Piston for printhead of 3D printer and printhead for 3D printer

A technology of 3D printers and print heads, which is applied in the direction of printing, process efficiency improvement, inking device, etc. It can solve the problems of inaccurate printing process, troublesome working steps, retention of gas inclusions, etc., and achieve improved repeatability and improved discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

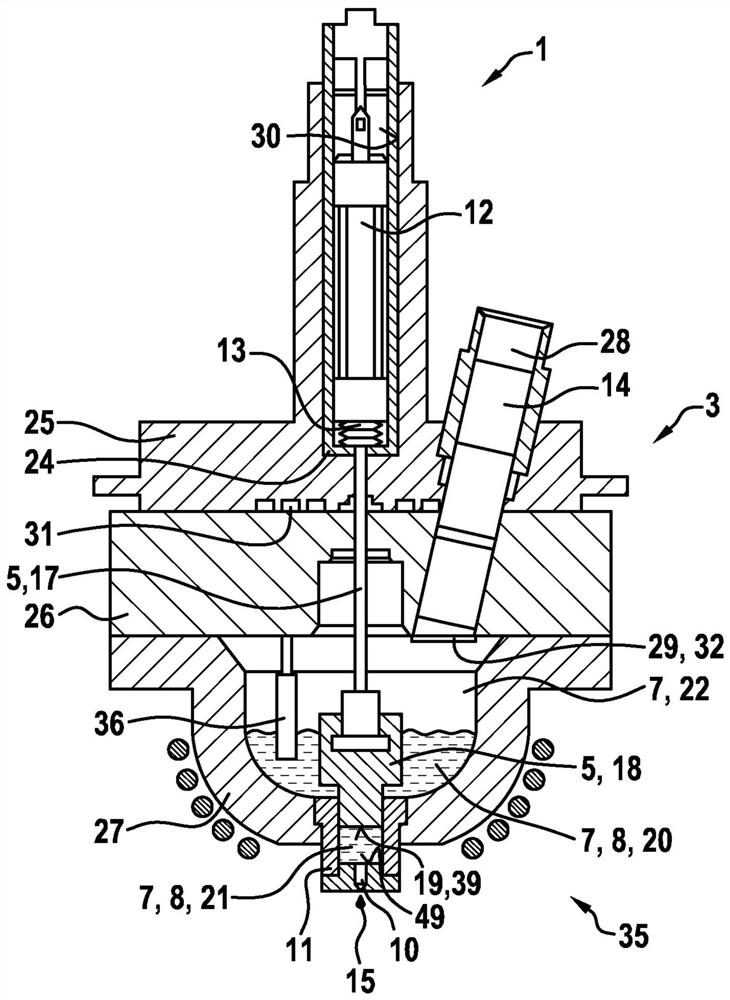

[0034] figure 1 An embodiment of a print head 1 for a 3D printer according to the invention is shown.

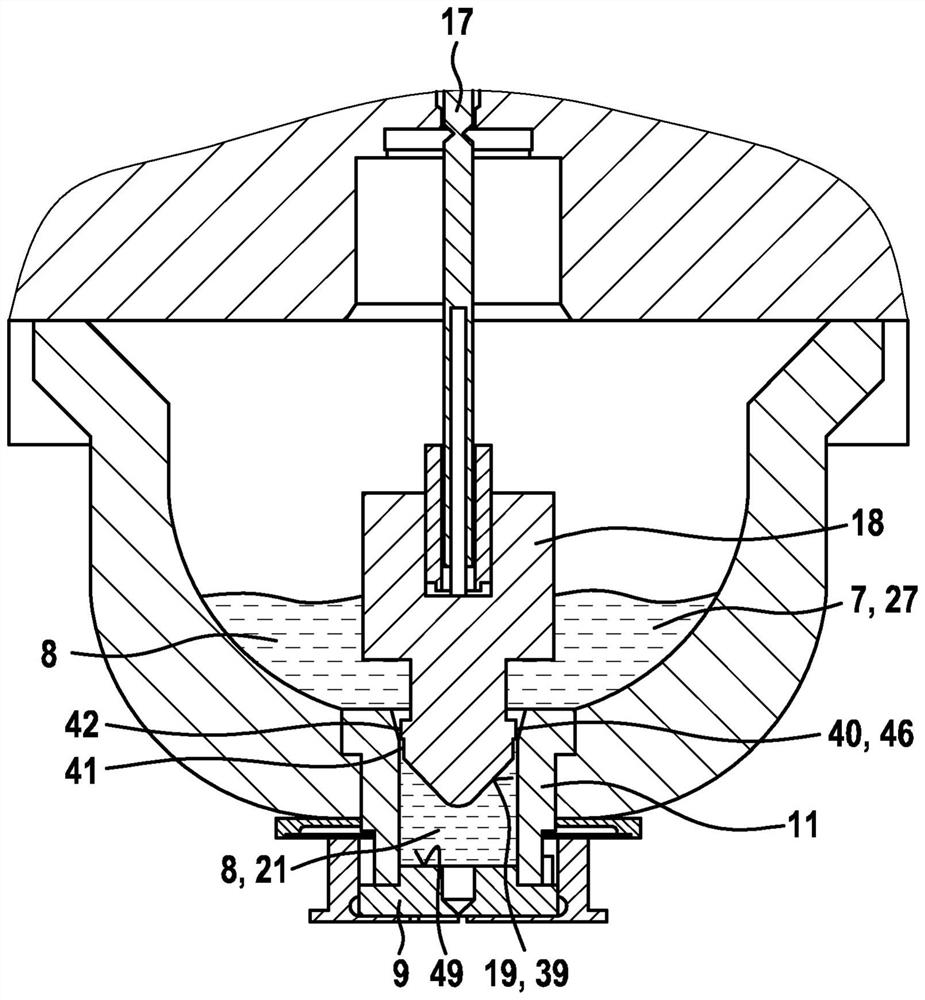

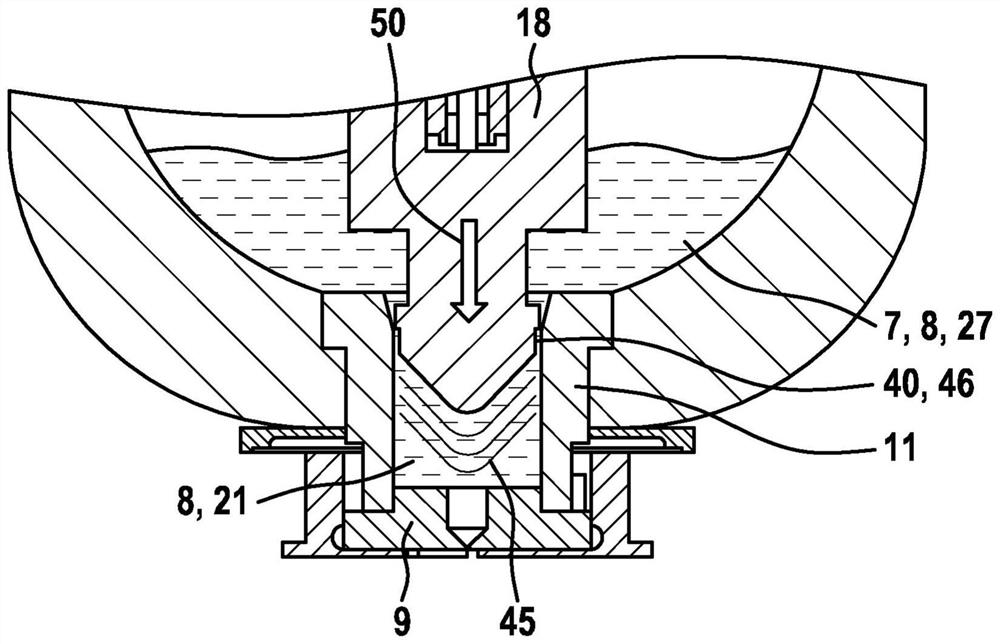

[0035] The print head 1 comprises a housing 3 , means 28 for supplying metal 14 in the solid phase, reservoirs 7 , 27 , nozzle means 2 with discharge openings 10 and a piston 5 . Furthermore, the print head comprises actuator means 12 for moving the piston 5 . The reservoirs 7 , 27 have a melting zone 20 and an extrusion chamber 21 for the liquid phase 8 of the metal 14 , wherein the melting zone 20 adjoins an inert gas atmosphere 22 and is connected to the extrusion chamber 21 in such a way that the piston 5 The movement of can cause the liquid phase 8 of the metal 14 to flow out through the discharge opening 10 . Liquid phase 8 of metal 14 or liquid metal 8 is also referred to as melt 8 and inert gas atmosphere 22 is formed by introducing inert gas 22 into reservoirs 7 , 27 . The inert gas atmosphere 22 is preferably introduced into the reservoir 7 , 27 via the cold reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com