Solder paste reflow soldering and glue fixing process

A technology of reflow soldering and solder paste, which is applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve the problems of no uniform specification of process steps, lower yield rate of PCB board, and easy oxidation of solder paste film, etc., to achieve weakening Intermittent wetting phenomenon, reducing the cracking of the original, reducing the effect of bridging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

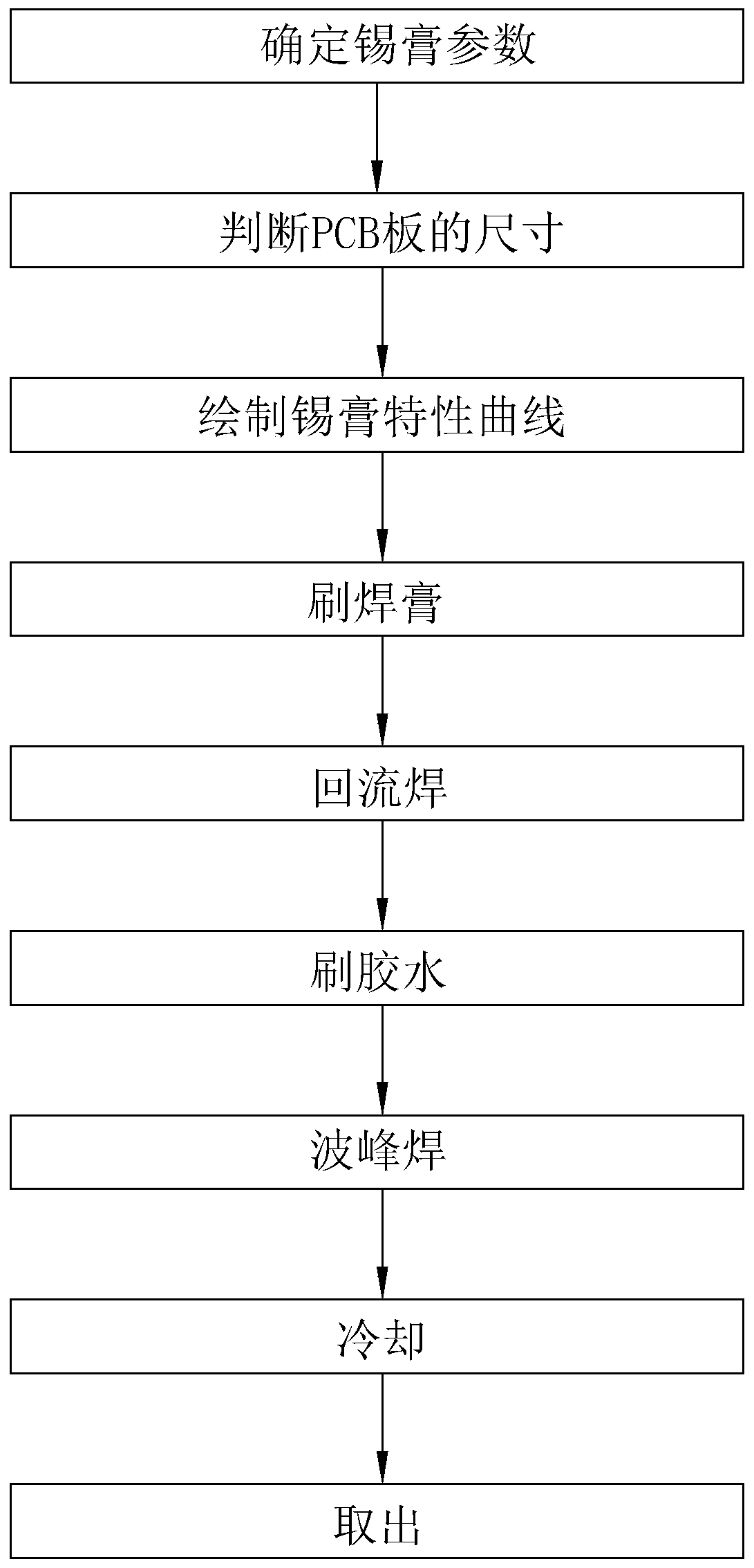

[0043] Embodiment: a kind of solder paste reflow soldering and glue fixation process, refer to figure 1 , including the following steps:

[0044] 1. Determine the parameters of the solder paste, including: the initial temperature of the preheating zone, the range of the temperature rise slope; the temperature range and time range of the holding zone; the peak temperature range of the reflow zone, the range of the liquid phase state, the melting point of the solder paste, and the freezing point of the solder paste .

[0045] 2. Judging the size of the PCB board, including large board, medium board and small board; when it is a large board, the solder paste parameters take the upper limit value, and when it is a medium board and small board, the solder paste parameters take the upper and lower limits Median.

[0046]3. Draw the solder paste characteristic curve, and adjust the reflow oven according to the solder paste characteristic curve, so that the PCB production furnace te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com