Wear- and corrosion- proof metal ceramic knife edge material

A technology of corrosion-resistant metals and blades, applied in the field of plastic pelletizing knives, can solve problems such as difficult control, affecting material properties, and deterioration of material properties, achieving durability and service life, good oxidation resistance, and low manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

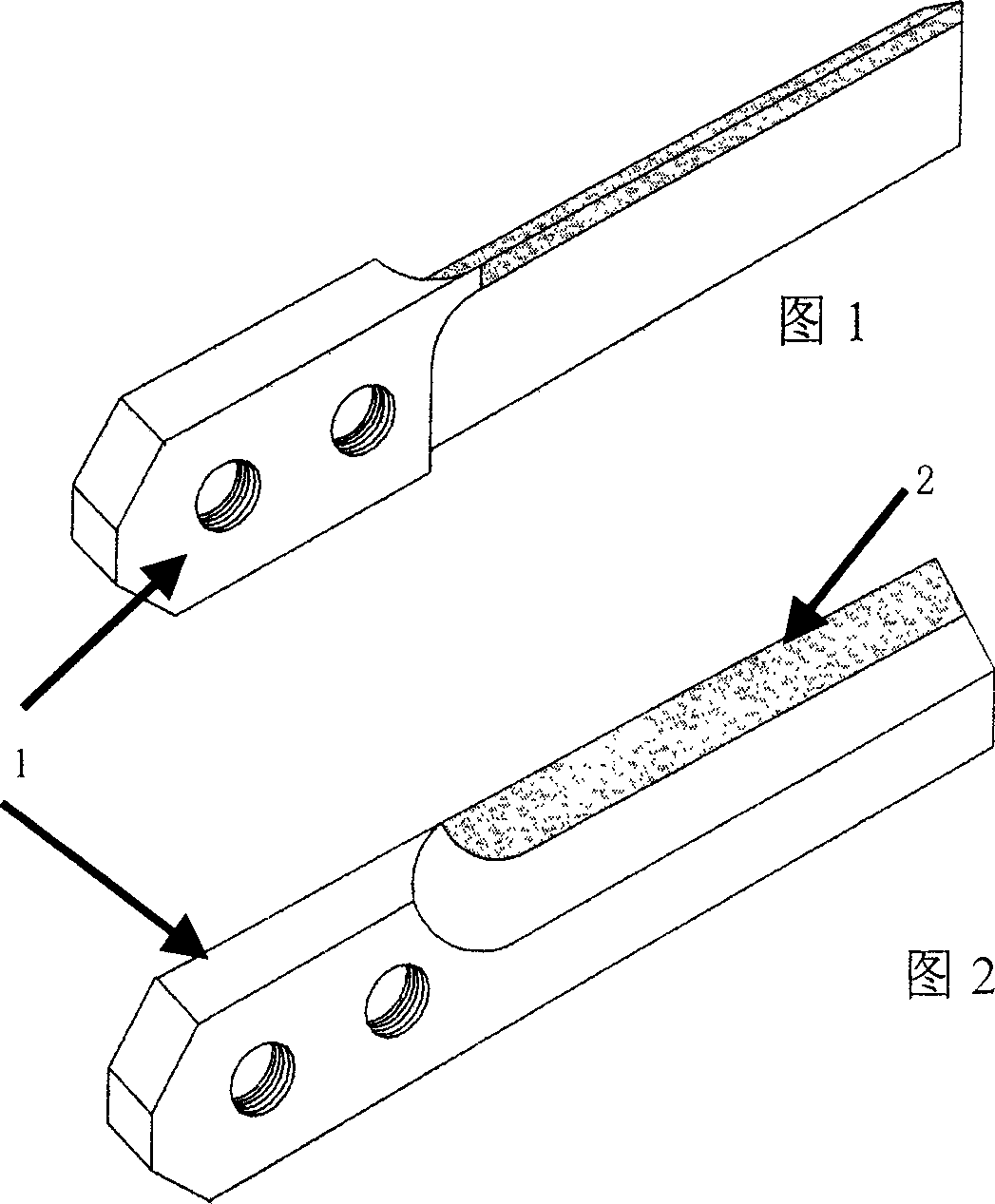

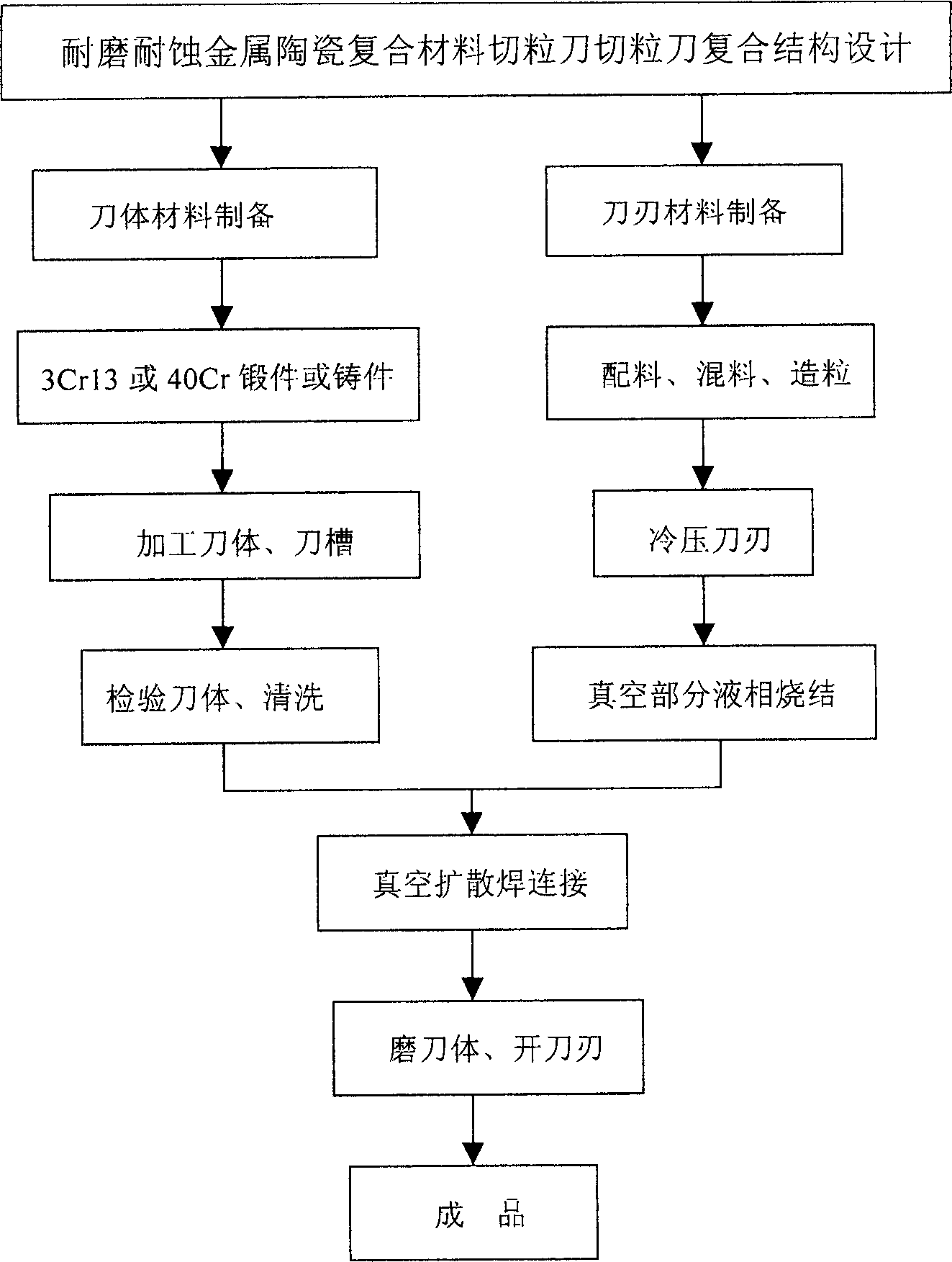

Method used

Image

Examples

Embodiment 1

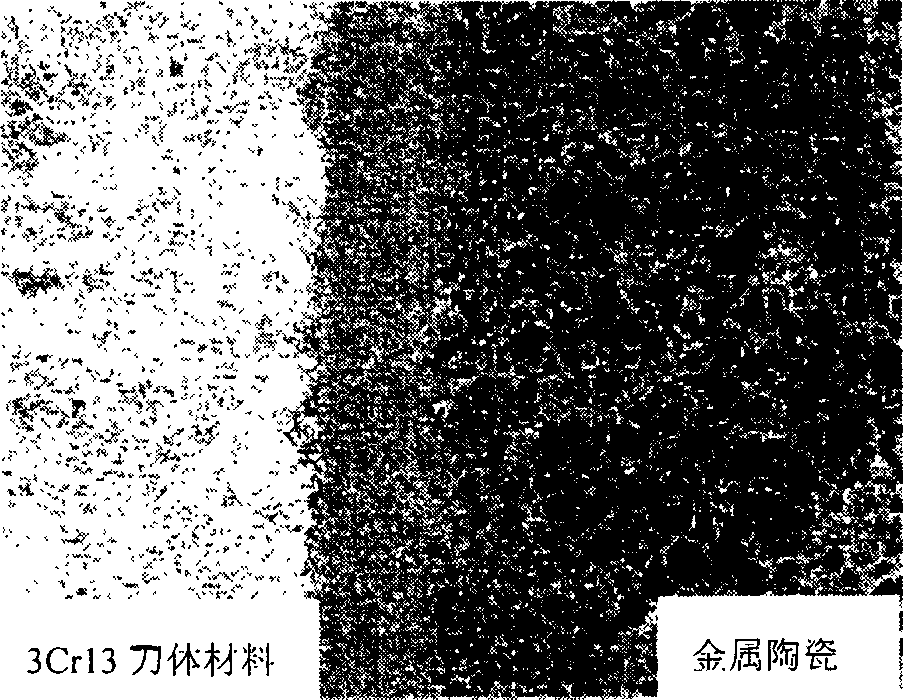

[0026] Embodiment 1: Preparation of wear-resistant and corrosion-resistant cermet blade material:

[0027] 40.0wt.% of Ni powder, 10.0wt.% of Cr powder, 1.0wt% of Al powder, 2.0wt% of Ti powder, and the balance of TiC particles with an average diameter of 3.5μm are mechanically mixed, and after granulation, they are cold-pressed at 120MPa , the vacuum sintering temperature is 1370°C, and the holding time is 30min.

Embodiment 2

[0028] Embodiment 2: Preparation of wear-resistant and corrosion-resistant cermet blade material:

[0029] 40wt.% of Ni powder, 10.0wt% of Cr powder, 1.0wt% of Al powder, 2.0wt% of Ti powder, 0.5wt.% of Mo powder, and the balance is mechanically mixed with TiC particles with an average diameter of 3.5 μm. Formed under cold pressure at 120MPa, vacuum sintering temperature is 1375°C, and holding time is 30min.

Embodiment 3

[0030] Embodiment 3: Preparation of wear-resistant and corrosion-resistant cermet blade material:

[0031] 30wt.% of Ni powder, 6.0wt% of Cr powder, 0.8wt% of Al powder, 1.8wt% of Ti powder, and the balance of TiC particles with an average diameter of 3.5μm are used for mechanical mixing. The sintering temperature is 1375°C, and the holding time is 25 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com