Heat-resistant aluminum alloy containing Mo-Be and preparation method of heat-resistant aluminum alloy containing Mo-Be

An aluminum alloy, mo-be technology, applied in the field of Mo-Be-containing heat-resistant aluminum alloy and its preparation, can solve the problems of high-temperature instantaneous strength and high-temperature lasting strength, and improve heat-resistant stability, strength and heat resistance. The effect of improving the property, improving the high temperature strength and high temperature durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

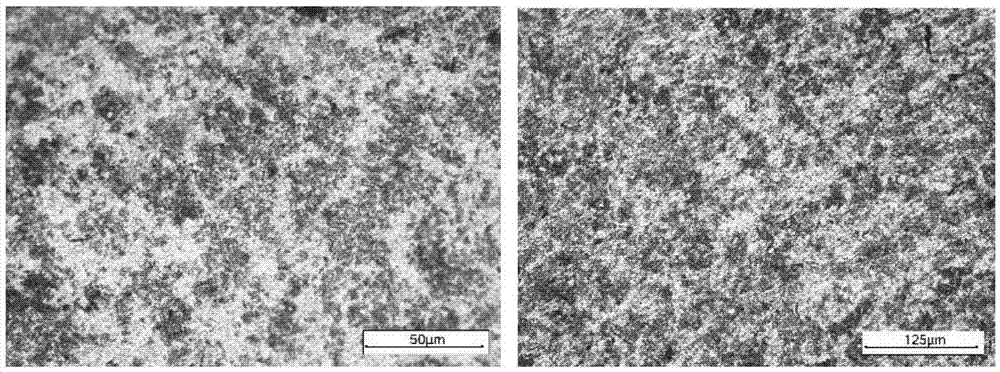

Image

Examples

Embodiment 1

[0029] Mo-Be heat-resistant aluminum alloy, its chemical composition according to mass percentage is: Cu: 7%, Mn: 0.6%, Ni: 0.7%, Cr: 0.4%, Be: 0.35%, Mo: 0.4%, V: 0.3 %, Ti: 0.25%, B: 0.01%, Ce: 2.8%, La: 1.8%, and the balance is Al and unavoidable impurities.

[0030] A method for preparing a heat-resistant aluminum alloy containing Mo-Be, comprising the steps of:

[0031] Step 1, smelting:

[0032] Put the aluminum-chromium master alloy into the crucible, heat it to 920°C, and after it is completely melted, lower the furnace temperature to 790°C;

[0033] According to the set alloy composition, add aluminum-copper master alloy, aluminum-manganese master alloy, aluminum-beryllium master alloy, aluminum-nickel master alloy, aluminum-molybdenum master alloy, aluminum-vanadium master alloy, aluminum-titanium-boron master alloy, aluminum rare earth master alloy and aluminum , After more than 2 / 3 of the charge is melted, add HZ-WYF smokeless covering agent, the amount of coveri...

Embodiment 2

[0043] The chemical composition of heat-resistant aluminum alloy containing Mo-Be is as follows: Cu: 6.5%, Mn: 0.65%, Ni: 0.55%, Cr: 0.35%, Be: 0.4%, Mo: 0.3%, V: 0.25 %, Ti: 0.2%, B: 0.01%, Ce: 2.5%, La: 2%, and the balance is Al and unavoidable impurities.

[0044] A method for preparing a heat-resistant aluminum alloy containing Mo-Be, comprising the steps of:

[0045] Step 1, smelting:

[0046] Put the aluminum-chromium master alloy into the crucible, heat it to 920°C, and after it is completely melted, lower the furnace temperature to 780°C;

[0047] According to the set alloy composition, add aluminum-copper master alloy, aluminum-manganese master alloy, aluminum-beryllium master alloy, aluminum-nickel master alloy, aluminum-molybdenum master alloy, aluminum-vanadium master alloy, aluminum-titanium-boron master alloy, aluminum rare earth master alloy and aluminum , After more than 2 / 3 of the charge is melted, add HZ-WYF smokeless covering agent, the amount of covering ...

Embodiment 3

[0056] Mo-Be heat-resistant aluminum alloy, its chemical composition according to the mass percentage is: Cu: 6%, Mn: 0.7%, Ni: 0.6%, Cr: 0.3%, Be: 0.35%, Mo: 0.3%, V: 0.3 %, Ti: 0.25%, B: 0.015%, Ce: 2.8%, La: 2%, and the balance is Al and unavoidable impurities.

[0057] A method for preparing a heat-resistant aluminum alloy containing Mo-Be, comprising the steps of:

[0058] Step 1, smelting:

[0059] Put the aluminum-chromium master alloy into the crucible, heat it to 930°C, and after it is completely melted, lower the furnace temperature to 800°C;

[0060] According to the set alloy composition, add aluminum-copper master alloy, aluminum-manganese master alloy, aluminum-beryllium master alloy, aluminum-nickel master alloy, aluminum-molybdenum master alloy, aluminum-vanadium master alloy, aluminum-titanium-boron master alloy, aluminum rare earth master alloy and aluminum , After more than 2 / 3 of the charge is melted, add HZ-WYF type smokeless covering agent, the amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com