Improved-type desulfurization and denitrification spray gun

An improved technology for desulfurization and denitrification, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods. It can solve the problems of small radiation area of the spray gun, high surface temperature of the spray gun, and short service life. The effect of large area, enhanced effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

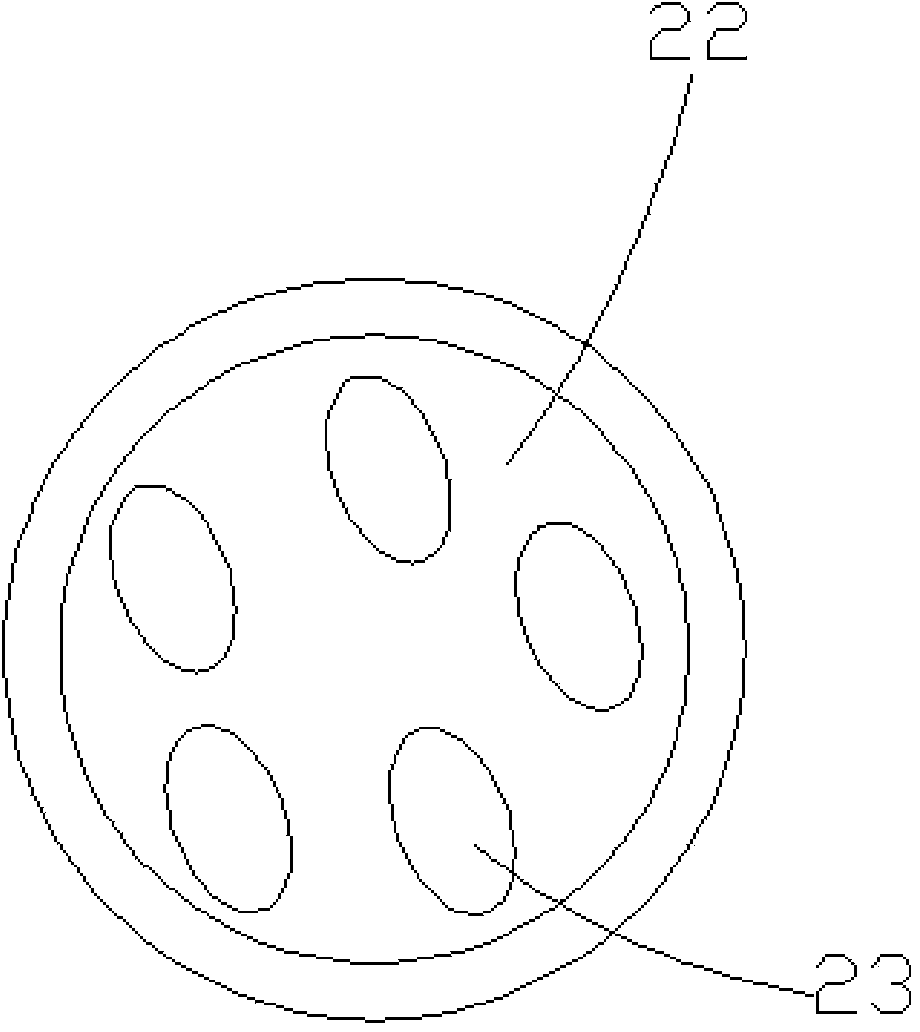

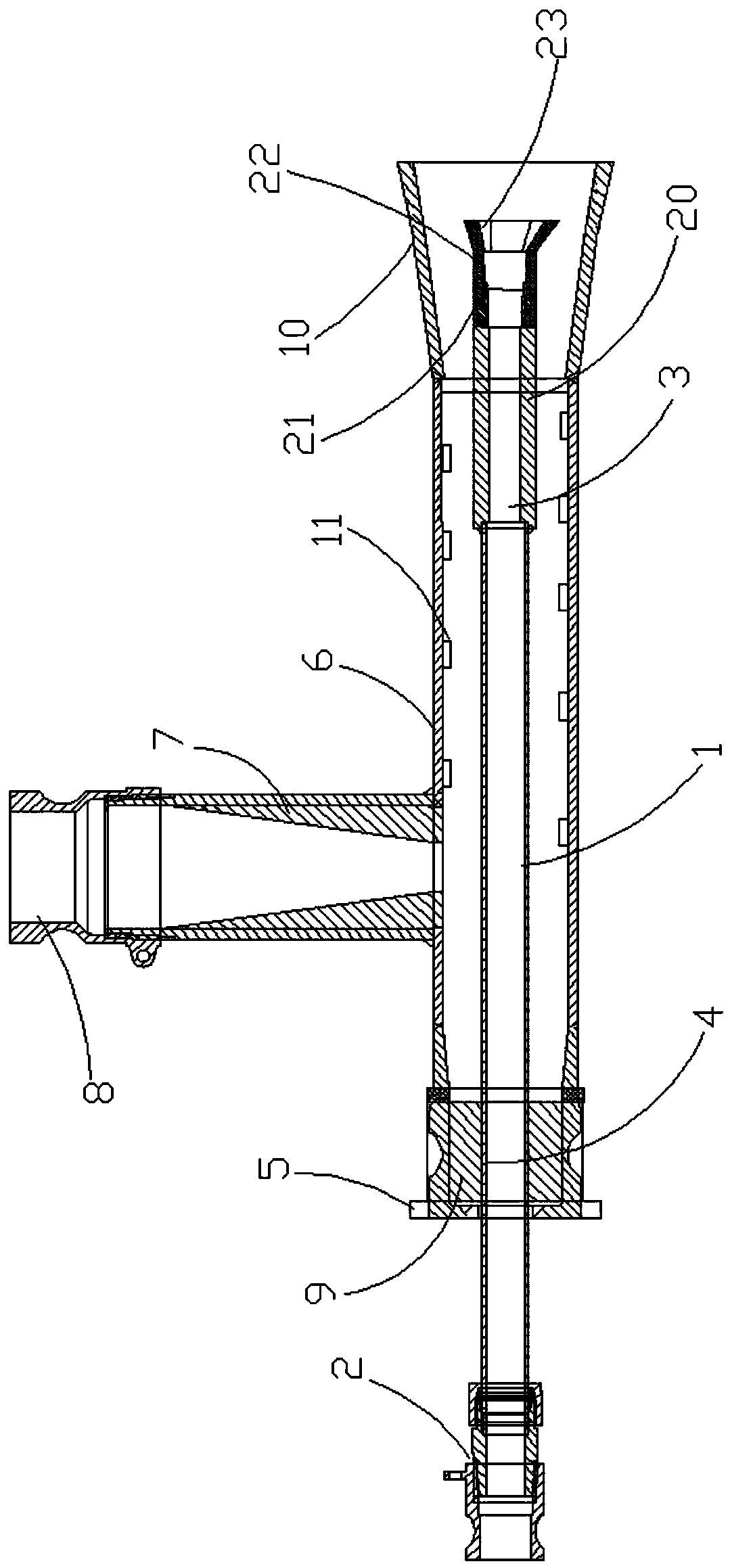

[0020] Such as figure 1 and figure 2 As shown, the present invention relates to a spray gun for improved desulfurization and denitrification, which is characterized in that: it includes a spray gun inner tube 1, one end of the spray gun inner tube 1 is welded with a joint 2, and the other end is welded with a spray gun tip 3; the spray gun inner tube The outer wall of 1 forms a threaded area 4, a stop ring 5 is provided on one side of the threaded area 4, and a spray gun sleeve 6 threadedly connected with the threaded area 4 is provided, and an inlet pipe 7 is arranged on the spray gun sleeve 6. The inlet pipe 7 is provided with a cooling pipe 8 .

[0021] In the present invention, one end of the spray gun sleeve 6 and the stop ring 5 are provided with a head 9, and the other end is provided with a horn-shaped flare 10; the inner wall of the spray gun sleeve 6 is provided with 2 -3 guides 11 arranged spirally at equal intervals, the guides 11 are spirally arranged at an ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com