High-specific surface active graphene with mesoporous and preparation method and application thereof

A high specific surface, graphene technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, inorganic chemistry, etc., can solve the problem of excessive reaction, low production efficiency, and ineffective activation of activators and other problems to achieve the effect of reducing the difficulty of operation and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

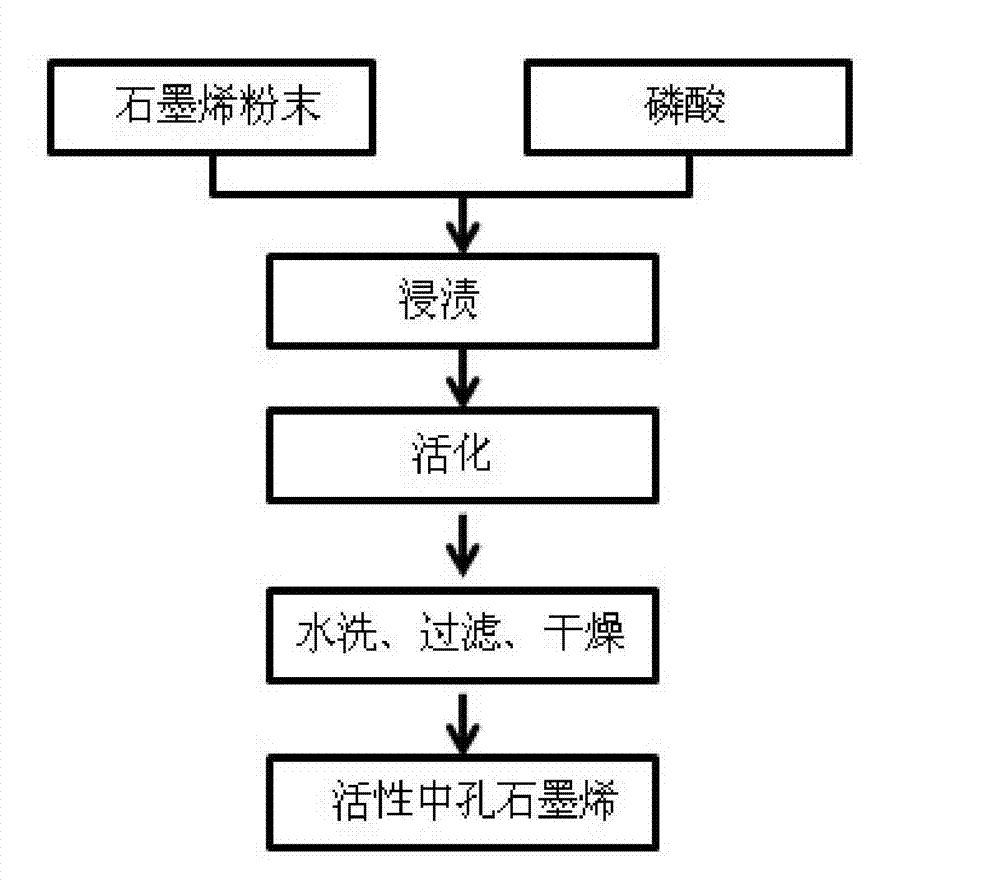

[0053] A method utilizing phosphoric acid as an activator to prepare a high specific surface active graphene material with mesopores, comprising the following preparation steps:

[0054] Graphene is obtained by exfoliating graphite oxide by microwave, and 30g of graphene is weighed; phosphoric acid with a concentration of 85wt% and graphene are mixed and impregnated at a weight ratio of 3:1 for 2 days, and the impregnation temperature is 55°C; then the uniformly mixed raw materials are loaded into nickel In the reactor, after the reactor is closed, nitrogen is introduced to replace the air in the reactor, and the temperature is raised under the protection of nitrogen at a rate of 10-12°C / min, and the activation starts at 550°C, and the temperature is kept for 120min. After the reaction is completed, it is protected by nitrogen Lower the temperature to room temperature, take out the product, wash it with water, and dry it to make the product. Its BET specific surface area is 200...

Embodiment 2

[0056] A method utilizing phosphoric acid as an activator to prepare a high specific surface active graphene material with mesopores, comprising the following preparation steps:

[0057] Graphene is obtained by exfoliating graphite oxide by microwave, and 40g of graphene is weighed; phosphoric acid with a concentration of 85wt% and graphene are mixed and impregnated at 5:1 by weight for 20h, and the immersion temperature is 45°C; then the uniformly mixed raw materials are loaded into nickel In the reactor, after the reactor is closed, nitrogen gas is introduced to replace the air in the reactor, and the temperature is raised under the protection of nitrogen gas at a heating rate of 10-12°C / min to 450°C and dehydration at a constant temperature of 120min; then continue at a heating rate of 10- 12°C / min, heat up to 800°C, start activation, keep the temperature for 120min, after the reaction is completed, cool down to room temperature under the protection of nitrogen, take out the...

Embodiment 3

[0059] A method utilizing phosphoric acid as an activator to activate and prepare a high specific surface active graphene material with mesopores, comprising the following preparation steps:

[0060]Graphene is obtained by exfoliating graphite oxide by microwave, and 30g of graphene is weighed; phosphoric acid with a concentration of 85% and graphene are mixed and impregnated at a weight ratio of 4:1 for 1d, and the impregnation temperature is 50°C; then the uniformly mixed raw materials are loaded into nickel In the reactor, after the reactor is closed, argon is introduced to replace the air in the reactor, and the temperature is raised under the protection of argon at a rate of 10-12°C / min, and activation starts at 400°C, and the temperature is maintained for 120min. Cool down to room temperature under the protection of argon, take out the product, wash with water, and dry to make the product. The BET specific surface area is 1600m 2 / g, the pore volume is 1.0cm 3 / g, the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com