Woody electric wave absorber

A radio wave absorbing material, wood technology, applied in the direction of magnetic material, inorganic material magnetism, circuit, etc., can solve the problem of less degree of freedom, and achieve the effect of improving the degree of freedom of design and superior radio wave absorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

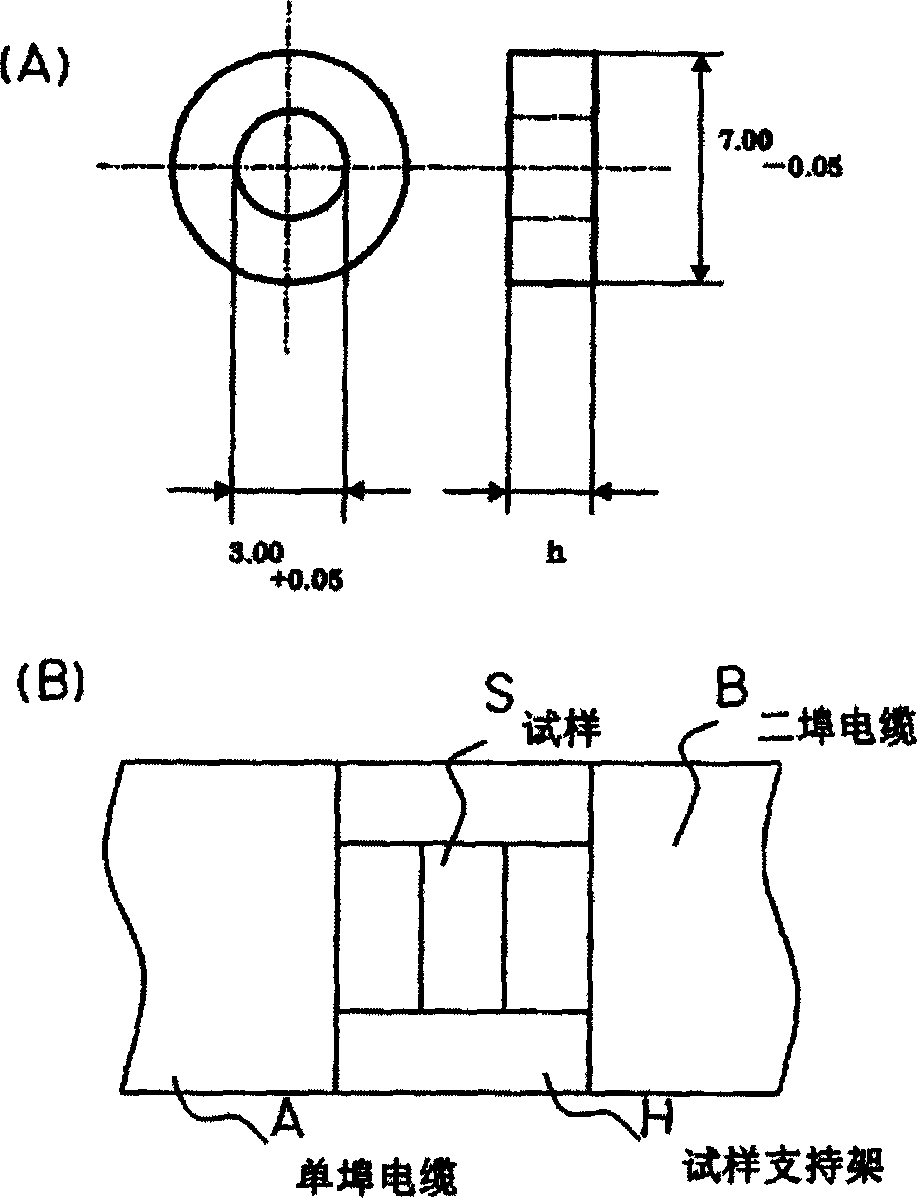

[0056] When the total volume content of ferrite powder and stainless steel powder Vs = 20vol%, the ratio (volume) of the two is the ratio shown in Table 2 and vinyl acetate resin latex adhesive (adhesive for woodworking) ) mixed and clamped on - two fiberboards with a thickness of 2.5mm (specific gravity 0.9g / cm 3 ) was allowed to dry for about 96 hours to prepare laminated magnetic wood samples. The thickness of the magnetic layer was 4.0 mm.

[0057]

[0058] stainless steel only

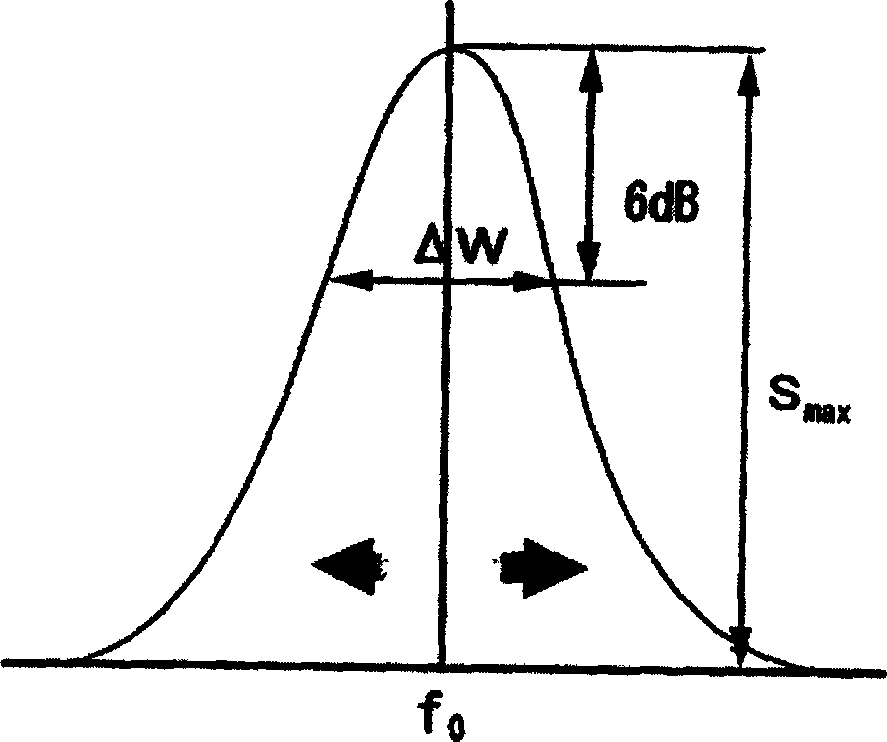

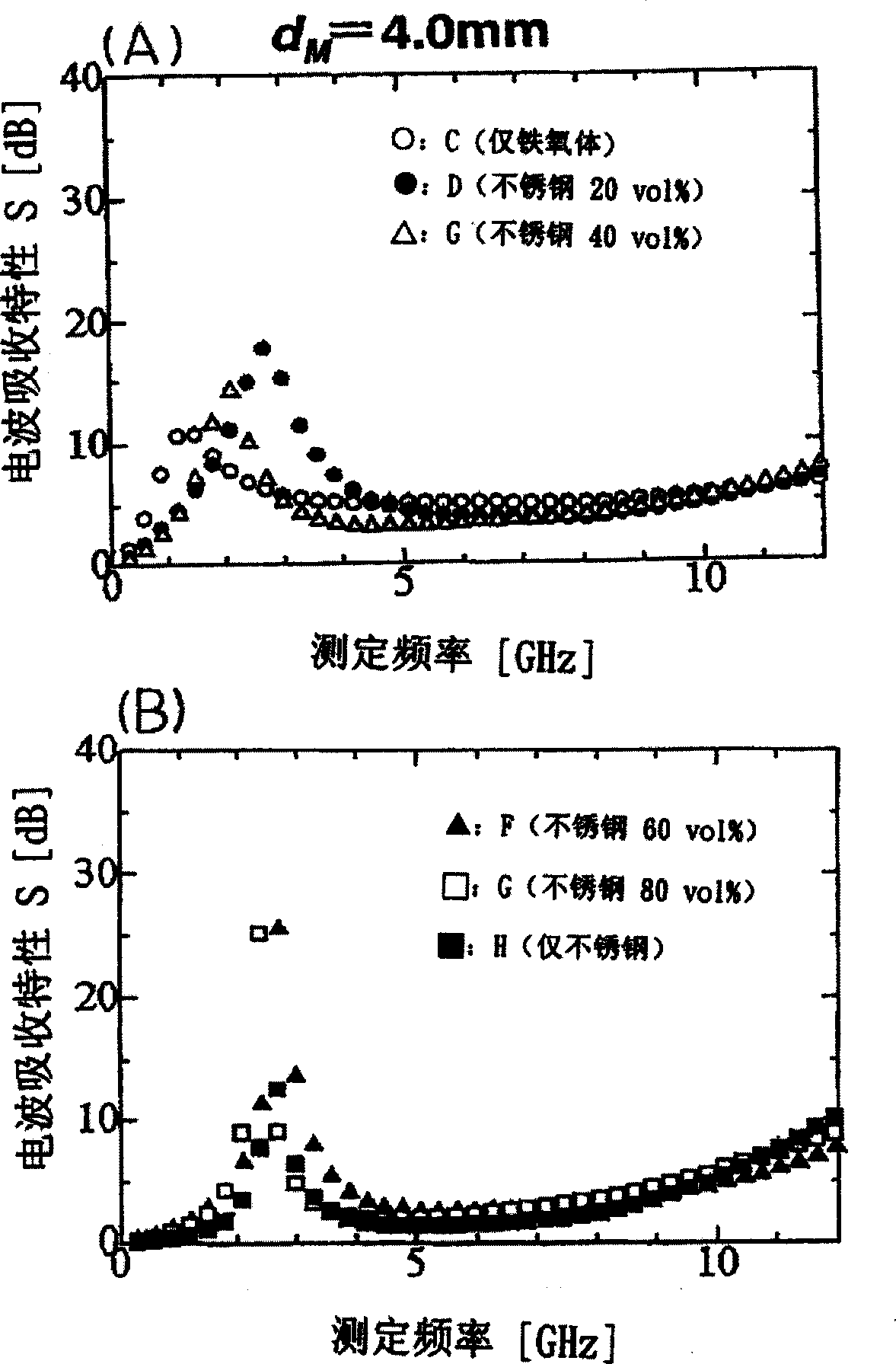

[0059] image 3 (A), (B) are the measurement results showing the radio wave absorption in the range of measurement frequency 0.05-12 GHz. Depend on image 3 , in the magnetic layer dm = 4.0mm, although the ferrite powder sample (20F) can obtain about 11dB of radio wave absorption near 1.5GHz, the ratio to stainless steel is 20vol% (20FS 14), 60vol% ( 20FS32), 80vol% (20FS41) samples can respectively obtain about 18dB, 26dB, 25dB of radio wave absorption in the vicinity of 2...

Embodiment 2

[0061] A laminated magnetic wood sample was prepared under the same conditions as in Example 1 except that the thickness of the magnetic layer was 1.0 mm. Figure 4 (A) and (B) show the measurement results of the radio wave absorption in the range of measurement frequency 0.05-12 GHz. For samples with only ferrite powder (20F) and stainless steel powder with a ratio of 40vol% (20FS23), radio wave absorption of 30dB and 25dB can be obtained at around 7GHz and 6GHz, respectively. The lower the internal ratio of the stainless steel powder, the higher the radio wave absorption tends to be. Also, as the internal ratio increases, the radio wave absorption capacity tends to decrease, and at the same time, the center frequency tends to shift to a lower frequency.

Embodiment 3

[0063] Except that the internal ratio (S:F) of ferrite powder and stainless steel powder is 2:3, and the thickness of the magnetic layer is respectively set to 0.5mm, 1.0mm, 1.5mm, 2.0mm, 4.0mm, the rest is the same as in Example 1 conditions to make laminated magnetic wood samples. Fig. 5 shows the measurement results of the radio wave absorption in the measurement frequency range of 0.05 to 12 GHz. When the thickness of the magnetic layer is 1.5mm, the maximum radio wave absorption of about 30dB can be obtained around 4.5GHz. It can be seen that as the thickness of the magnetic layer increases, the center frequency will shift to the low frequency band. In addition, when the internal ratio of the stainless steel powder is low, the thinner the magnet layer, the higher the radio wave absorption tends to be.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Center frequency | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com