Preparation method of novel biochar

A new type of bio-carbon technology, applied in the field of material processing, can solve the problems of unfavorable use of straw returning machinery, limited application scope of straw returning, and decreased air quality, so as to increase the speed of carbonization, increase the absorption rate, and reduce the carbonization temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

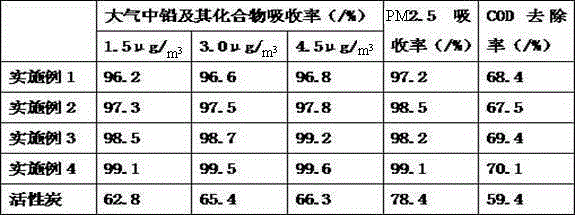

Examples

Embodiment 1

[0024] A preparation method of novel biochar, comprising the following steps:

[0025] (1) Take the plant straw and crush it into powder, then soak it with 4.5% ammonium acetate aqueous solution at room temperature for 25-40 minutes, press out the moisture in the plant straw powder, and then use formic acid, sodium nitrate, tannic acid, water Cook the mixed liquor prepared according to the weight ratio of 6:0.5:2:3, the cooking temperature is 118-125°C, the cooking time is 25-40min, and filter to obtain the filtrate and filter residue;

[0026] (2) Wash the filter residue with clean water to remove the floating acid on the surface of the straw powder;

[0027] (3) Cooking the filtrate to remove the acid liquid and moisture inside, washing the solid residue obtained by cooking with clear water, cooking again, combining the obtained solid with the filter residue obtained in step (2), and drying;

[0028] (4) Mix the solid matter and carbon powder obtained in step (3) evenly at ...

Embodiment 2

[0031] In step (5), after the carbonization treatment for 3-5 minutes, the raw material is extruded with an extruder at a pressure of 3 MPa, and the raw material is pressed into blocks. Other steps are with embodiment 1.

Embodiment 3

[0033] After the treatment in step (4) is completed, use KMnO with a mass fraction of 0.5% 4 Soak the raw materials in the solution and vibrate for 15 minutes with ultrasonic waves, then soak them in 2% potassium acetate solution for 20 minutes, and dry them under the protection of nitrogen. Other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com