Apparatus and method for vertically-structured passive components

A technology of passive components and electronic devices, applied in the direction of electrical components, semiconductor devices, electric solid devices, etc., to achieve the effect of reducing bridging and/or insufficient soldering and reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

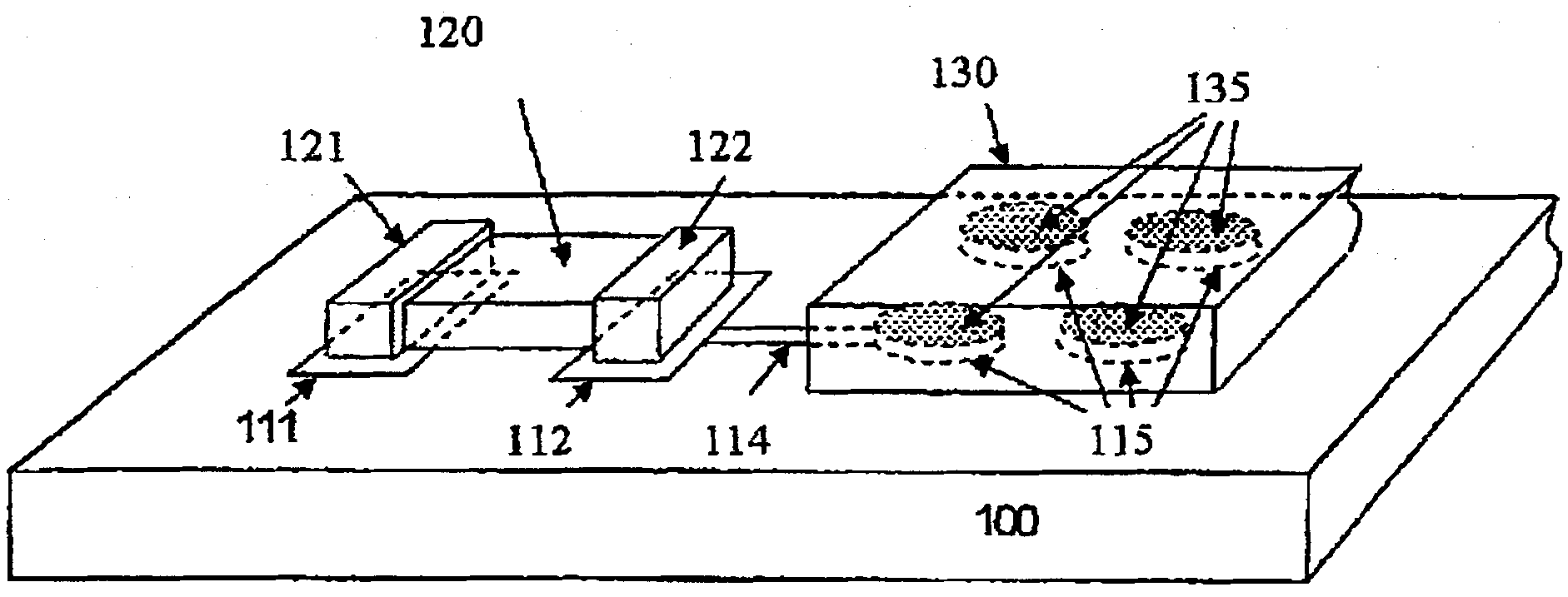

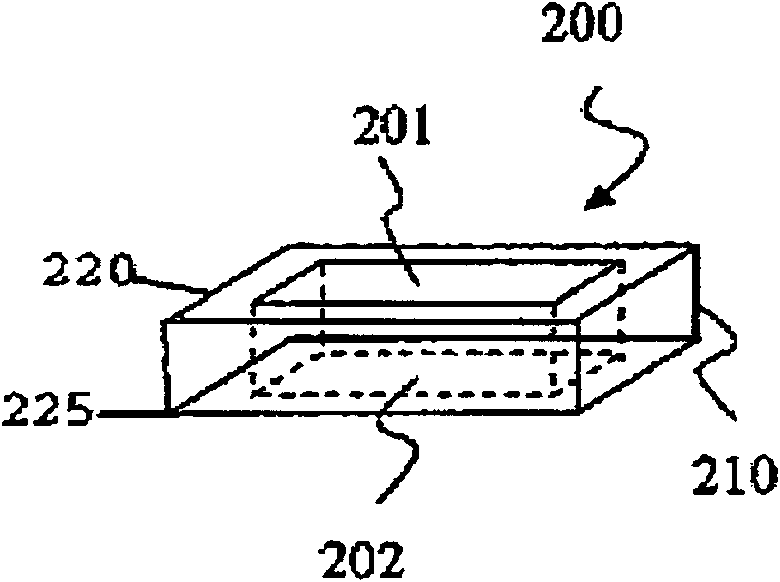

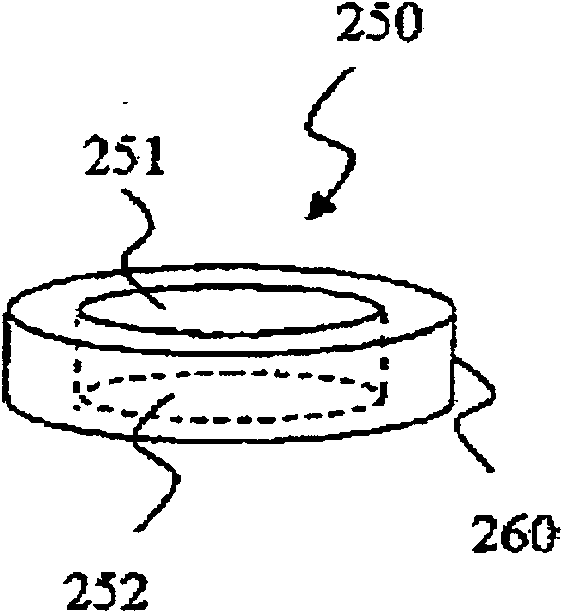

[0051] Preferred embodiments of the present invention will be described with reference to the various drawings, where like numbers refer to elements that are identical or functionally similar. Also in illustrations, the leftmost digit of each number corresponds to the illustration in which that number is first used.

[0052] "A specific embodiment" or "a specific embodiment" mentioned in the specification means that a feature, structure or characteristic described in relation to the specific embodiment is included in at least one specific embodiment of the present invention. The phrases "in a specific embodiment" or "a specific embodiment" appearing in different places in the specification do not necessarily refer to the same specific embodiment.

[0053] In addition, in the description, the selection of words is based on the principle of easy reading and description, and is not used to limit or restrict the object of the present invention. Therefore, the disclosure of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com