Chitosan cross-linked and modified acrylamide compound as well as preparation method thereof and application thereof

A chitosan cross-linking and acrylamide technology, which is applied in chemical instruments and methods, drilling compositions and other directions, can solve problems such as high price and achieve the effects of low cost, good stability and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]A kind of preparation method of chitosan crosslinking modified acrylamide compound, its preparation steps are as follows:

[0045] 1) At 60°C, completely dissolve 0.08g of chitosan in 50mL of glacial acetic acid with a mass fraction of 2%, add 0.15g of potassium persulfate, and after 10min, add 50mL of 8g of acrylamide, at 100 rpm Carry out free radical polymerization reaction 2h under the stirring speed of 2h, synthesize the first step product;

[0046] 2) The product obtained in step 1) was placed at 100° C. for a nucleophilic reaction for 4 hours to obtain the final polymer gel.

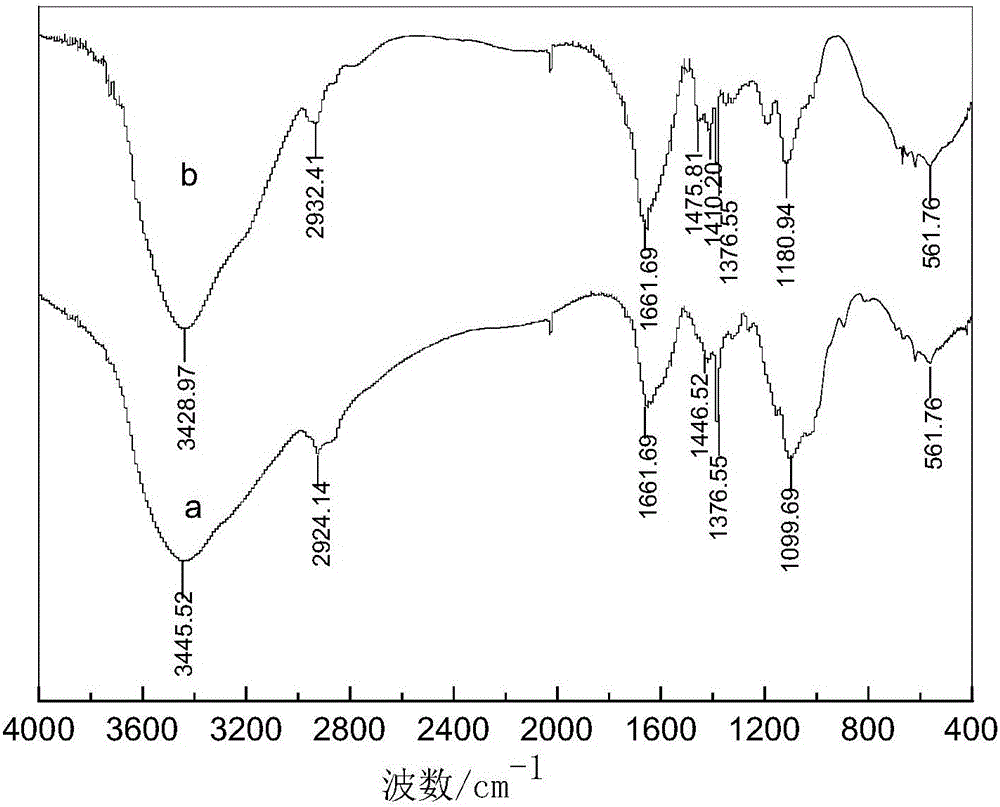

[0047] Infrared spectroscopy tests were carried out on chitosan and the polymer gel purified by ethanol. Obtain the infrared spectrogram, as attached figure 1 The spectrogram analysis results are shown in Table 1.

[0048] Table 1 FTIR analysis results of CS and AM / CS crosslinked polymers

[0049]

[0050] Depend on figure 1 And Table 1 shows that: with figure 1 Compared with the sp...

Embodiment 2

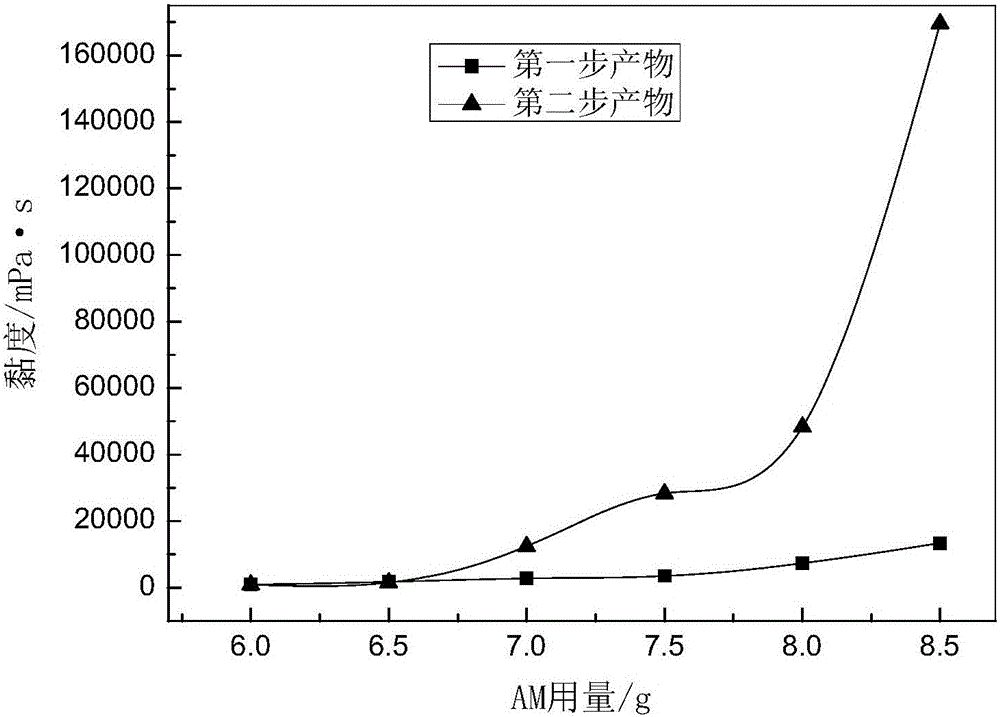

[0052] Taking the amount of acrylamide as a variable, 6 sets of experiments were carried out to prepare chitosan cross-linked modified acrylamide compounds. The preparation steps are as follows:

[0053] 1) At 60°C, completely dissolve 0.08g of chitosan in 50mL of 2% glacial acetic acid, add 0.15g of ammonium persulfate, and after 10min, add a certain amount of acrylamide solution 50mL, at 100 Carry out free radical polymerization reaction 2h under the stirring speed of revolution / second, synthesize the first step product;

[0054] 2) Place the product obtained in step 1) at 100°C for a nucleophilic reaction for 3 hours to obtain a polymer gel (the product of the second step);

[0055] Wherein, the consumption of acrylamide is shown in Table 1.

[0056] During the test, NDJ-8S viscometer was used to measure the viscosity of the first step product and the second step product. The influence of the amount of acrylamide on the viscosity of the system is shown in the attached fi...

Embodiment 3

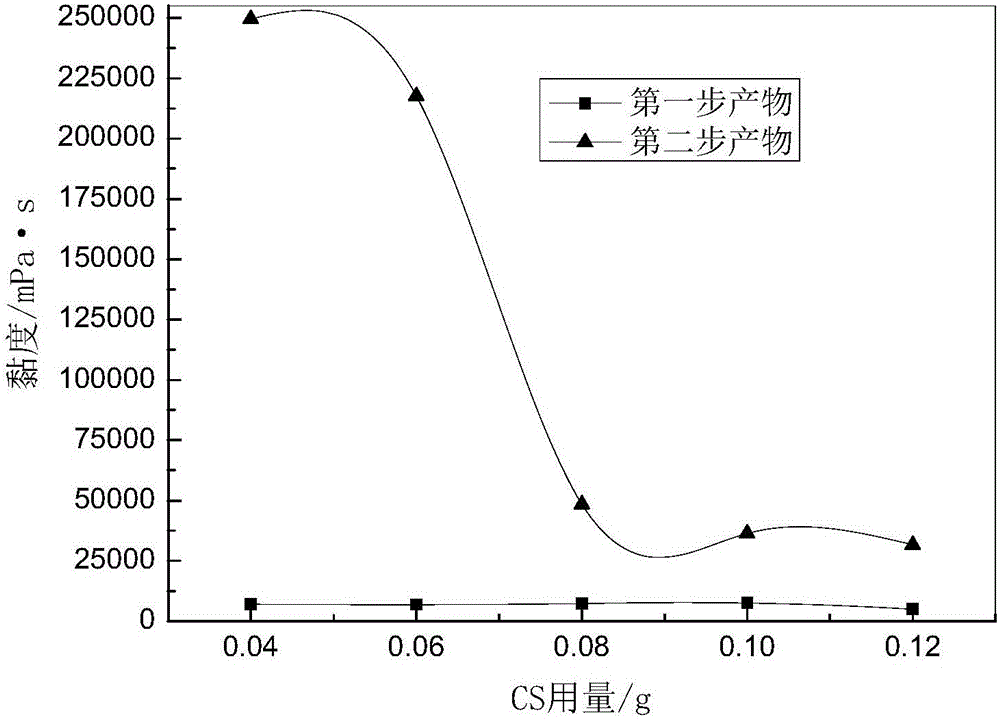

[0061] With the amount of chitosan as a variable, 5 sets of experiments were carried out to prepare chitosan cross-linked modified acrylamide compounds. The preparation steps are as follows:

[0062] 1) At 60°C, a certain amount of chitosan was completely dissolved in 50 mL of glacial acetic acid with a mass fraction of 2%, and 0.15 g of potassium persulfate-sodium sulfite was added (the molar ratio of the two was 1:1). After 10 min, Then add 50 mL of a solution of 8 g of acrylamide, carry out free radical polymerization for 2 h at a stirring speed of 100 rpm, and synthesize the product of the first step;

[0063] 2) Place the product obtained in step 1) at 100°C for a nucleophilic reaction for 3.5 hours to obtain a chitosan cross-linked modified acrylamide compound (the product of the second step);

[0064] Wherein, the consumption of chitosan is shown in Table 2.

[0065] During the test, the viscosity of the first step product and the second step product was measured with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com