Patents

Literature

41results about How to "Beautiful luster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

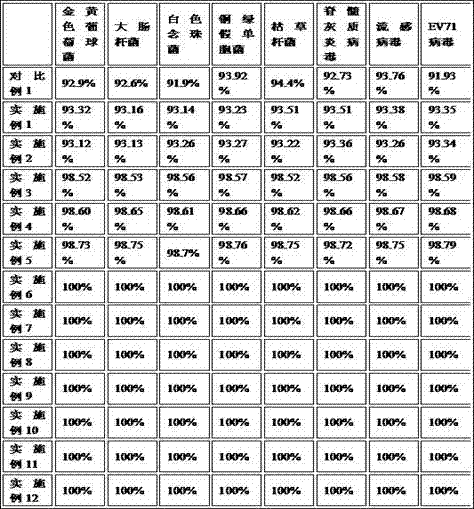

Hand-care disposable disinfection gel and preparation method thereof

ActiveCN104873432ASimple preparation processHigh sterilization rateCosmetic preparationsToilet preparationsSolventChemistry

The invention relates to a hand-care disposable disinfection gel and a preparation method thereof. The hand-care disposable disinfection gel comprises ethanol, a bactericide, a cosolvent, a thickener, an emollient, essence and a PH regulator, wherein the essence is used as a carrier to cover pungent odor of ethanol. The hand-care disposable disinfection gel has the advantages of being bactericidal, washing-free, not sticky and greasy, and comfortable in smell, and caring hands. The preparation method comprises the following steps: the thickener swells in purified water fully to prepare a liquid A; meanwhile, the bactericide and the cosolvent are added in ethanol to be mixed uniformly to prepare a liquid B; then, the liquid B is poured into the liquid A; the emollient and the essence are poured in the liquid A, after purified water is supplemented to be sufficient, the PH regulator is added to regulate the PH value to 6.0-8.0, and the uniform mixing is performed.

Owner:HENAN HUIBO MEDICAL CO LTD

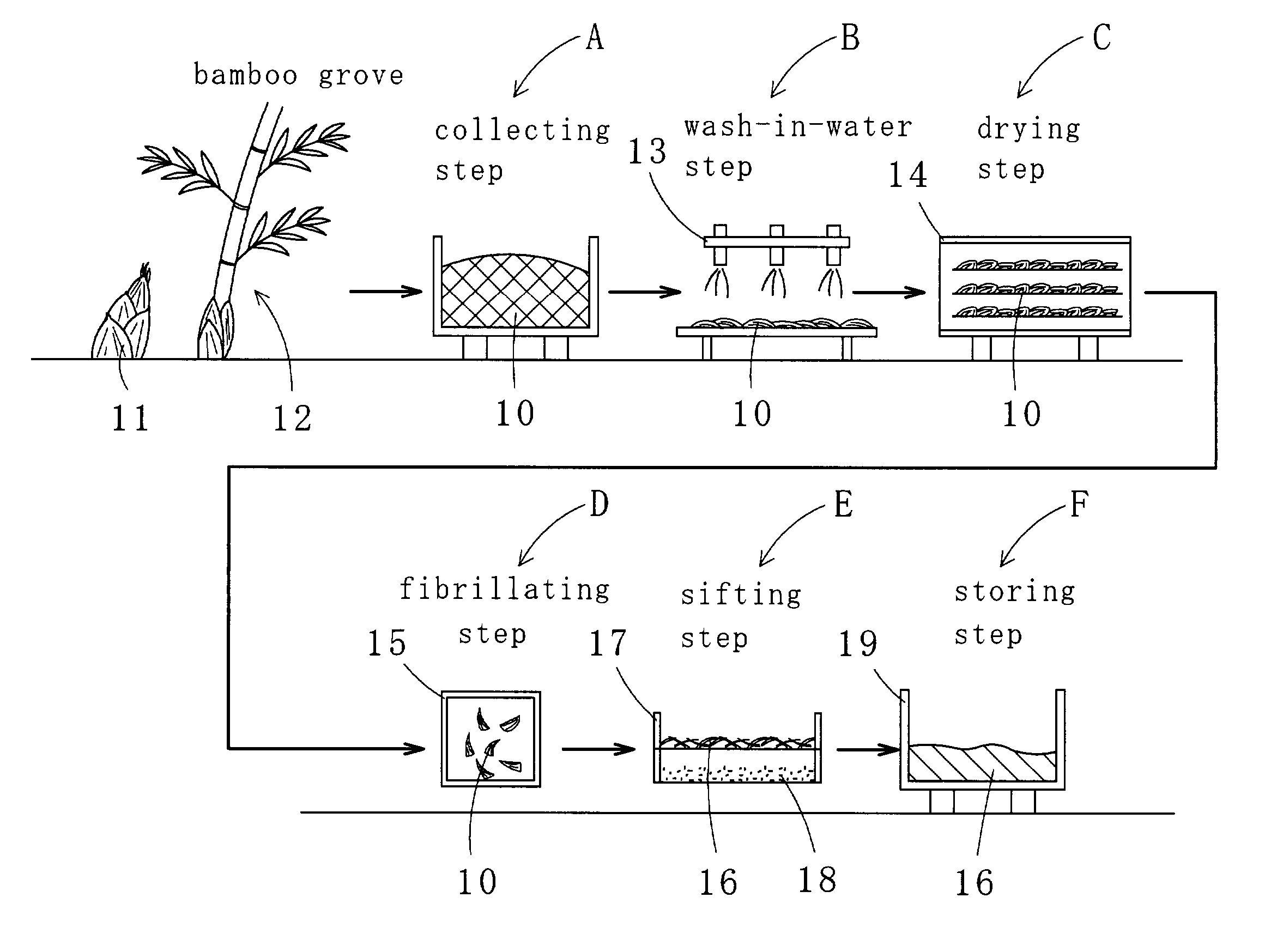

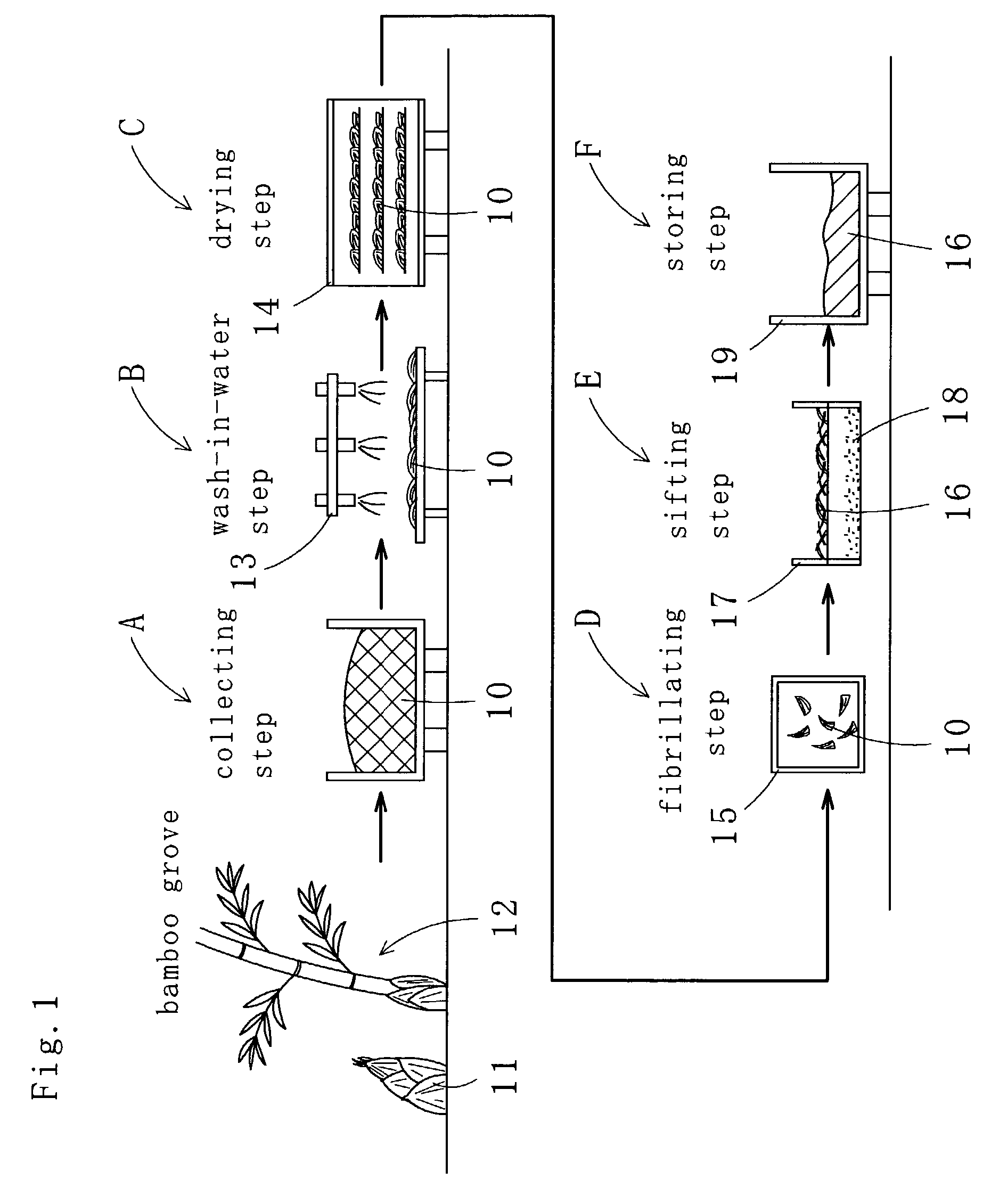

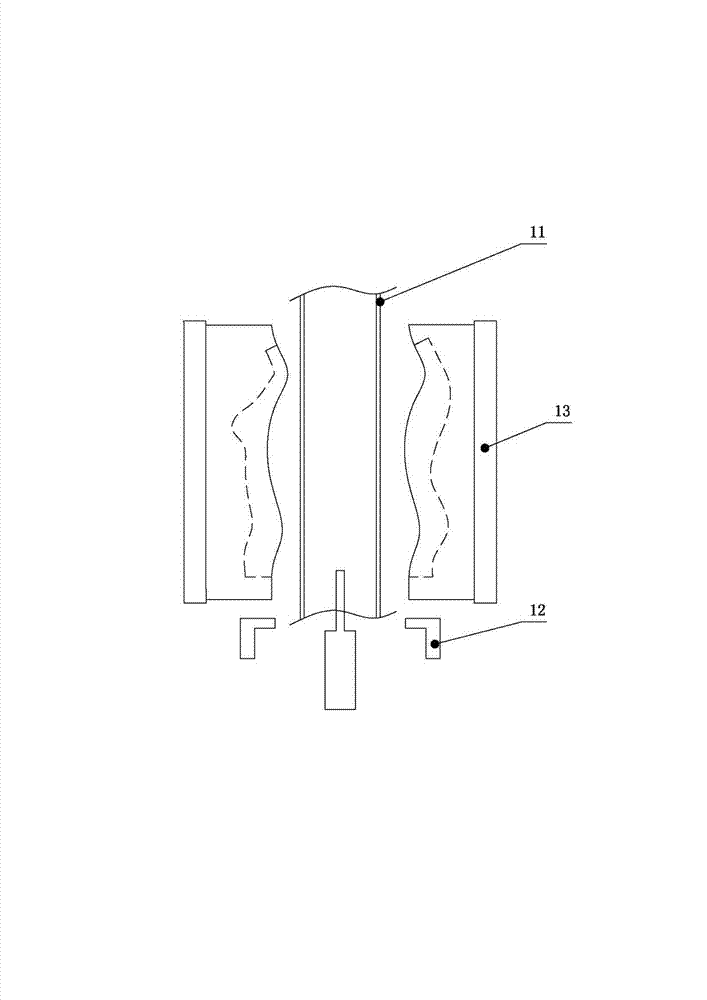

Yam and cloths made mainly from bamboo sheaths and methods for manufacturing the same

InactiveUS7060211B2Reduce the degree of polymerizationEasy to usePillowsArtificial filaments from cellulose solutionsFiberChemical treatment

The present invention provides yarn and cloths made by utilizing bamboo fiber and methods for manufacturing these yarn and cloths, thereby the bamboo fiber can be utilized by being extracted from sheaths of bamboo shoots or bamboo sheaths that generate at the root of bamboo abundantly, which have been left as they are or mostly disposed of as wastes. By fibrillating or chemically treating bamboo sheaths 10 which is a main raw material, bamboo fiber 16 mainly comprising cellulose is obtained, and then it is formed into yarn by spinning. A cloth is produced as woven or knitted fabric using the yarn.

Owner:KATSUYAMA TECHNOS

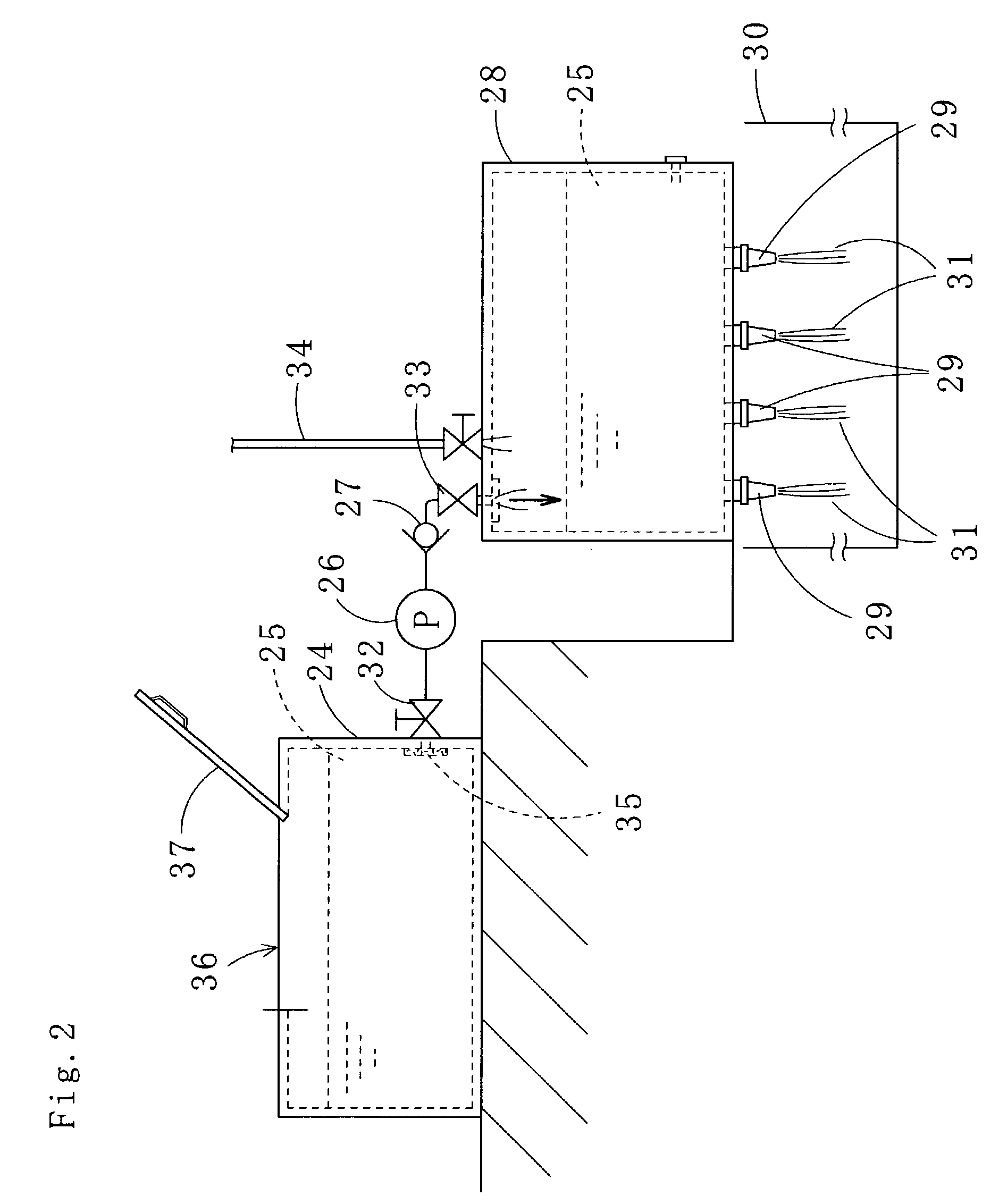

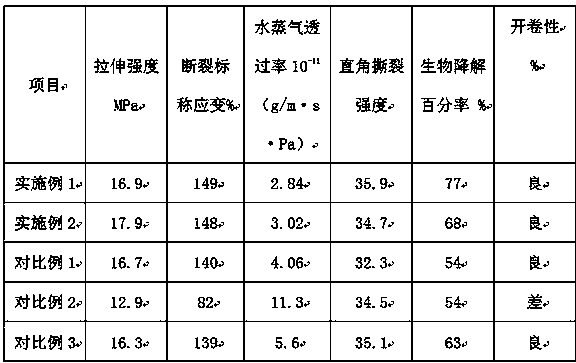

Environment-friendly degradable edible film packaging material

InactiveCN109054105AHigh strengthAct as a crosslinking agentFlexible coversWrappersNon toxicityPermeation

The invention discloses an environment-friendly degradable edible film packaging material. The environment-friendly degradable edible film packaging material is prepared from the following raw materials in parts by weight: 43-77 parts of modified starch, 22-61 parts of dandelion extract, 13-17 parts of konjac gelatin powder, 32-57 parts of edible gelatin, 21-37 parts of modified casein, 10-15 parts of carboxymethyl cellulose, 3-9 parts of chitosan, 2-7 parts of plasticizers, 7-13 parts of agar, 1-3 parts of citric acid, 2-4 parts of antibacterial liquid, 0.5-1.5 parts of plant extract, 2-4 parts of cactus juice, 2-6 parts of glutinous rice juice and 2-7 parts of carrot powder. The environment-friendly degradable edible film packaging material has the advantages of edibility, capability ofpackaging food, preventing oxygen permeation and protecting the original taste of fatty food, high nutritional value after eating, capability of meeting environmental safety requirements, non-toxicity, safety, high oxygen permeation resistance, water and oil resistance, high temperature resistance, easiness in degradation, high strength, good comprehensive performance and high cost performance.

Owner:合肥旭亚新材料科技有限公司

Method for producing metallic leatherette paper

ActiveCN101581056ABeautiful lusterQuality improvementSpecial visual effect coatingsNon-fibrous pulp additionWater basedDry weight

The invention relates to a method for producing metallic leatherette paper. The method comprises the following steps of production of base paper, impregnation processing, bottom coating, top coating and embossing, wherein the top coating adopts an air knife coating method, by which the coating for the top coating prepared from pearl essence RS611 and metallic leatherette oil KL3101 is evenly coated on the surface of the paper after the bottom coating; the weight of the pearl essence RS611 is 8 to 12 percent of the total absolute dry weight of the coating for the top coating, the coating quantity for the top coating is between 8 and 10g / m, the drying temperature is between 125 and 128 DEG C, and the speed is 30m / min; and the embossing treatment is performed, so that the metallic leatherette paper with leather feeling and metallic luster is obtained. The method has the advantages of easy production and low production cost; the surface of the metallic leatherette paper produced by the method has the leather feeling, and the metallic leatherette paper is soft and can be folded freely; moreover, the metallic leatherette paper also has the metallic feeling, beautiful luster and high quality, so that the metallic leatherette paper is water-based environment-friendly metallic leatherette paper.

Owner:SHANDONG KAILI SPECIAL PAPER

Repairing agent for damaged skin and preparation method thereof

InactiveCN107303253AHigh activityEnhance immune protectionCosmetic preparationsToilet preparationsViscous liquidChamomile extract

The invention discloses a repairing agent for damaged skin, which is composed of the following components in mass percentage: β-glucan 5-10; propylene glycol 10-20; golden chamomile extract 5-10; purslane extract 5‑10; Aloe Vera Extract 5‑10; Chitosan 2‑6; Panthenol 2‑6; Sodium Hyaluronate 0.2‑0.5; Oligopeptide‑10.2‑0.5; And through the addition of ingredients and stirring into a viscous liquid through continuous cooling, the preparation method of the repair agent is formed, so that the repair agent prepared can improve the immunity of the human body, repair damaged cells, repair capillaries, and reduce the damage of nerve ending sheaths in the skin. Threshold, replenish and maintain skin moisture and other three-dimensional multi-faceted skin repairs, so that the skin returns to a healthy state.

Owner:长沙星工场生物科技有限公司

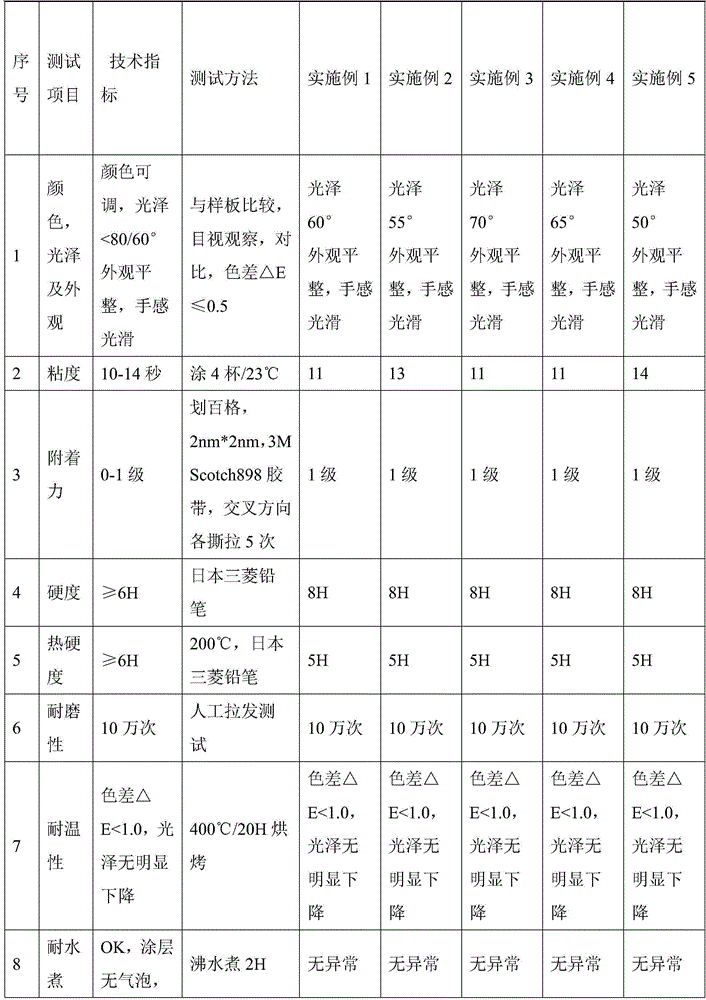

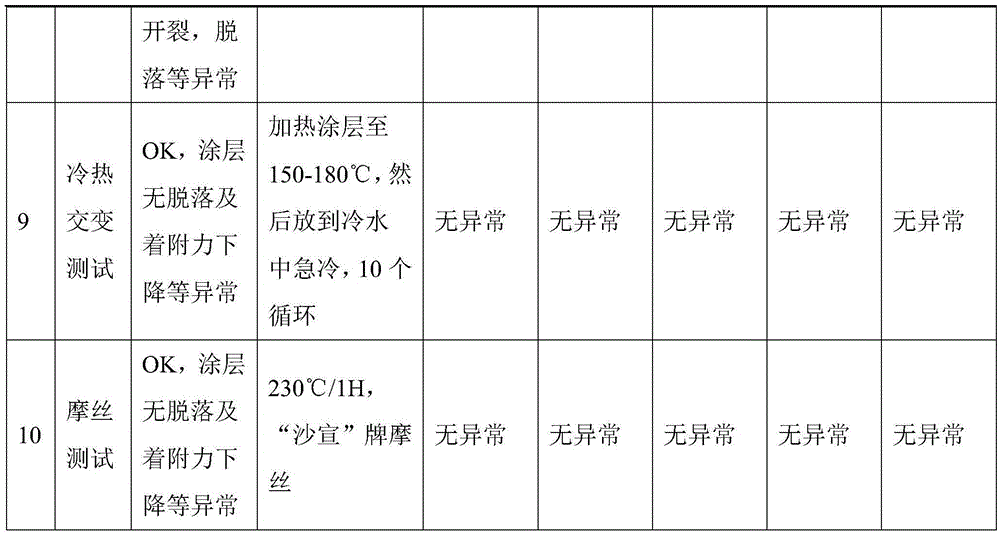

High-abrasion-resistance, high-temperature-resistant and water-cooking-resistant aqueous ceramic paint

The invention discloses high-abrasion-resistance, high-temperature-resistant and water-cooking-resistant aqueous ceramic paint, which is prepared by mixing a component A, a component B and a component C according to a mass ratio of 666: 333: 1, wherein the component A is prepared from the following components in percentages by mass: 26 percent to 30 percent of silica sol, 13 percent to 15 percent of antimony solution, 5 percent to 13 percent of inorganic high-temperature-resistant pigment and 8 percent to 12 percent of silicon dioxide; the component B is prepared from the following components in percentages by mass: 30 percent to 34 percent of silicane, 0.4 percent to 0.6 percent of wetting agent and 0.4 percent to 0.6 percent of flatting agent; the component C is 0.1 percent of catalyst. The paint prepared by the invention not only has the attractive luster and appearance and the nice hand feeling of conventional aqueous ceramic paint, but also has ultrahigh hardness and hot hardness and excellent abrasion resistance, can be up to over 100,000 times in manual hair pulling test, and further has excellent water cooking resistance, temperature resistance and corrosion resistance. The ceramic paint which is provided by the invention and is prepared by adopting a silane coupling agent has many advantages of high temperature resistance, high hardness, noninflammability, no smoke, super weatherability, environment friendliness, nontoxicity, colorfulness and the like.

Owner:DONGGUAN RUNTIAN CHEM CO LTD

Preparation method for garden outdoor preservative wood

ActiveCN106217535AConsistent colorBeautiful lusterWood treatment detailsOpen tank impregnationMagnesium saltCarbonization

The invention discloses a preparation method for garden outdoor preservative wood and belongs to the technical field of garden greening. The preparation method comprises the steps that poplar which is cheap and easy to get serves as a raw material, and the poplar is soaked with a tetrabutyl titanate ethanol solution after being naturally dried in the air, so that the solution is absorbed by cells, in the program warming and carbonization processes, nutritional components inside the poplar are carbonized, ethanol is volatilized, and tetrabutyl titanate is hydrolyzed into titanium dioxide which serves as an antibiotic component and is dispersed into wood fibers; the pretreated poplar is then soaked with magnesium sulfate and subjected to liquid nitrogen freezing and soaking unfreezing, so that the solution fully enters the wood fibers; the poplar is then fumigated with high-pressure ammonia, so that magnesium salt crystal whiskers are formed inside the wood fibers, and the purpose of improving the wood strength is achieved; and the garden outdoor preservative wood is finally obtained through drying. The garden outdoor preservative wood obtained through the preparation method is free of pollution to water and soil in the using process, excellent in preservative performance and capable of effectively resisting encroachment of fungi, bacteria and moths, is a safe, natural and environment-friendly preservative and moth-proof building material and can be widely applied and popularized.

Owner:珠海经济特区园海绿化工程有限公司

Aerosol foam or pump foam product for hair treatment

InactiveUS7597898B2Avoid disadvantagesImprove quality requirementsCosmetic preparationsBiocideSolventHair treatment

The foam product for hair treatment includes a composition containing a cationic cellulose derivative, chitosan, acid for partial or complete neutralization of the chitosan and a suitable solvent. The weight ratio of the cationic cellulose derivative to the chitosan is less than 2. The composition is either provided with a propellant or is foamed with a mechanically operated foam-making device.

Owner:WELLA GMBH

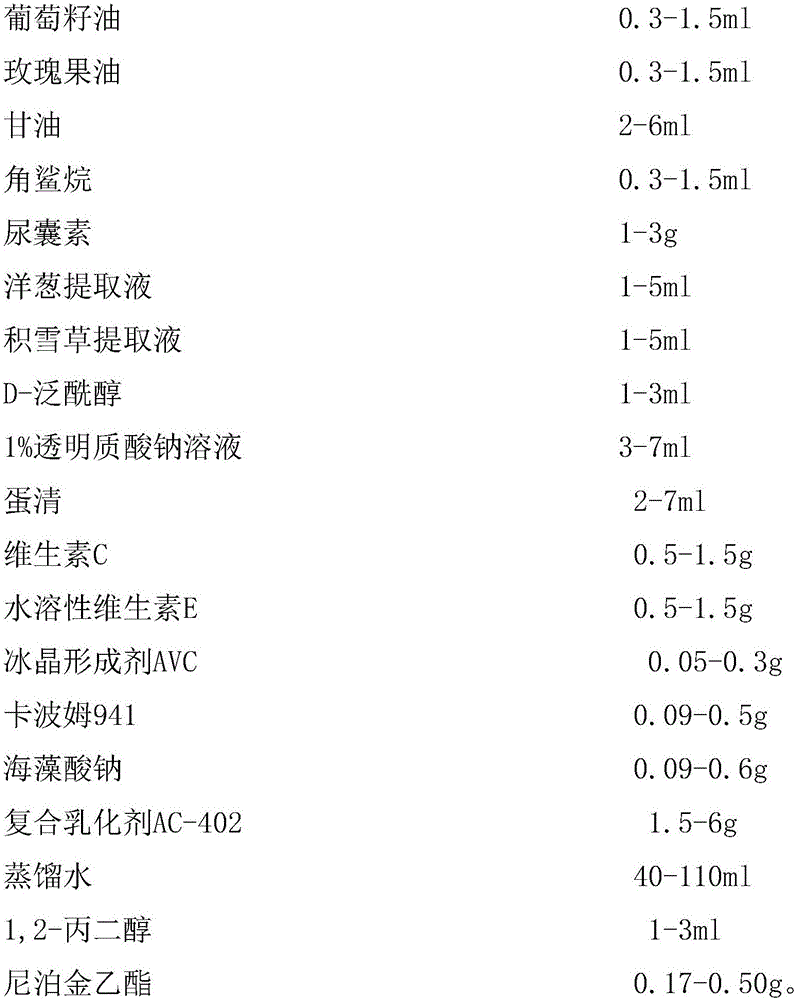

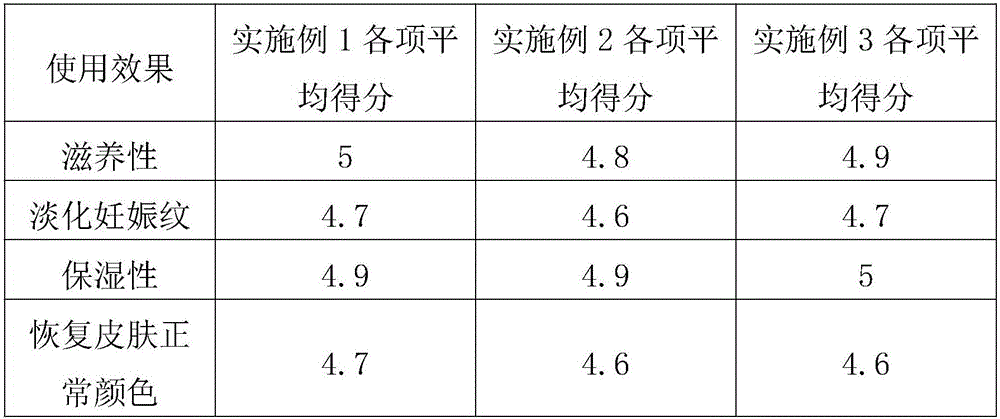

Skincare lotion for fading stretch marks and preparation method thereof

ActiveCN106727122AImprove ductilityPromote circulationCosmetic preparationsToilet preparationsCentella asiatica extractWrinkly skin

The invention discloses skincare lotion for fading stretch marks and a preparation method thereof. The lotion contains the following substances: olive oil, grape seed oil, rosehip oil, glycerol, squalane, allantoin, onion extract, centella asiatica extract, D-panthenol, 1% sodium hyaluronate solution, egg white, vitamin C, water-soluble vitamin E, ice crystal forming agent AVC, carbomer 941, sodium alginate, composite emulsifier AC-402, distilled water, 1,2-propylene glycol, and ethylparaben. Compared with the prior art, the lotion prepared by the method provided by the invention has safe components, is easy to absorb, has a very good nourishing and moisturizing effect, can fade the stretch marks, adiposity marks, and orange peel marks, eliminate a crepe paper type appearance of the stretch marks, improve microcirculation, improve postnatal abdominal well laxation, strengthen metabolism, shallow the color of the stretch marks, narrow the width of the stretch marks, and restore the normal color of skin, and can also achieve a very good nourishing and skincare effect to make the skin delicate, tender, and incomparably smooth.

Owner:杭州千岛湖蓝色天使实业有限公司

Hand-protecting disposable disinfection gel and preparation method thereof

ActiveCN104873432BImprove smellImprove permeabilityCosmetic preparationsToilet preparationsSolventPurified water

The invention relates to a hand-care disposable disinfection gel and a preparation method thereof. The hand-care disposable disinfection gel comprises ethanol, a bactericide, a cosolvent, a thickener, an emollient, essence and a PH regulator, wherein the essence is used as a carrier to cover pungent odor of ethanol. The hand-care disposable disinfection gel has the advantages of being bactericidal, washing-free, not sticky and greasy, and comfortable in smell, and caring hands. The preparation method comprises the following steps: the thickener swells in purified water fully to prepare a liquid A; meanwhile, the bactericide and the cosolvent are added in ethanol to be mixed uniformly to prepare a liquid B; then, the liquid B is poured into the liquid A; the emollient and the essence are poured in the liquid A, after purified water is supplemented to be sufficient, the PH regulator is added to regulate the PH value to 6.0-8.0, and the uniform mixing is performed.

Owner:HENAN HUIBO MEDICAL CO LTD

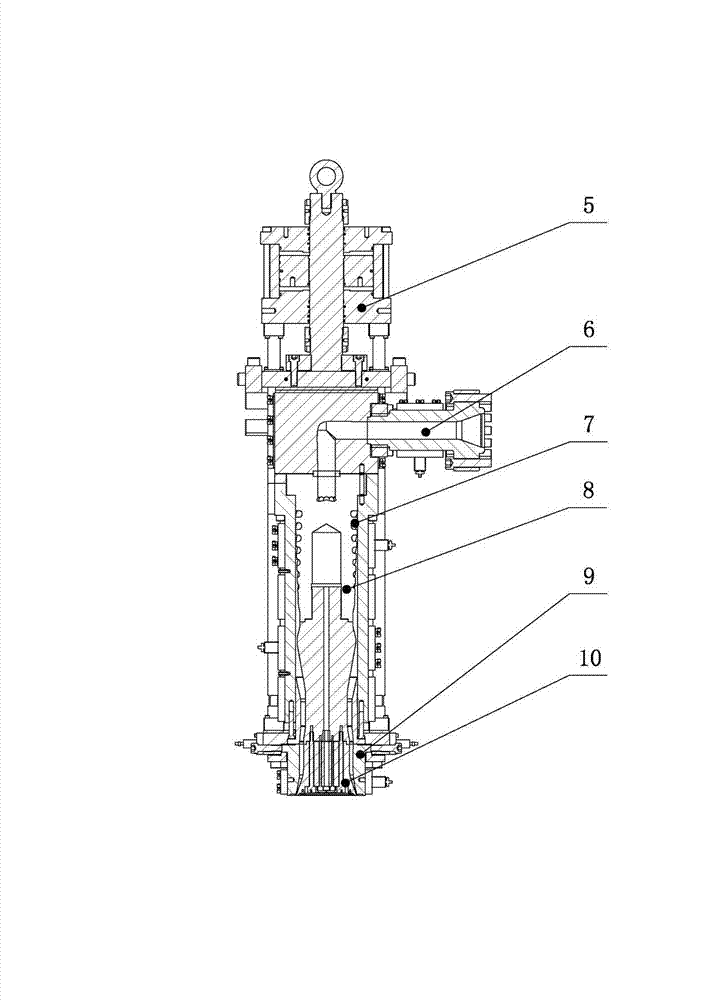

Model model forming process

InactiveCN102765184AHigh-grade and beautiful surfaceBeautiful lusterScreen printingEnvironmental resistance

The invention discloses a model model forming process. A model model is formed in one time through a hollow blow molding machine by adopting a polycarbonate sizing material, and then the follow-up process of spraying, screen printing and assembling and the like can be performed. The forming process is simple in method, high in automation degree and production efficiency and low in production cost. The product is light, attractive and high-end, fall-resistant, abrasion-resistant, low in transporting cost and loss, low in after-sales cost, convenient to recycle after scrap, green and environment-friendly, meets the development requirements of energy saving and environment protection at present, and is certainly one of the main stream development directions of the model industry.

Owner:东莞大同塑料制品有限公司

Production method of environment-friendly PU metal leatherette paper

ActiveCN106245457ASimple production methodAny foldFlexible coversMechanical working/deformationMetalCoated paper

The invention discloses a production method of environment-friendly PU metal leatherette paper. The production method comprises selecting original leatherette backing paper, impregnating, prime-coating, topcoating and embossing; the topcoating uses a comma knife coating manner, and a top coating is evenly coated on the prime-coated paper, wherein the top coating comprises a waterborne gold-silver powder and a waterborne PU resin, the waterborne gold-silver powder in the top coating accounts for 15-20% of the total dry component of the top coating, the topcoating amount is 5-7g / m<2>, the drying temperature is 130-140 DEG C, and the lathing speed is 35-50m / min. The production method is low in cost, the surface of the prepared leatherette paper has a leather texture, is soft and loose and can be randomly folded, the leatherette paper also shows a strong metal and heavy impression and is high in grade, and the gloss is attractive.

Owner:安徽天艺纸业科技有限公司

Production method of anti-slip and highlight leatherette paper

ActiveCN106351055AHigh strengthImprove water resistanceNon-fibrous pulp additionCoatings with pigmentsSurface brightnessPulp and paper industry

The invention disclsoes a production method of anti-slip and highlight leatherette paper. The production method comprises: selecting original leatherette base paper, impregnating and machining, carrying out primary finishing, carrying out prime coating, carrying out primary surface coating, carrying out secondary finishing, carrying out secondary surface coating, applying gloss oil, applying anti-slip gloss oil and embossing, wherein in the primary surface coating and the secondary surface coating, a paper surface is coated with surface coating ink by adopting an intaglio full coating manner; the drying temperature is 110 DEG C to 120 DEG C and the turning speed is 20m / min to 60m / min. The production method provided by the invention is simple in process and low in cost; the produced leatherette paper has an anti-slip functional characteristic; meanwhile, the surface brightness is high; the leatherette paper has a leather bright feeling and a paper soft and loose feeling, and can be randomly folded and rolled; the leatherette paper is glossy and attractive, has bright color and luster and a high grade; a product can keep stable and non-slipping, can be adsorbed on a bearing object very well and is not stuck inversely.

Owner:安徽天艺纸业科技有限公司

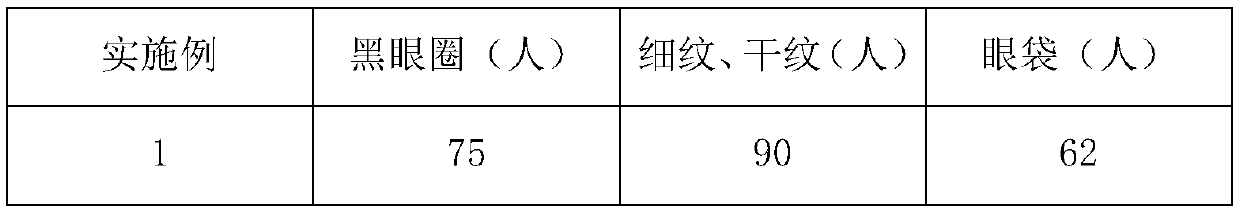

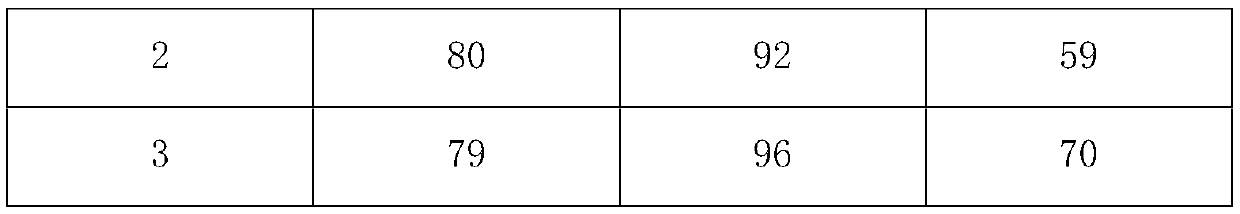

Composition capable of lightening dark circles and removing eye puffiness and eye wrinkles

PendingCN110063916ALips are soft and elasticBeautiful lusterCosmetic preparationsToilet preparationsSodium polyacrylateSodium hyaluronate

The invention belongs to the technical field of medical beauty skin care, and particularly relates to a composition capable of lightening dark circles and removing eye puffiness and eye wrinkles. Thecomposition is prepared from, by mass, 5.0-6.0% of bio-saccharide gum-1, 0.01-0.03% of sodium hyaluronate, 2.0-5.0% of a hamamelis virginiana extract, 0.3-0.5% of allantoin, 0.5-0.8% of hesperidin methyl chalcone, 0.1-0.2% of a chelating agent, 2.0-3.0% of tartaric acid, 1.0-3.0% of 1,2-hexanediol, 0.1-0.2% of a preservative, 0.1-0.2% of sodium polyacrylate, 2.0-4.0% of glycerinum and the balancedistilled water. The composition has effects of moisturizing, repairing dry wrinkles, lightening the dark circles and astringing the eye puffiness; effective ingredients can penetrate into the eye muscle bottom to care the eye skin; the adopted preservative is safe for the human body and can be used by customers securely.

Owner:丁蓉

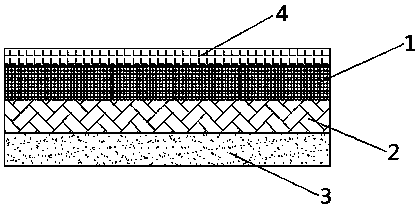

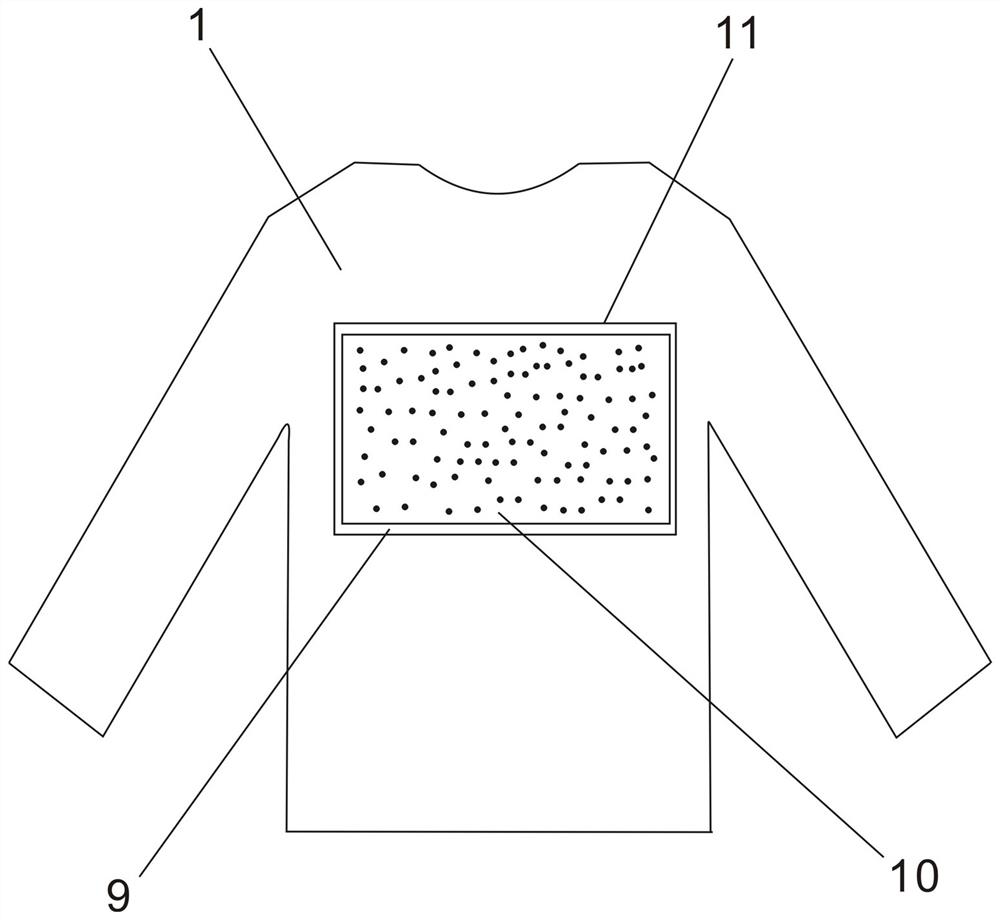

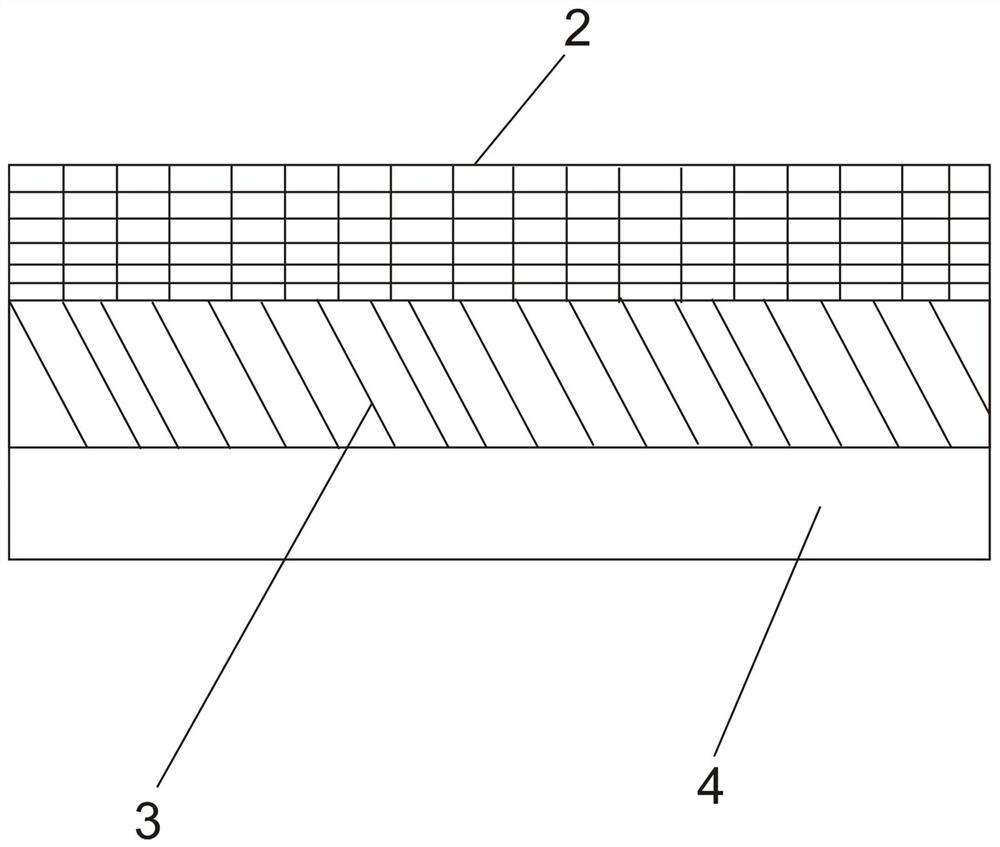

Composite garment fabric with mosquito-repellent and antibacterial functions

InactiveCN108099290AFunction to drive awaySimple structureSynthetic resin layered productsCellulosic plastic layered productsFiberThermal insulation

The invention relates to the technical field of composite garment fabrics, and discloses a composite garment fabric with mosquito-repellent and antibacterial functions. The composite garment fabric includes a skin-friendly layer, a thermal-insulation layer and a waterproof film layer which are arranged in sequence from the inside to the outside; and an insect repellent layer is arranged on the waterproof film layer. The garment fabric provided by the invention adopts a four-layer structure, the mosquito repellent layer is arranged at the outermost layer, the mosquito repellent layer can be directly in contact with outer air, and a mosquito repellent smell emitted by the insect repellent layer can be directly emitted into the air and play a role in driving away mosquitoes; and the garment fabric has a simple structure and reasonable design, so that the layers have a synergistic joint effect, and at the same time the effects of each layer of functional fibers can be better played, the layers complement each other, and the garment fabric integrates softness, comfortableness, and mosquito repelling, antibacterial, waterproof and thermal-insulation functions.

Owner:广东黛柔服饰有限公司

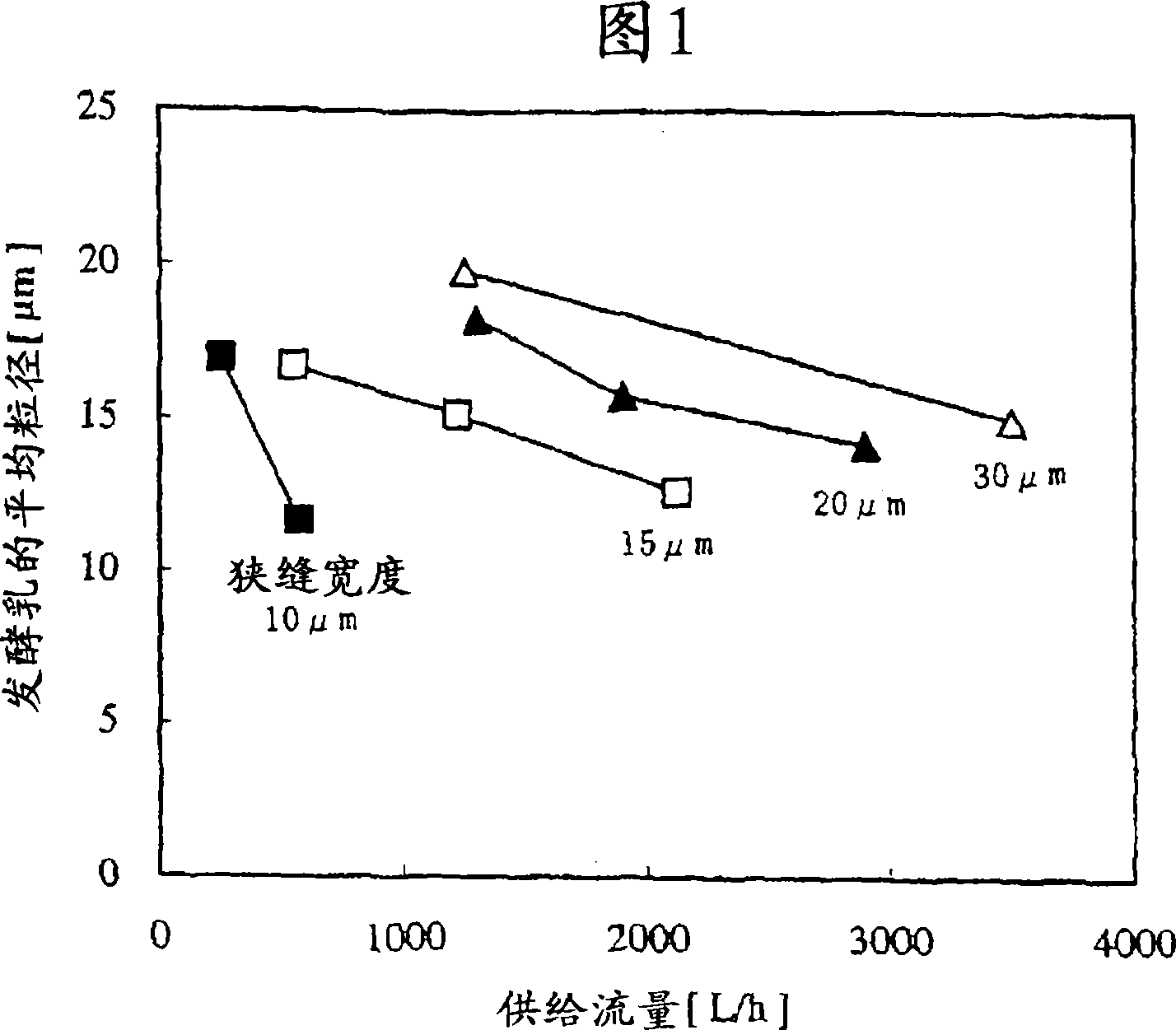

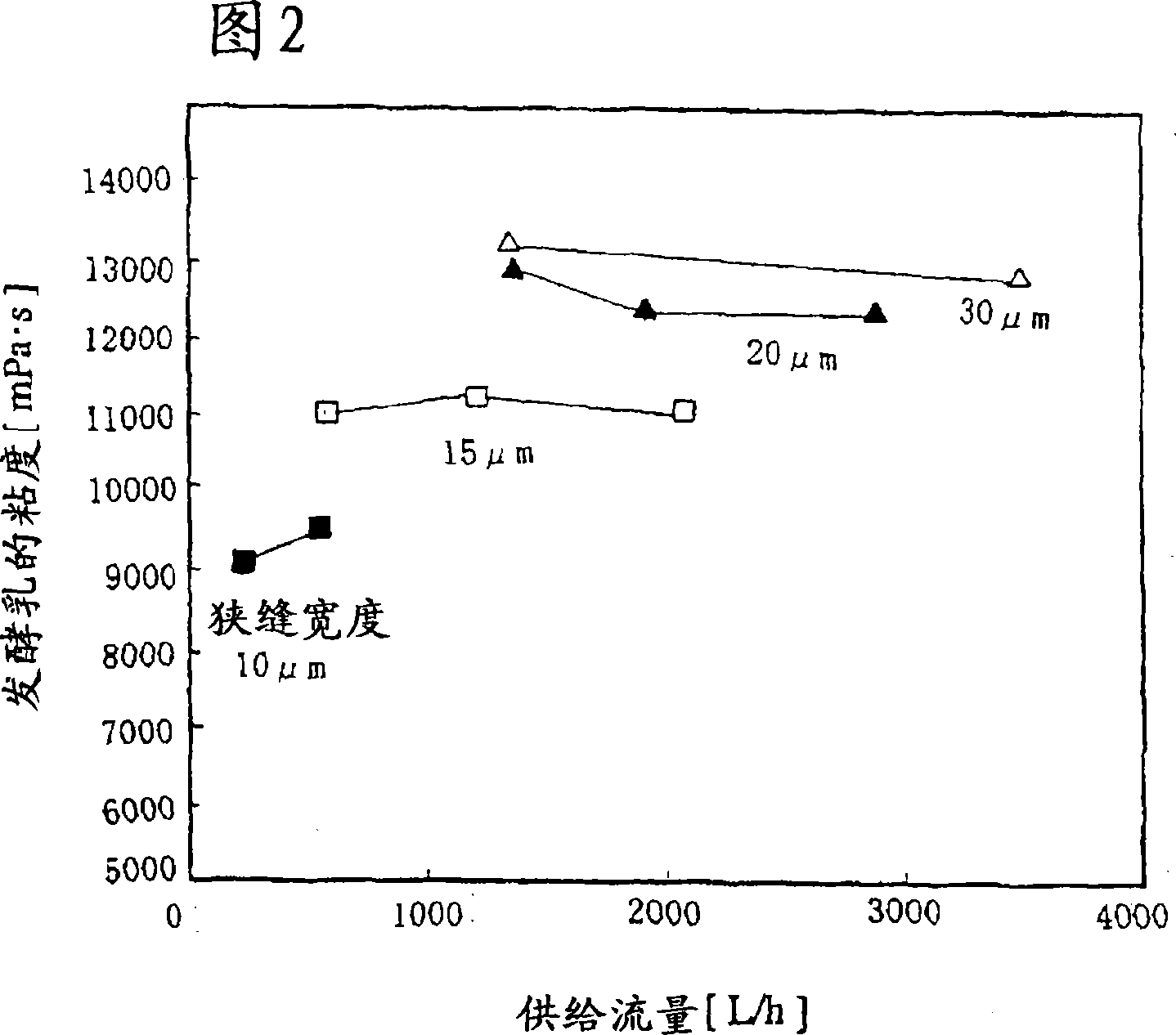

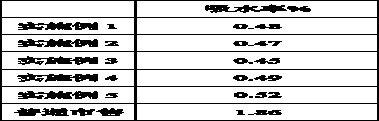

Fermented milk and process for producing the same

The invention provides a fermented milk, such as soft yogurt, that has appropriate viscosity and body and is free from roughness in palatability and in appearance, and provide a process for producing the same. There is provided a process for producing a fermented milk of 10 to 20 [mu]m average particle diameter and = 8000 mPa s viscosity, and provided a process for producing a fermented milk of 10 to 20 [mu]m average particle diameter and = 8000 mPa s viscosity wherein no stabilizer is added or a minute amount of stabilizer is added. There are provided, produced by these processes, a fermented milk of 10 to 20 [mu]m average particle diameter and = 8000 mPa s viscosity and a fermented milk of 10 to 20 [mu]m average particle diameter and = 8000 mPa s viscosity wherein no stabilizer is added or a minute amount of stabilizer is added.

Owner:MEIJI CO LTD

Production process of tencel wool blended yarn

The invention relates to a production process of tencel wool blended yarn. The process is characterized by including the following steps: step I. selecting tencel fiber and merino wool in a blending ratio of 70% to 30%, wherein the specification of the tencel fiber is 1.4 dtex tencel fiber and the specification of the merino wool is 17.2 mic merino wool; step II. through the working procedures ofsliver mixing, first needle combing, second needle combing, third needle combing and fourth needle combing, combining the tencel fiber and the merino wool and then drafting the fiber to form roving sliver, combing the roving sliver to make the roving sliver as straight as possible with a final needle speed of 180-200 m / min; step III. adopting rubber rollers with medium elasticity and hardness, wherein the rubber rollers are conducive to strengthening the control of floating fiber, reducing twisting triangle area and improving yarn quality; and step IV. steaming yarn for three times, treating at 30-60 DEG C for 0.5 hour, and vacuum standing for 30 minute; and after treatment at 85 DEG C for 0.5 hour, vacuum standing for 30 minutes, and finally, treating at 90 DEG C for 0.5 hour. According to the process, the excellent characteristics of the high-proportion tencel wool blended yarn are utilized, the production cost is reduced, and the product quality is improved.

Owner:ZHANGJIAGANG YANGTSE SPINNING CO LTD

Spraying process for water-resistant white true stone paint

PendingCN110644732AAvoid it happening againImprove aestheticsBuilding constructionsComposite materialMaterial technology

The invention relates to the technical field of outer wall space decoration materials, in particular to a spraying process for water-resistant white true stone paint. The spraying process comprises the following steps: (1) base treatment: cleaning disintegrating slag and dirt on a wall; (2) scratching a filling material; (3) arranging a cutting line; (4) spraying a primer: spraying a colored primer, wherein the color of the primer is consistent to that of a finishing coat and a black primer is sprayed to the cutting line; (5) spraying the finishing coat: after the primer is dried and cured, polishing the surface of the primer, and spraying the finishing coat after dust cleaning; and (6) spraying finish-coat paint: after the finishing coat is dried and cured, polishing the finishing coat, then cleaning dust and spraying the finish-coat paint. After the primer is sprayed, the primer is polished once, a base plane can be smoothened to form an isolating layer, so that ageing of the finishing coat caused by water vapor and alkaline substances in the wall space is avoided. The primer is polished, so that the coarseness of the surface can be improved, and therefore, the finishing coat iscombined with the primer better.

Owner:Jiangsu Jiunuo Architectural Materials Technology Co Ltd

A kind of production method of non-slip high-gloss leather-filled paper

ActiveCN106351055BHigh strengthImprove water resistanceNon-fibrous pulp additionCoatings with pigmentsSurface brightnessPulp and paper industry

The invention disclsoes a production method of anti-slip and highlight leatherette paper. The production method comprises: selecting original leatherette base paper, impregnating and machining, carrying out primary finishing, carrying out prime coating, carrying out primary surface coating, carrying out secondary finishing, carrying out secondary surface coating, applying gloss oil, applying anti-slip gloss oil and embossing, wherein in the primary surface coating and the secondary surface coating, a paper surface is coated with surface coating ink by adopting an intaglio full coating manner; the drying temperature is 110 DEG C to 120 DEG C and the turning speed is 20m / min to 60m / min. The production method provided by the invention is simple in process and low in cost; the produced leatherette paper has an anti-slip functional characteristic; meanwhile, the surface brightness is high; the leatherette paper has a leather bright feeling and a paper soft and loose feeling, and can be randomly folded and rolled; the leatherette paper is glossy and attractive, has bright color and luster and a high grade; a product can keep stable and non-slipping, can be adsorbed on a bearing object very well and is not stuck inversely.

Owner:安徽天艺纸业科技有限公司

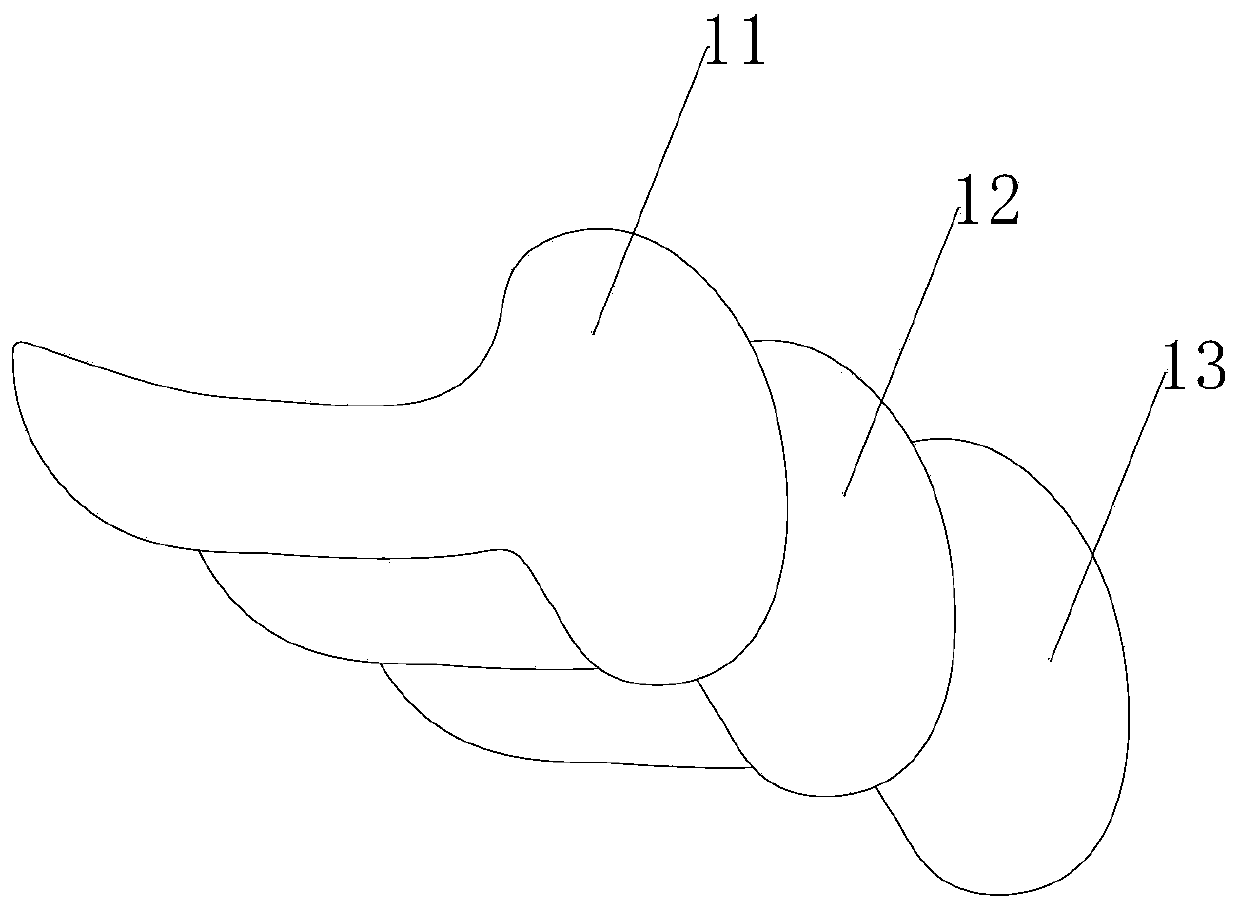

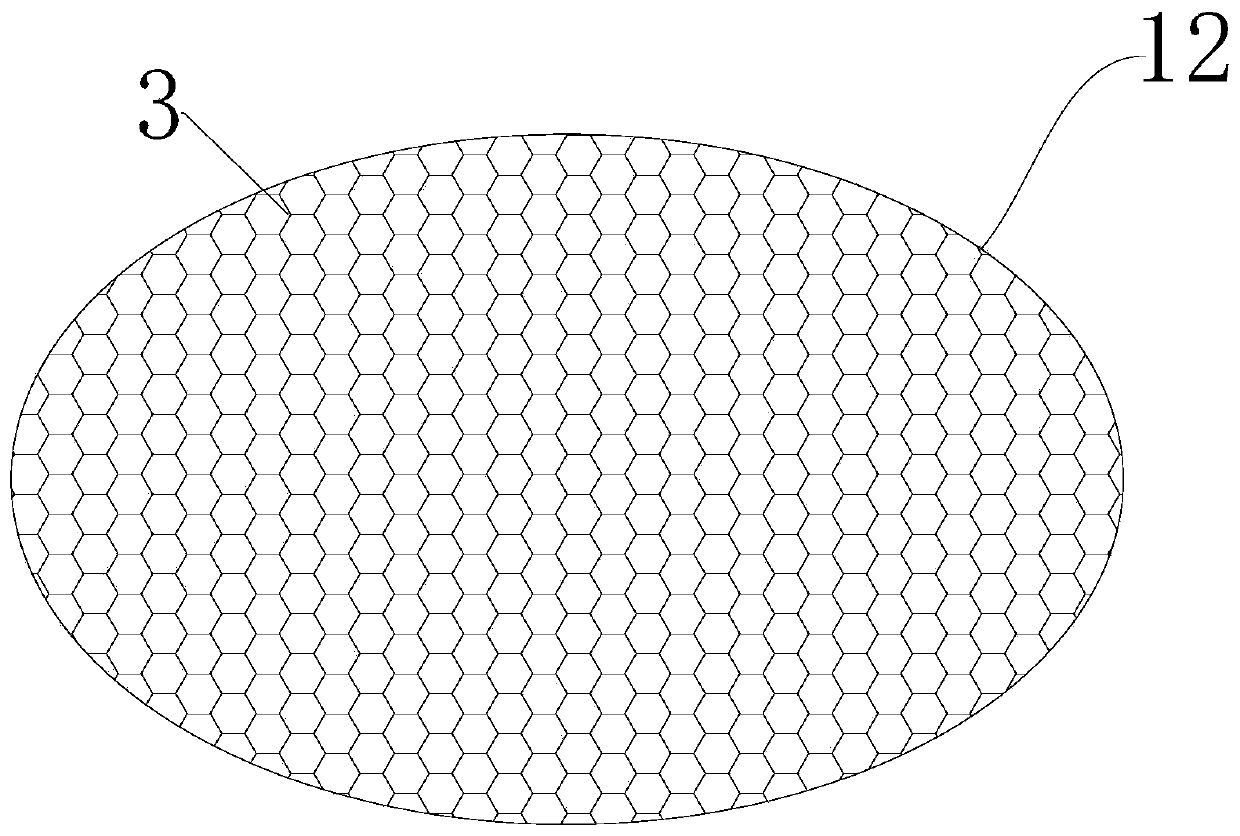

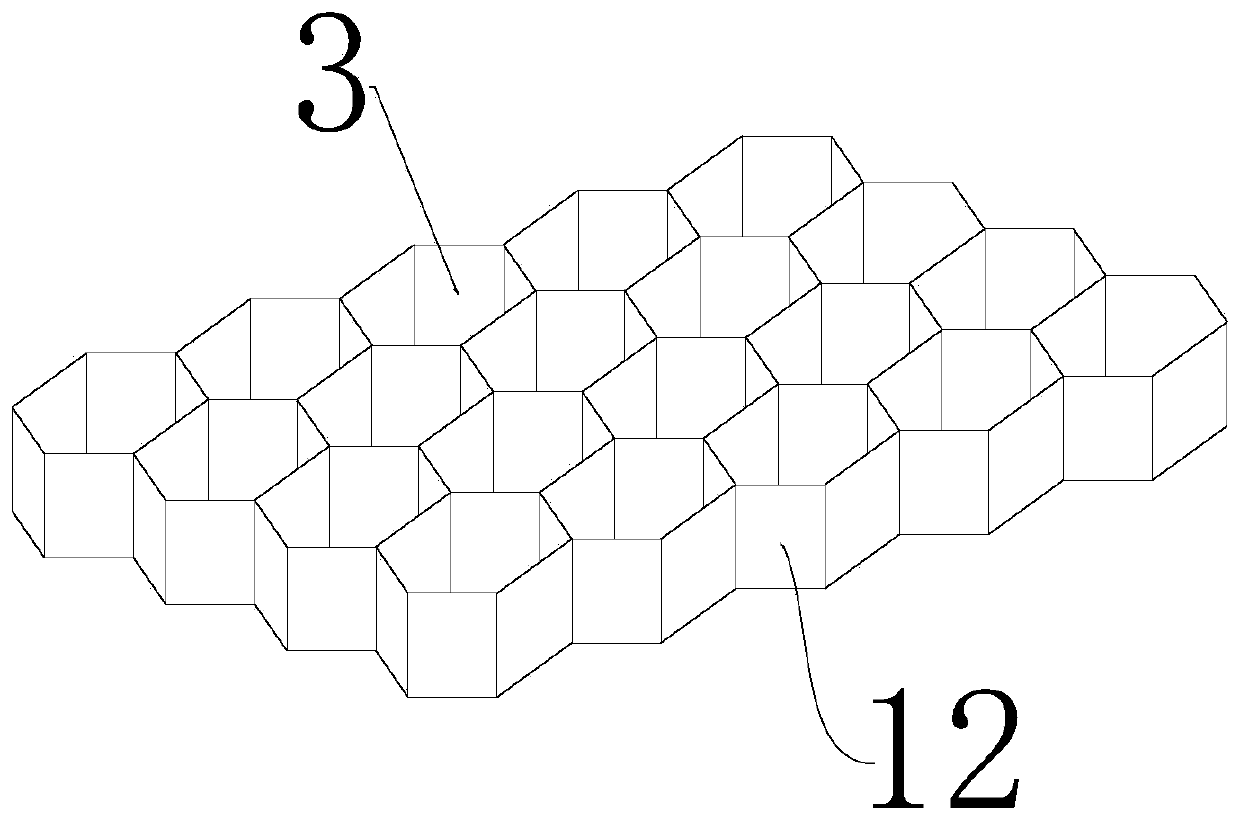

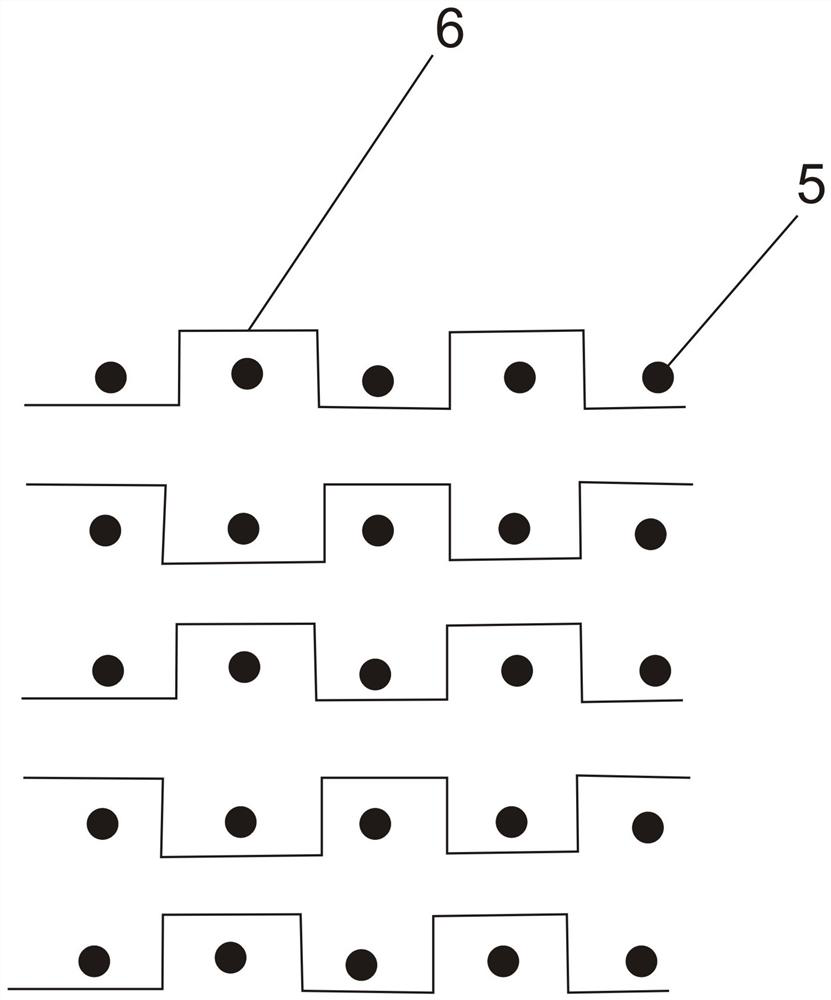

3D mesh interlaced eye mask and preparation method thereof

PendingCN110101585AProtect water absorptionPrevent moisture lossCosmetic preparationsToilet preparationsPreservativeHoneycomb

The invention belongs to the technical field of medical beautifying and skin care, and particularly relates to a 3D mesh interlaced eye mask and a preparation method thereof. The eye mask comprises aneye mask body, and the eye mask body comprises an outer protective layer, a substrate layer and an inner protective layer which fit one another in sequence; the surface of the substrate layer is provided with a plurality of through holes, and the substrate layer is partitioned by the through holes into a three-dimensional honeycomb mesh structure; the through holes and surface of the substrate layer are covered with eye hydrophilic gel. The amount of the hydrophilic gel capable of being loaded by the eye mask is 10 times that of a common eye mask, the three-dimensional honeycomb mesh structure is light and thin in application feel, and the use experience is good; the 3D mesh interlaced eye mask has the functions of supplementing water, repairing dry lines, weakening dark circles and converging the eye bags; active ingredients can penetrate into the skin interiors of the eyes to protect the skin of the eyes; an adopted preservative is safe to the human body and can be used by consumerssafely.

Owner:丁蓉

Snake gall facial mask and preparation method thereof

InactiveCN107397712AHave metabolismPromote growthCosmetic preparationsToilet preparationsSkin complexionSkin elasticity

The invention relates to a snake gall facial mask and a preparation method thereof. The effective constituents of the snake gall facial mask are prepared from the following raw materials of, by weight, 80-90 parts of deionized water, 6-12 parts of butanediol, 2-8 parts of glycerinum, 6-16 parts of propylene glycol, 0.02-0.06 part of sodium hyaluronate, 0.1-0.7 part of allantoin, 0.4-1 part of polyglycerylmetharylate and propylene glycol, 4-12 parts of rose hydrosol, 0.1-0.6 part of camellia oil, 0.2-1 part of a snake gall extracting solution, 0.8-2.2 parts of aloe gel and 0.2-1 part of PE9010. The snake gall facial mask is capable of repairing damaged skin rapidly, increasing the water content of the skin, moistening the skin, improving dim complexion, enhancing the skin elasticity, compacting the skin and achieving whitening and freckle-removing, and has the characteristics of resisting and preventing wrinkles, preventing acne, removing scars, achieving sun protection and after-sun repair and the like.

Owner:广西小燕蛇业有限公司

New lip gloss

InactiveCN105832629AGood flexibilityImprove tensile propertiesCosmetic preparationsMake-upPolyvinyl alcoholLotion

The invention discloses new lip gloss, and relates to the technical fields of beauty treatment and beauty makeup. The new lip gloss is mainly manufactured from polyvinyl alcohol and natural plant pigment, with the addition of multiple safe edible components for moistening and protecting the skin. After being applied to the lip, the lip gloss gradually air-dries in about 5 min and forms a membrane layer that can be torn down, and the color of the lip gloss is printed on the lip. During the air-drying process, the components for moistening and protecting the skin in the lip gloss play an excellent effect on skin moistening and protection. The problem that dermatitis is caused, for the lip is hurt when the lip gloss membrane formed on the lip is peeled is solved. Meanwhile, the natural plant pigment can be easily cleaned up through an oil cleansing lotion, so that the problem that allergy of the lip is caused, for the lip gloss is difficult to remove is solved.

Owner:覃碧

Blue 18K gold for hydrogen sulfide corrosion-resisting jewelry and process thereof

The invention discloses blue 18K gold for hydrogen sulfide corrosion-resisting jewelry and a process thereof. The blue 18K gold is prepared from the following alloy components in percentage by weight:0.1-0.2wt.% of Be, 1.2-1.5wt.% of Mo, 0.4-0.6wt.% of V, 1.5-1.8wt.% of In, 0.4-0.5wt.% of Sc, 0.1-0.2wt.% of Sm, 74.0-76.0wt.% of Au and the balance aluminum. The blue 18K gold overcomes the currentsituation that existing blue K gold is insufficient in performance, and breaks through the development bottleneck in the field of jewelry effectively. It can be expected that plenteous economical fruits and social benefits can be obtained by implementation and industrialization of the material.

Owner:GUANGZHOU YUZHI TECH CO LTD

Whitening, moisturizing and skin-care mask and preparation method thereof

InactiveCN111904916ASimple processShort production hoursCosmetic preparationsAntipyreticHydantoic acidGlycerol

The invention discloses a whitening, moisturizing and skin-care mask. The whitening, moisturizing and skin-care mask is characterized by comprising the following components in parts by weight: 2-4 parts of hydantoic acid-modified hyperbranched chitosan, 1-3 parts of 4-amino phlorizin-modified tetrahydroxyflavone-7-beta-D-glucuronide, 0.3-0.6 part of gentian extract, 0.5-0.8 part of caragana sinicaextract, 0.2-0.5 part of sorbaria sorbifolia extract, 0.8-1.2 parts of eucalyptus extract, 0.6-1.2 parts of polyvinylpyrrolidone, 0.1-0.2 part of a transdermal agent, 5-10 parts of glycerol and 50-60parts of deionized water. The invention further discloses a preparation method of the whitening, moisturizing and skin-care mask. The whitening, moisturizing and skin-care mask disclosed by the invention is remarkable in whitening and moisturizing effects, small in skin irritation, free of drug dependence and excellent in skin feeling, and further has multiple skincare effects of resisting bacteria, diminishing inflammation, resisting ultraviolet rays and the like.

Owner:姚增来

Highly moistening and moisturizing toning lotion

InactiveCN104161688AHas moisture distributionPrevent moisture lossCosmetic preparationsToilet preparationsPreservativeIrritation

A highly moistening and moisturizing toning lotion comprises the raw materials by weight: 2.0 of 1,3-butanediol, 0.1 of allantoin, 0.5 of hydrogenated castor oil, a proper amount of an essence, 10.0 of ethanol, a proper amount of a preservative agent, 0.1 of hyaluronic acid, deionized water added to 100, and 0.2 of sodium citrate. The amounts and physicochemical properties of the raw materials generate a synergistic effect, so as to achieve the effects of removing dead skin and controlling oil secretion. The toning lotion has the pH value close to the pH value of human skin, thereby having no irritation to the skin; and after the toning lotion is used, the skin obviously feels comfortable and soft and has no greasy feeling, and the toning lotion has obvious moisturizing and antioxidant effects.

Owner:周玉翠

Environment-friendly garment

PendingCN112471627AReduce pollutionShiny brightProtective garmentSpecial outerwear garmentsDermal exposureEngineering

The invention relates to an environment-friendly garment. The environment-friendly garment is composed of a garment body; an outer layer is formed by interweaving warp yarns and weft yarns in a one-upand one-down circulating mode; an inner layer is formed by interweaving tencel fibers and bamboo fibers, wherein the tencel fibers have high hygroscopicity, beautiful gloss, soft hand feeling, good drapability and good gracefulness, and the bamboo fibers have the characteristics of good air permeability, instantaneous water absorption, strong wear resistance, good dyeing property and the like, have the functions of natural antibiosis, bacteriostasis, acarus killing, deodorization and ultraviolet resistance, can be matched with the tencel fibers to enable the fabric to have comfortable and cool feeling and droop feeling, to prevent bacteria from breeding and to be comfortable to contact with the skin; and a cooling interlayer is arranged on the back surface of the garment body, a cooling material sheet is arranged in the cooling interlayer, the cooling material sheet comprises a non-woven fabric layer, an environment-friendly ice particle layer is clamped in the non-woven fabric interlayer, environment-friendly ice is a macromolecule water gathering compound prepared from water absorption resin, the service life of the environment-friendly ice exceeds 10 years under non-sunlight, and even if the cooling interlayer containing the environment-friendly ice is damaged, no pollution is caused, the environment-friendly ice is non-toxic, does not burn or explode, is non-corrosive, canbe repeatedly used, and has the advantages of low cost, environmental protection and the like, and makes the garment have a cooling function.

Owner:安徽苏博伦服饰有限公司

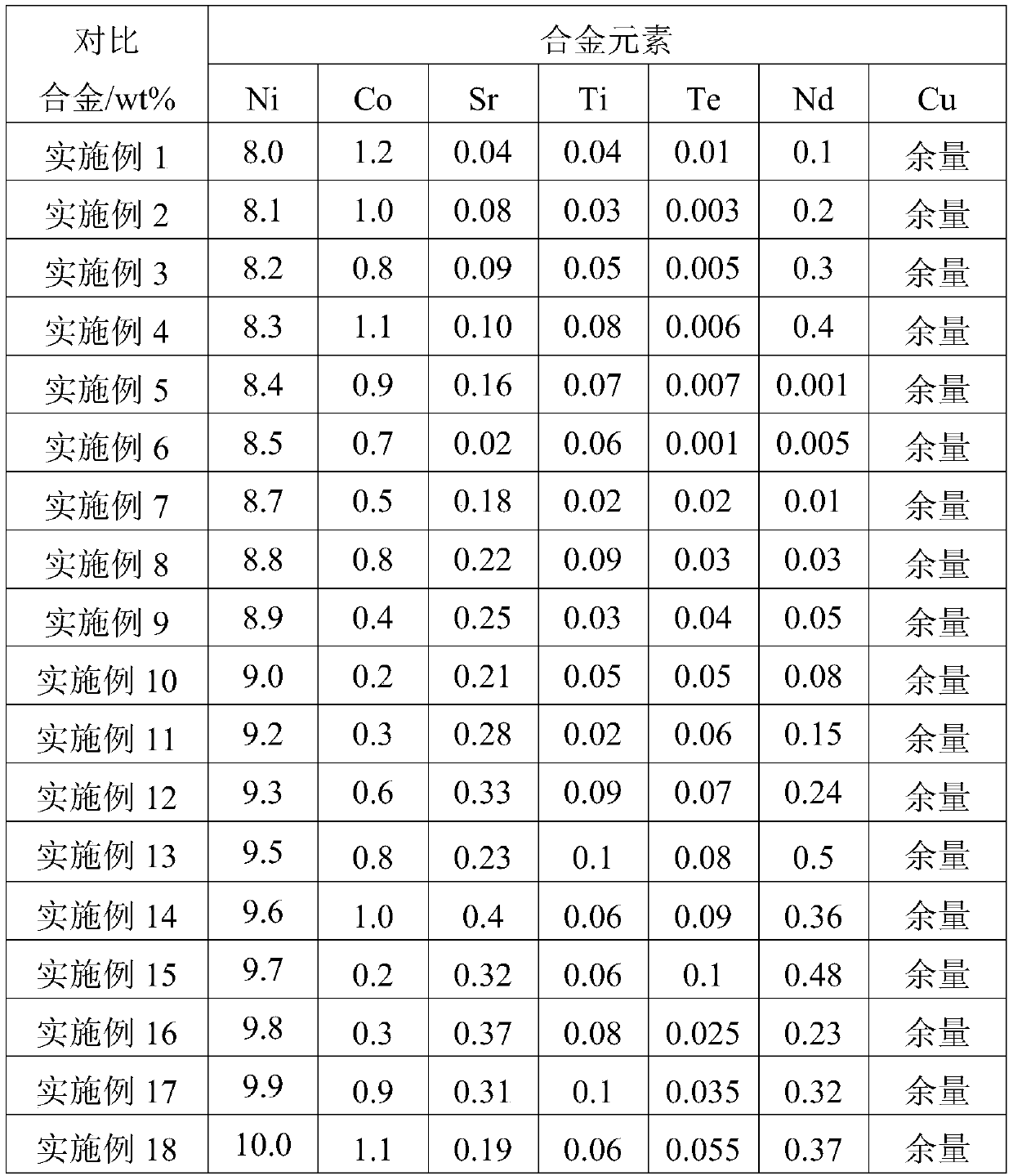

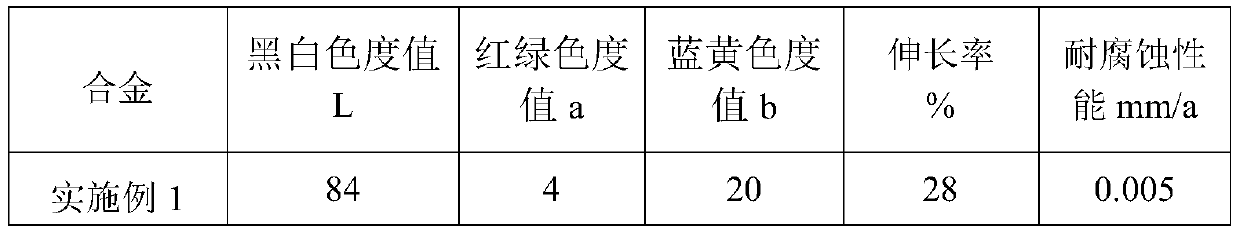

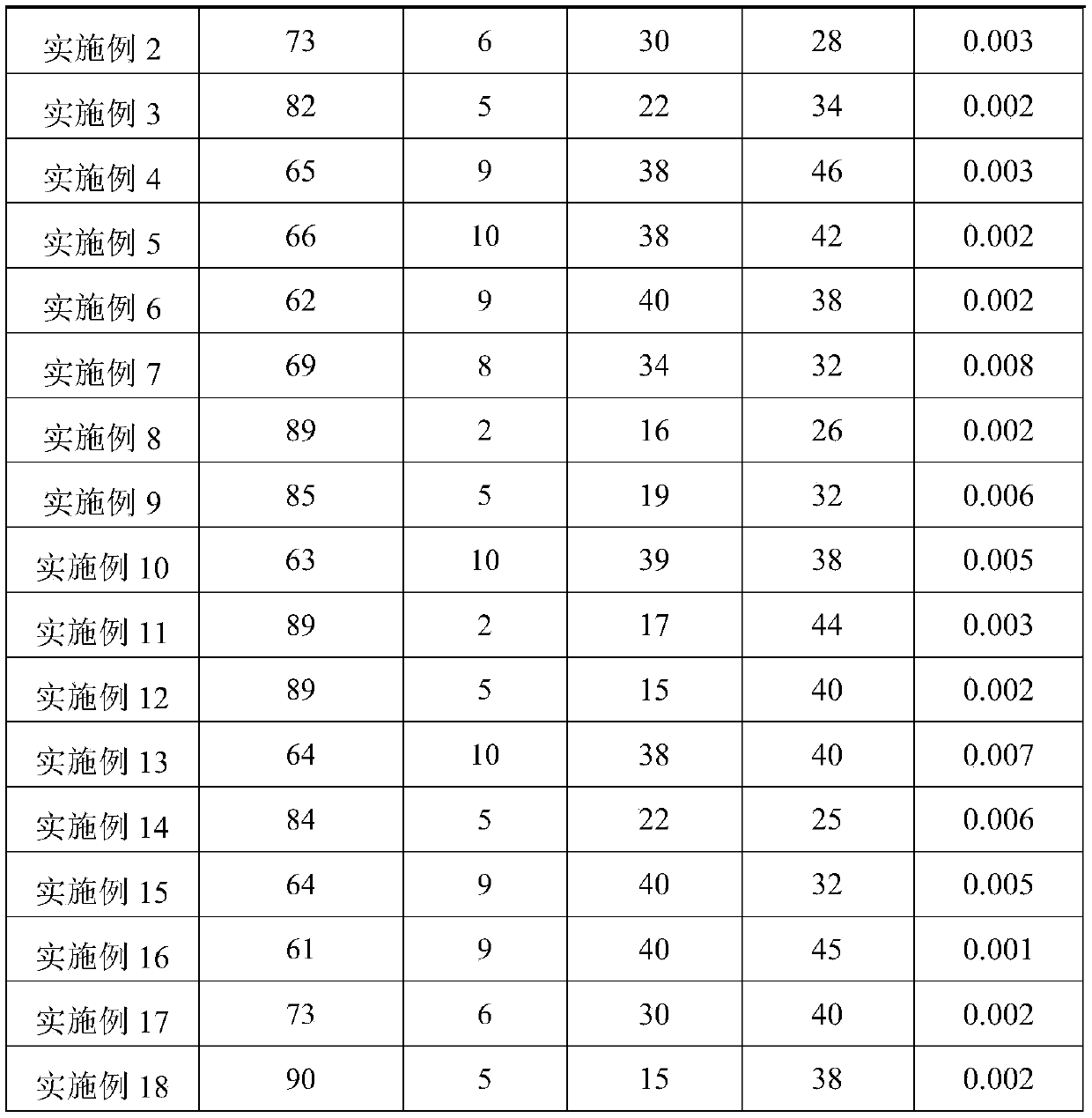

Champagne gold copper alloy material and preparation method thereof

ActiveCN111593228AGood chemical stabilityImproved color stabilityMetal rolling arrangementsMetallic materialsGold color

The invention discloses a champagne gold copper alloy material and a preparation method thereof, and belongs to the technical field of non-ferrous metal material processing. The material comprises thefollowing composition of, with contents as blow, 8 wt%-10 wt% of Ni, 0.2 wt%-1.2 wt% of Co, 0.02 wt%-0.1 wt% of Ti, 0.02 wt%-0.4 wt% of Sr, 0.001 wt%-0.1 wt% of Te, 0.001 wt%-0.5 wt% of Nd, and the balance Cu. The black and white chromatic value L of an alloy final product reaches 60-90, a red and green chromatic value a reaches 2-10, a blue and yellow chromatic value b reaches 20-40, a glossy and beautiful champagne gold is achieved, the plastic elongation delta is greater than or equal to 25%, the anti-corrosion performance is less than or equal to 0.008 mm / a, and the material can be applied in the fields of coinage, decoration, art design and the like.

Owner:GRIMAT ENG INST CO LTD

Poisonless gorgeous coating for wooden handicraft surface processing

InactiveCN107629555ANo pollutionAvoid harmStarch coatingsElectrically-conductive paintsSlurryDefoaming Agents

The invention discloses a poisonless gorgeous coating for wooden handicraft surface processing. The poisonless gorgeous coating consists of the following materials in parts by weight: 30 to 40 parts of water, 5 to 15 parts of shell powder, 5 to 15 parts of pearl powder, 10 to 15 parts of calcium carbonate, 1 to 3 parts of nanoscale cobalt oxide, 0.1 to 0.5 parts of dispersant, 0.05 to 0.5 parts ofhumectant, 0.1 to 0.5 parts of defoaming agent, 5 to 10 parts of plant extract, 6 to 10 parts of sticky rice milk and 5 to 10 parts of PEG emulsifier. The coating disclosed by the invention does notcontain formaldehyde and VOC (volatile organic compounds), has any peculiar smell, pollutes the air and harms to the human body, moreover, the coating can quickly dry, and the demand pursued by peopleon zero formaldehyde, zero pollution, environment protection, nature and health is sufficiently satisfied. Since the coating is prepared by combining the pearl powder, the shell powder and the plantextract, the obtained coating can present unique colors and gloss after being applied to the surface of a handicraft and drying.

Owner:重庆市龙凤工艺品有限公司

Flexible skin-beautifying massage cream

InactiveCN106902012AHas moisture distributionPromote growthCosmetic preparationsToilet preparationsHuman bodyPolyvinyl alcohol

A flexible massage cream for beautifying and nourishing skin. The raw materials and weight ratios in the formula are: 1.5 parts of polyvinylpyrrolidone, 7 parts of polyvinyl alcohol, 8 parts of polyethylene glycol, 4 parts of glyceryl monostearate, 3 parts of mink oil, 4 parts of white oil, 5 parts of lanolin, 2 parts of allantoin, 12 parts of ginseng extract, 1.5 parts of borax, 20 parts of ethanol, appropriate amount of pigment, appropriate amount of fragrance, and deionized water to 100 parts. The dosage and physical and chemical properties of each raw material described in the present invention produce a synergistic effect, thereby achieving the effects of cleaning, sterilizing and promoting metabolism. The pH value of the invention is close to that of human skin, and has no irritation to the skin; after use, the skin feels comfortable, soft, and non-greasy, and has obvious effects of deep cleaning and deep care.

Owner:荥阳市藤本保健品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com