Porous dephosphorization filter material based on kieselguhr and silicon earth and preparation method thereof

A technology of diatomite and silica, which is applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of limited adsorption capacity, poor water flow through, and difficult to popularize, and achieve removal of The effect is obvious, the water quality is stable, and the material is widely used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

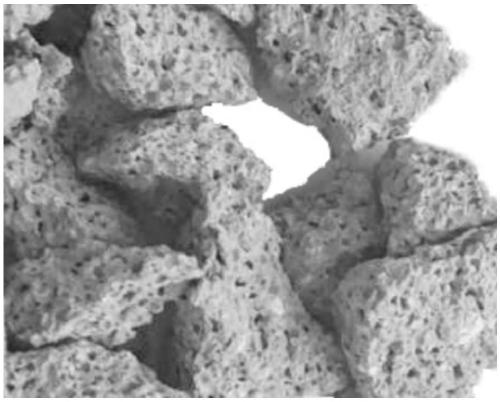

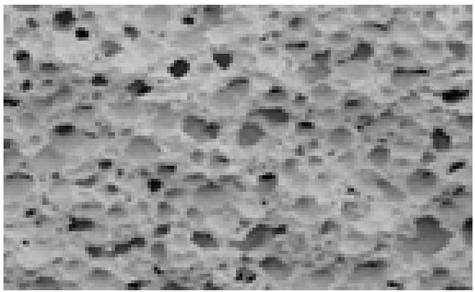

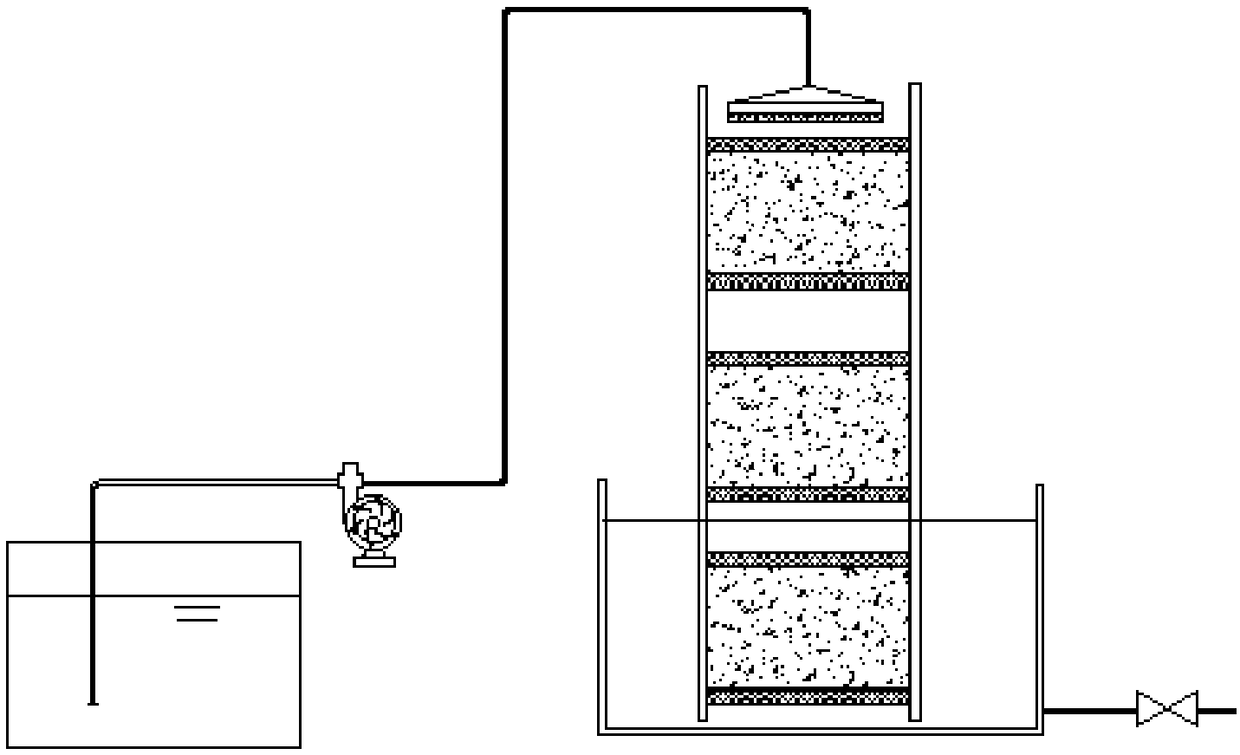

[0021] A porous phosphorus removal filter material comprises the following components by weight: 30% of diatomite; 50% of silica; 7% of lime; 8% of cement; 3% of gypsum; The specific surface area of porous phosphorus removal filter material based on diatomite and silica is 61.26×10 4 cm 2 / g, the intragranular porosity is 42.11%. The filter material is particles with a diameter of 1 to 3 cm. The apparent density of the filter material is 0.59g / cm 3 . The porosity is 53.12%.

[0022] In addition, the present invention also discloses the method for preparing the porous phosphorus removal filter material based on diatomite and silica, comprising the following steps:

[0023] A) pulverizing diatomaceous earth and silica;

[0024] B) Mix diatomite powder, silica powder, cement, lime, gypsum and aluminum powder evenly according to the proportion, add water and stir and pour into the mold;

[0025] C) After demoulding, it is naturally cured for 5 days at normal temperature; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com