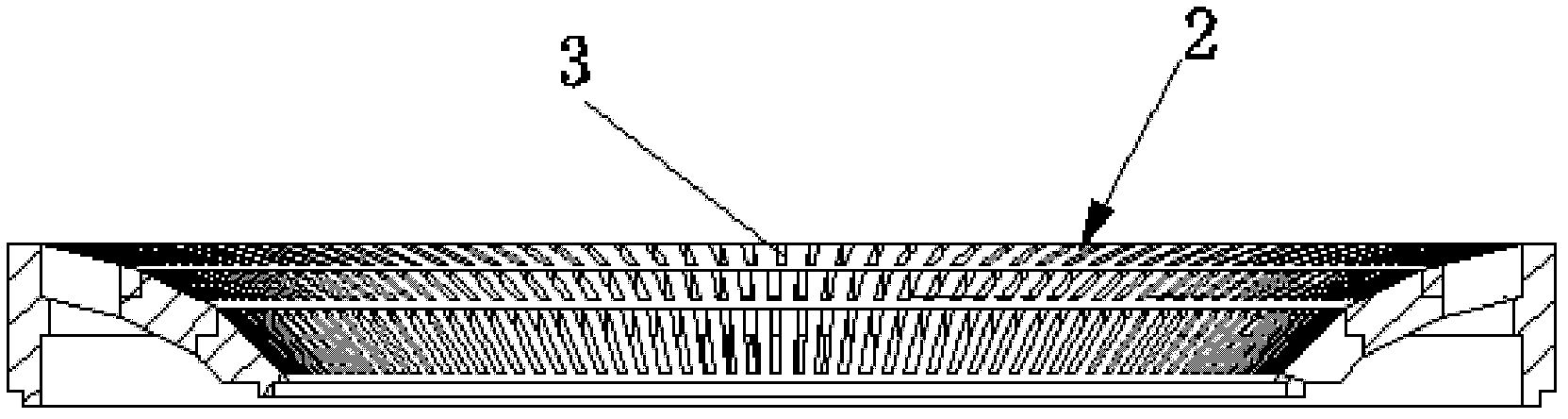

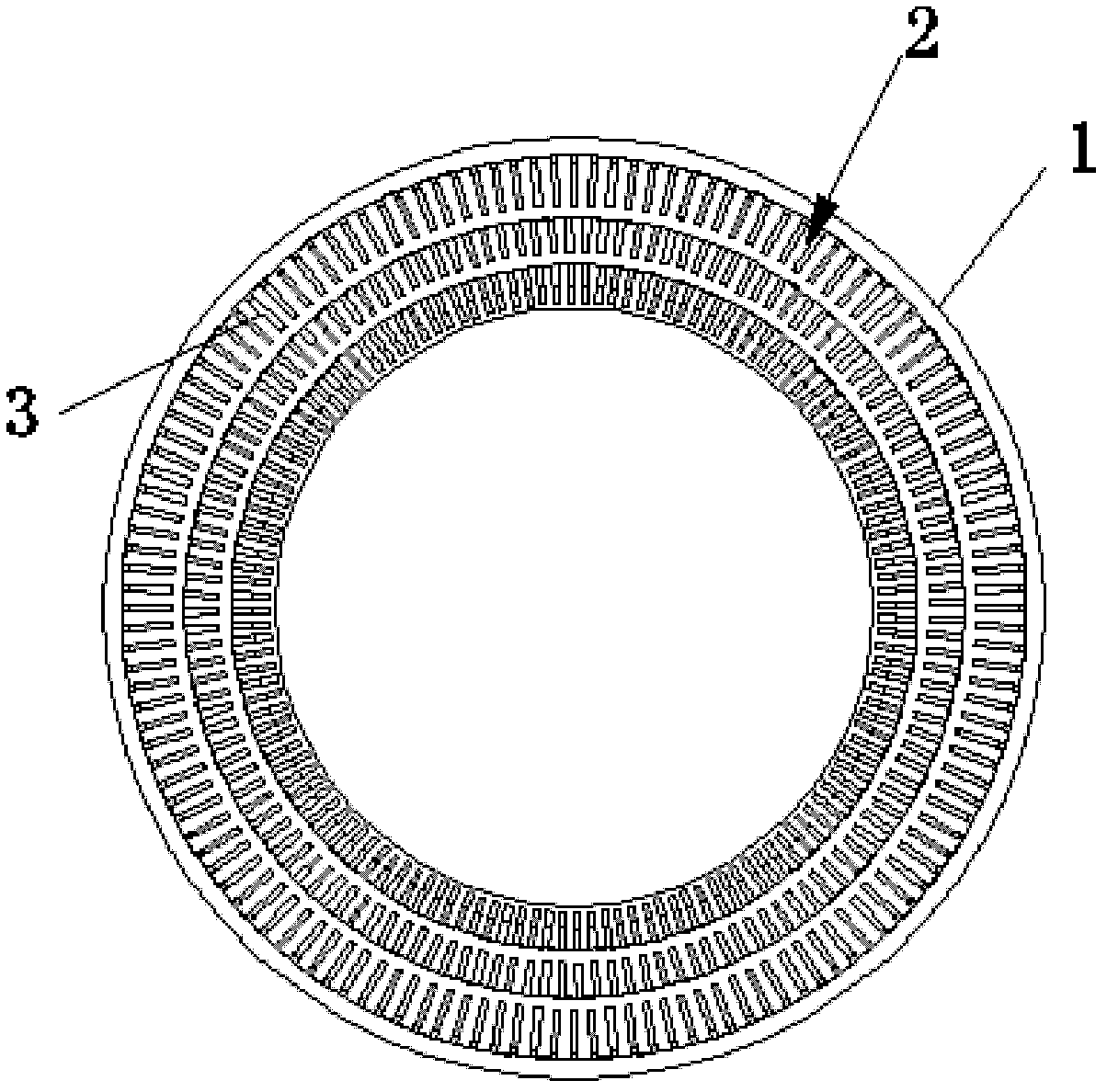

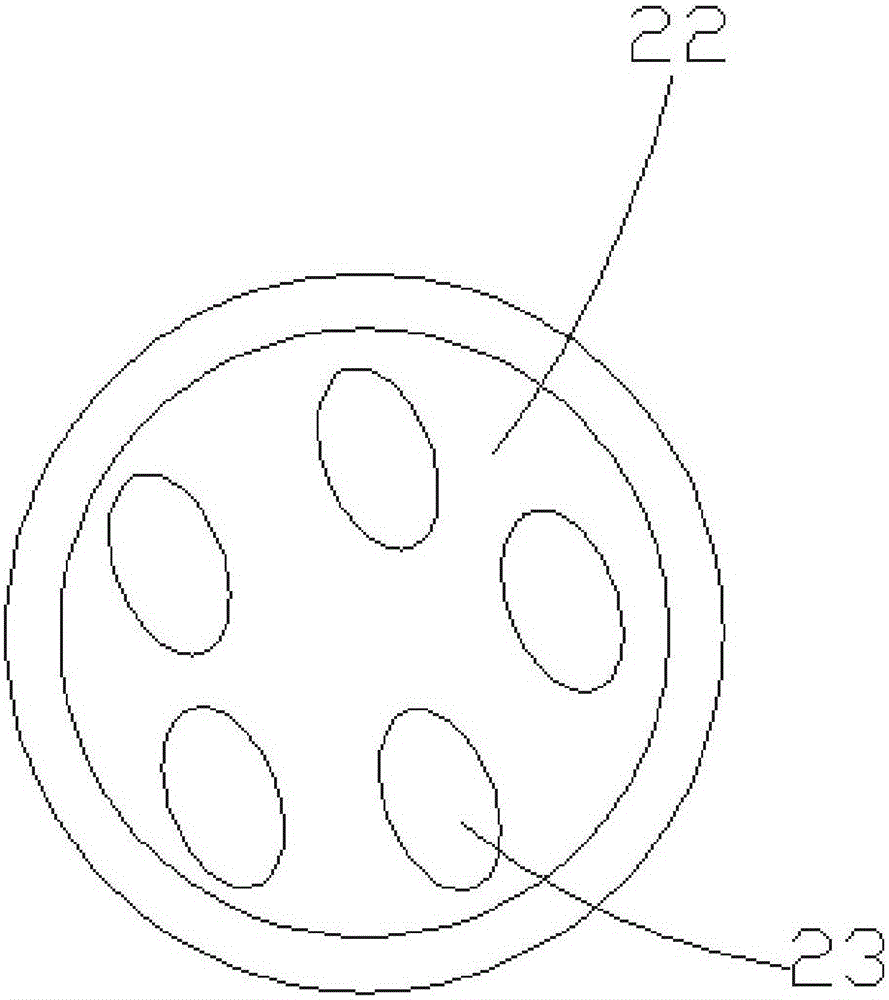

Ultrasonic tool head

ActiveCN103028540BRadiation area is largeUneven radiated sound intensityMechanical vibrations separationBody shapeUltrasonic radiation

The invention relates to an ultrasonic tool head. The ultrasonic tool head is provided with an installation hole which is used for connecting an ultrasonic transducer or an amplitude amplifier pole, the ultrasonic tool head is an ultrasonic radiation head which is of a circular ring body shape or is similar to the circular body shape, and the ultrasonic tool head at least is provided with one first circular ring curved surface which is used for radiating ultrasonic waves by adopting a bending vibration way. According to the ultrasonic tool head disclosed by the invention, a single flat-surface radiation surface is replaced by utilizing a radiation curved surface with the curvature, and thus the radiation area of the ultrasonic tool head is greatly increased; meanwhile, the radiation surface of the ultrasonic tool head, which is of a circular ring shape or similar to the circular ring shape, adopts radial radiation which is similar to the circular ring shape, and thus the uniformity of a sound field in liquid or gas is better; and the radiation curved surface adopts the bending vibration way, thus the transmission direction of vibration is changed, the radiation sound intensity is more uniform, the using flexibility of the ultrasonic tool head is increased, and the ultrasonic tool head is suitable for the welding of the ultrasonic waves of which the cross sections are similar to round surfaces and can be used as the amplitude amplifier pole.

Owner:HANGZHOU SUCCESS ULTRASONIC EQUIP

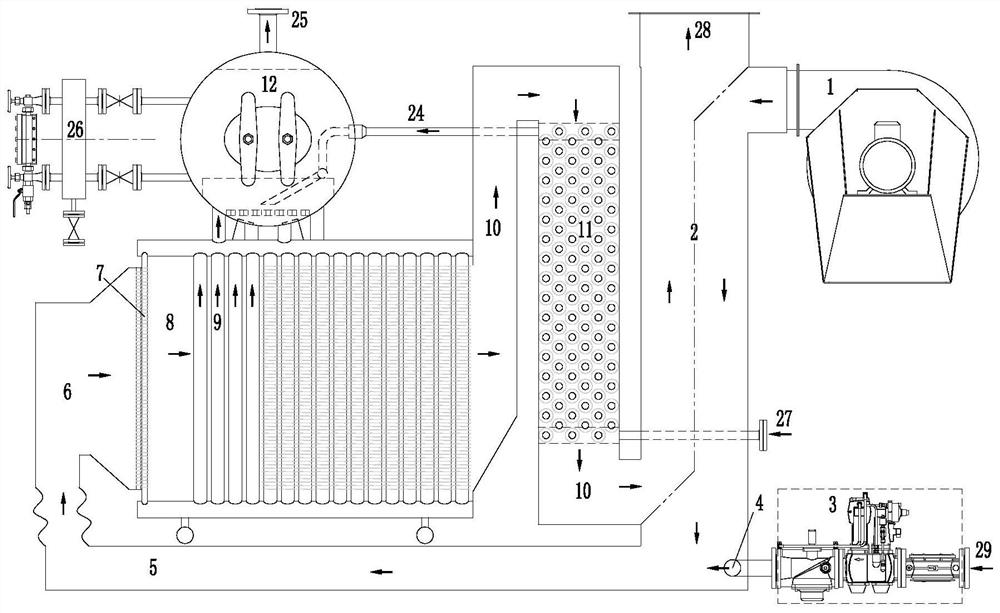

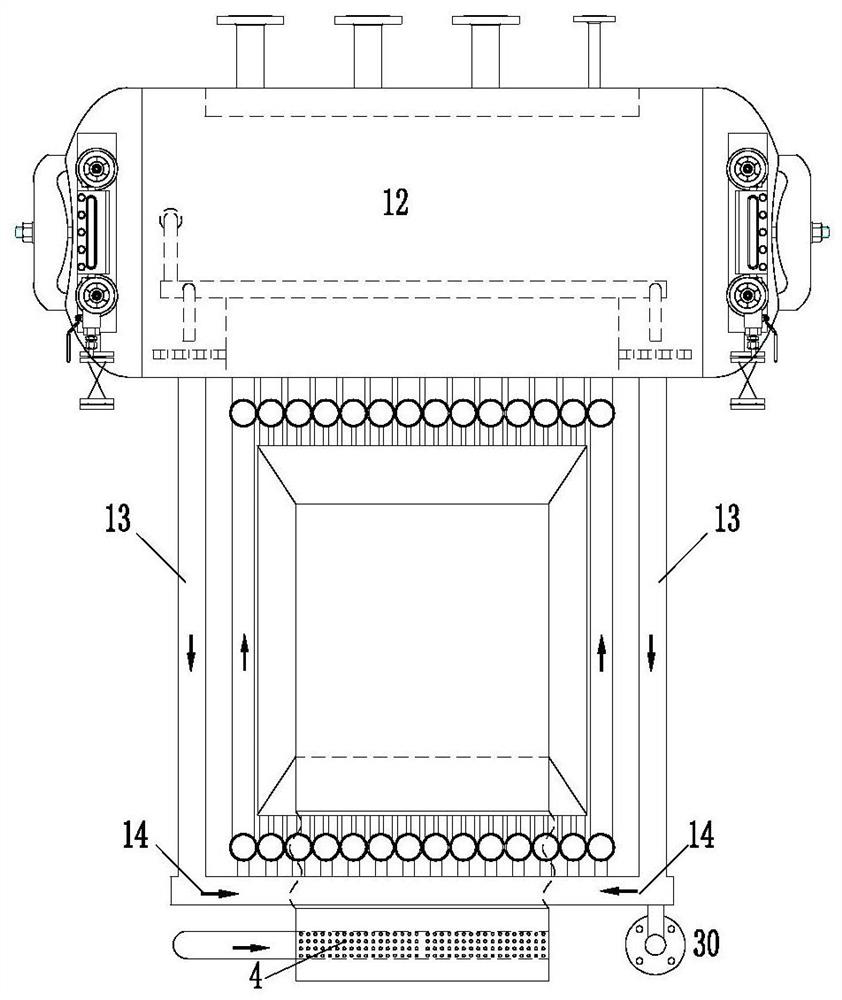

Novel low-nitrogen-emission cold flame combustion integrated steam boiler

PendingCN112032698AHigh degree of standardizationSimple quality control managementBoiler water tubesCombustion processAir preheaterLight pipe

The invention relates to a novel low-nitrogen-emission cold flame combustion integrated steam boiler which comprises a draught fan, an air preheater, a gas valve set, a gas distribution pipe, an air flue, an air distribution chamber, water cooling fire grates, hearths, convection areas, a flue, an energy saver, a steam pocket, a descending pipe, a descending communication pipe and a water level controller. A heating surface adopts a standard modular design and consists of two groups of membrane wall modules and a plurality of groups of fire grate convection area modules; the capacity of the boiler can be randomly combined and adjusted through the number of the fire grate convection area modules; each fire grate convection area module is composed of a module leading-in pipe, a module lowercollecting box, a fire grate finned pipe, a convection area light pipe, a convection area finned pipe, a module upper collecting box and a module leading-out pipe; each module can be divided into three functional areas, namely a water-cooling fire grate, a hearth and a convection area; the water-cooling fire grates are composed of porous ceramics and finned pipes; and mixed gas of air and naturalgas evenly flows to spiral fin areas on the finned pipes through small holes in the porous ceramics, and enters the hearths so as to be combusted after being preheated along channels among spiral fins.

Owner:JIANGSU SHUANGLIANG BOILER

Ferrous waste acid treating equipment with multiple aeration trays

PendingCN107963735AHigh synthesis efficiencyImprove space utilizationWater aerationSustainable biological treatmentSpent acidAeration

The invention discloses ferrous waste acid treating equipment with multiple aeration trays. The ferrous waste acid treating equipment comprises a reaction kettle, a first stirring mechanism, a secondstirring mechanism, a first aeration tray, a second aeration tray and a third aeration tray, the first stirring mechanism, the second stirring mechanism, the first aeration tray, the second aeration tray and the third aeration tray are arranged in the reaction kettle, the first stirring mechanism and the second stirring mechanism are arranged on the side wall of the reaction kettle, rotating facesof stirring blades of the first stirring mechanism and the second stirring mechanism are parallel to the vertical direction, each of the first aeration tray and the second aeration tray is arranged on the side wall of the reaction kettle and comprises a plurality of aeration holes, the third aeration tray is arranged at the bottom of the reaction kettle and comprises a plurality of aeration holes, the first stirring mechanism faces the first aeration tray, the second stirring mechanism faces the second aeration tray, the reaction kettle is provided with a waste acid inlet positioned at the top and a waste acid outlet positioned at the bottom, and each of the waste acid inlet and the waste acid outlet is provided with a valve.

Owner:张家港洁利环保科技有限公司

Waste gasification melting furnace

ActiveCN106642138BRealize continuous gasification and melting processingLarge amount of processingIncinerator apparatusCombustorHeat losses

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Waste Gasification Melting Combustion System

ActiveCN106524176BRealize continuous gasification and melting processingLarge amount of processingIncinerator apparatusCombustion systemSlag

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

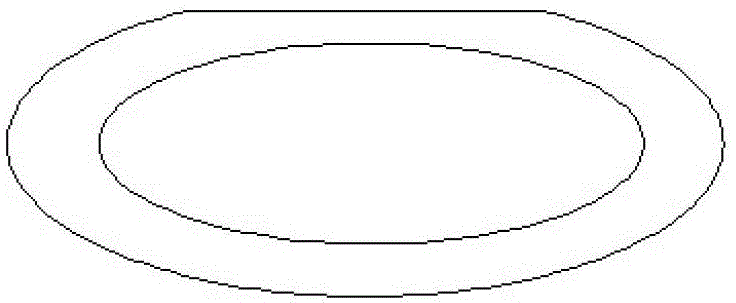

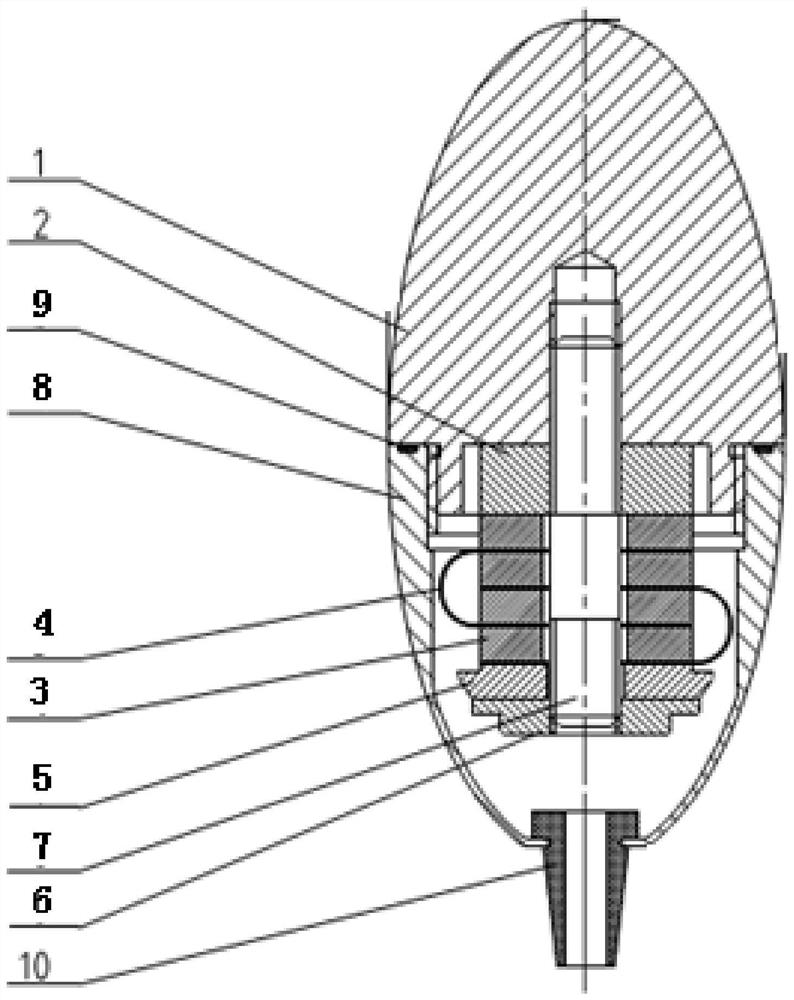

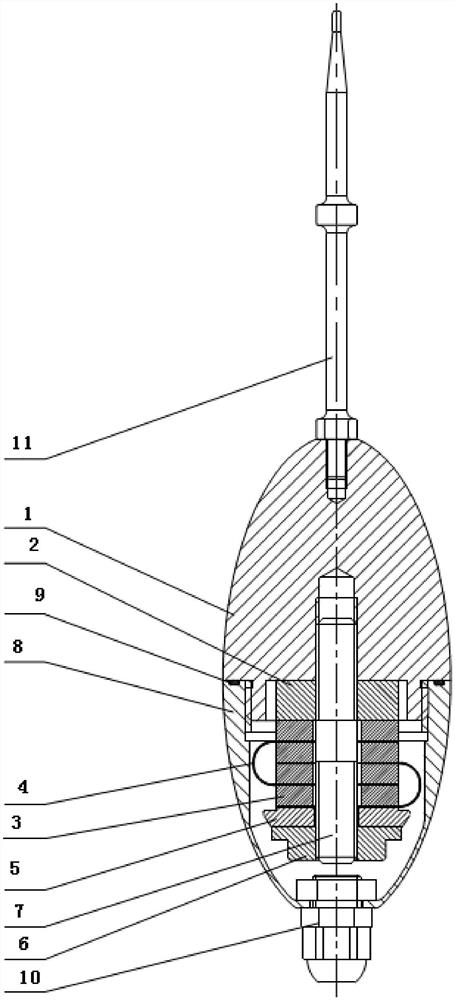

An ellipsoid portable ultrasonic transducer

ActiveCN109453980BReduce noiseIncreased Applicable Electric Power CapabilityMechanical vibrations separationUltrasonic sensorAcoustic energy

Owner:杭州瑞利超声科技有限公司

Antenna, hinge and electronic equipment

ActiveCN109786927BGood directionSmall sizeDigital data processing detailsAntenna supports/mountingsElectrical connectionEngineering

The embodiment of the present application provides an antenna, a hinge and an electronic device. The antenna includes a carrier body and an antenna body. The carrier body is in the shape of a cylinder and has a groove on it. The groove is on a plane perpendicular to the center line of the carrier body. The cross-section on the top is trapezoidal, and the opening of the groove increases along the radial direction of the carrier towards the side away from the centerline; the antenna body includes a first antenna part and a second antenna part, and the first antenna part is arranged on the side of the groove along the centerline direction. The bottom of the groove, the second antenna part is arranged on the outer arc surface of the carrier, the second antenna part can be covered with the entire outer arc surface, and a hollow part is also formed on the second antenna part, and one end of the first antenna part is along the concave The edge of the side wall of the groove is extended to form a first extension for electrically connecting with the second antenna part. The above-mentioned antenna body has good directivity, has a small size, can be installed on a hinge shaft with a small size, and has good performance.

Owner:HEFEI LCFC INFORMATION TECH

Novel outer ring gear cover for burner and burner manufactured thereby

The invention discloses a novel outer ring gear cover for a burner. The outer ring gear cover consists of a ring-shaped fixing ring and a burning part, wherein the periphery of the burning part is detachably sleeved with the fixing ring; the burning part is formed by sequentially and detachably sleeving a plurality of coaxial ring-shaped burning rings; the heights of the side elevations of the plurality of burning rings are decreased from the outer side edge of the burning part to the center to form a step; a plurality of flame hole slots are formed in each burning ring at intervals, and the openings of the flame hole slots are formed in the upper surface of the burning part. Compared with a conventional integrated structure, a burner manufactured by the outer ring gear cover improves the deformation resistance of the outer ring gear cover, increases the contact area between the outer ring gear cover and a pot bottom and effectively improves the heat efficiency; the flame-out angle of the burner can be adjusted according to actual conditions, so that the burning is more sufficient; besides, when the outer ring gear cover fails to work and requires replacement during the use, the only requirement is to replace a certain burning ring failing to work, so that both time and cost are greatly saved.

Owner:SAKURA BATH & KITCHEN PRODS CHINA

Megahertz-level wide-beam high-power transmission-reception integrated acoustic array

ActiveCN107015217AMake up for the lack of narrow beamCompact structureWave based measurement systemsElectric power transmissionAcoustic array

The invention provides a megahertz-level wide-beam high-power transmission-reception integrated acoustic array. The acoustic array is characterized in that the acoustic array comprises an emission array, a reception array, a signal transmission line and a packaging body, the emission array receives acoustic wave signals from the signal transmission line and emits megahertz-level, wide-beam, and high-power very high frequency acoustic wave signals to a water target, the reception array is used for receiving reflection echoes of the water target and sending reflection echo signals to the signal transmission line, a plurality of emission transducer plates form an emission group, a plurality of same emission groups are distributed side by side at intervals to form the emission array, the reception array is formed by a plurality of single reception transducer plates, the number of the reception transducer plates is consistent with the number of the emission transducer plates of one emission group, the signals between the emission transducer plates and between the emission groups are connected in a parallel manner, and the signals between the single reception transducer plates are connected in a parallel manner. According to the acoustic array, the functions are composite, the structure is compact, megahertz-level acoustic waves can be emitted, and the reflection echoes of the water target can be received.

Owner:NAVAL UNIV OF ENG PLA

Improved spray gun for desulfurization and denitrification

InactiveCN103990367BExtended service lifeReduce outputDispersed particle separationAgricultural engineeringCooling pipe

The invention discloses an improved-type desulfurization and denitrification spray gun. The improved-type desulfurization and denitrification spray gun comprises a spray gun inner pipe and a spry gun sleeve, wherein a joint is welded at one end of the spray gun inner pipe, and the other end of the spray gun inner pipe is welded with a spray gun head; the outer wall of the spray gun inner pipe forms a threaded region, and one side of the threaded region is provided with a stop ring; the spray gun sleeve is in threaded connection with the threaded region; the spray gun sleeve is provided with an inlet pipe; the inlet pipe is provided with a cooling pipe; an end socket is arranged between one end of the spray gun sleeve and the stop ring, and the other end of the spray gun sleeve is provided with a trumpet-shaped flaring; the inner wall of the spray gun sleeve is provided with 2-3 spirally arranged flow guide elements at intervals. According to the invention, the desulfurization and denitrification operation efficiency is improved, and meanwhile the service life is prolonged.

Owner:姜建勇

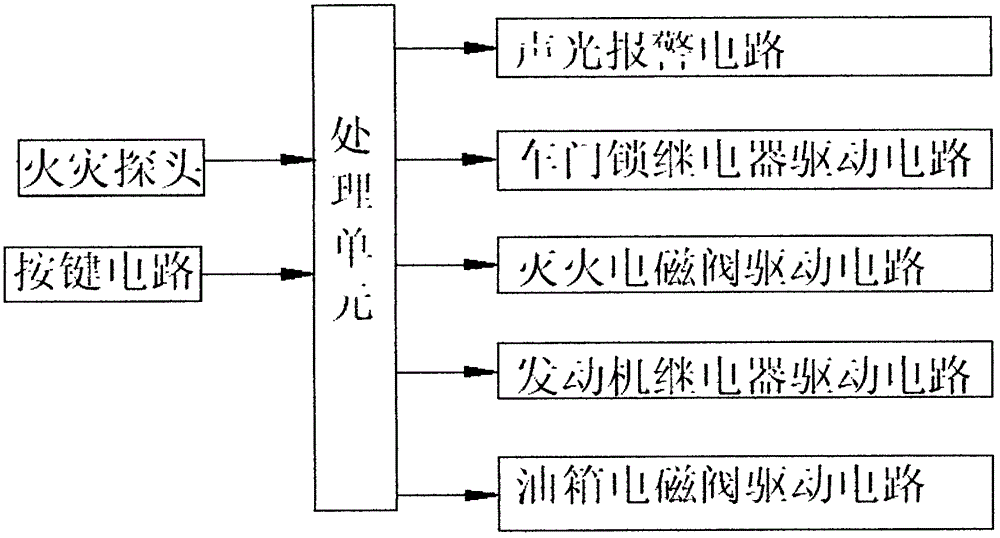

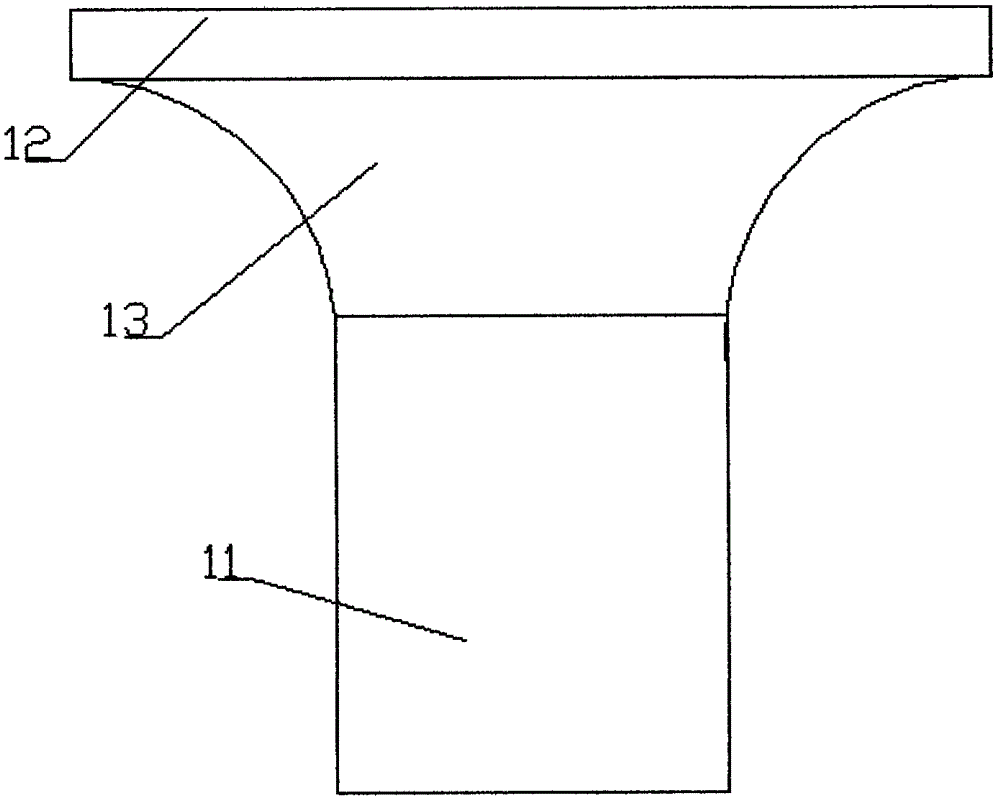

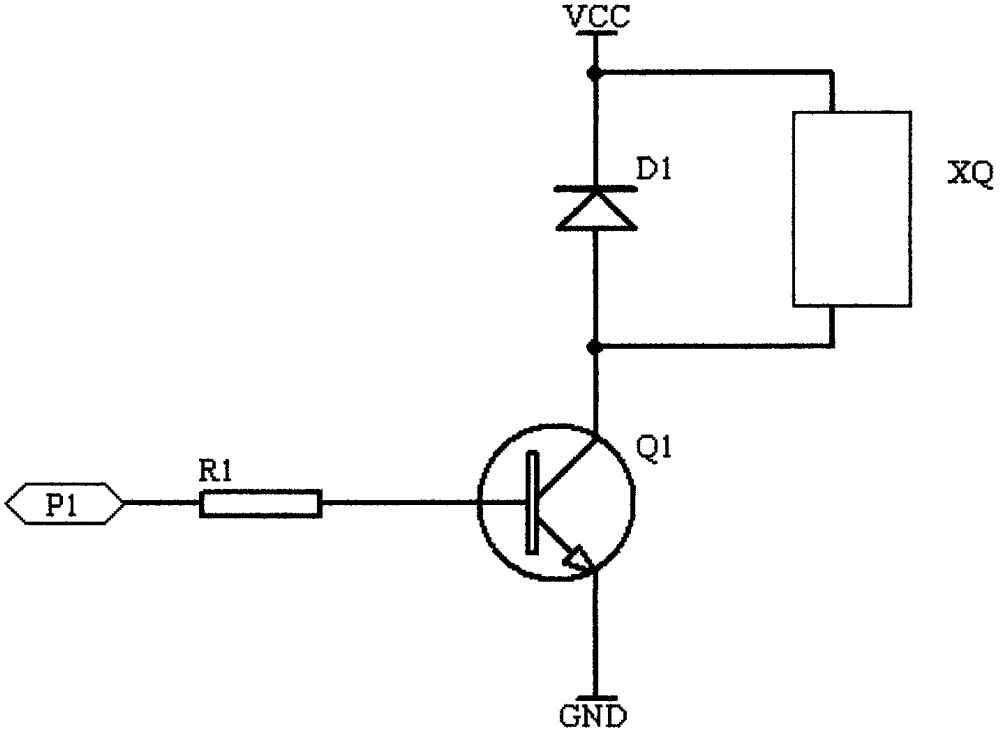

Automatic fire extinguishing system for vehicle

An automatic fire extinguishing system for a vehicle comprises a fire extinguishing agent container, a fire disaster probe, a power module and a system central control module, wherein the fire extinguishing agent container, the fire disaster probe, the power module and the system central control module are arranged in the vehicle; the power module provides direct current for work of a system, an outlet of the fire extinguishing agent container is connected with a fire extinguishing pipeline with a fire extinguishing electromagnetic valve, and a fire extinguishing nozzle is formed in the tail end of the fire extinguishing pipeline; the system central control module comprises a processing unit, a vehicle door lock relay drive circuit, a fire extinguishing electromagnetic valve drive circuit, an engine relay drive circuit and an oil tank electromagnetic valve drive circuit; the signal output end of the fire disaster probe is connected with the processing unit, and the signal output end of the processing unit is connected with the vehicle door lock relay drive circuit, the fire extinguishing electromagnetic valve drive circuit, the engine relay drive circuit and the oil tank electromagnetic valve drive circuit; and the fire disaster probe and the fire extinguishing nozzle are arranged in the vehicle, when the warning condition happens, a fire extinguishing agent is sprayed out of the fire extinguishing nozzle, and casualties and property losses brought by the fire disaster can be reduced to the maximum limit.

Owner:李振凯

A Portable Multipurpose Ultrasonic Transducer Based on Ellipsoid Shell

ActiveCN109201441BIncreased Applicable Electric Power CapabilityReduce noiseMechanical vibrations separationUltrasonic sensorEngineering

The invention discloses a portable multi-purpose ultrasonic transducer based on an ellipsoidal shell, which mainly includes an ellipsoidal radiation head, etc., a front cover, a piezoelectric ceramic sheet, an electrode sheet, a back cover, and a back cover nut. The upper part is connected in series to form a transducer vibrator. The transducer vibrator is connected with the ellipsoidal radiation head through the protruding part of the screw to form the whole transducer. The whole transducer is connected with the stepped slender tool head to form an ultrasonic transducer. The device is placed in the ellipsoid shell and the two are sealed and supported through the sealing ring and the thread on the ellipsoidal radiation head. The bottom of the ellipsoid shell is connected with the watertight plug to ensure its overall watertight characteristics. The invention improves the ability of the transducer to apply electric power; greatly reduces the noise radiated by the transducer through the water tank; makes the transducer both portable and aesthetically pleasing; has cavitation corrosion resistance; collects partial cleaning of clothes and cleaning of the water tank , small diameter cup cleaning and other purposes in one.

Owner:杭州瑞利超声科技有限公司

Efficient iron-containing waste acid treatment structure

InactiveCN110975778AEffective operabilityHigh synthesis efficiencyWater treatment parameter controlWater contaminantsThermal insulationElectric machinery

The invention discloses an efficient iron-containing waste acid treatment structure. The device comprises a tank body; a stirring mechanism is mounted at the bottom of the tank body; aeration holes are uniformly distributed in the inner side wall of the tank body; the stirring mechanism comprises a motor positioned below the tank body, a shaft body output by the motor, and blades driven by the shaft body; the shaft body extends into the tank body from the bottom of the tank body in a sealed mode; the blades are located in the tank body; a waste acid inlet and a waste acid outlet are formed inthe top and the bottom of the tank body respectively; an interlayer is formed on the side wall of the tank body, and annular heating bodies are evenly distributed in the interlayer. Through the annular heating bodies and a thermal insulation material, the device is effectively subjected to heating operation and heat preservation operation, the synthesis efficiency is high, the process is simple, the space utilization rate is high, the cost is reduced, manpower and labor are saved, the aeration mechanism is arranged on the side wall surface of the whole reaction kettle, the radiation surface islarge, and the reaction speed can be increased.

Owner:张家港洁利环保科技有限公司

Waste melting and solidification treatment system and method

ActiveCN106524175BRealize continuous gasification and melting processingLarge amount of processingIncinerator apparatusCombustorSlag

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com