High-abrasion-resistance, high-temperature-resistant and water-cooking-resistant aqueous ceramic paint

A ceramic coating and high temperature resistant technology, used in anti-corrosion coatings, coatings, etc., can solve problems such as cracking or peeling, poor adhesion, poor toughness, etc., and achieve excellent boiling resistance and temperature resistance, ultra-high hardness and The effect of hot hardness, excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

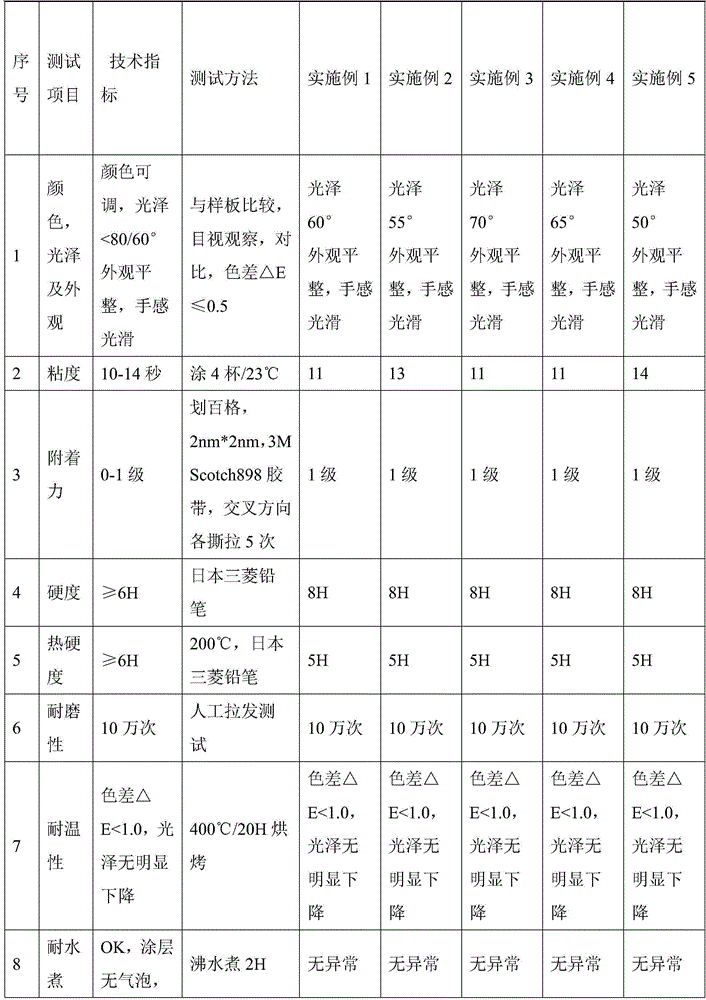

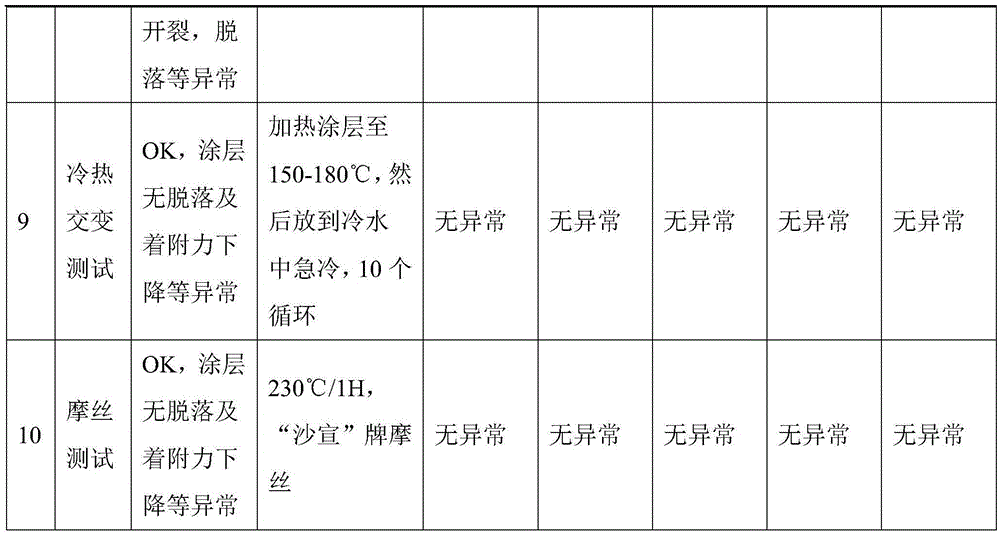

Examples

Embodiment 1

[0024] Component A: Components by mass percentage: 30% of silica sol, 13.6% of antimony solution, 13% of inorganic high temperature resistant pigment and 10% of silicon dioxide;

[0025] Component B: components by mass percentage: 32.3% silane, 0.5% wetting agent, 0.5% leveling agent, the silane adopts silane coupling agent;

[0026] Component C: 0.1% catalyst, the catalyst being glacial acetic acid.

[0027] The mass ratio of the silica sol to the antimony solution is greater than or equal to 2:1, and the pH value of the silica sol is controlled at 9-10.

Embodiment 2

[0029] Component A: Components by mass percentage: 29% silica sol, 13% antimony solution, 12.6% inorganic high temperature resistant pigment and 12% silicon dioxide;

[0030] Component B: components by mass percentage: 32.3% silane, 0.4% wetting agent, 0.6% leveling agent, the silane adopts silane coupling agent;

[0031] Component C: 0.1% catalyst, the catalyst being glacial acetic acid.

[0032] The mass ratio of the silica sol to the antimony solution is greater than or equal to 2:1, and the pH value of the silica sol is controlled at 9-10.

Embodiment 3

[0034] Component A: Components by mass percentage: 30% of silica sol, 15% of antimony solution, 13% of inorganic high temperature resistant pigment and 8.6% of silicon dioxide;

[0035] Component B: components by mass percentage: 32.2% silane, 0.5% wetting agent, 0.6% leveling agent, the silane uses a silane coupling agent;

[0036] Component C: 0.1% catalyst, the catalyst being glacial acetic acid.

[0037] The mass ratio of the silica sol to the antimony solution is greater than or equal to 2:1, and the pH value of the silica sol is controlled at 9-10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com