Electrode material of porous charcoal super capacitor and preparation method thereof

A technology for supercapacitors and electrode materials, applied in the manufacture of capacitors, hybrid/electric double-layer capacitors, electrolytic capacitors, etc., to achieve the effects of high energy density and power density, simple preparation process and low carbonization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

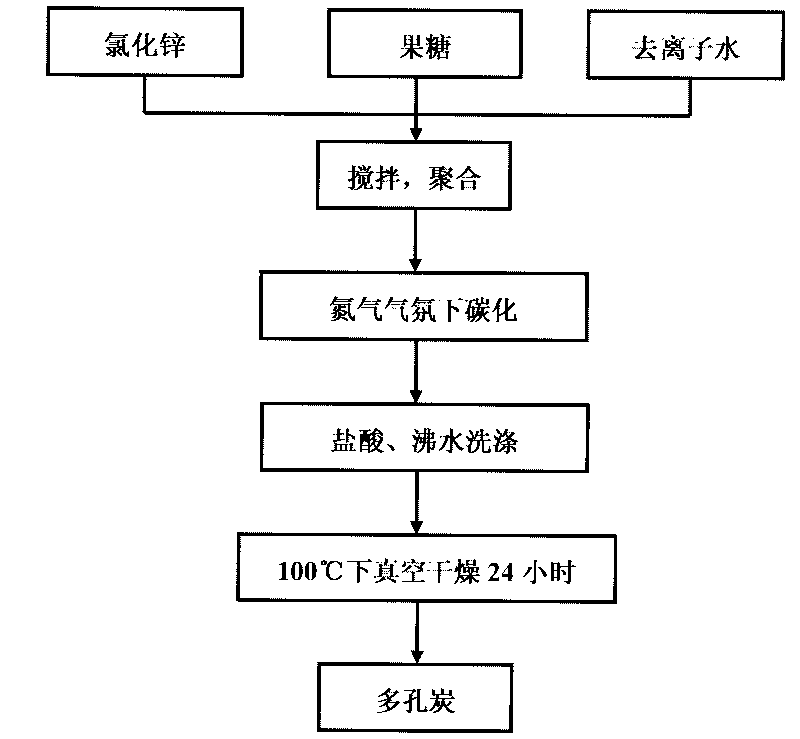

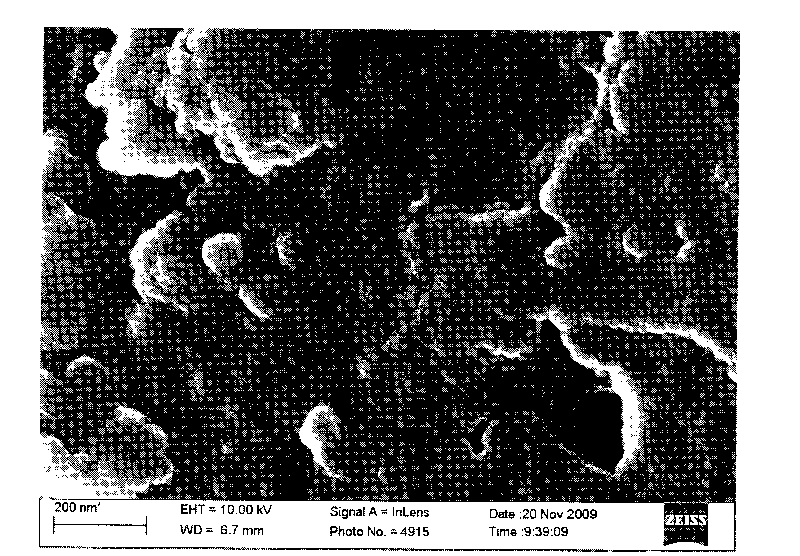

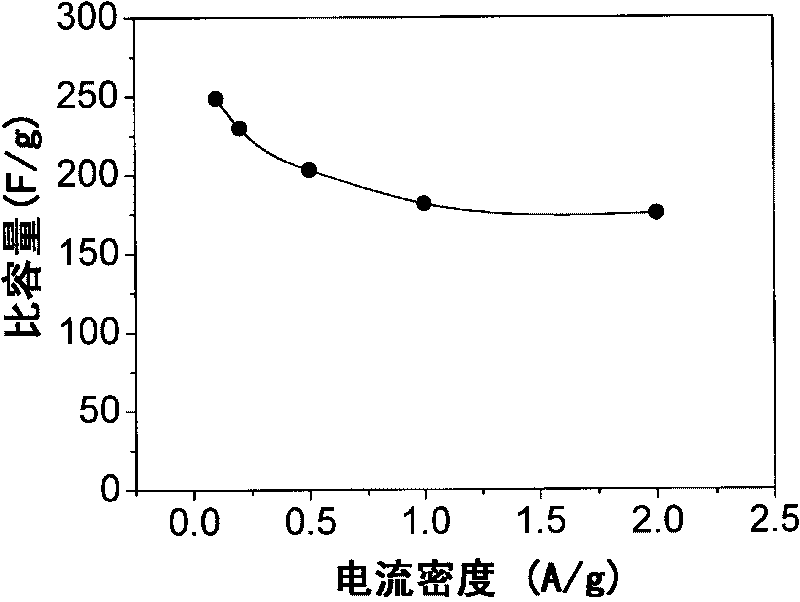

[0016] Dissolve 9 grams of fructose and 34 grams of zinc chloride in 35 milliliters of deionized water, stir in an oil bath at 85°C for 3 hours, then put them in an oven at 120°C for 4 hours. Then carbonization was carried out at 450° C. for 2 hours under the protection of argon, and the heating rate was 5° C. / min. Wash with 500 ml of hydrochloric acid and 500 ml of boiling water, and dry under vacuum at 100°C for 24 hours. The scanning electron microscope image of the porous carbon thus obtained is shown in figure 2 As shown, the particle size of the porous carbon is 2-30nm. Nitrogen adsorption analysis test shows that the specific surface area of porous carbon is 1416m 2 / g; pore volume 0.95cm 3 / g, has two kinds of pores, mesopore and micropore, the diameter of mesopore is 2.02nm, and the diameter of micropore is 0.44nm. The capacitance test of this electrode material in the electrolyte of 1M KOH shows that ( image 3 ), at 0.1Ag -1 Under the current density, the m...

Embodiment 2

[0018] The difference between embodiment 2 and embodiment 1 is that the carbonization temperature is different, and the others are the same. details as follows:

[0019] Dissolve 9 grams of fructose and 56 grams of zinc chloride in 35 milliliters of deionized water, stir in an oil bath at 85°C for 3 hours, then put them in an oven at 130°C for 1 hour. Then carbonization was carried out at 700°C for 3 hours under the protection of argon with a heating rate of 5°C / min. Wash with 500 ml of hydrochloric acid and 500 ml of boiling water, and dry under vacuum at 100°C for 24 hours. The scanning electron microscope image of the porous carbon thus obtained is shown in Figure 4 As shown, the particle size of the porous carbon is uniform, the shape is regular, and the particle size is 2-30nm. Nitrogen adsorption analysis test shows that the specific surface area of porous carbon is 1323m 2 / g, pore volume 2.04cm 3 / g, with mesopores and micropores, the mesopore diameter is 3.88n...

Embodiment 3

[0021] Dissolve 2 grams of fructose and 80 grams of zinc chloride in 60 milliliters of deionized water, stir in an oil bath at 85°C for 3 hours, and then put them in an oven at 130°C for 5 hours. Then carbonization was carried out at 750° C. for 2 hours under the protection of argon, and the heating rate was 5° C. / min. Wash with 500 ml of hydrochloric acid and 500 ml of boiling water, and dry under vacuum at 100°C for 24 hours. The particle size of the porous carbon is uniform, the shape is regular, and the particle size is 7-40nm. When the current density is 1Ag-1, the specific capacitance of porous carbon can reach 210F / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com