New-generation full-element chelated-state food-grade liquid bacterial fertilizer and preparation method thereof

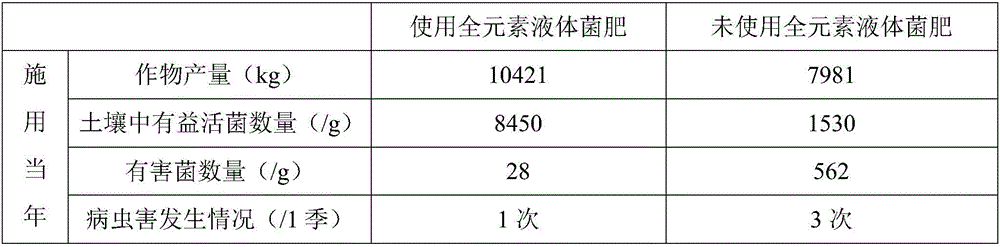

A technology of liquid bacteria and chelated state, which is applied in the preparation of liquid fertilizers, organic fertilizers, and nitrogen fertilizers. It can solve the problems of low trace element content, unguaranteed yield, and unstable properties, so as to achieve sufficient content, maintain yield, and ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

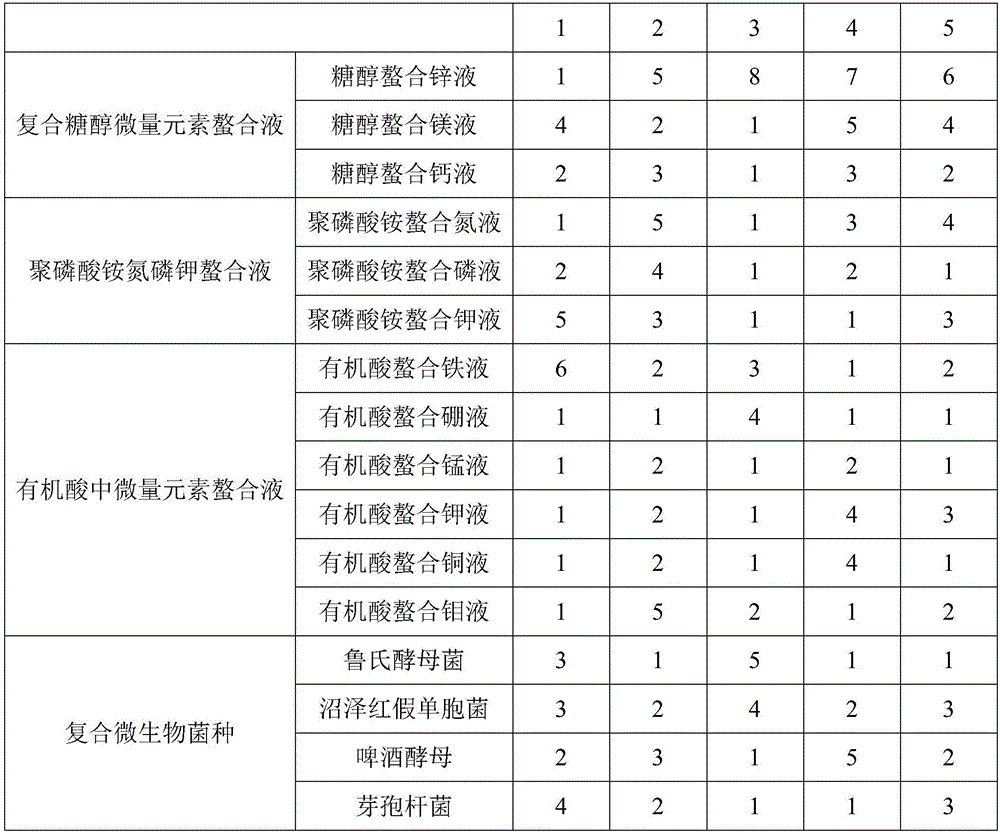

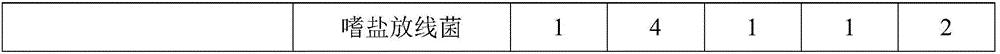

Examples

Embodiment

[0062] The new-generation full-element chelated state food-grade liquid bacterial fertilizer of the present embodiment is prepared according to the following steps:

[0063] 1) Clean the fermentation tank, check the tank body for electrical leakage and turn on the power to start a trial run to ensure smooth flow of water and normal operation of all components.

[0064] 2) Add water and molasses in the fermenter, and put the bran in a stainless steel box and hang it on the tank wall.

[0065] 3) Close the manhole cover, turn on the stirring system and the heating system, and pay attention to keep 1 / 2 of the carbon dioxide exhaust port and the jacket exhaust port open.

[0066] 4) When the temperature of the jacket water reaches 90°C or the temperature in the tank reaches 85°C, turn off the stirring system and the heating system, and start the sealed high-temperature sterilization.

[0067] 5) After 30 minutes, start to turn on the stirring system and add water to cool down, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com