Biomass porous carbon/prussian blue composite material and preparation method thereof

A technology of Prussian blue and composite materials, applied in the field of biomass porous carbon/Prussian blue composite materials and its preparation, can solve the problems of high carbonization temperature, imperfect technology, low conversion rate, etc., to reduce carbonization temperature and expand raw materials source, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

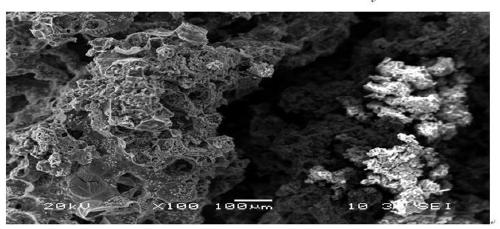

Image

Examples

Embodiment 1

[0035] A biomass porous carbon / Prussian blue composite material, the main constituent elements and the corresponding mass fraction ratio are, C:N:O:K:Fe:Cl=70:3.1:16:4.4:2.5:2.1; the main organic Functional groups include: cyano group, hydroxyl group, alkyl group, benzene ring, benzene ring substituent, etc. The biomass porous carbon is the main body of the composite material, and Prussian blue substances are attached to the surface layer and pores of the biomass porous carbon.

Embodiment 2

[0037] A biomass porous carbon / Prussian blue composite material, the main constituent elements and the corresponding mass fraction ratio are, C:N:O:K:Fe:Cl =69:3.8:15:3.2:4.6:3.4; the main organic Functional groups include: cyano group, hydroxyl group, alkyl group, benzene ring, benzene ring substituent, etc. The biomass porous carbon is the main body of the composite material, and Prussian blue substances are attached to the surface layer and pores of the biomass porous carbon.

Embodiment 3

[0039] A method for preparing a biomass porous carbon / Prussian blue composite material, the specific method and steps are:

[0040] (1) Acid elution of metal ions: take 30g of dry reed stalks, soak them in 3mol / L hydrochloric acid solution at 60°C, stir well at a stirring speed of 500rap / min, pickle for 4h, and then filter 3 times. Wash with 300mL ultrapure water each time until the pH is about 7 to obtain reed stalks without metal ions;

[0041] (2) Swelling modification of reed stalks: Take 20g of metal ion-free reed stalks obtained in step (1), soak them in 300mL swelling solution at 20°C, swell for 30-120min, and then filter 1-3 times , and then washed with 100-200 mL of absolute ethanol to obtain swollen reed stalks, the swelling solution is a mixture of tetrahydrofuran and toluene, and the volume ratio of tetrahydrofuran to toluene is 1:2;

[0042] (3) Loading porous carbon pore-forming agent and Prussian blue reactant: configure K with potassium fulvic acid and ferric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com