Material suitable for remanufacturing of 35CrMnSiA and 42CrMo cutting teeth and laser cladding method

A laser cladding and remanufacturing technology, applied in metal material coating process, coating and other directions, can solve the problem that Fe-based alloy powder can no longer meet the requirements of production and use, reduce particle bridging, solve toughness reduction, improve The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

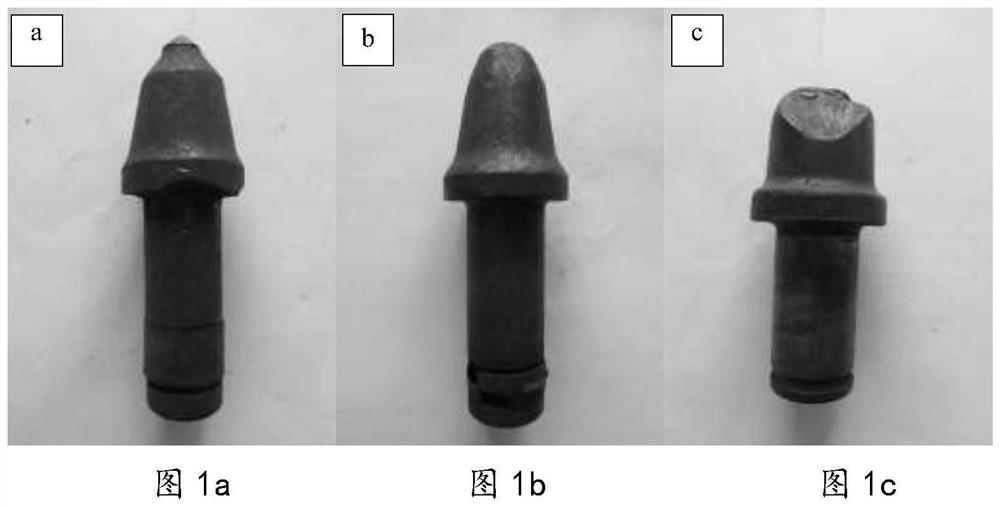

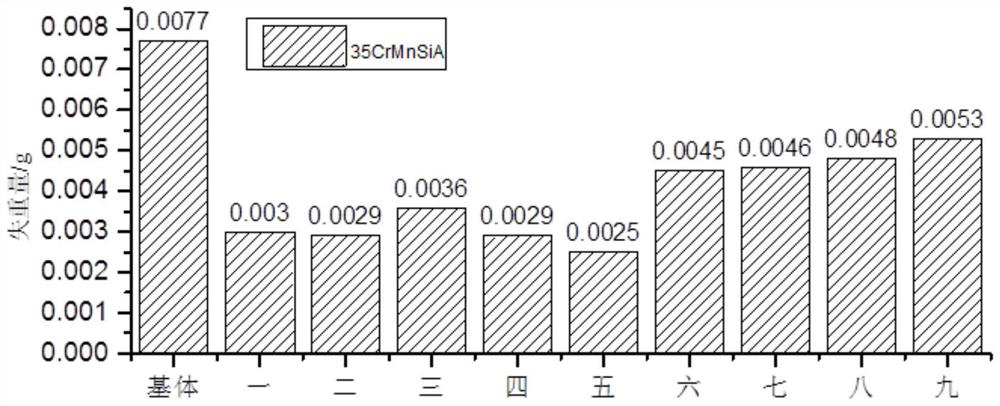

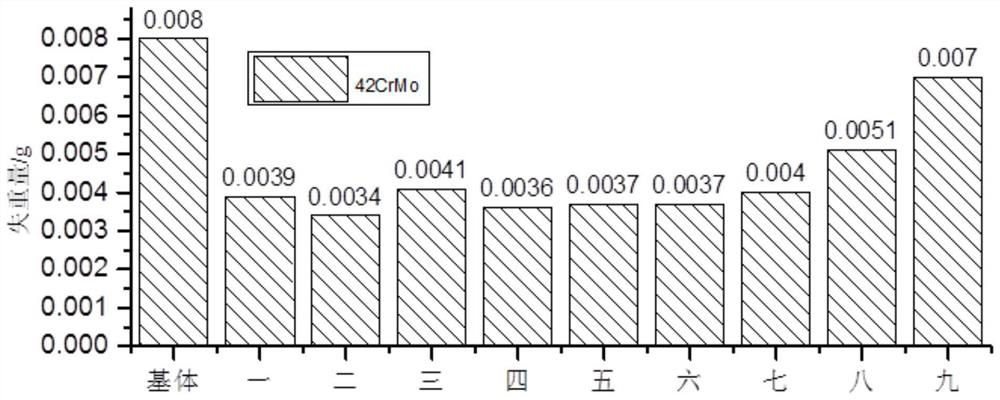

[0065] The first part is research on formula suitable for both 35CrMnSiA and 42CrMo pick remanufacturing materials

[0066] 1. Suitable for the preparation of 35CrMnSiA and 42CrMo pick remanufacturing materials

[0067] 1. Preparation of Fe-based alloy powder

[0068] Fe-based alloy powder has the advantages of low cost and good wear resistance after forming, and has good wettability with steel parts. Considering the working conditions of the pick, it needs to withstand sliding wear, impact wear and abrasive wear. Powder-based, in which high-melting carbide, nitride, boride and oxide ceramic particles are added, which can be used as a hard phase in the structure to improve wear resistance. According to the strengthening mechanism of steel, elements C, Cr, and Al are selected as strengthening elements, among which the solid solution strengthening effect of C is more obvious, and some compounds can be formed by C, Cr, and Al to play a role of dispersion strengthening. The down...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com