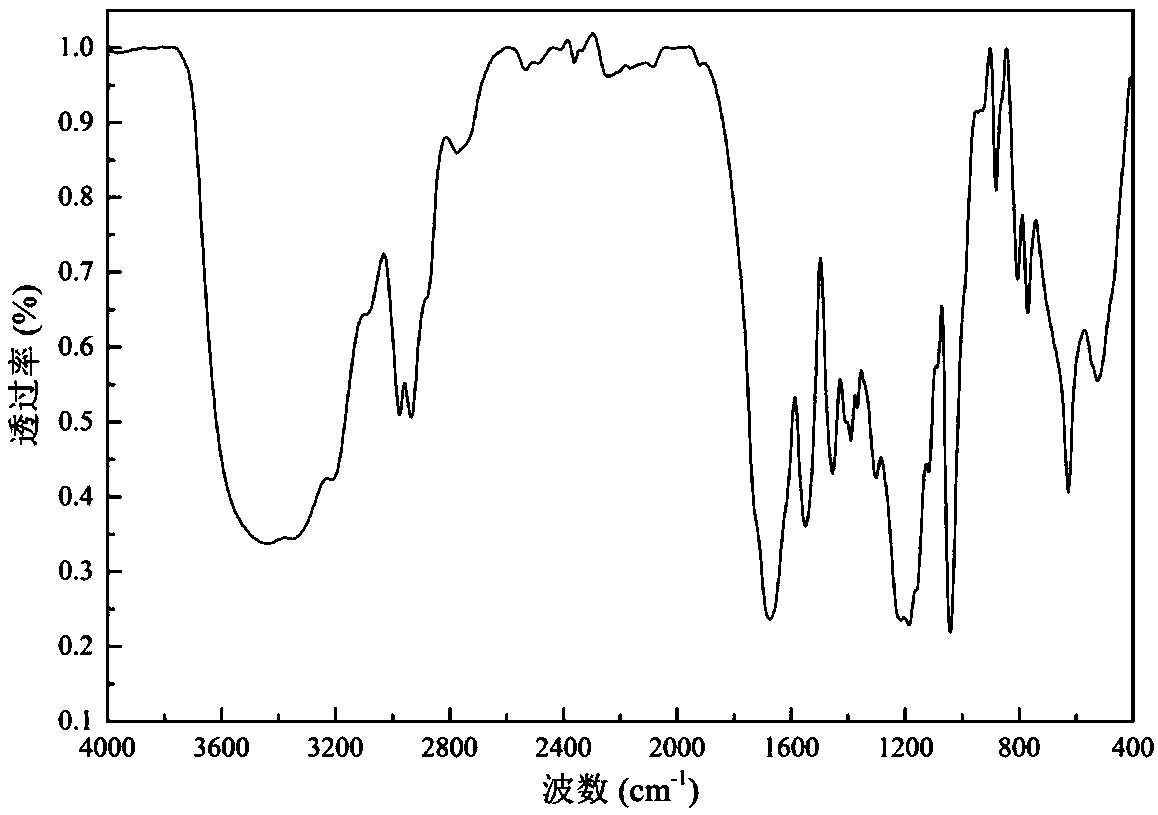

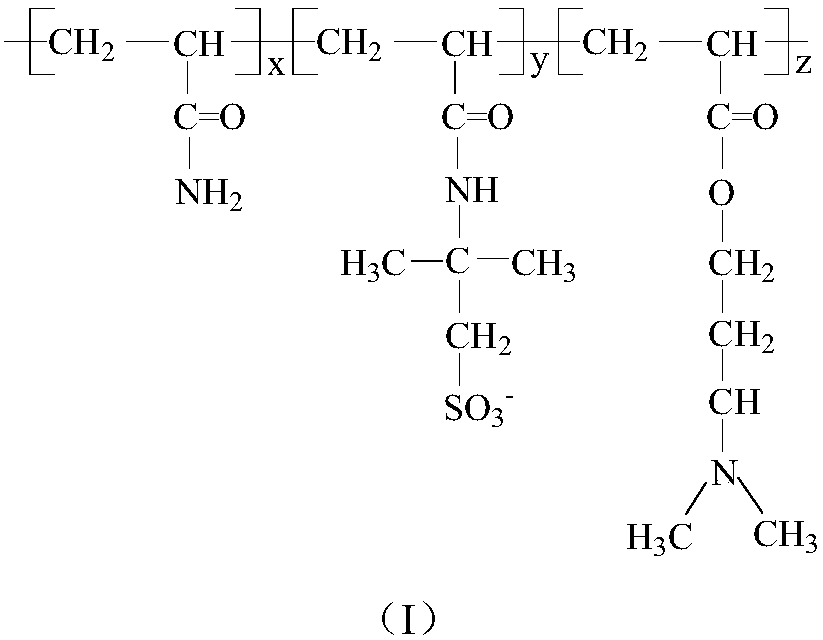

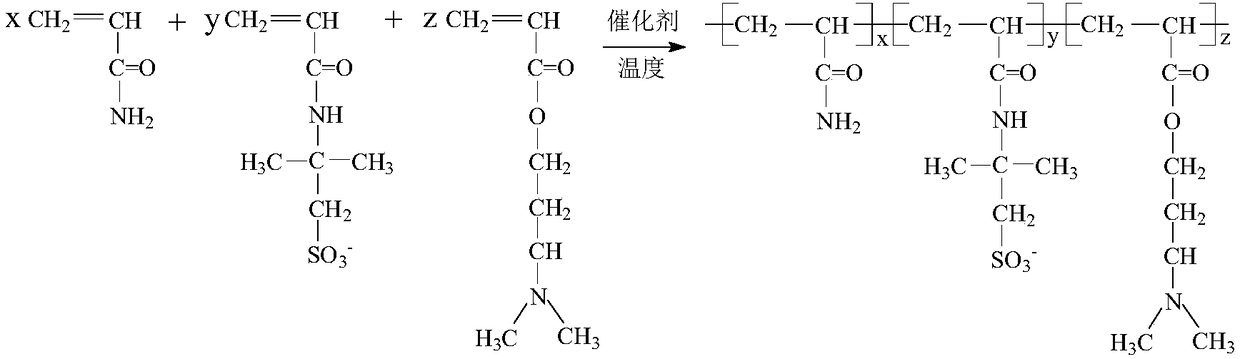

Ultra-high temperature-resistant anionic polymer fluid loss additive for drilling fluid and completion fluid and preparation method thereof

A fluid loss reducer, anionic technology, applied in the field of drilling fluid and completion fluid, can solve the problems of short reaction time, high initiation temperature, low initiation efficiency, etc., achieve good solubility, good rubber protection performance, reduce filtration Lost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Weigh 64.8 grams of acrylamide and 43.0 grams of dimethylaminoethyl methacrylate in a 2.5-liter reactor equipped with a stirrer, reflux condenser, nitrogen protection device, temperature sensor and heating device, and pour into the reaction kettle, add 500 ml of tap water, and stir at a high speed to make it fully dissolved; weigh 132.2 grams of 2-acrylamide-2-methylpropanesulfonic acid and dissolve it in 300 ml of tap water, and then use 10-14 mol / liter Adjust the pH to 7 with the NaOH solution and pour it into the reaction kettle; fully stir the reactant mixture in the reaction kettle. Take by weighing 0.72 gram of azobisisobutylamidine hydrochloride and be dissolved in 100 milliliters of tap water, be placed in reactor after stirring and dissolving completely; In reactor, supplement tap water addition to 1600 milliliters, control reactant total concentration is 15%, the solution in the reactor was stirred rapidly for 5 minutes. Under the protection of nitrogen, stir...

Embodiment 2

[0048] Add 1000 kg of tap water to a stainless steel corrosion-resistant reaction kettle with a capacity of 3-3.5 tons equipped with a stirrer, reflux condenser, nitrogen protection device, thermometer and heating device, turn on the stirrer, and add at a rate of 25 kg / min 2-acrylamide-2-methyl-propanesulfonic acid is 211.8kg, stir for 10 minutes, add sodium hydroxide solid at a rate of 5 kg / min, adjust the pH value to 7-7.5, add tap water to 1500 kg, control the temperature below 40°C; add 96.3 kg of acrylamide at a rate of 25 kg / min, add 500 kg of tap water, and stir for 10 minutes; then add 53.2 kg of dimethylaminoethyl methacrylate, and stir for 5 minutes; Weigh 1.038 kg of azobisisobutylamidine hydrochloride, dissolve it in 25 kg of tap water, and pour it into a reaction kettle. Continue to add tap water to the reaction kettle until the total weight of tap water is 2400kg, blow nitrogen, stir for 30 minutes, then heat up to 55-58°C, react for 4 hours and cool to room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com