Method for preparing carbon-doped titanium oxide or/and titanium carbide from titanium-containing mineral or slag

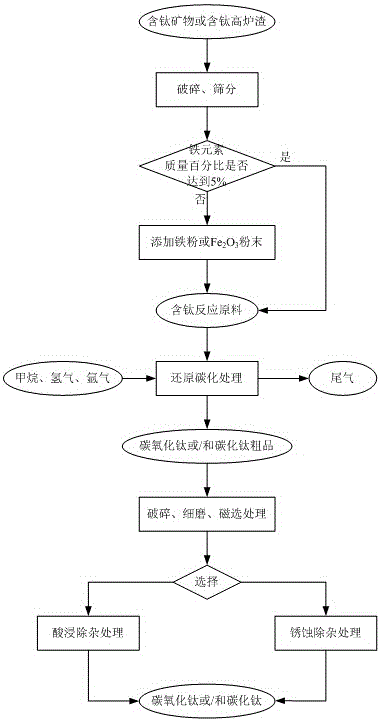

A technology for titanium oxycarbide and titanium minerals, which is applied in the field of preparing titanium oxycarbide or/and titanium carbide, can solve the problems of high preparation temperature, high cost, low production efficiency, etc. in the production process, so as to speed up the production reaction rate and save energy consumption. Cost, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0063] This embodiment uses TiO 2 To prepare titanium oxycarbide or / and titanium carbide with 81% high titanium slag, the specific steps are as follows:

[0064] (1) TiO 2 The 81% high-titanium slag is crushed into powder and sieved. It is required that particles with a particle size of less than 140 mesh in the powdered titanium-containing material obtained by sieving account for more than 80% of the total weight of the powdered titanium-containing material.

[0065] (2) It is determined by composition analysis that the mass percentage of iron contained in the titanium-containing powder obtained by sieving in this example is 6.0% (more than 5%), so there is no need to add iron powder or Fe 2 O 3 Powder, directly use powdered titanium-containing material as raw material for titanium-containing reaction.

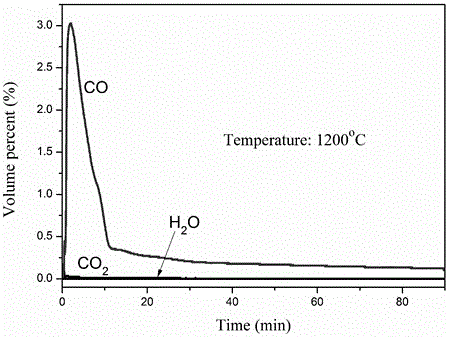

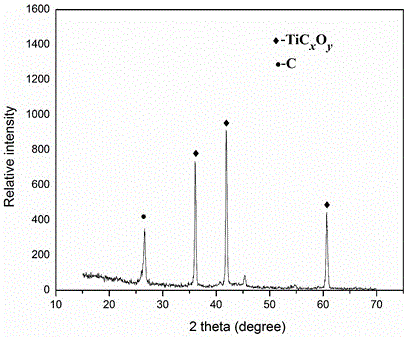

[0066] (3) Put the obtained titanium-containing powder material into a crucible, then put it into a fixed bed, and continuously pass a mixture of methane:hydrogen:argon at 6%:40%:54%...

example 2

[0071] This embodiment uses TiO 2 To prepare titanium oxycarbide or / and titanium carbide with a content of 45% ilmenite, the specific steps are as follows:

[0072] (1) TiO 2 The content of 45% ilmenite is crushed into powder and sieved. It is required that particles with a particle size of less than 140 mesh in the powdered titanium-containing material obtained by sieving account for more than 80% of the total weight of the powdered titanium-containing material.

[0073] (2) It is determined by composition analysis that the mass percentage of iron contained in the powder titanium-containing material obtained by sieving in this embodiment is 35.8% (greater than 5%), so there is no need to add iron powder or Fe 2 O 3 Powder, directly use powdered titanium-containing material as raw material for titanium-containing reaction.

[0074] (3) Put the obtained titanium-containing reaction raw material into a MgO crucible, and then put it into a fluidized bed to pass a mixture of methane:hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com