Method for preparing high emulsibility wheat mucedin

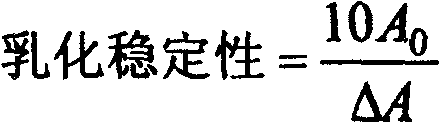

A wheat gluten protein and emulsifying technology, applied in vegetable protein processing and other directions, can solve the problems of large amount of modifying reagent, high production cost, expensive acetylation reagent, etc., improve emulsifying ability and emulsifying stability, reduce surface Tension, the effect of increasing electronegativity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take by weighing 50g raw material wheat gluten protein, with 0.1mol / L H 2 SO 4 The solution is configured as a suspension with a mass fraction of 5%, heat-preserved and stirred at 80°C for 1 hour, cooled to 55°C, adjusted to 8.5 with 2mol / L NaOH, and added with 2.5g of sodium tripolyphosphate. During the reaction, use the same alkali The pH value of the solution to control the phosphorylation reaction is 8.5, the phosphorylation reaction time is 1h, and 1mol / L H 2 SO 4 The solution is neutralized to neutral, washed, dehydrated and dried to obtain the product.

Embodiment 2

[0028] Take by weighing 50g raw material wheat gluten protein, with 0.3mol / L H 2 SO 4 The solution is configured as a suspension with a mass fraction of 8%, heat-preserved and stirred at 70°C for 1.5h, cooled to 30°C, adjusted to pH 8.5 with 2mol / L KOH, added 10g of sodium tripolyphosphate, and used the same base during the reaction The pH value of the solution control phosphorylation reaction is 8.5, the phosphorylation reaction time is 1.5h, 1mol / L H 2 SO 4 The solution is neutralized to neutral, washed, dehydrated and dried to obtain the product.

Embodiment 3

[0030] Weigh 50g of raw wheat gluten, prepare a suspension with a mass fraction of 3% with 0.5mol / L HCl solution, heat and stir at 90°C for 0.5h, cool to 45°C, and add 2mol / L Na 2 CO 3 Adjust the pH value of the solution to 8.5, add 4.0g sodium tripolyphosphate, use the same alkali solution to control the pH value of the phosphorylation reaction to 8.5 during the reaction, the phosphorylation reaction time is 2h, neutralize to neutral with 1mol / L HCl solution, wash , dehydrated and dried to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com