Shield adhesive and preparation method thereof

A technology of shield glue and adhesive, applied in adhesives, mining equipment, shaft equipment, etc., can solve the problems of poor bonding effect of adhesives, difficult bonding of EPDM rubber, and difficult bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

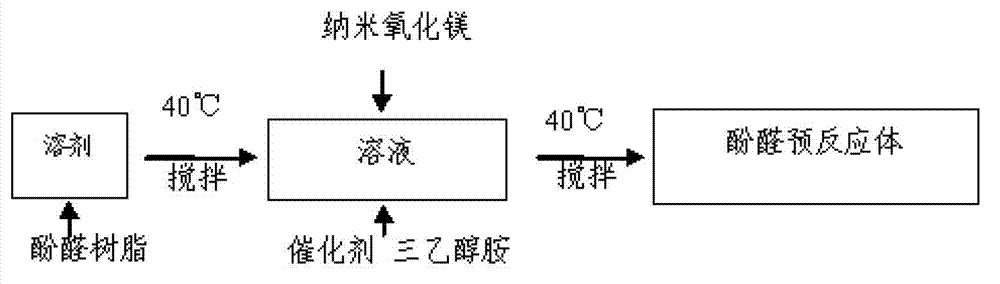

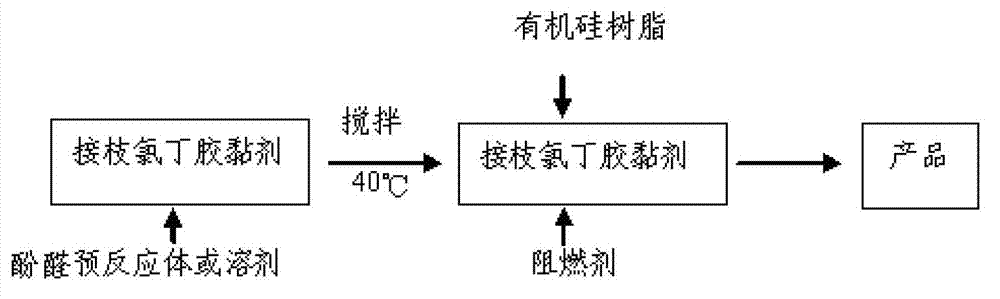

[0048] Embodiment 1 Preparation of shield adhesive

[0049] Mix 20kg of dimethyl carbonate, 20kg of ethyl acetate, and 60kg of cyclohexane evenly in the reactor, add 40kg of nano-aluminum metal phenolic resin, heat to 40°C, turn on the stirrer until the nano-aluminum metal phenolic resin is completely dissolved, Add 4kg of nano-magnesium oxide and 0.22kg of catalyst triethanolamine, keep the temperature at 40°C, and react for 14h to obtain a phenolic pre-reaction body.

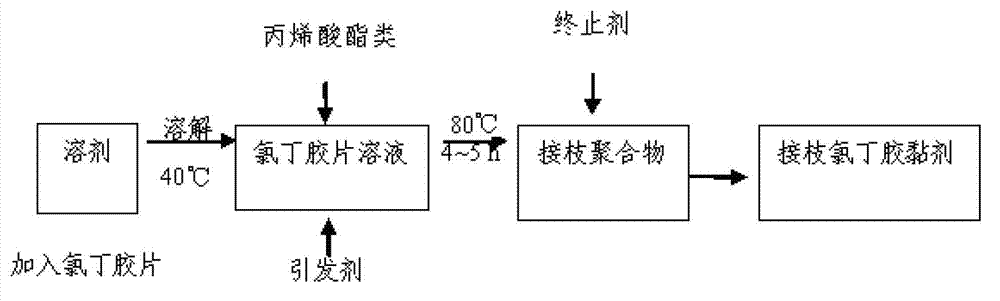

[0050] Mix 20kg of dimethyl carbonate, 20kg of ethyl acetate, and 60kg of cyclohexane evenly in the reactor, add 70kg of neoprene film A90, 20kg of A30, and after completely dissolving at 40°C, add 25kg of MMA, 7kg of styrene, acrylic acid -2-Hydroxypropyl ester 17kg, acrylic acid 1kg, 50kg in total, after stirring evenly, then add initiator benzoyl peroxide 1kg and nano magnesium oxide 4kg, heat up to 80°C, after reacting for 4 hours, add terminator terephthalate Phenol 1kg, cooled to obtain grafted neoprene...

Embodiment 2

[0052] Example 2 Preparation of shield adhesive

[0053] Mix 20kg of dimethyl carbonate, 20kg of ethyl acetate, and 60kg of cyclohexane evenly in the reactor, add 40kg of phenolic resin, heat to 40°C, turn on the agitator until the phenolic resin is completely dissolved, and add 4kg of nano-magnesium oxide With 0.22kg of catalyst triethanolamine, the temperature was kept at 40°C, and reacted for 15 hours to obtain a phenolic pre-reaction body.

[0054] Mix 20kg of dimethyl carbonate, 20kg of ethyl acetate, and 60kg of cyclohexane evenly in the reactor, add 75kg of neoprene film A90, 25kg of A30, and after completely dissolving at 40°C, add 25kg of MMA, 10kg of styrene, acrylic acid -2-Hydroxypropyl ester 12kg, acrylic acid 3kg, after a total of 50kg, after stirring evenly, then add initiator benzoyl peroxide 1.5kg and nano-magnesium oxide 4kg, heat up to 80°C, after reacting for 4.5h, add terminator to Hydroquinone 1.2kg, cooling, obtains graft neoprene.

[0055] Add the pre...

Embodiment 3

[0056] Example 3 Preparation of shield adhesive

[0057] Mix 20kg of dimethyl carbonate, 20kg of ethyl acetate, and 60kg of cyclohexane in the reactor, add 40kg of phenolic resin, heat to 40°C, turn on the agitator until the phenolic resin is completely dissolved, and add 4kg of nano-magnesium oxide With 0.22kg of catalyst triethanolamine, the temperature was kept at 40°C, and reacted for 16 hours to obtain a phenolic pre-reaction body.

[0058]Mix 20kg of dimethyl carbonate, 20kg of ethyl acetate, and 60kg of cyclohexane evenly in the reactor, add 80kg of neoprene film A90, 30kg of A30, after completely decomposing at 40°C, add 25kg of MMA, 13kg of styrene, acrylic acid - 10kg of 2-hydroxypropyl ester, 2kg of acrylic acid, 50kg in total, after stirring evenly, then add 1.5kg of initiator benzoyl peroxide and 4kg of nano-magnesium oxide, heat up to 80°C, and after reacting for 5 hours, add terminator p-benzene Diphenol 1.5kg, cooling, obtains graft neoprene.

[0059] Add the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com