Viscosity reduction type polycarboxylate superplasticizer and preparation method thereof

A viscous polycarboxylate and water reducing agent technology, applied in the field of concrete admixtures, can solve the problems of reducing polycarboxylate coating and adsorption capacity, low hydrophilicity and strong rigid side chain, high viscosity, etc., to achieve suitable Large-scale production, reduced coating effect, reduced bridging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

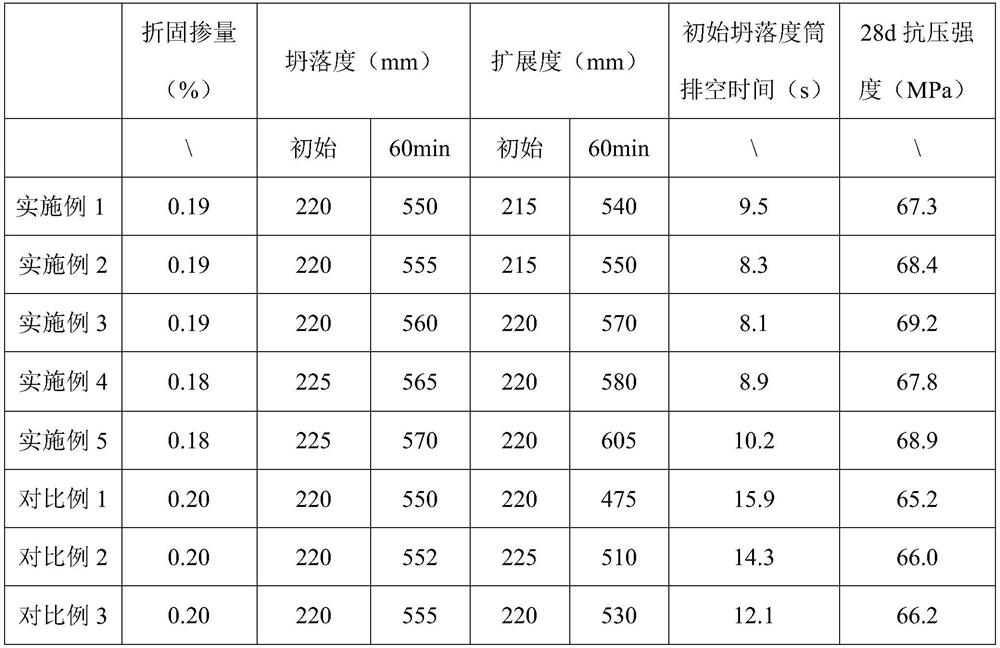

Examples

Embodiment 1

[0031] This embodiment provides a viscosity-reducing polycarboxylate water reducer and its preparation method, specifically:

[0032] S1, the unsaturated vinyl ether (R 1 is methylene, R 2 for C 30 alkylene) and deionized water into the reactor for stirring and dissolving, while raising the temperature of the reactor to 30°C;

[0033] S2. Dissolving acrylic acid, vinylphosphonic acid and 2-methyl-2-acrylic acid-2-sulfoethyl ester in deionized water to obtain liquid A, dissolving ascorbic acid and thioglycolic acid in deionized water to obtain liquid B;

[0034] S3, add hydrogen peroxide to the reactor described in step S1, and start dropping A liquid and B liquid simultaneously after 10min, and the time of adding A liquid and B liquid is 2h, keep warm for 1h after dropping ;

[0035] S4. Add NaOH solution to the reactor to adjust the pH to 6, and add water to adjust the solid content to 40%, to obtain the viscosity-reducing polycarboxylate superplasticizer.

[0036] The m...

Embodiment 2

[0038] The difference between this embodiment and embodiment 1 is: The mass ratio is 100:4:4:4:1:0.3:1.

Embodiment 3

[0040] The difference between this embodiment and embodiment 1 is: The mass ratio is 100:6:6:6:1:0.3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com