Modified biomass charcoal for treating arsenic pollution as well as preparation method and application of modified biomass charcoal

A biomass charcoal, biomass raw material technology, applied in the recovery of water pollutants, polluted soil, chemical instruments and methods, etc., can solve the problems of high energy consumption, cumbersome operation process, no cost saving, etc. The effect of short, wide adaptability and low application cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

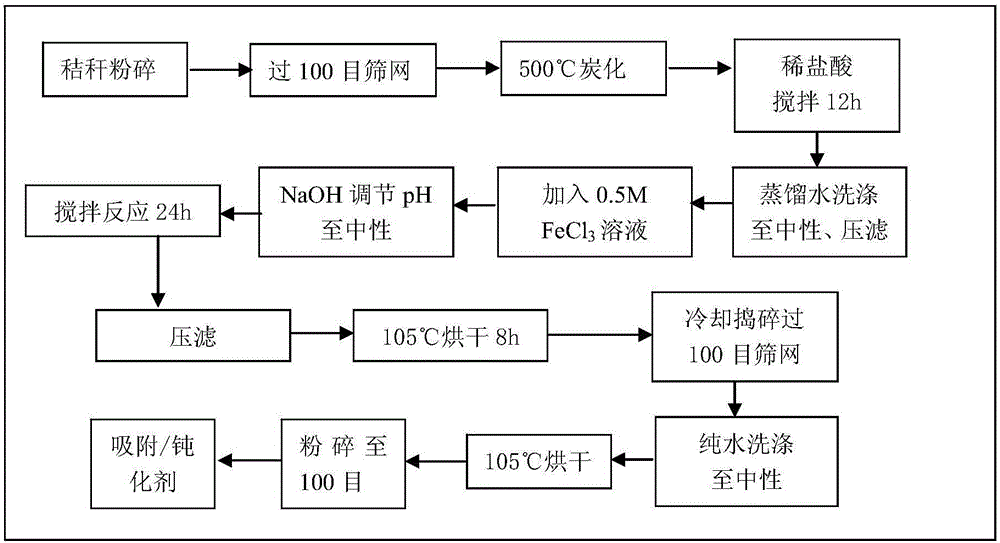

[0068] A preparation method of modified biochar, such asfigure 1 shown, including the following steps:

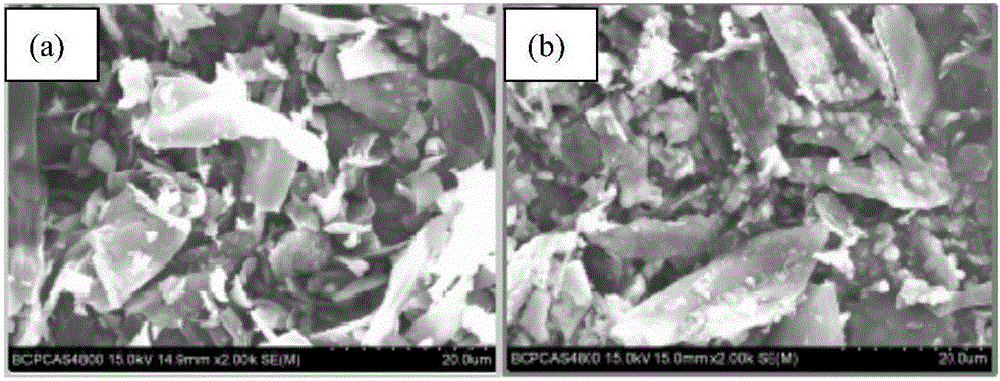

[0069] (1) Crush the straw and pass it through a 100-mesh sieve, and then carbonize it in a carbonization furnace at a temperature of 500°C for 6 hours, then cool it to 30°C to obtain biochar (such as figure 2 (a));

[0070] (2) React the solid-liquid ratio of 1g:10mL biochar with the concentration of 1mol / L hydrochloric acid solution under the condition of stirring speed of 120r / min, the reaction temperature is 30°C, and the reaction time is 12h. After the reaction, the solid liquid separation to obtain a solid substance, the solid substance was washed with distilled water until the pH value was neutral, press-filtered, the obtained solid substance was dried at 70°C, and crushed to 100 mesh to obtain pretreated biochar;

[0071] (3) Pretreated biochar with a solid-to-liquid ratio of 1g:10mL and FeCl with a concentration of 0.5mol / L 3 The solution was reacted for 24 hour...

Embodiment 2-4

[0074] Except that the wheat stalks in step (1) were replaced by cotton stalks, rice straws and corn stalks, the rest were the same as in Example 1, and modified cotton stalk charcoal, modified rice straw charcoal and modified corn stalk charcoal were respectively obtained.

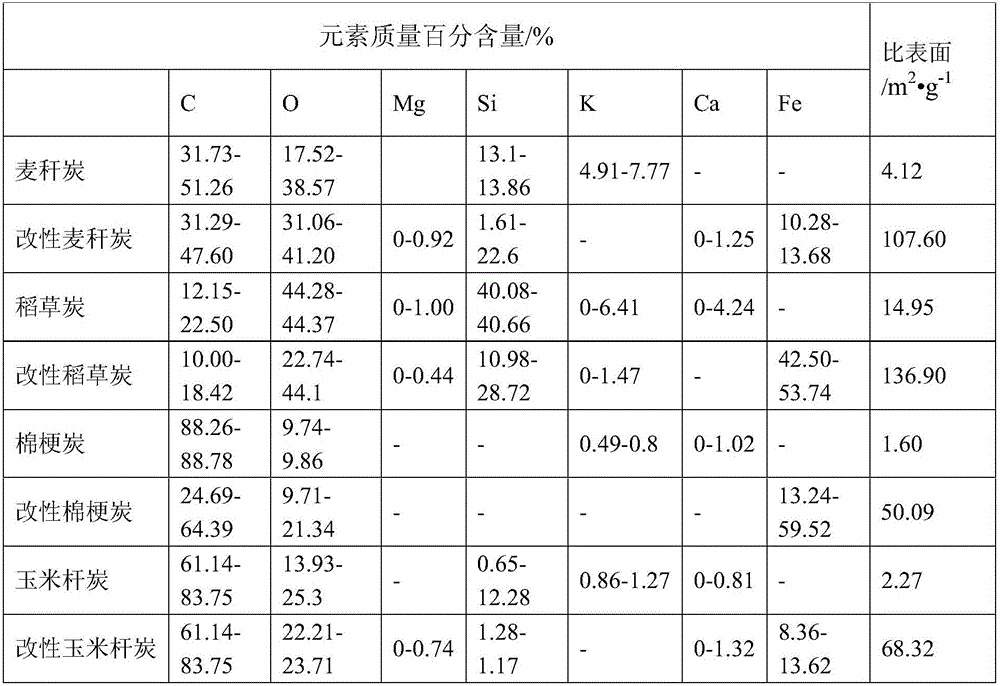

[0075] The main chemical components of the biochar in Examples 1-4 before and after modification were analyzed, and the analysis results are shown in Table 1.

[0076] Table 1 The main chemical components and specific surface area of biochar before and after modification

[0077]

[0078] Among them, "-" means no data.

[0079] It can be seen from Table 1 that compared with unmodified, the specific surface area of the modified biochar increased by 8.15-30.3 times; the iron content increased greatly, and its mass percentage could reach 59.52%. The increase in the specific surface area means that The increase of adsorption sites and adsorption capacity, and the increase of iron content indicate that...

Embodiment 5

[0081] A preparation method of modified biochar, comprising the steps of:

[0082] (1) Wheat straw was crushed through a 100-mesh sieve, placed in a carbonization furnace at 500°C for 8 hours, and cooled to room temperature to prepare biochar;

[0083] (2) Add 400mL of hydrochloric acid solution with a concentration of 1mol / L to every 50g of biochar, stir and react for 12h, press filter, wash with distilled water for more than 3 times until the pH is neutral, and obtain a solid substance, which is dissolved in 80 °C drying and crushing, passing through a 100-mesh sieve to obtain pretreated biochar;

[0084] (3) Add 500 mL of FeCl with a concentration of 0.5 mol / L to 50 g of pretreated biochar 3 solution, adjust the pH to 7 with sodium hydroxide solution, stir at 30°C for 48 hours, press filter to obtain a mud cake;

[0085] (4) Dry the mud cake at 100°C for 12 hours, cool it to room temperature, smash it through a 100-mesh sieve, wash it with pure water until the effluent is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com