Heat-resisting steel plate

A steel plate, heat-resistant technology, applied in the field of heat-resistant steel plates, can solve the problems of difficult large-area construction, poor metal adhesion, high production costs, and achieve excellent adhesion and workability, heat resistance and hot hardness better, The effect of excellent solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

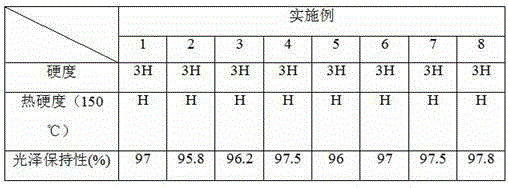

Examples

Embodiment 1

[0026] The heat-resistant steel sheet involved in this embodiment is prepared by coating and baking the pre-coated steel sheet with a base coating and a surface coating in sequence, wherein the base coating is applied to the surface of the pre-coated steel sheet to form a base coating , Calculated by weight percentage, the base coating contains the following components:

[0027] Silicone modified polyester resin: 30%; filler: 20%;

[0028] Silicone coupling agent: 1%; Phthalate: 0.5%;

[0029] Solvent: 48.5%.

[0030] The surface coating is applied to the surface of the base coating film to form a surface coating. The surface coating includes the following components in terms of weight percentage:

[0031] Silicone modified polyester resin: 40%; pigment: 10%;

[0032] Polyamide curing agent: 5%; filler: 10%;

[0033] Silicone coupling agent: 1.2%; solvent: 33.8%.

[0034] The following is a further description of the composition of the above components:

[0035] Silicone modified polyester...

Embodiment 2

[0040] The heat-resistant steel sheet involved in this embodiment is prepared by coating and baking the pre-coated steel sheet with a base coating and a surface coating in sequence, wherein the base coating is applied to the surface of the pre-coated steel sheet to form a base coating , Calculated by weight percentage, the base coating contains the following components:

[0041] Silicone modified polyester resin: 50%; filler: 46%;

[0042] Silicone coupling agent: 2%; Phthalate: 1%;

[0043] Solvent: 1%.

[0044] The surface coating is applied to the surface of the base coating film to form a surface coating. The surface coating includes the following components in terms of weight percentage:

[0045] Silicone modified polyester resin: 60%; Pigment: 15%;

[0046] Polyamide curing agent: 7%; filler: 15%;

[0047] Silicone coupling agent: 1.8%; solvent: 1.2%.

[0048] The following is a further description of the composition of the above components:

[0049] Silicone modified polyester resin...

Embodiment 3

[0054] The heat-resistant steel sheet involved in this embodiment is prepared by coating and baking the pre-coated steel sheet with a base coating and a surface coating in sequence, wherein the base coating is applied to the surface of the pre-coated steel sheet to form a base coating , Calculated by weight percentage, the base coating contains the following components:

[0055] Silicone modified polyester resin: 45%; filler: 46%;

[0056] Silicone coupling agent: 1.5%; Phthalate: 0.5%;

[0057] Solvent: 7%.

[0058] The surface coating is applied to the surface of the base coating film to form a surface coating. The surface coating includes the following components in terms of weight percentage:

[0059] Silicone modified polyester resin: 55%; Pigment: 12%;

[0060] Polyamide curing agent: 6%; filler: 14%;

[0061] Silicone coupling agent: 1.5%; solvent: 11.5%.

[0062] The following is a further description of the composition of the above components:

[0063] Silicone modified polyester ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com