Method for preparing porous carbon material through polyester low-temperature carbonization

A porous carbon material, low-temperature carbonization technology, applied in the preparation/purification of carbon, can solve the problems of high energy consumption and high carbonization temperature, and achieve the effects of reducing carbonization temperature, improving utilization rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

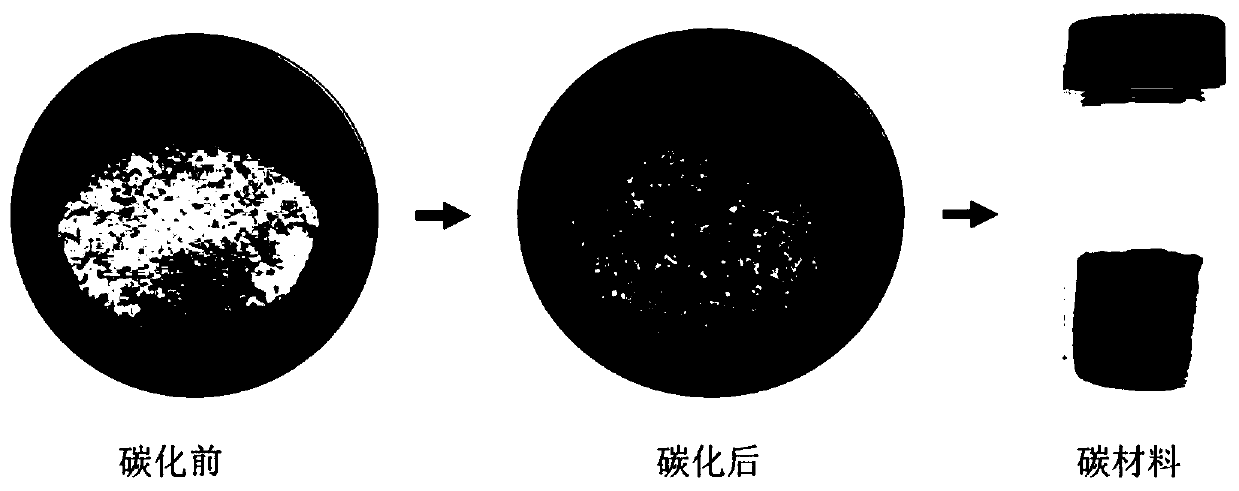

Image

Examples

Embodiment 1

[0046] (1) Weigh 5g of polyethylene terephthalate and 5g of zinc oxide (produced by Sinopharm Chemical Reagent Co., Ltd.), put them into a ball mill, stir and mix at a speed of 50r / min for 10min, and obtain a homogeneous mixture of the two.

[0047] (2) Transfer the mixture obtained in step (1) to a crucible, put the crucible in a muffle furnace, set the muffle furnace to heat at a rate of 5°C / min, to a carbonization temperature of 320°C, and Keep warm at high temperature for 30min.

[0048] (3) After the muffle furnace is naturally cooled, the carbonized product is obtained, and the carbonized product is placed in a 0.5mol / L hydrochloric acid solution and soaked for 6 hours, then washed with water until neutral, and dried to obtain the carbon material, and the carbon material is weighed, The yield was 42 wt%. After adding 1mol / L ammonia solution dropwise to the filtrate, a precipitate is obtained, and zinc oxide can be recovered after drying and calcining.

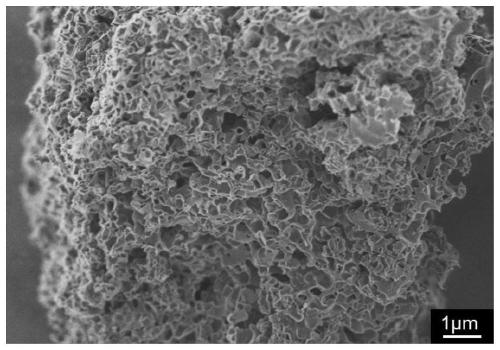

[0049] The prep...

Embodiment 2

[0051] (1) Weigh 5g of polydiallyl terephthalate and 10g of copper oxide (produced by Sinopharm Chemical Reagent Co., Ltd.), put them into a ball mill, stir and mix at a speed of 50r / min for 10min, and obtain a uniform mixture of the two.

[0052] (2) Transfer the mixture obtained in step (1) to a crucible, put the crucible in a muffle furnace, set the muffle furnace to heat at a rate of 5°C / min, to a carbonization temperature of 340°C, and Keep warm at high temperature for 30min.

[0053] (3) After the muffle furnace is naturally cooled, the carbonized product is obtained, and the carbonized product is placed in a 0.5mol / L sulfuric acid solution and soaked for 6 hours, then washed with water until neutral, and dried to obtain the carbon material, and the quality of the carbon material is weighed, The yield was 33 wt%. After adding 1mol / L ammonia solution dropwise to the filtrate, a precipitate is obtained, and the copper oxide can be recovered after drying and calcining.

...

Embodiment 3

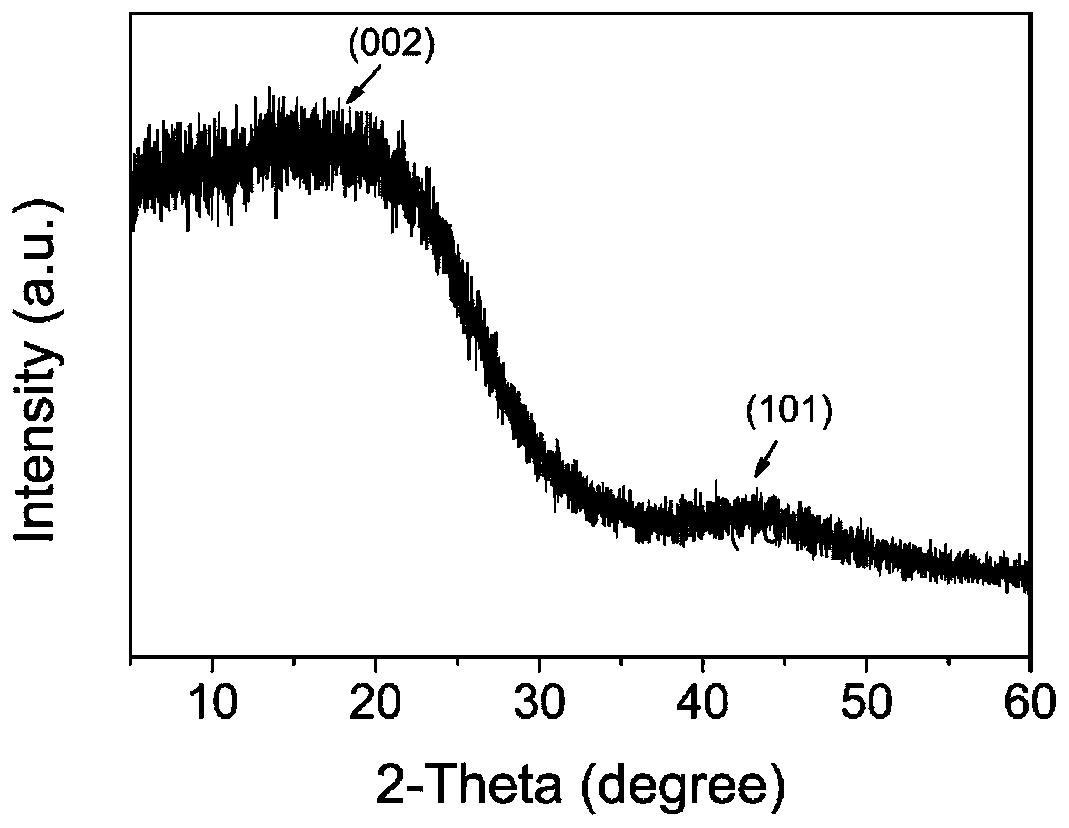

[0056] The carbonization temperature in the above-mentioned Example 1 was changed to 340° C., and the other steps remained unchanged, and a porous carbon material was obtained after post-treatment, with a yield of 38 wt%. The X-ray diffraction spectrum of the prepared carbon material is as follows image 3 shown. The carbon material prepared by carbonization of polyethylene terephthalate and zinc oxide was characterized by X-ray diffraction. It can be clearly seen from the figure that there are two diffraction characteristic peaks at the positions of 20o and 43o, corresponding to the (002) and (101) crystal planes of graphite, respectively. This shows that the prepared carbon material has the characteristics of amorphous carbon and partial graphitization. In addition, the prepared porous carbon material has a specific surface area as high as 1200 m 2 / g( Figure 4 ), with abundant micropores (50 nanometers), while the specific surface area of carbon materials prepared by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com