Method for preparing nanopowder of tungsten carbide

A nano-tungsten carbide and nano-technology, which is applied in the field of preparation of nano-tungsten carbide powder, can solve the problem of violent growth of nano-scale tungsten oxide or tungsten powder particles, and achieve the effect of simple equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

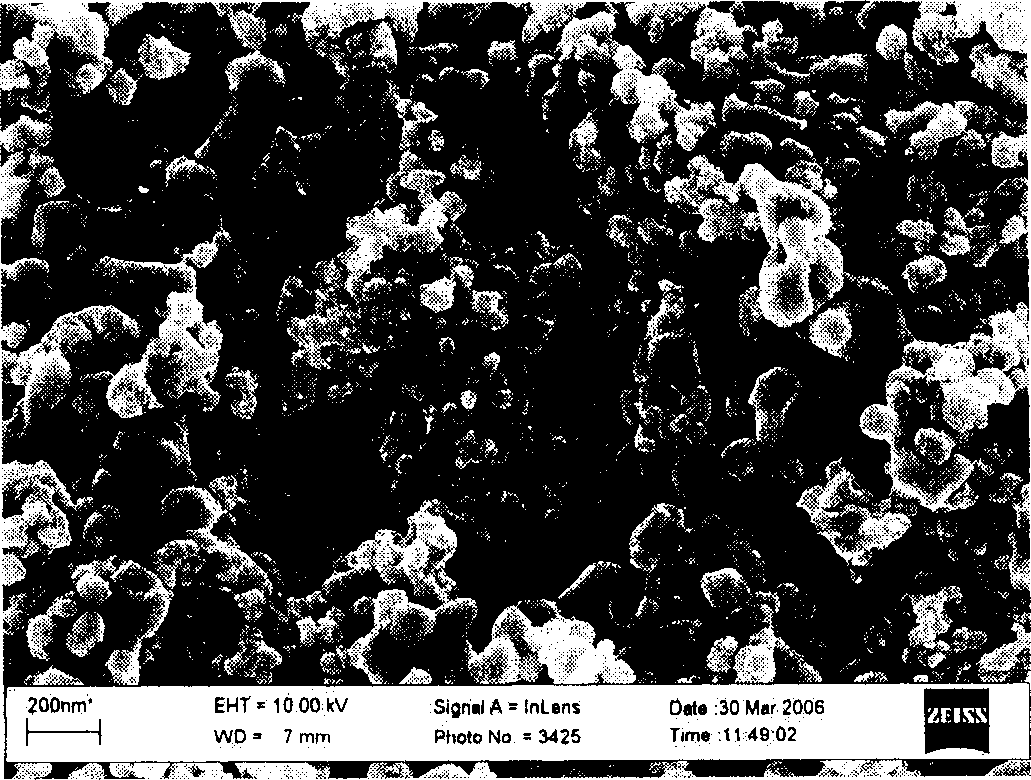

[0019] Embodiment 1: The W powder with an average particle diameter of 60.6nm is used as a raw material to prepare WC powder with an average particle diameter of 87.9nm, which should be completed according to the following steps.

[0020] 1. Dissolve the alcohol-soluble phenolic resin in absolute ethanol, configure it as an ethanol solution of 0.5g / ml phenolic resin, add 300ml of the above-mentioned phenolic resin ethanol solution to each kg of nano W powder, and process it in an ultrasonic dispersion device for 3 hours. Stir at the same time, and then heat the slurry to 100° C. to volatilize absolute ethanol to obtain a mixture of phenolic resin-coated nanometer W particles.

[0021] 2. Carbonize the mixture in a vacuum furnace at a temperature of 950° C. for 60 minutes and a vacuum of 200 Pa to obtain nano WC powder with an average particle size of 85.5 nm and a total carbon content of 8.13%.

[0022] 3. The nano-WC powder with high carbon content obtained by vacuum carboniz...

Embodiment 2

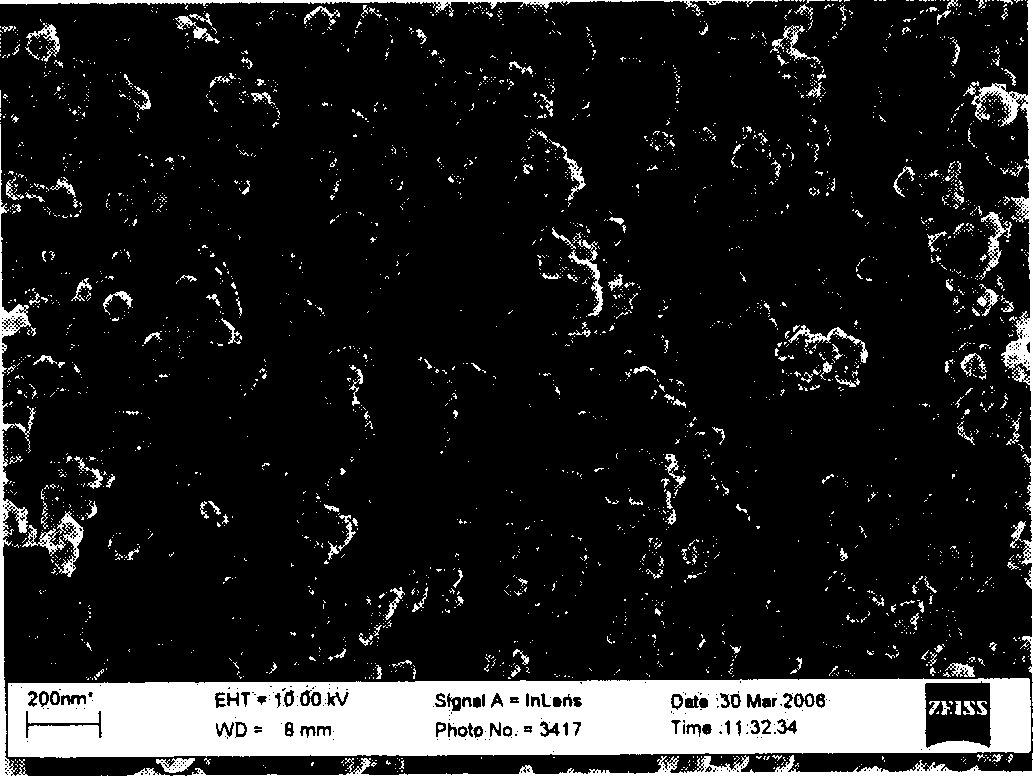

[0024] Embodiment 2: The W powder with an average particle diameter of 48.5nm is used as a raw material to prepare WC powder with an average particle diameter of 75.4nm, which should be completed according to the following steps.

[0025] 1. Dissolve the alcohol-soluble phenolic resin in absolute ethanol, configure it as an ethanol solution of 0.8g / ml phenolic resin, add 250ml of the above-mentioned phenolic resin ethanol solution in every kg of nano W powder, and process it in an ultrasonic dispersion device for 5 hours, Stir at the same time, and then heat the slurry to 90° C. to volatilize absolute ethanol to obtain a mixture of nano W particles coated with phenolic resin.

[0026] 2. Carbonize the mixture in a vacuum furnace at a temperature of 910° C. for 120 minutes and a vacuum of 300 Pa to obtain nano WC powder with an average particle size of 73.8 nm and a total carbon content of 9.47%.

[0027] 3. The nano-WC powder with high carbon content obtained by vacuum carboni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com