Long-acting tackifying phenolic resin and preparation method thereof

A phenolic resin, long-term technology, used in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxy compounds, etc., can solve problems such as difficulty in meeting requirements, and achieve stable product performance, high long-term viscosity increase, and high viscosity retention rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

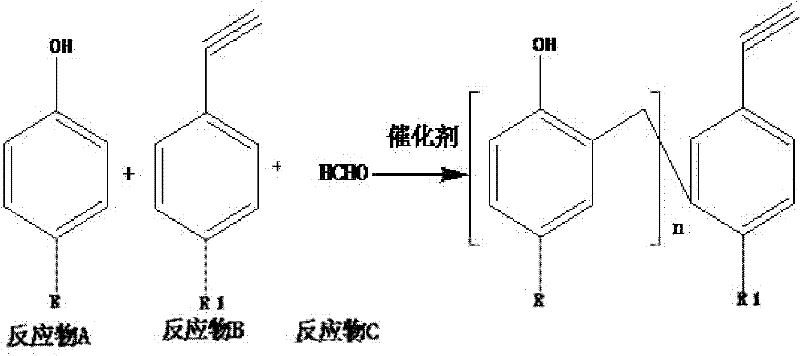

Method used

Image

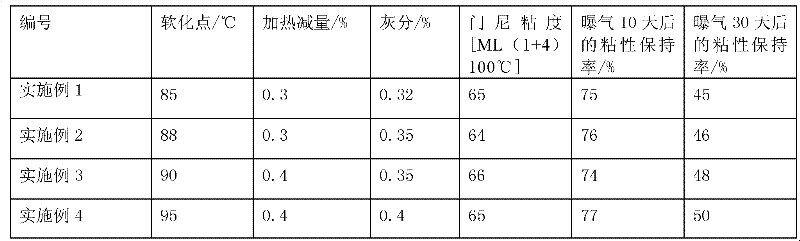

Examples

Embodiment 1

[0025] (1), measure p-tertyl phenol, phenylacetylene, solid formaldehyde and oxalic acid respectively at a molar ratio of 1:0.70:0.2:0.05;

[0026] (2), add p-tertoctylphenol in the reactor, heat up to its complete melting;

[0027] (3), add solid formaldehyde, stir;

[0028] (4), add oxalic acid, reaction reflux 5 hours;

[0029] (5), cool down to 80°C, add transphenylacetylene, and continue to stir for 1 hour;

[0030] (6), dehydration under reduced pressure to 180 DEG C, stop reaction, obtain this long-acting thickening phenolic resin product;

Embodiment 2

[0032] (1), measure p-tetraoctylphenol, p-hydroxyphenylacetylene, solid formaldehyde and sulfuric acid respectively at a molar ratio of 1: 0.75: 0.3: 0.01;

[0033] (2), add p-tertoctylphenol in the reactor, heat up to its complete melting;

[0034] (3), add solid formaldehyde, stir;

[0035] (4), add sulfuric acid, reaction refluxes 5 hours;

[0036] (5), cool down to 80°C, add p-hydroxyphenylacetylene, and continue to stir for 1 hour;

[0037] (6), dehydration under reduced pressure to 180 DEG C, stop reaction, obtain this long-acting thickening phenolic resin product;

Embodiment 3

[0039] (1), measure p-tetylphenol, p-methoxyphenylacetylene, solid formaldehyde and benzenesulfonic acid respectively at a molar ratio of 1: 0.78: 0.4: 0.05;

[0040] (2), add p-tertoctylphenol in the reactor, heat up to its complete melting;

[0041] (3), add solid formaldehyde, stir;

[0042] (4), add benzenesulfonic acid, reaction refluxed 5 hours;

[0043] (5), cool down to 80°C, add p-methoxyphenylacetylene, and continue to stir for 1 hour;

[0044] (6), dehydration under reduced pressure to 180 DEG C, stop reaction, obtain this long-acting thickening phenolic resin product;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com