Positive pole piece and lithium ion battery containing pole piece

A technology of positive pole piece and positive current collector, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of scarcity of cobalt resources, difficult to popularize and use, and poor resistance to overcharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A lithium-ion battery positive electrode sheet and a lithium-ion battery using the positive electrode, the specific preparation steps of which are as follows:

[0062] 1. Preparation of ternary materials:

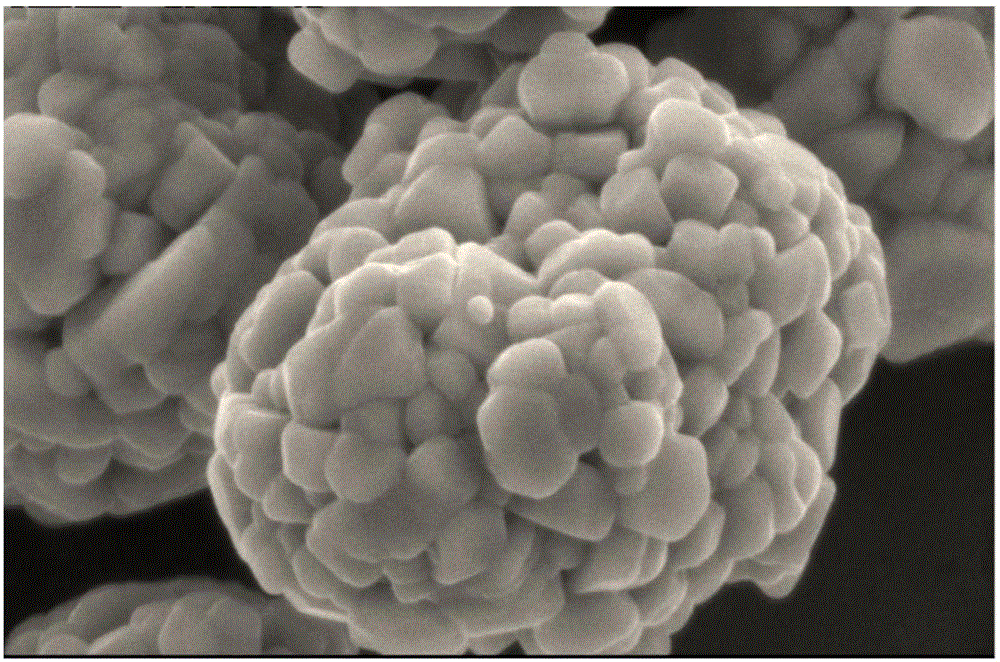

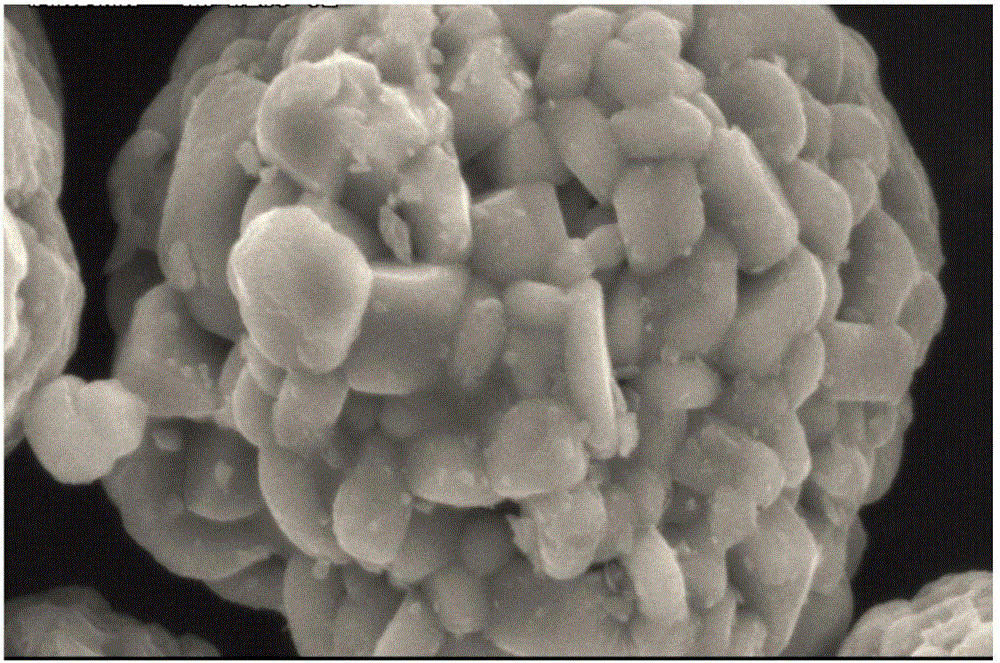

[0063] 1.1 MnSO 4 , Ni(NO 3 ) 2 、CoCl 2 The solution is mixed evenly, the molar ratio of the three metal elements is Co:Ni:Mn=0.6:0.2:0.2, and then mixed with the precipitant NH 4 HCO 3 Reaction, using co-precipitation to prepare the precursor;

[0064] 1.2 Treat the precursor in an air atmosphere at 500°C for 5 hours to obtain a composite oxide containing Ni, Co, and Mn elements;

[0065] 1.3 Add Li to the composite oxide containing Ni, Co, Mn elements 2 CO 3 , the molar ratio is 1≤Li:(Ni+Mn+Co)≤1.1, after ball milling and mixing uniformly, treat it at 900°C for 10 hours in the air atmosphere to prepare the conventional ternary material LiCo 0.6 mn 0.2 Ni 0.2 o 2 .

[0066] 2. Preparation of positive pole piece:

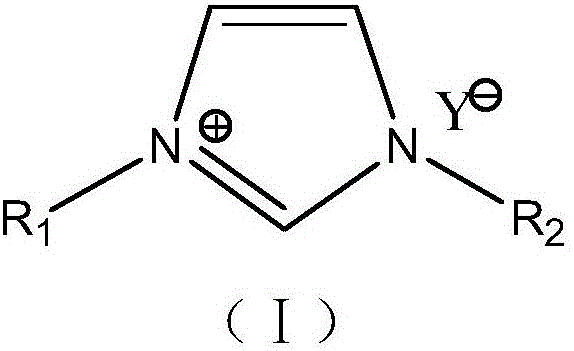

[0067] 2.1 Dissolve the prepared terna...

Embodiment 2

[0072] 1. Preparation of ternary material: Refer to Example 1 for the first three steps, and change the ratio of the three metal elements, Co:Ni:Mn=0.6:0.3:0.1, to prepare a modified ternary material.

[0073] 2. Refer to Example 1 for the preparation of the positive electrode sheet.

[0074] 3. Refer to Example 1 for the preparation of the negative electrode.

[0075] 4. For battery assembly, refer to Example 1.

Embodiment 3

[0077] 1. Preparation of ternary material: Refer to Example 1 for the first three steps, and change the ratio of the three metal elements, Co:Ni:Mn=0.6:0.1:0.3, to prepare a modified ternary material.

[0078] 2. Refer to Example 1 for the preparation of the positive electrode sheet.

[0079]3. Refer to Example 1 for the preparation of the negative electrode.

[0080] 4. For battery assembly, refer to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com