Preparation method of high-vibration-compaction low-specific-surface-area lithium iron phosphate made by positive pole material

A low specific surface area, positive electrode material technology, applied in the direction of chemical instruments and methods, phosphorus compounds, battery electrodes, etc., can solve the problems of poor processing performance, low tap density, high specific surface area, etc., to achieve good electrochemical performance, vibration The effect of high density and low specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 5.1molLi 2 CO 3 , 10.0mol NH 4 h 2 PO 4 , 5.0molFe 2 o 3 Add to the mixing tank, add 850ml deionized water, add 0.05molMnO while stirring 2 , 0.05molTiO 2 , 110g of glucose and 25g of polyacrylic acid, stirred and mixed evenly, transferred to a ball mill for ball milling for 2-3 hours, and the obtained slurry was sprayed and granulated to form a powder. powder in N 2 Sintering in a rotary furnace at 450°C for 5h in the atmosphere. After cooling, put it into a mixing tank, add 400g of water-soluble starch, 25g of polyacrylic acid and 850ml of deionized water, stir and mix evenly, transfer to a ball mill for 2~3 hours, and spray the obtained slurry to form a powder. The powder was added into the rotary kiln, under N 2 Sinter at 650°C for 10 hours in the atmosphere, then heat up to 800°C for 20 hours, cool, sieve, classify and obtain the product.

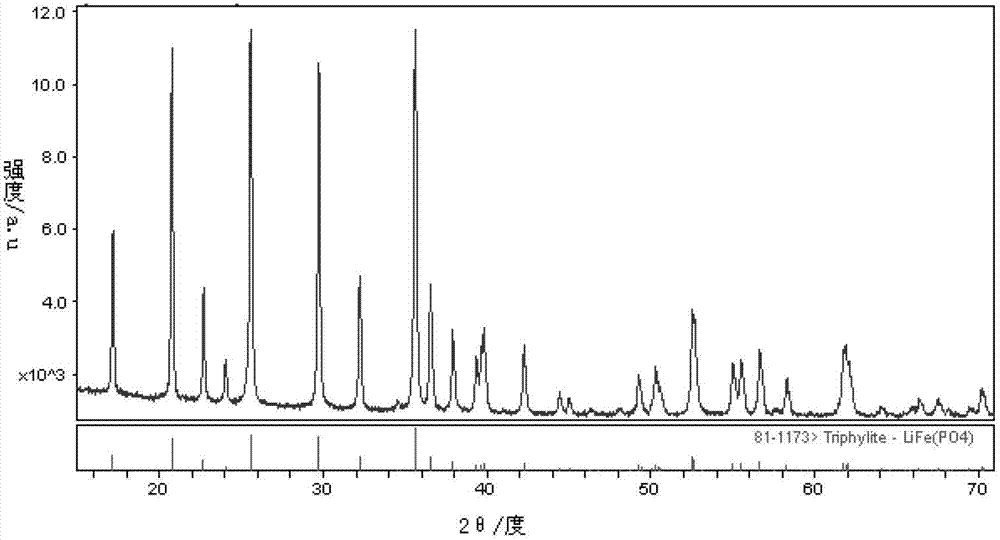

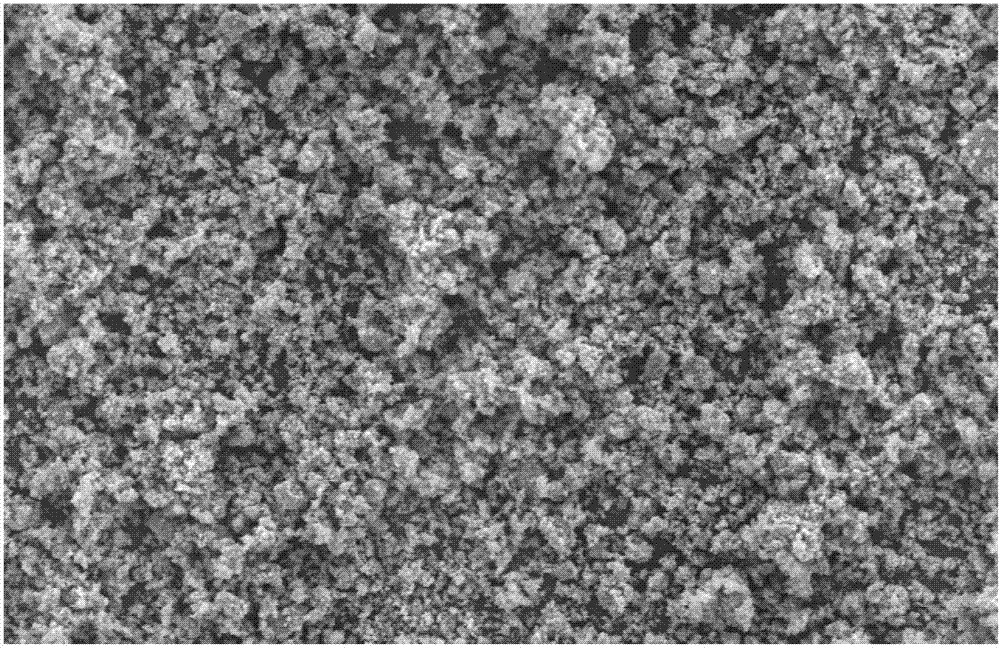

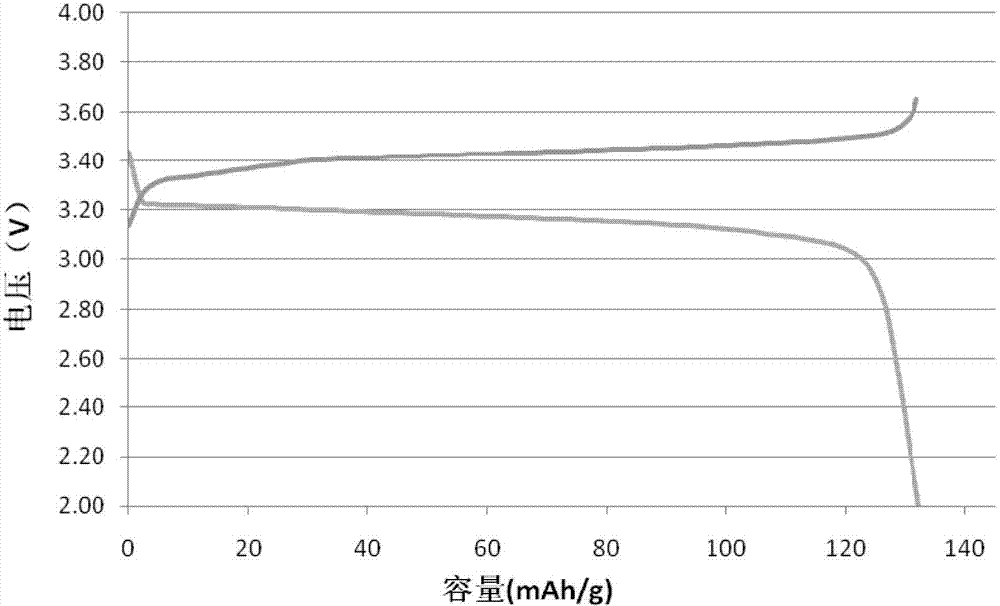

[0024] The tap density of the resulting product is 1.80g / cm -3 , the specific surface area is 6.0m 2 / g, the carb...

Embodiment 2

[0028] 5.1molLi 2 CO 3 , 10.0mol FePO 4 Add to the mixing tank, add 900ml deionized water, add 0.05molMnO while stirring 2 , 0.05molMgO, 120g sucrose and 25g polyacrylic acid, stirred and mixed evenly, transferred to a ball mill for ball milling for 2-3 hours, and the obtained slurry was sprayed and granulated to form a powder. powder in N 2 Sintering in a rotary furnace at 450°C for 9h in the atmosphere. After cooling, transfer to a stirring tank, add 400g chitosan, 25g polyethylene glycol and 860ml deionized water, stir and mix evenly, transfer to a ball mill for ball milling for 2-3 hours, and spray the obtained slurry to form a powder. The powder was added into the rotary kiln, under N 2 Sinter at 650°C for 10 hours in the atmosphere, then heat up to 800°C for 20 hours, cool, sieve, classify and obtain the product.

[0029] The tap density of the resulting product is 1.76g / cm -3 , the specific surface area is 6.2m 2 / g, the carbon content is 1.70%.

[0030] The ma...

Embodiment 3

[0032] 5.1molLi 2 CO 3 , 10.0mol FePO 4 Add to the mixing tank, add 900ml deionized water, add 0.03molMnO while stirring 2 , 0.03molV 2 o 5 , 0.04molMgO, 120g fructose and 25g polyethylene glycol, stirred and mixed evenly, transferred to a ball mill for ball milling for 2-3 hours, and the obtained slurry was sprayed and granulated to form a powder. powder in N 2 Sintering in a rotary furnace at 480°C for 8h in the atmosphere. After cooling, transfer to a stirring tank, add 400g chitosan, 25g polyethylene glycol and 860ml deionized water, stir and mix evenly, transfer to a ball mill for ball milling for 2-3 hours, and spray the obtained slurry to form a powder. The powder was added into the rotary kiln, under N 2 Sinter at 600°C for 15 hours in the atmosphere, then heat up to 820°C for 20 hours, cool, sieve, classify and obtain the product.

[0033] The tap density of the resulting product is 1.70g / cm -3 , the specific surface area is 6.5m 2 g, the carbon content is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com