Surfactant for changing surface wettability of compact sandstone as well as preparation method and application of surfactant

A surfactant and tight sandstone technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of reducing the relative permeability of hydrocarbons in rocks, low temperature resistance, poor salt resistance, etc., to reduce oil and water The interfacial tension, the preparation method is simple and easy, and the effect of improving the recovery degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Mix 1 weight part of monoglyceride laurate with 32 weight parts of white oil to make an oil phase solvent, then add 5 parts by weight of sodium sulfomethylated lignosulfonate to prepare an oil phase mixed solution;

[0031] 2) Add 23 parts by weight of amidopolyoxyethylene ether magnesium disulfate and 8 parts by weight of methyl polyoxyethylene ether to 51 parts by weight of water, stir and dissolve, adjust the pH value to 9.2, and prepare an aqueous phase solution;

[0032] 3) Add the water phase solution into the oil phase mixed solution, add 0.13 parts by weight of azobisisoheptanonitrile to carry out polymerization reaction, stir and heat up to 70°C, and react at this temperature for 17 hours to obtain a polymer Polymer; wherein, the mass ratio of the aqueous phase solution to the oil phase mixed solution is 1:2.2;

[0033] 4) Mix 50 parts by weight of 3-trimeric epoxyhexafluoropropanemidopropyl (2-sulfurous acid) ethyl dimethyl ammonium and 17 parts by weight o...

Embodiment 2

[0036] 1) 3 parts by weight of propylene glycol fatty acid ester and 31 parts by weight of isopropanol are mixed to make an oil phase solvent, and then 5 parts by weight of hydroxymethylated calcium lignosulfonate are added to obtain an oil phase mixed solution;

[0037] 2) Add 18 parts by weight of sodium octylphenol polyoxyethylene ether sulfate and 9 parts by weight of polyoxyethyl glyceryl ether to 58 parts by weight of water, stir and dissolve, adjust the pH value to 8.8, and prepare an aqueous phase solution;

[0038] 3) Add the water phase solution into the oil phase mixed solution, add 0.10 parts by weight of benzoyl peroxide to carry out polymerization reaction, stir and heat up to 60°C, and react at this temperature for 15 hours to obtain a polymer polymer matter; wherein, the mass ratio of the aqueous phase solution to the oil phase mixed solution is 1:2.5;

[0039] 4) Mixing 38 parts by weight of 3-trimeric epoxyhexafluoropropaneamidopropyl (2-sulfurous acid) ethyl...

Embodiment 3

[0042] 1) Mix 2 parts by weight of monoglyceride laurate with 40 parts by weight of naphtha to make an oil phase solvent, then add 8 parts by weight of hydroxymethylated calcium lignosulfonate to prepare an oil phase mixed solution;

[0043] 2) Add 16 parts by weight of sodium lauryl alcohol polyoxyethylene ether disulfate and 7 parts by weight of polyoxypropylene glyceryl ether to 55 parts by weight of water, stir and dissolve, adjust the pH value to 8.5, and prepare an aqueous phase solution ;

[0044] 3) Add the aqueous phase solution into the oil phase mixed solution, add 0.15 parts by weight of benzoyl tert-butyl peroxide for polymerization reaction, stir and heat up to 65°C, and react at this temperature for 18 hours to obtain High molecular polymer; wherein, the mass ratio of the aqueous phase solution to the oil phase mixed solution is 1:2;

[0045] 4) mixing 45 parts by weight of sodium perfluoropropyl alkyl sulfonate and 20 parts by weight of rhamnolipid to prepare ...

PUM

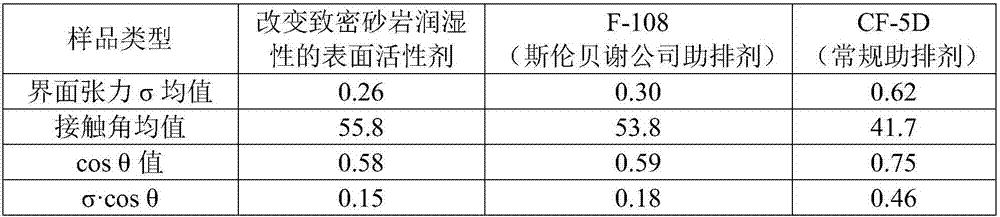

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com