Recording paper

A recording paper and paper substrate technology, applied in magnetic recording, data recording, recording information storage, etc., can solve problems such as outflow of printed matter and leakage of confidential information, and achieve the effect of inhibiting the appearance of wrinkles and inhibiting transfer failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

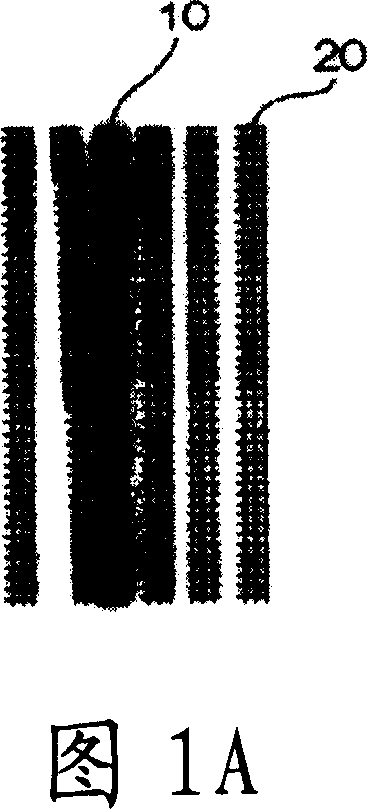

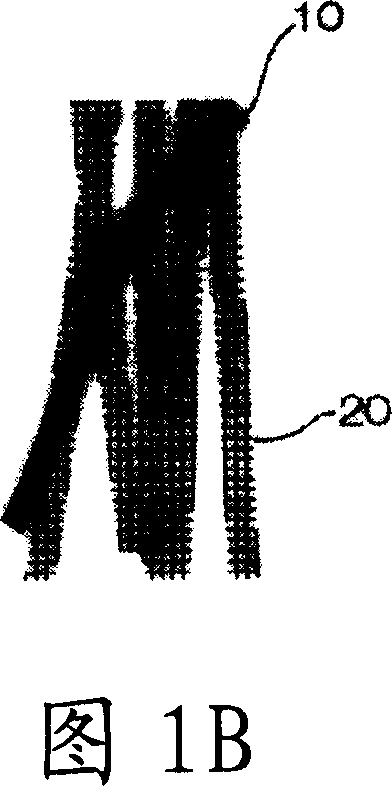

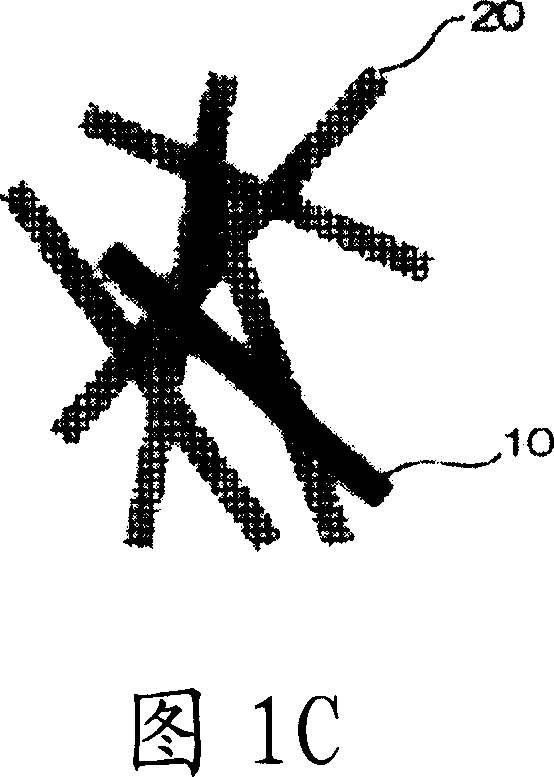

Method used

Image

Examples

Embodiment 1

[0103] 90 parts by mass of LBKP (bleached kraft pulp of broad-leaved tree) (freeness (CSF)=400ml), 10 parts by mass of NBKP (bleached kraft pulp of coniferous tree) (freeness (CSF)=450ml) and 15 parts by mass of magnetic fiber (composition : Fe-Co-Si, length 30 mm, diameter 30 μm) were mixed to provide pulp slurry, and 0.7 parts by mass of polyacrylamide resin (trade name: PS3874-20, Arakawa Chemical Industry Co., Ltd. manufactured by the company). The resulting mixture was diluted with white water to prepare a papermaking stock slurry having a pH of 5.8 and a solid matter concentration of 0.4%.

[0104] Using an oriented sheet former (Oriented Sheet Former) (trade name; manufactured by Kumagai Riki Kogyo Co., Ltd.), the speed of the papermaking network is 1200m / min, and the injection pressure of the raw material slurry is 0.5kg / cm 2 Next, the papermaking raw material slurry is made into paper. Using a square plate press (manufactured by Kumagai Riki Kogyo Co., Ltd.), at 5kg...

Embodiment 2

[0106] 90 parts by mass of LBKP (freeness (CSF) = 400 ml) and 10 parts by mass of NBKP (freeness (CSF) = 450 ml) were mixed to give a pulp slurry, and 0.7 parts by mass of polypropylene used as a paper strengthening agent was added thereto Amide resin (trade name: PS3874-20, manufactured by Arakawa Chemical Industry Co., Ltd.). The resulting mixture was diluted with white water to prepare a first papermaking stock slurry having a pH of 5.8 and a solid matter concentration of 0.4%.

[0107] Using an oriented sheet former (trade name; manufactured by Kumagai Riki Kogyo Co., Ltd.), the papermaking wire speed is 1500m / min, and the raw material slurry injection pressure is 0.4kg / cm 2 The basis weight of the papermaking raw material slurry is 30g / m 2 The first paper substrate layer.

[0108] Next, using an oriented sheet former (trade name; manufactured by Kumagai Riki Kogyo Co., Ltd.), at a papermaking wire speed of 1500 m / min and a raw material slurry injection pressure of 0.4 k...

Embodiment 3

[0112] 90 parts by mass of LBKP (freeness (CSF) = 400 ml) and 10 parts by mass of NBKP (freeness (CSF) = 450 ml) were mixed to give a pulp slurry, and 0.7 parts by mass of polypropylene used as a paper strengthening agent was added thereto Amide resin (trade name: PS3874-20, manufactured by Arakawa Chemical Industry Co., Ltd.) and 6 parts by mass of precipitated calcium carbonate (TAMAPEARL TP-121, manufactured by Okutama Industry Co., Ltd.) used as a filler. The resulting mixture was diluted with white water to prepare a first papermaking stock slurry having a pH of 5.8 and a solid matter concentration of 0.4%.

[0113] Using an oriented sheet former (trade name; manufactured by Kumagai Riki Kogyo Co., Ltd.), the speed of the papermaking wire is 600m / min, and the injection pressure of the raw material slurry is 1.2kg / cm 2 The basis weight of the papermaking raw material slurry is 30g / m 2 The first paper substrate layer.

[0114] Next, using an oriented sheet former (trade n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com