A hot roller laser restoration method allowing surface hardness after restoration to be 58 HRC or above

A laser repairing and hot rolling technology, applied in the field of laser cladding, can solve the problems of poor surfacing, easy cracks, insufficient hardness, etc., and achieve high fusion rate, optimized overlap, and uniform thickness and hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The specific steps of the laser repair method of the hot roll of the present embodiment are as follows:

[0024] A. Pretreat the surface of the hot roll to be repaired, and test and analyze the hot roll.

[0025] Remove the dust, oil and rust on the hot roll; detect the size of each part of the hot roll, determine the failure part and its wear amount; check the radial and end runout of the hot roll to check whether the roll is deformed; remove the roll by grinding The fatigue layer of the failure part shall be 0.5mm, and shall be cleaned.

[0026] B. According to the failure analysis results of the hot roll, optimize the process parameters and perform multi-layer laser cladding.

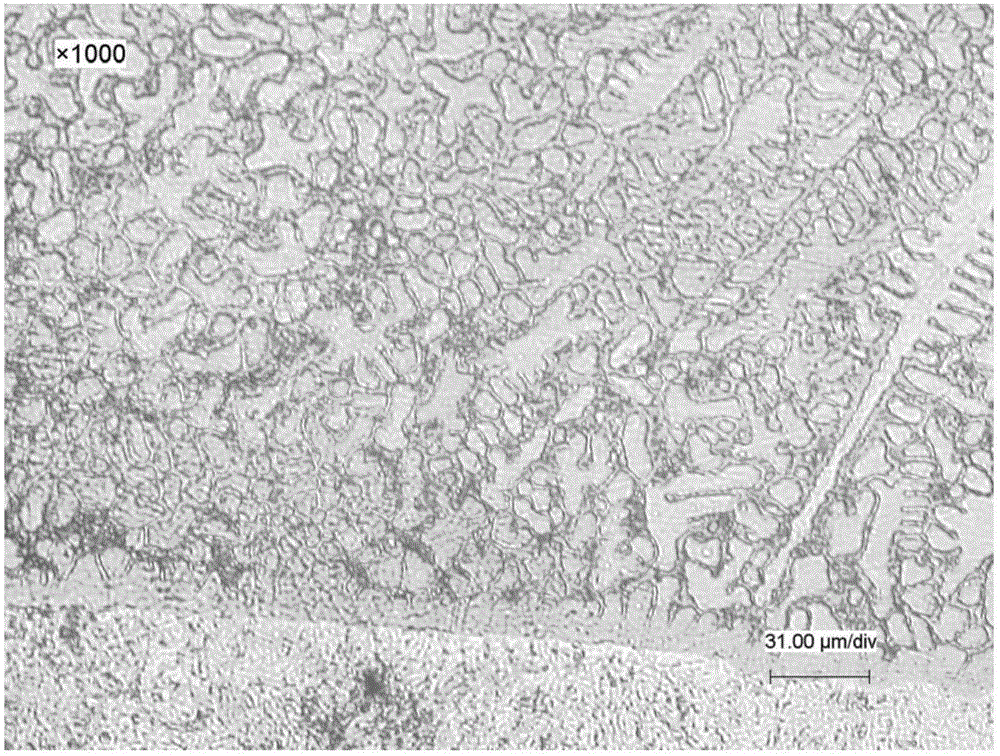

[0027] Using the preset powder feeding method, the fast cross-flow carbon dioxide laser is used as the light source to perform continuous spiral feed lap scanning on the hot roll; the laser power is 2150W, and the elevation (that is, the distance between the laser and the object, elevation = ...

Embodiment 2

[0036] The specific steps of the laser repair method of the hot roll of the present embodiment are as follows:

[0037] A. Pretreat the surface of the hot roll to be repaired, and test and analyze the hot roll.

[0038]Remove the dust, oil and rust on the hot roll; detect the size of each part of the hot roll, determine the failure part and its wear amount; check the radial and end runout of the hot roll to check whether the roll is deformed; remove the roll by grinding The fatigue layer of the failure part shall be 0.5mm, and shall be cleaned.

[0039] B. According to the failure analysis results of the hot roll, optimize the process parameters and perform multi-layer laser cladding.

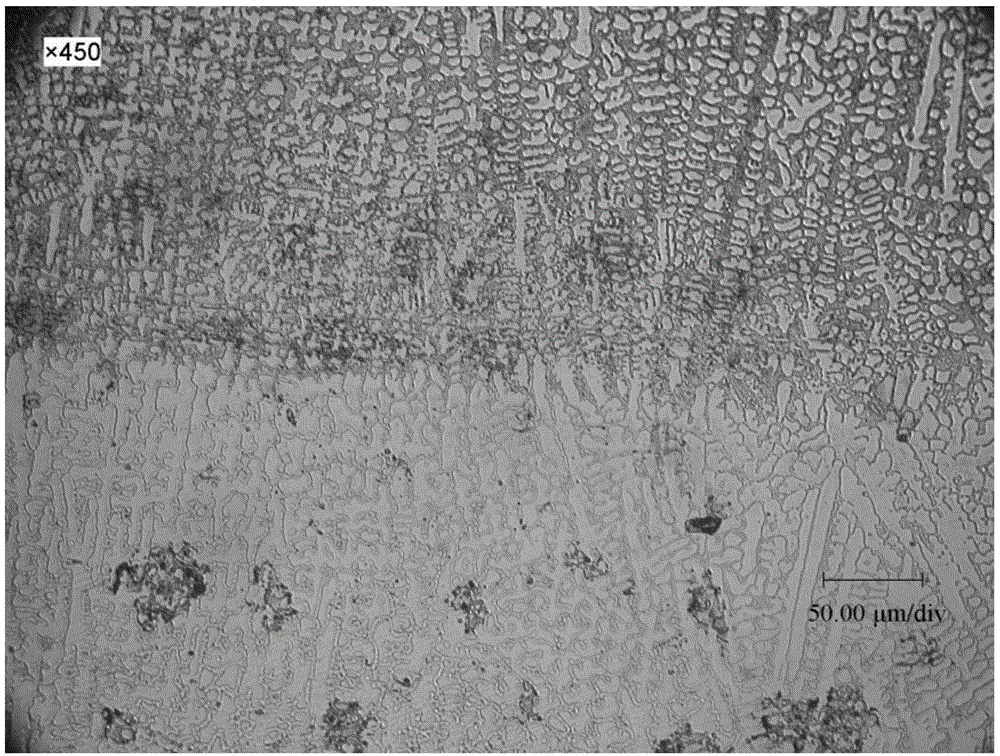

[0040] Using the preset powder feeding method, the fast cross-flow carbon dioxide laser is used as the light source to carry out continuous spiral feed lap scanning on the hot roll; the laser power is 2160W, the elevation is 235mm, the spot size is 12mm×1.8mm, and the scanning speed is 150mm / m...

Embodiment 3

[0049] The specific steps of the laser repair method of the hot roll of the present embodiment are as follows:

[0050] A. Pretreat the surface of the hot roll to be repaired, and test and analyze the hot roll.

[0051] Remove the dust, oil and rust on the hot roll; detect the size of each part of the hot roll, determine the failure part and its wear amount; check the radial and end runout of the hot roll to check whether the roll is deformed; remove the roll by grinding The fatigue layer of the failure part shall be 0.5mm, and shall be cleaned.

[0052] B. According to the failure analysis results of the hot roll, optimize the process parameters and perform multi-layer laser cladding.

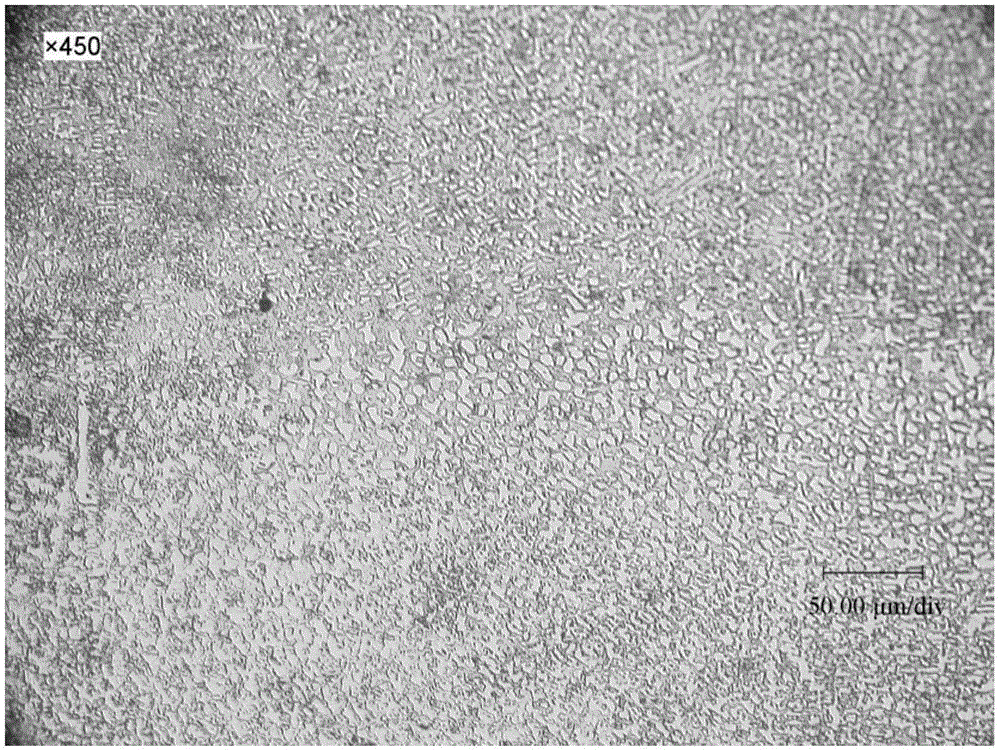

[0053] Using the pre-set powder feeding method, the fast cross-flow carbon dioxide laser is used as the light source to perform continuous spiral feed lap scanning on the hot roll; the laser power is 2200W, the elevation is 240mm, the spot size is 12mm×1.8mm, and the scanning speed is 140mm / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com