Method for improving morphology of capacitor holes

A technology of capacitance and morphology, which is applied in the direction of capacitors, circuits, electrical components, etc., can solve problems affecting the performance of memory, and achieve the effect of reducing the difficulty of lithography and etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

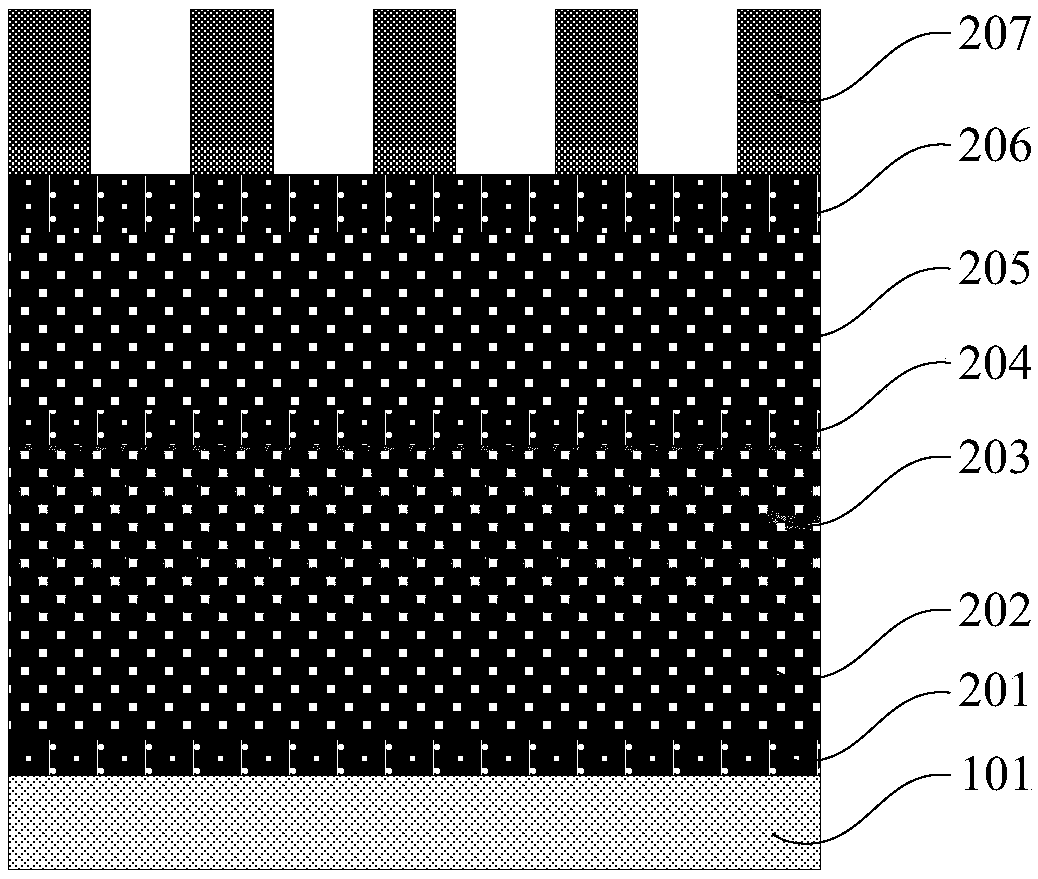

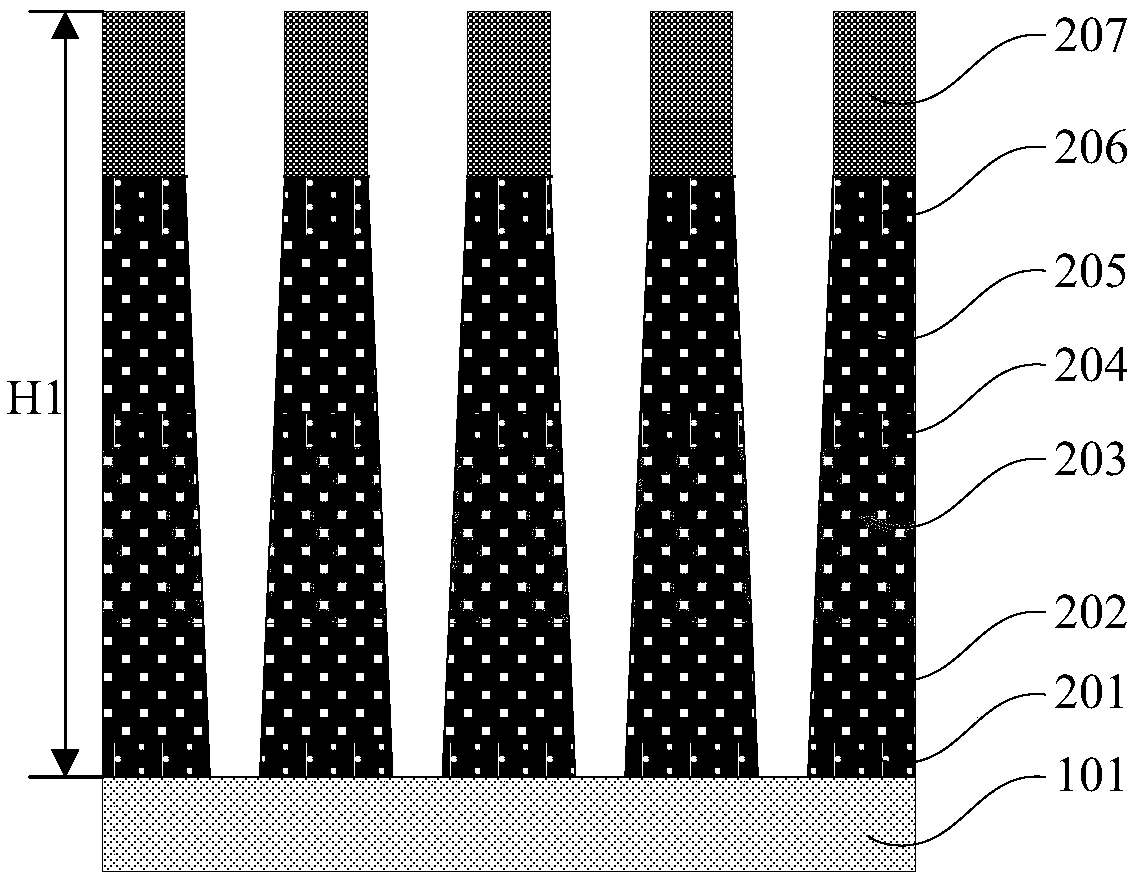

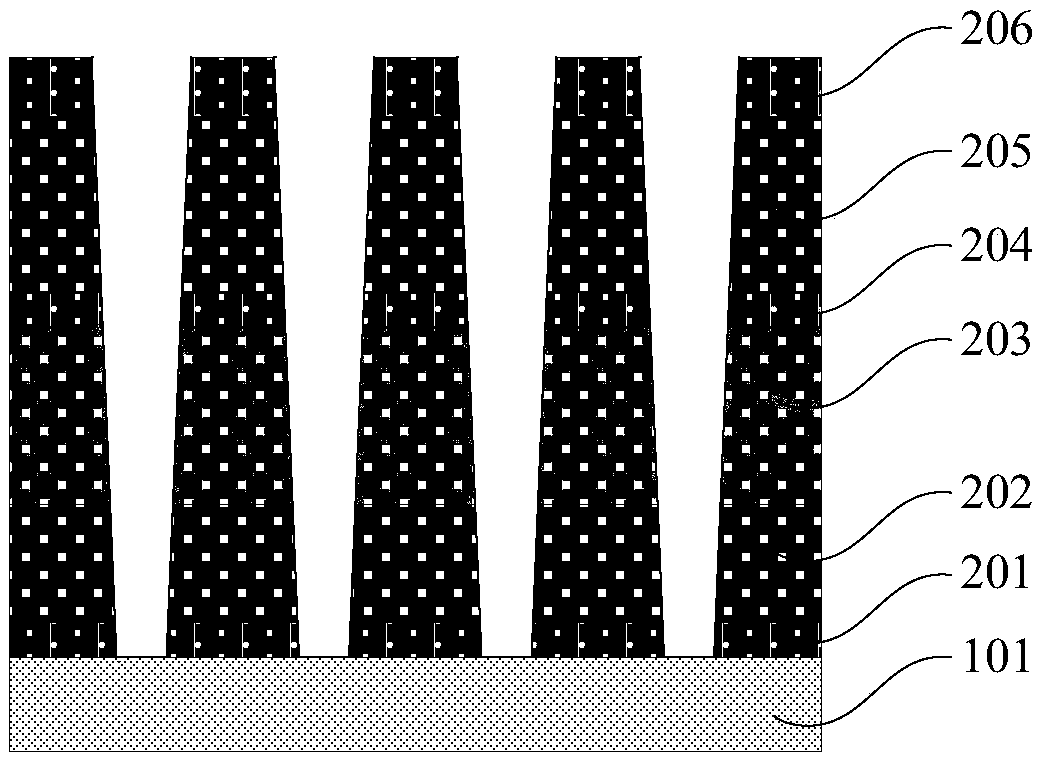

[0078] This embodiment provides a method for improving the morphology of capacitor holes, such as Figure 4 As shown, the method for improving the capacitor hole morphology in this embodiment at least includes the following steps:

[0079] S01, providing a semiconductor substrate, on which an etch stop layer, at least one capacitive sacrificial oxide layer, a second capacitive sacrificial oxide layer, a first capacitive supporting layer, and a third capacitive sacrificial oxide layer are sequentially deposited;

[0080] S02, form a patterned hard mask (406) on the surface of the third capacitor sacrificial layer, and pattern the third capacitor sacrificial oxide layer until the first capacitor support layer stops, and The upper opening of the capacitor hole is formed in the oxide layer;

[0081] S03, depositing a barrier layer on the sidewall and top of the upper opening of the capacitor hole;

[0082] S04, etching the first capacitor supporting layer, at least one capacitor...

Embodiment 2

[0108] This embodiment also provides a method for improving the morphology of capacitor holes, and its similarities with Embodiment 1 will not be repeated here.

[0109] The differences between this embodiment and Embodiment 1 are:

[0110] In this embodiment, when the above step S03 is performed, the barrier layer 407 is deposited on the sidewall, top and bottom of the upper opening of the capacitor hole formed, but the barrier layer at the bottom of the upper opening of the capacitor hole is relatively small, for example, in this embodiment In a preferred embodiment, the bottom of the upper opening of the capacitor hole is only covered with a very thin layer of barrier film. In this way, when forming the lower opening of the capacitor hole by subsequent etching, a step of etching the barrier layer at the bottom of the lower opening of the capacitor hole is included.

[0111] Although in this embodiment, the thickness of the barrier layer at the bottom of the upper opening o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com