Lead-carbon composite material, and preparation method and application thereof

A composite material, lead-carbon technology, used in hybrid capacitor electrodes, electrical components, battery electrodes, etc., can solve the problem of difficult to form porous carbon materials, achieve inhibition of negative electrode sulfation, improve capacitance characteristics, and reduce electrode polarization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Dissolve 10.5kg of glucose in 100L of deionized water, then add 50kg of lead powder to the solution, mix in a ball mill at 100r / min for 1h, move the mixture into a vacuum drying oven, and dry at 50°C for 4h at a vacuum of 50kpa , to form a uniformly dispersed mixture, and then, while stirring, add 15L of 98% (mass fraction) concentrated sulfuric acid to the mixture at a rate of 1L / min, stir for half an hour, and let it stand at 50°C for 8 hours. The product was alternately washed four times with absolute ethanol and deionized water, dried in vacuum at 55° C. for 8 hours, and the vacuum degree was 100 kPa to obtain a lead-carbon composite material. After testing, the carbon content in the composite material is about 18% (mass fraction).

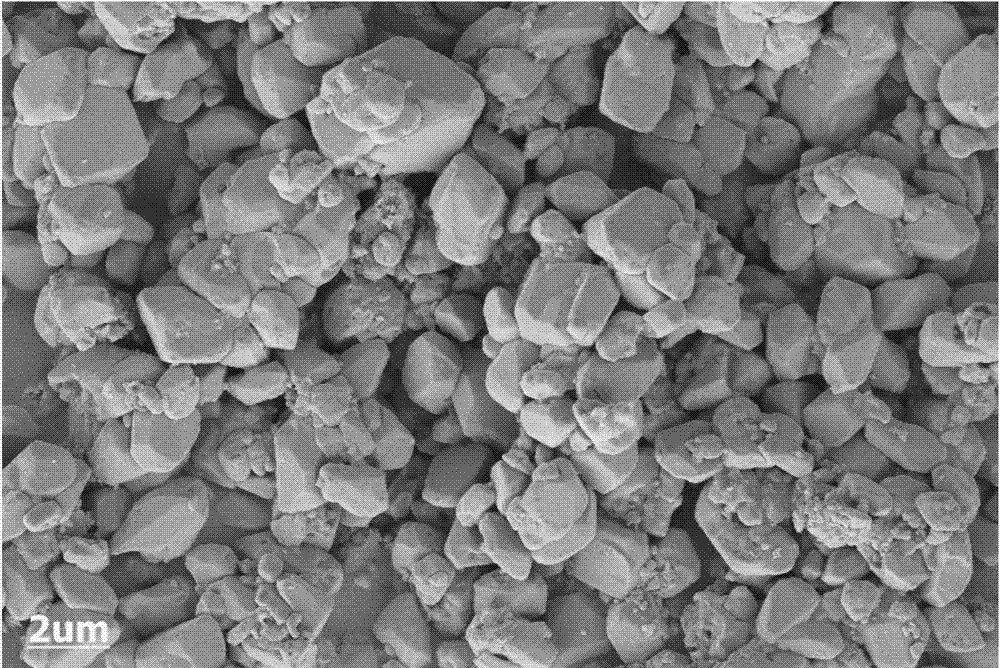

[0041] figure 1 Shown is the scanning electron microscope picture of the lead-carbon composite material. In the figure, the lead particles present a regular polyhedral structure and are uniformly dispersed around the carbon. The two ar...

Embodiment 2

[0046] Dissolve 10.5kg of glucose in 100L of deionized water, then add 50kg of lead powder to the solution, mix in a ball mill at 100r / min for 1h, move the mixture into a vacuum drying oven, and dry for 4h at 60°C with a vacuum of 50kpa , to form a mixture, then add 20L of 93% concentrated sulfuric acid to the mixture at a rate of 1L / min, stir for half an hour, leave to react at 50°C for 8 hours, wash the product four times alternately with absolute ethanol and deionized water, Vacuum drying at 55° C. for 8 hours with a vacuum degree of 100 kPa to obtain a lead-carbon composite material. After testing, the carbon content in the composite material is about 15% (mass fraction).

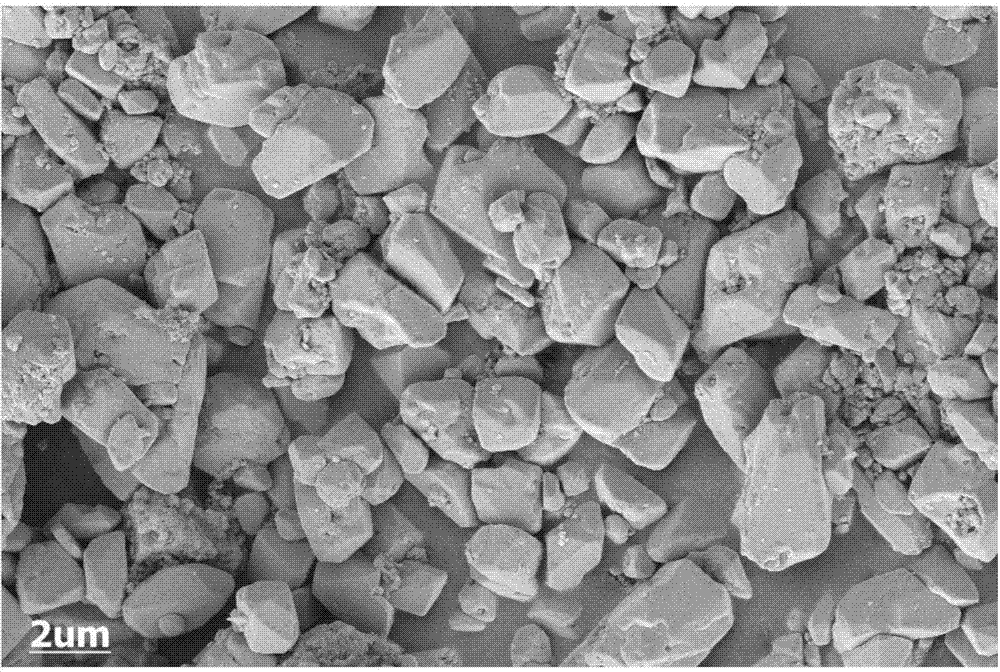

[0047] figure 2 Shown is the scanning electron microscope picture of the lead-carbon composite material. In the figure, the lead particles present a regular polyhedral structure and are evenly dispersed around the carbon. The two are in close contact, but not aggregated.

[0048] The above-mentioned ...

Embodiment 3

[0050] Dissolve 10.5kg of fructose in 100L of deionized water, then add 50kg of lead powder to the solution, mill in a ball mill at 150r / min for 1h, move the mixture into a vacuum drying oven, and dry at 60°C for 4h at a vacuum of 50kpa , to form a uniformly dispersed mixture, then add 20L of 93% concentrated sulfuric acid to the mixture at a rate of 1.5L / min, stir for 20 minutes, let it stand at 60°C for 8 hours, and wash the mixture alternately with absolute ethanol and deionized water The product was dried four times in vacuum at 55° C. for 8 hours with a vacuum degree of 100 kPa to obtain a lead-carbon composite material. After testing, the carbon content in the composite material is about 19% (mass fraction).

[0051] SEM images (not provided) of the lead-carbon composite with figure 1 , figure 2 Similarly, the lead particles present a regular polyhedral structure and are evenly dispersed around the carbon, and the two are in close contact, but not aggregated.

[0052...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com