Egg custard with elastic and crisp taste and production process thereof

A technology of custard and taste, applied in the field of food processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

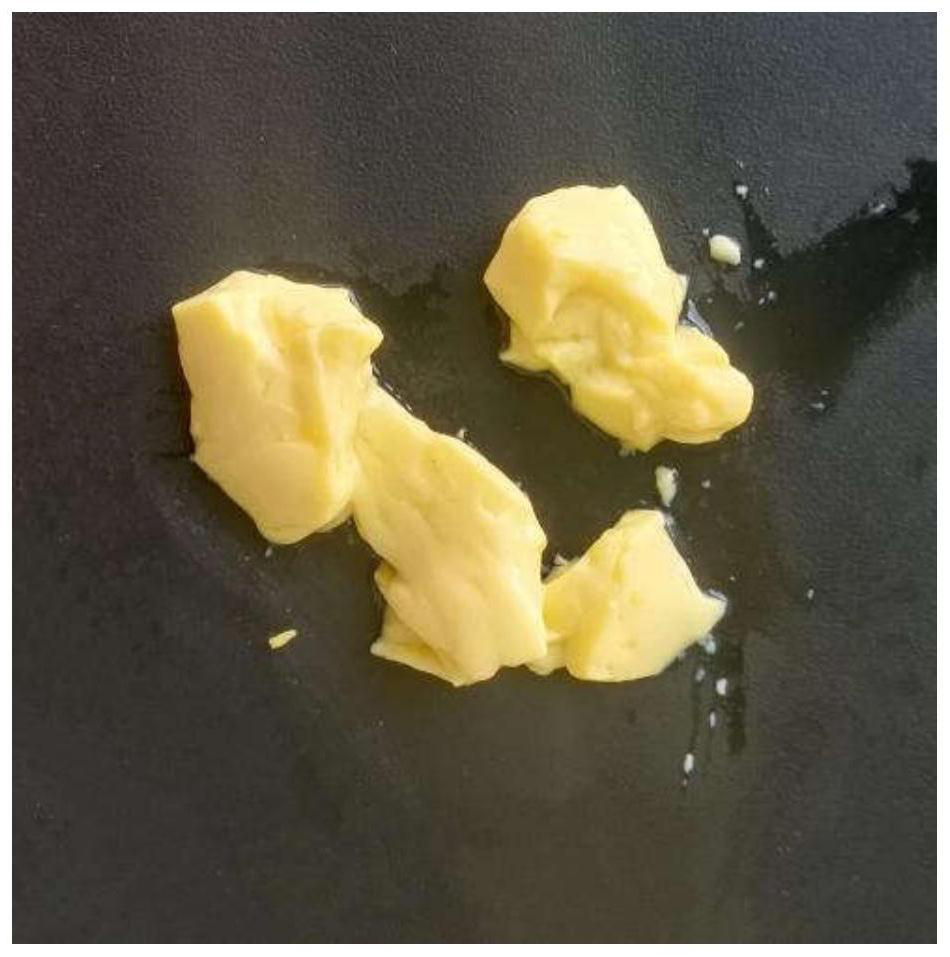

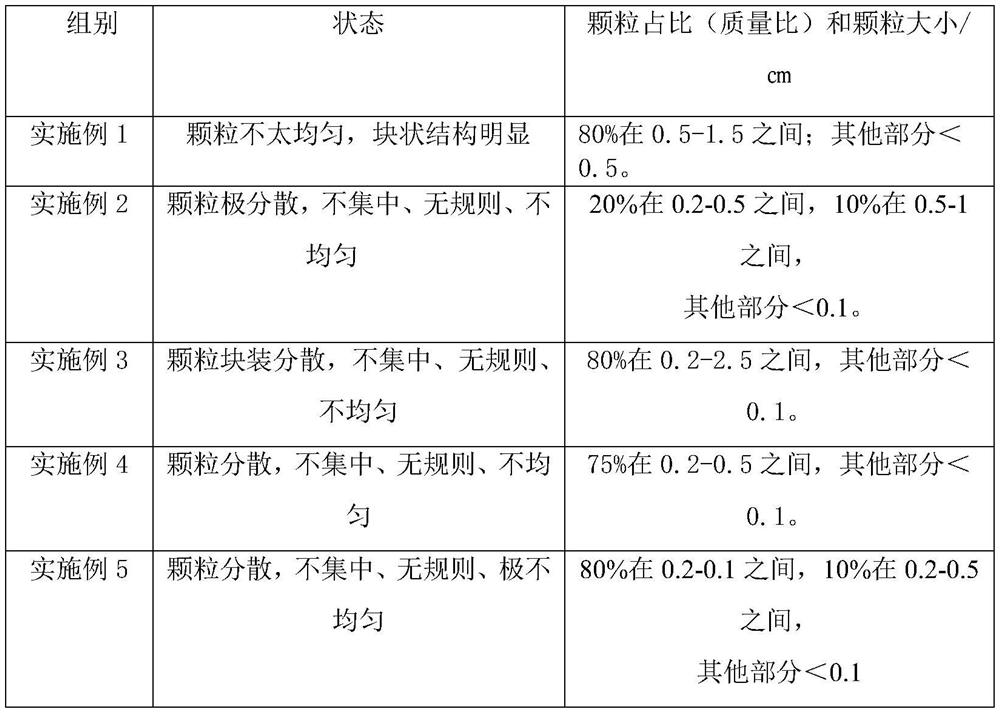

Image

Examples

preparation example Construction

[0035] A kind of preparation method of egg custard with crispy mouthfeel, described method comprises the following steps:

[0036] S1: Using fresh eggs as raw materials, obtain whole egg liquid, disperse and stir well, and then pasteurize;

[0037] S2: the obtained product is subjected to gradient cooling and then stored;

[0038] S3: After the egg liquid processed by the above process is thawed, water is added, and after mixing, it is placed in a steamer for steaming to obtain an egg custard with a crispy texture.

[0039] Preferably, in the method, before evenly dispersing, the whole egg liquid is also filtered, and the filtering mesh number is 30-60 mesh.

[0040] Preferably, in the step S1, the speed of dispersing and stirring is 100-500 rpm.

[0041] Preferably, in the step S1, the pasteurization conditions are: a sterilization temperature of 55-65° C. and a time of 3-10 minutes.

[0042] Preferably, in the step S2, the gradient cooling conditions are: 0-4°C for 2-4h, ...

Embodiment 1

[0052] A kind of preparation method of egg custard with crispy mouthfeel, described method comprises the following steps:

[0053] S1: Using fresh eggs as raw materials, obtain whole egg liquid, disperse and stir well, and then pasteurize;

[0054] S2: the obtained product is subjected to gradient cooling and then stored;

[0055] S3: After the egg liquid processed by the above process is thawed, water is added, and after mixing, it is placed in a steamer for steaming to obtain an egg custard with a crispy texture.

[0056] Among them: the speed of dispersing and stirring is 300rpm,

[0057] Pasteurization: sterilization temperature 60℃, time 8min;

[0058] In step S2, the obtained product is subjected to gradient cooling: refrigerate at 4°C for 3h, store at -10°C for 2h, cool to -12°C for 15h, and freeze at -18°C for 24h;

[0059] In step S3, the frozen egg liquid is thawed and mixed evenly at a ratio of egg liquid: water = 1:2.5, and after the water is boiled, it is put int...

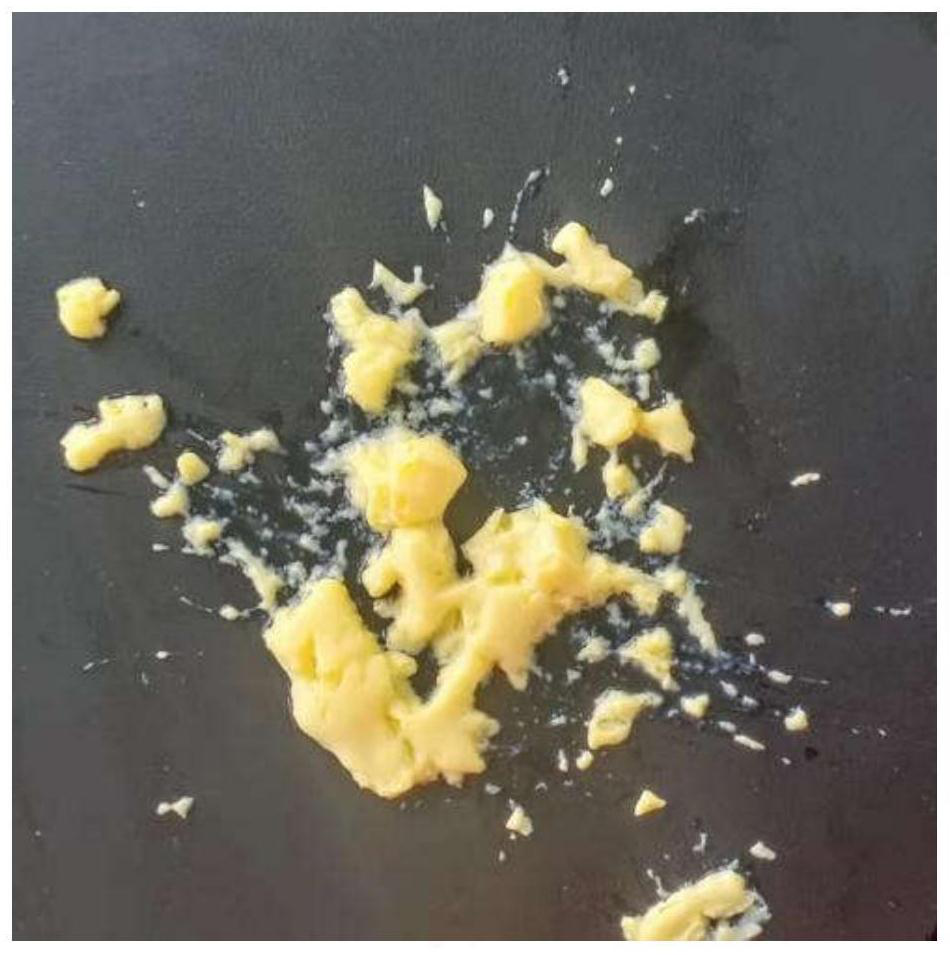

Embodiment 2

[0062] Example 2 (based on Example 1, the difference lies in the temperature reduction conditions)

[0063] The difference lies in the step 2 gradient cooling in the method:

[0064] Gradient cooling conditions: Gradient cooling of the obtained product: -10°C for 2h, -18°C for 24h cryopreservation;

[0065] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com