Method for recovering metallic copper in mud by using microorganism and special device

A technology of microorganisms and metal copper, applied in the field of metal copper, can solve the problems of polluted soil, surface and groundwater sources, high treatment costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

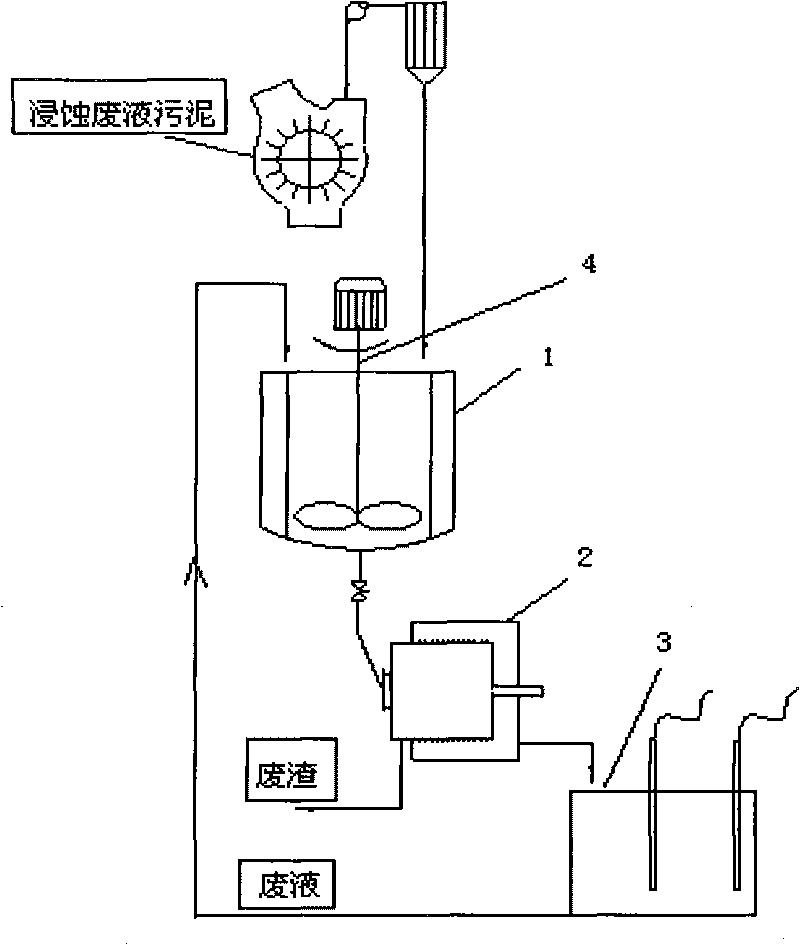

Method used

Image

Examples

Embodiment 1

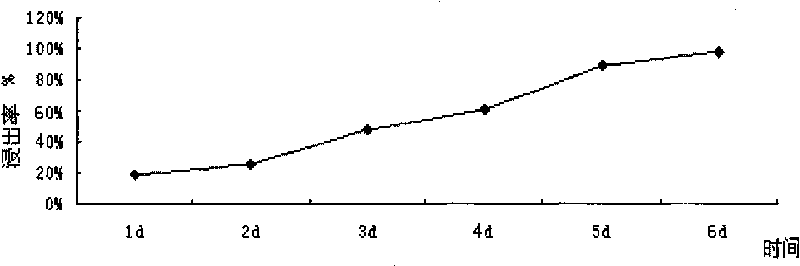

[0020] Experiment of leaching Cu in the sludge discharged from PCB cleaning wastewater treatment by T.f bacteria at room temperature

[0021] 1.1 Experimental design

[0022] The liquid culture medium of T.f bacterium is 9K medium composition (g / L): (NH 4 ) 2 SO 4 3,K 2 HPO 4 0.5, MgSO 4 ·7H 2 O 0.5, KCl 0.1, Ca(NO 3 ) 2 0.01, ferrous sulfate 40, adjust the pH to 3. Add 40L of the above culture medium into the reactor, and add 4kg of sludge (the Cu content is 11g·kg -1 ). Inoculate 2L of acclimatized T.f(B) bacterial solution (by measuring the turbidity on a spectrophotometer, the control strain density is about 5×10 8 unit / ml), turn on the heater, and the stirrer controls the stirring speed to 200rpm / min.

[0023] The total culture time was 6 days (days), and samples were collected every day to determine the Cu content in the leaching solution.

[0024] 1.2 Determination method

[0025] First use aqua regia (HCl:HNO 3 =3:1) Digest the sludge and leaching solut...

Embodiment 2

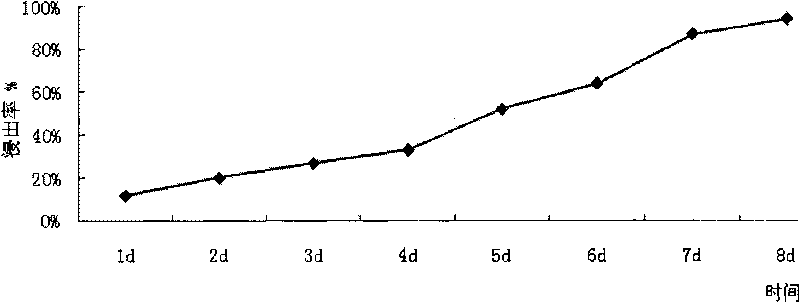

[0030] T.t bacteria leaching Cu in sludge discharged after electroplating cleaning wastewater treatment at room temperature

[0031] 2.1 Experimental design

[0032] The composition of T.t bacteria culture medium is (g / L): (NH 4 ) 2 SO 4 0.5,K 2 HPO 4 4. MgSO 4 ·7H 2 O 0.5, CaCl 0.3, sulfur powder 5g, water 1000ml, adjust the pH to 2.5. 40L of the above-mentioned culture medium was added into the reactor, and 4kg of sludge (with a Cu content of 23g·kg -1 ). Inoculate 2L of domesticated T.t bacteria solution (by measuring the turbidity on a spectrophotometer, the control strain density is about 9×10 7 unit / ml), turn on the heater and aerator, and the stirrer controls the stirring speed to 400rpm / min.

[0033] The total incubation time was 9 days, and samples were collected every day to determine the Cu content in the leachate.

[0034] 2.2 Determination method

[0035] First use aqua regia (HCl:HNO 3 =3:1) Digest the sludge and leaching solution in a 50ml colorim...

Embodiment example 3

[0040] Combined leaching of Cu from sludge discharged from PCB industry by T.f and T.t bacteria at room temperature

[0041] 3.1 Experimental design

[0042] The composition of the medium is (g / L): (NH 4 ) 2 SO 4 3,K 2 HPO 4 0.5, MgSO 4 ·7H 2 O0.5, KCl 0.1, Ca(NO 3 ) 2 0.01, ferrous sulfate 22g, sulfur powder 2g, water 1000ml, adjust the pH to 2.5. Add 300L of the above culture medium into the reactor, and add 30kg of sludge (the Cu content is 18g·kg -1 ). Inoculate 15L of domesticated T.f and T.t bacteria liquid (by measuring the turbidity on the spectrophotometer, the control strain density is about 5×10 8 unit / ml), turn on the heater and aerator, and the stirrer controls the stirring speed to 400rpm / min.

[0043] The total incubation time was 5 days, and samples were collected every day to determine the Cu content in the leachate.

[0044] 3.2 Determination method

[0045] First use aqua regia (HCl:HNO 3 =3:1) Digest the sludge and leaching solution in a 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com