Ultrahigh-strength aluminum alloy with high strength and high hardenability and preparation method of ultrahigh-strength aluminum alloy

A high-hardenability, ultra-high-strength technology, applied in the field of non-ferrous metals, can solve the problems of reducing the safety factor of aircraft, low alloy strength, low Mg content, etc., and achieve the effect of optimizing the effective strengthening phase of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0025] Below in conjunction with embodiment technical solution of the present invention will be described in further detail:

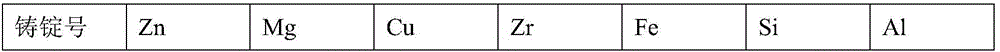

[0026] Table 1 gives examples of the chemical composition and weight percentage of the novel ultra-high-strength aluminum alloy proposed by the present invention.

[0027] Table 1: Chemical composition and weight percentage of new ultra-high-strength aluminum alloys

[0028] Table 1

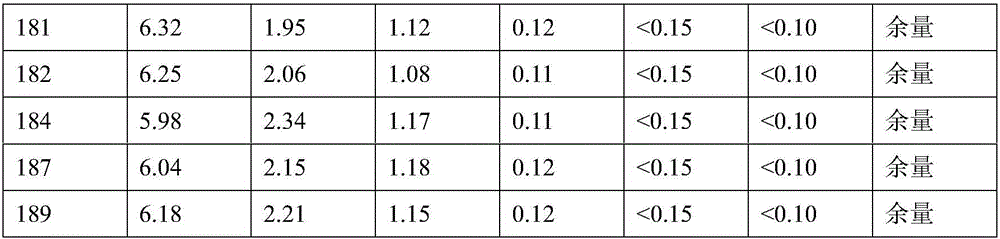

[0029]

[0030]

[0031] The steps of the preparation process of the alloy are:

[0032] (1) According to the chemical composition and weight percentage of the alloy, the ingredients are required;

[0033] (2) Melting in a smelting furnace, the melting temperature is 720-780°C;

[0034] (3) Refining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com