Carbon-free high-speed steel and preparation method thereof

A high-speed steel and high-speed technology, applied in the field of carbon-free high-speed steel and its preparation, can solve the problems of not improving material hardness and material brittleness well, achieve superior tool material performance, improve tempering resistance and red hardness, The effect of controlling the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

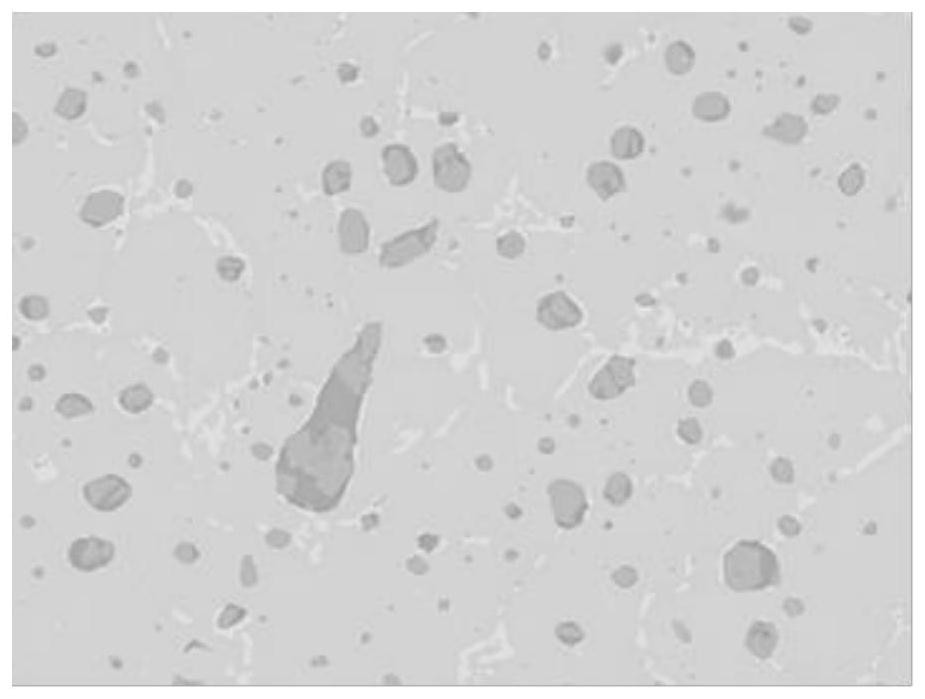

[0037] The present invention is a carbon-free high-speed steel and its preparation method, and its technical characteristics will be described through six specific examples. The preparation process in each described embodiment is the same, but the process parameters are different.

[0038] The carbon-free high-speed steel of the present invention is composed of 60-76% Fe powder, 14.85-24.95% Co powder, 9-15% Mo powder, 0.05-0.15% LaB 6 Powder composition; Said percentage is mass percent.

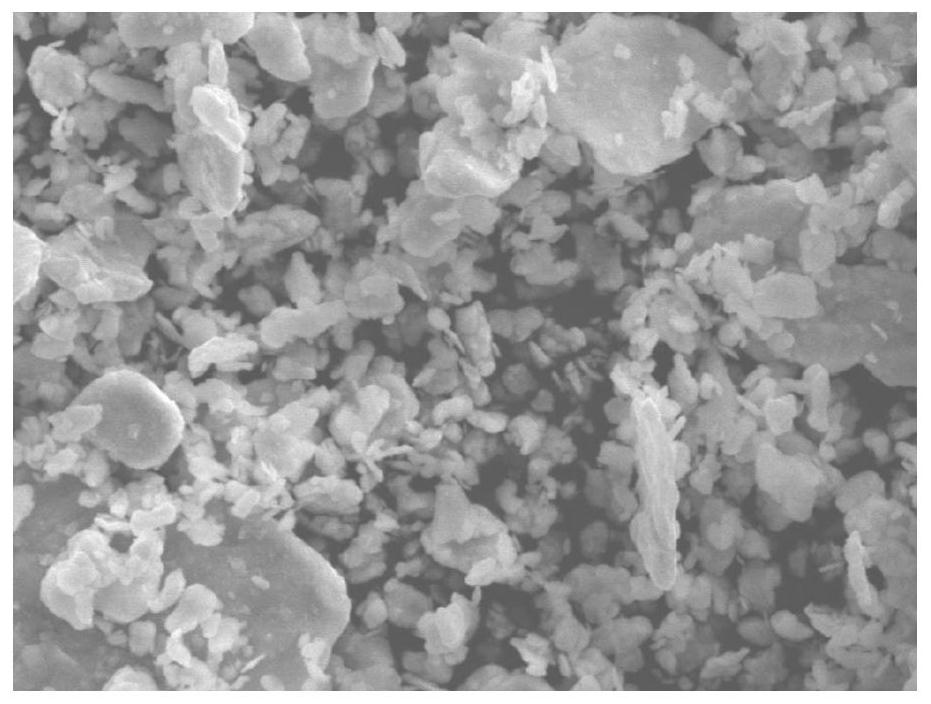

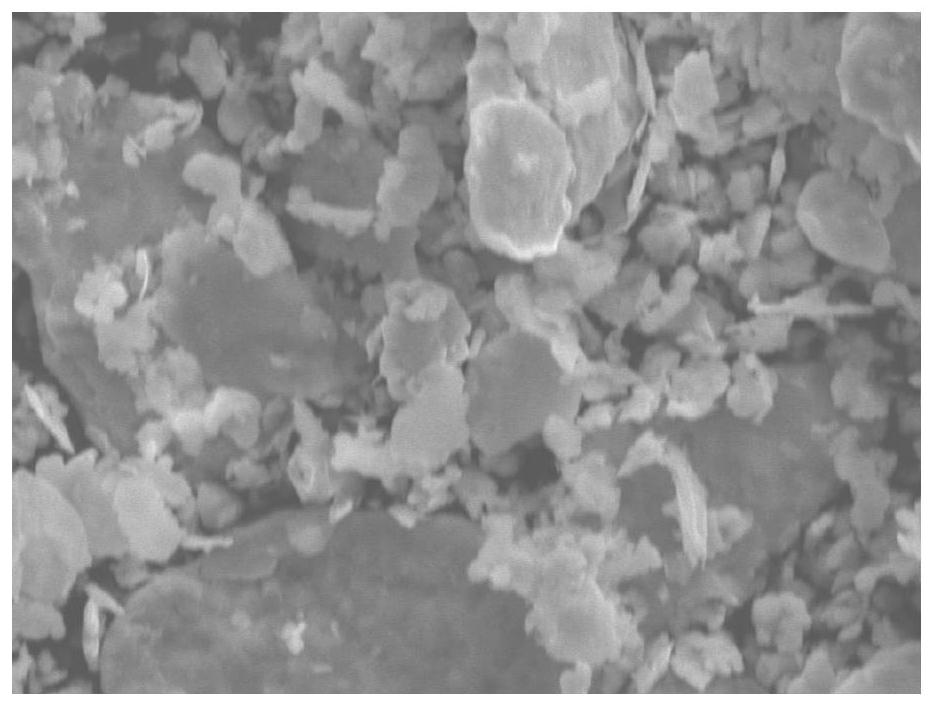

[0039] The Fe powder, Co powder, Mo powder and LaB 6 The purity of the powder is 99.9%, the purity is 100% by mass, and the particle size is 74-100um.

[0040] Table 1: Components of each example

[0041]

[0042] The concrete process that the present invention proposes to prepare described carbon-free high-speed steel is:

[0043] Step 1, ball milling:

[0044]Weigh the ingredients. The weighed raw material powder is placed in a ball mill, and absolute ethanol is added to perform b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com