High-speed steel and heat treatment technique thereof

A high-speed steel and a new type of technology, applied in the field of new high-speed steel and its heat treatment process, can solve the problems of low production cost and high manufacturing cost, and achieve the effects of increasing hardenability, reducing production cost and saving the amount of molybdenum used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]A new type of high-speed steel, the high-speed steel includes: carbon C0.95%, silicon Si0.3%, manganese Mn0.3%, chromium Cr10%, tungsten W4%, molybdenum Mo1.0%, vanadium V1. 0%, nickel Ni0.2%, cobalt Co1%, niobium Nb1.2%, titanium Ti0.3%, rare earth elements 0.05%, sulfur S≤0.015%, phosphorus P≤0.02%, and the rest is iron Fe.

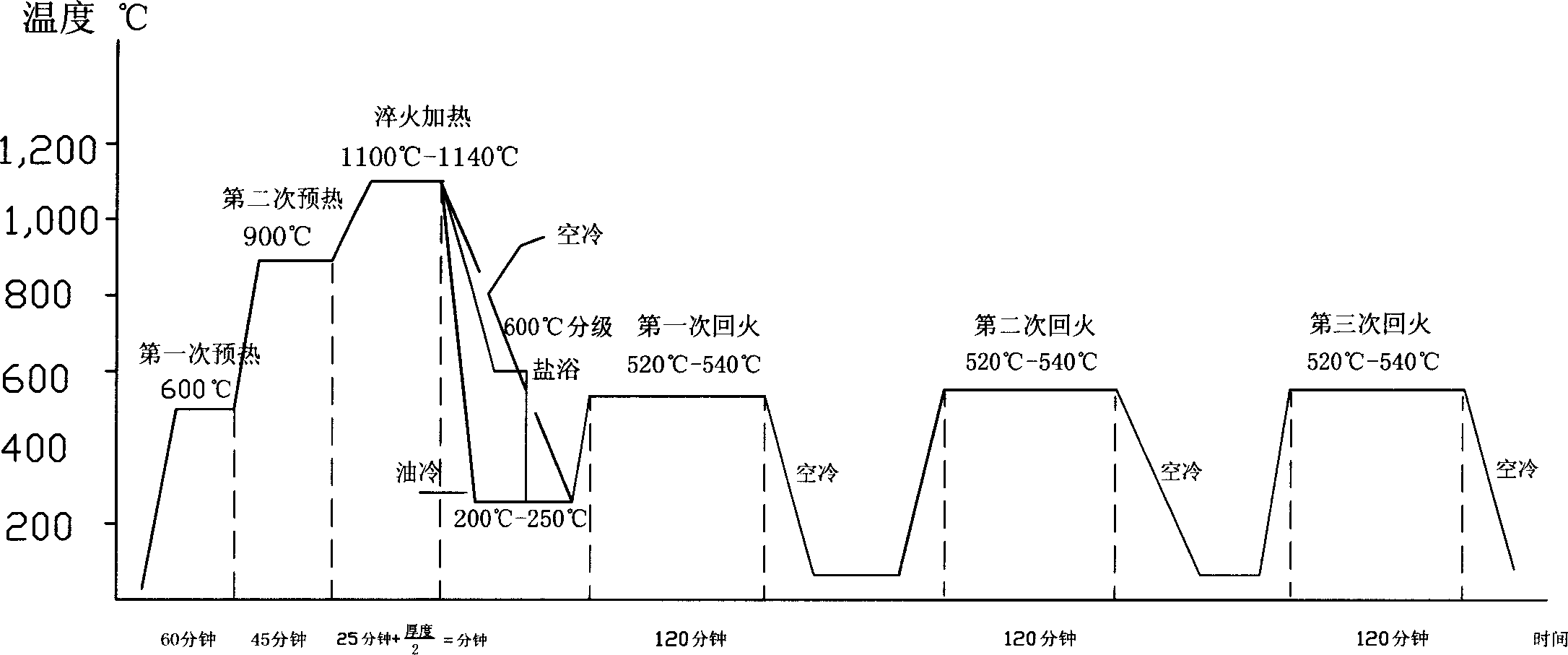

[0038] The heat treatment process of the above-mentioned novel chromium steel series high-speed steel comprises the following steps:

[0039] (1), the first preheating, the temperature is 600 ℃, and the preheating time is 60 minutes;

[0040] (2), the second preheating, the temperature is 900 ℃, and the preheating time is 45 minutes;

[0041] (3) Quenching heating, the quenching heating temperature is 1100°C-1140°C, the quenching time is: (25+material thickness / 2) minutes, and then oil-cooled to 200°C-250°C;

[0042] (4) For the first tempering, the tempering temperature is 520°C to 540°C, the tempering time is 120 minutes, and then air-cooled t...

Embodiment 2

[0046] A new type of high-speed steel, the high-speed steel includes: carbon C0.9%, silicon Si0.2%, manganese Mn0.2%, chromium Cr9.5%, tungsten W3.5%, molybdenum Mo0.6% by weight percentage , Vanadium V0.4%, Nickel Ni0.1%, Cobalt Co0.5%, Niobium Nb0.8%, Titanium Ti0.3%, Rare Earth Elements 0.05%, Sulfur S≤0.015%, Phosphorus P≤0.02%, the rest For iron Fe.

[0047] The heat treatment process of the above-mentioned novel chromium steel series high-speed steel comprises the following steps:

[0048] (1), the first preheating, the temperature is 600 ℃, and the preheating time is 60 minutes;

[0049] (2), the second preheating, the temperature is 900 ℃, and the preheating time is 45 minutes;

[0050] (3) Quenching heating, the quenching heating temperature is 1100℃~1140℃, the quenching time is: (25+material thickness / 2) minutes, then cooling in salt bath, grading heat preservation at 600℃, and then salt bath to 200℃~250℃ ;

[0051] (4) For the first tempering, the tempering temp...

Embodiment 3

[0055] A new type of high-speed steel, the high-speed steel includes: carbon C1.0%, silicon Si0.4%, manganese Mn0.4%, chromium Cr10.5%, tungsten W4.5%, molybdenum Mo1.5% by weight percentage , Vanadium V1.0%, Nickel Ni0.3%, Cobalt Co1.5%, Niobium Nb1.8%, Titanium Ti0.3%, Rare Earth Elements 0.05%, Sulfur S≤0.015%, Phosphorus P≤0.02%, the rest For iron Fe.

[0056] The heat treatment process of the above-mentioned novel chromium steel series high-speed steel comprises the following steps:

[0057] (1), the first preheating, the temperature is 600 ℃, and the preheating time is 60 minutes;

[0058] (2), the second preheating, the temperature is 900 ℃, and the preheating time is 45 minutes;

[0059] (3) Quenching heating, the quenching heating temperature is 1100°C-1140°C, the quenching time is: (25+material thickness / 2) minutes, and then air-cooled to 200°C-250°C;

[0060] (4) For the first tempering, the tempering temperature is 520°C to 540°C, the tempering time is 120 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com