Method for preparing cinnamomum camphora seedling raising organic fertilizer

A technology of organic fertilizer and camphor, which is applied in the field of preparing organic fertilizer for camphor seedling cultivation, can solve the problems of insufficient decomposition and fermentation, low nutrient content, and low fertilizer efficiency, so as to enrich organic matter content, increase soil voids, and promote reproduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

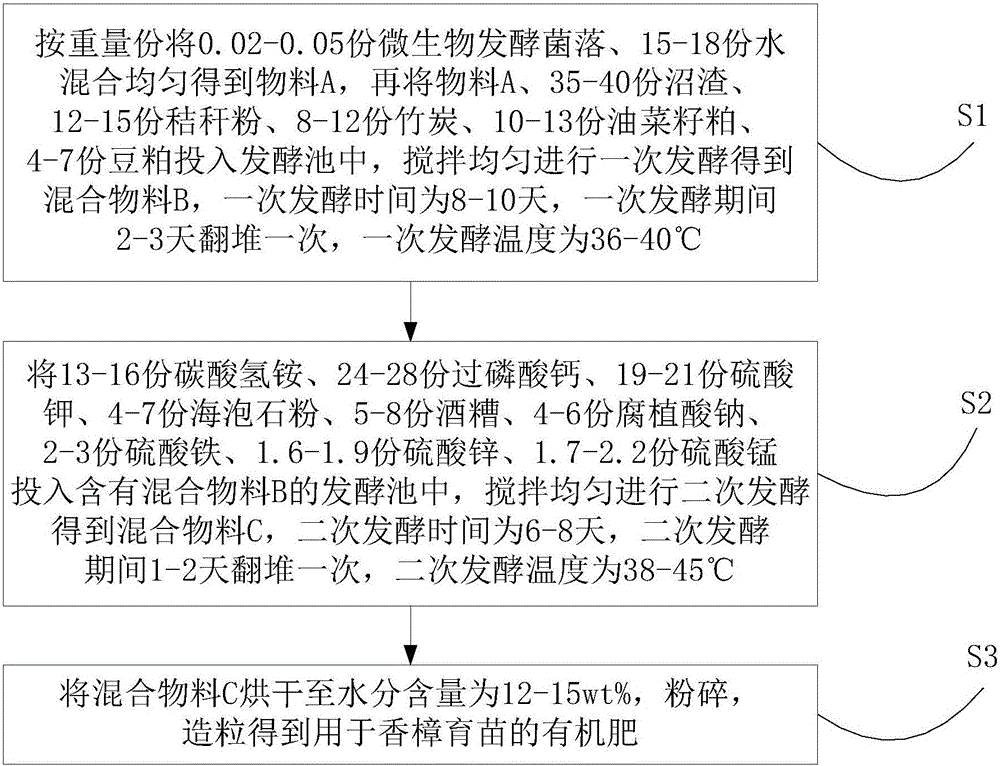

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation that the present invention proposes is used for the method for camphor seedling raising organic fertilizer, comprises the following steps:

[0028] S1. Mix 0.04 parts of microbial fermentation colony and 10 parts of water in parts by weight to obtain material A, and then mix material A, 35 parts of biogas residue, 14 parts of straw powder, 15 parts of water hyacinth, 7 parts of bamboo charcoal, and 9 parts of rapeseed meal 1. Put 3 parts of soybean meal into the fermentation tank, stir evenly and carry out a fermentation to obtain the mixed material B. The fermentation time is 12 days, and the pile is turned once every 2 days during the fermentation period. It is made by mixing Bacillus subtilis and Bacillus licheniformis at a ratio of 50:50; the moisture content of biogas residue is 60wt%; the straw powder is obtained by crushing wheat straw or rice straw; the particle size of bamboo charcoal is 5mm;

[0029] S2, 15 parts of ammonium bicarbonate, ...

Embodiment 2

[0032] A kind of preparation that the present invention proposes is used for the method for camphor seedling raising organic fertilizer, comprises the following steps:

[0033] S1. Mix 0.01 parts of microbial fermentation colony and 15 parts of water evenly by weight to obtain material A, and then mix material A, 30 parts of biogas residue, 17 parts of straw powder, 10 parts of water hyacinth, 10 parts of bamboo charcoal, and 6 parts of rapeseed meal 1. Put 6 parts of soybean meal into the fermentation tank, stir evenly and carry out a fermentation to obtain the mixed material B. The fermentation time is 10 days, and the pile is turned once every 3 days during the fermentation period. It is made by mixing Bacillus subtilis and Bacillus licheniformis at a ratio of 55:45; the moisture content of biogas residue is 70wt%; the straw powder is obtained by crushing wheat straw or rice straw; the particle size of bamboo charcoal is 3mm;

[0034]S2, 18 parts of ammonium bicarbonate, 28...

Embodiment 3

[0037] A kind of preparation that the present invention proposes is used for the method for camphor seedling raising organic fertilizer, comprises the following steps:

[0038] S1. Mix 0.03 parts of microbial fermentation colonies and 12 parts of water in parts by weight to obtain material A, and then mix material A, 33 parts of biogas residue, 15 parts of straw powder, 14 parts of water hyacinth, 8 parts of bamboo charcoal, and 8 parts of rapeseed meal 1. Put 4 parts of soybean meal into the fermentation tank, stir evenly and carry out a fermentation to obtain the mixed material B. The fermentation time is 11 days, and the heap is turned once every 2.5 days during the fermentation period. It is made by mixing Bacillus subtilis and Bacillus licheniformis at a ratio of 52:48; the moisture content of biogas residue is 64wt%; the straw powder is obtained by crushing wheat straw or rice straw; the particle size of bamboo charcoal is 4mm;

[0039] S2, 16 parts of ammonium bicarbona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com