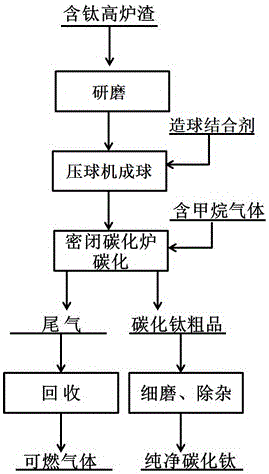

Titanium carbide preparation method based on carbonization titanium extraction treatment of titanium-bearing blast furnace slag

A carbonization treatment, blast furnace slag technology, applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of low efficiency, complex process, high energy consumption and cost, and achieve complex process and reduction efficiency High, the effect of improving the reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Aiming at the problems of complex process, low efficiency, high energy consumption and high cost of the titanium carbide preparation method in the prior art, a new titanium carbide preparation process needs to be considered.

[0034] The applicant found in the research of using natural gas to reduce iron ore that the natural gas needs to be reformed before reduction to make it into CO and H 2 , otherwise Fe will easily appear in the reduction product 3 c. Inspired from this phenomenon, if CH 4 As a carbonizing agent, it can react with oxides to prepare metal carbides. About CH 4 Why can metal carbides be prepared, Professor Ostrovski believes that CH 4 The decomposed carbon is different from the general solid carbonaceous reducing agent. The cluster formed by several carbon atoms is the basic reaction unit, and its chemical activity is very high, so it has stronger carbonization ability and carbonization rate. Therefore, theoretically, using CH 4 The main reducing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com