Preparation method of negative electrode slurry capable of reducing expansion of lithium ion battery

A lithium-ion battery and negative electrode slurry technology, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of easy subsidence of slurry, achieve the effects of reducing bridging phenomenon, improving capacity and safety, and inhibiting subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

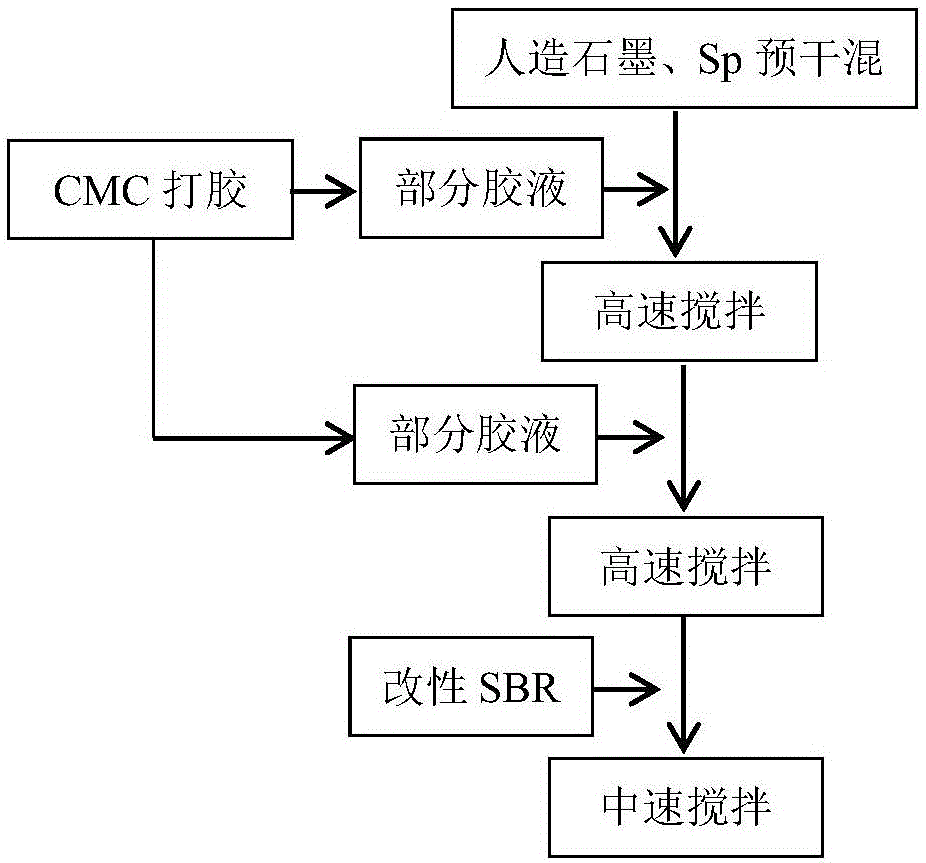

[0025] The negative electrode active material is made of isotropic pure artificial graphite through secondary granulation, the binder is modified SBR binder, the conductive agent is conductive carbon black Sp, the glue is CMC aqueous solution, and the modified SBR binder is in The mass percent content in the negative electrode slurry is 3%.

[0026] Negative electrode slurry preparation comprises the following steps: (1) pre-dry mixing artificial graphite and conductive carbon black Sp; (2) sodium carboxymethylcellulose is dissolved in deionized water to obtain a CMC glue solution with a concentration of 1.0%; (3) ) Add 10% of the CMC glue prepared in (2) into the mixture, set the rotation speed at 4000rpm, the revolution speed at 64rpm, and stir for 0.5h; (4) add the remaining 90% of the CMC glue, and set the rotation speed at 4000rpm , revolution speed 64rpm, stirring for 3h; (5) Add modified SBR binder, set rotation speed 2000rpm, revolution speed 40rpm, stir for 0.3h; (6) ...

Embodiment 2

[0040] In this embodiment, the negative electrode active material is made of isotropic pure artificial graphite through secondary granulation, the binder is modified SBR, the mass percentage content of modified SBR in the negative electrode slurry is 1%, and the conductive agent is conductive carbon. Black, glue solution is CMC aqueous solution.

[0041]The negative electrode slurry preparation comprises the following steps: (1) pre-dry mixing artificial graphite and conductive carbon black; (2) dissolving sodium carboxymethyl cellulose in deionized water to obtain a CMC glue solution with a concentration of 2.0%; (3) Add 35% of the CMC glue prepared in (2) into the mixture, set the rotation speed at 4000rpm, the revolution speed at 64rpm, and stir for 1h; (4) add the remaining 65% of the glue, set the rotation speed at 2500rpm, and the revolution speed 40rpm, stir for 1h; (5) Add hydroxylated SBR, stir at a medium speed, set the rotation speed at 2000rpm, revolution speed at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com