Bismuth ferrite based two-phase magnetic composite powder and preparation method thereof

A technology of composite powder and bismuth ferrite, which is applied in the field of material science, can solve the problems of small saturation magnetization and coercive field of bismuth ferrite powder, little research, limited application, etc., and is convenient for large-scale production and preparation. The method is simple and the effect of improving the comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

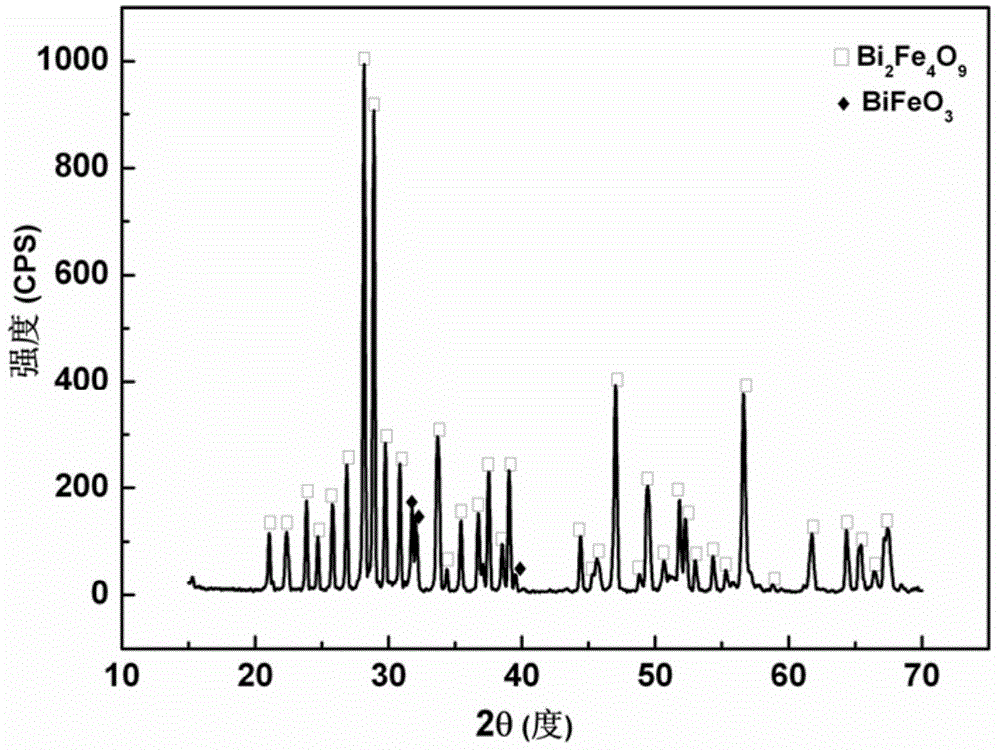

Embodiment 1

[0029] The general chemical formula Bi of a bismuth ferrite-based two-phase magnetic composite powder 2 Fe (4-x) co x o 9 , where x is the mass percentage of doped Co, x=0.01.

[0030] The preparation method of the above-mentioned bismuth ferrite-based two-phase magnetic composite powder comprises the following steps:

[0031] 1) According to the general chemical formula Bi 2 Fe (4-x) co x o 9 Analytical pure Bi(NO 3 ) 3 , Fe(NO 3 ) 3 9H 2 O and Co(NO 3 ) 2 9H 2After O is mixed, then add citric acid aqueous solution, then adopt ethylenediamine to adjust the pH value to be 6, at room temperature, under magnetic stirring, stir 2 hours to obtain sol; Wherein, the amount of the substance of the citric acid in the citric acid aqueous solution is Bi (NO 3 ) 3 , Fe(NO 3 ) 3 9H 2 O and Co(NO 3 ) 2 9H 2 3 times the amount of the total substance of the metal ion in O; the quality of water in the citric acid aqueous solution is Bi(NO 3 ) 3 , Fe(NO 3 ) 3 9H 2 O...

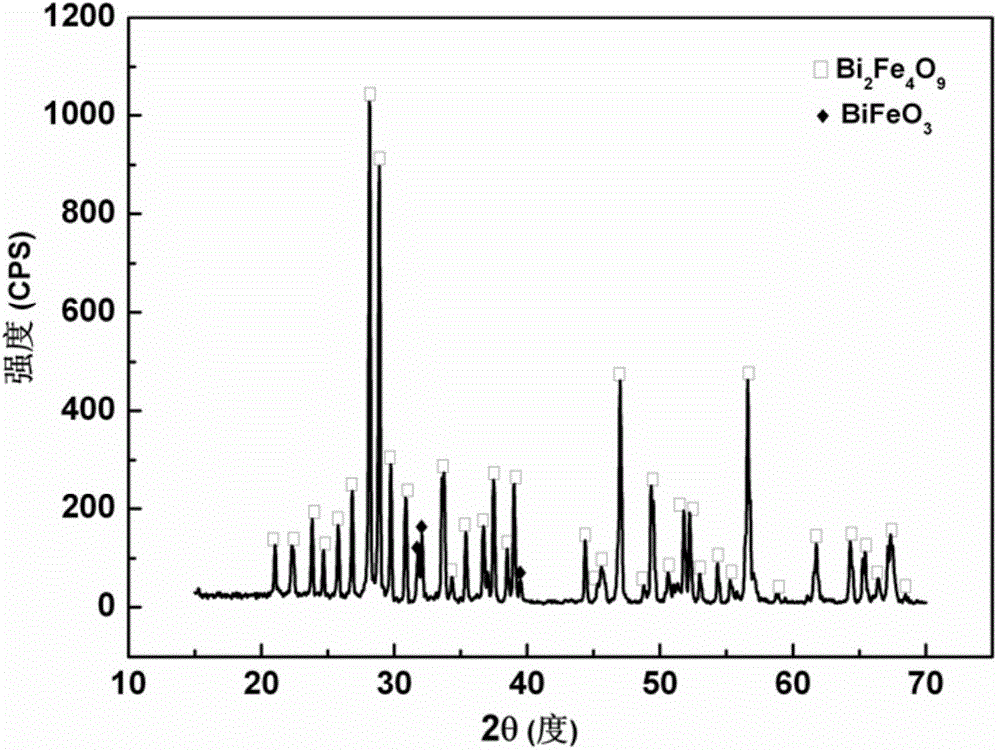

Embodiment 2

[0036] The general chemical formula Bi of a bismuth ferrite-based two-phase magnetic composite powder 2 Fe (4-x) co x o 9 , where x is the mass percentage of doped Co, x=0.02.

[0037] The preparation method of the above-mentioned bismuth ferrite-based two-phase magnetic composite powder comprises the following steps:

[0038] 1) According to the general chemical formula Bi 2 Fe (4-x) co x o 9 Analytical pure Bi(NO 3 ) 3 , Fe(NO 3 ) 3 9H 2 O and Co(NO 3 ) 2 9H 2 After O is mixed, then add citric acid aqueous solution, then adopt ethylenediamine to adjust the pH value to be 7, at room temperature under magnetic stirring, stir 3 hours to obtain sol; Wherein, the amount of the substance of the citric acid in the citric acid aqueous solution is Bi (NO 3 ) 3 , Fe(NO 3 ) 3 9H 2 O and Co(NO 3 ) 2 9H 2 4 times the amount of the total substance of the metal ion in O; the mass of water in the citric acid aqueous solution is Bi(NO 3 ) 3 , Fe(NO 3 ) 3 9H 2 O an...

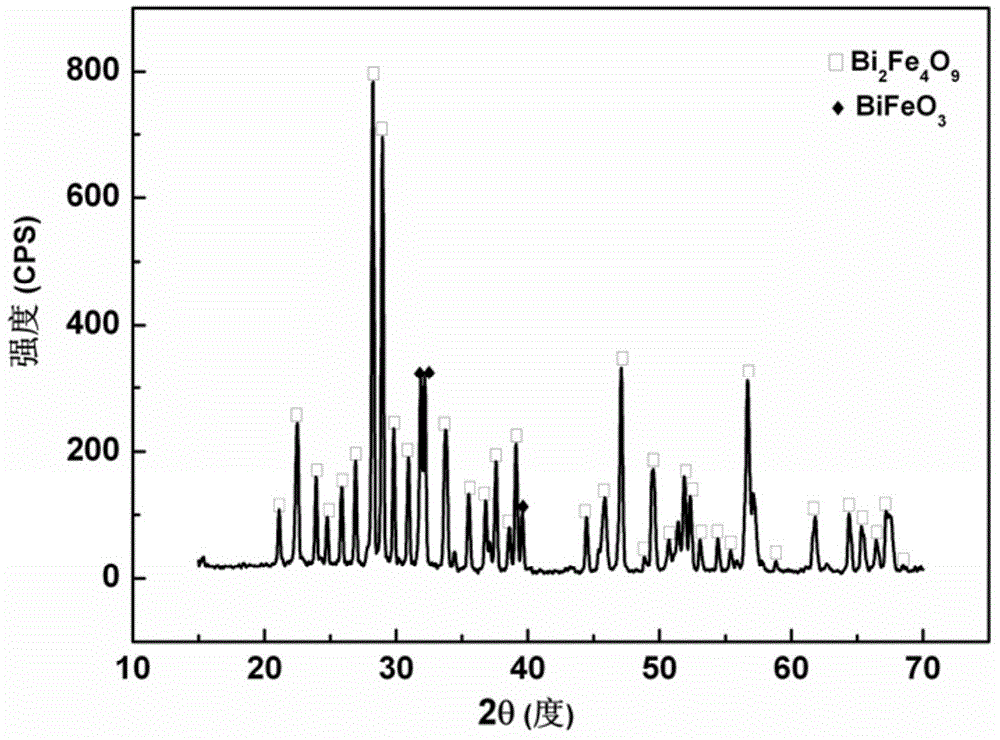

Embodiment 3

[0043] The general chemical formula Bi of a bismuth ferrite-based two-phase magnetic composite powder 2 Fe (4-x) co x o 9 , where x is the mass percentage of doped Co, x=0.05.

[0044] The preparation method of the above-mentioned bismuth ferrite-based two-phase magnetic composite powder comprises the following steps:

[0045] 1) According to the general chemical formula Bi 2 Fe (4-x) co x o 9 Analytical pure Bi(NO 3 ) 3 , Fe(NO 3 ) 3 9H 2 O and Co(NO 3 ) 2 9H 2 After O is mixed, then add citric acid aqueous solution, then adopt ethylenediamine to adjust the pH value to be 6.5, at room temperature under magnetic stirring, stir 2.5 hours to obtain sol; Wherein, the amount of the substance of the citric acid in the citric acid aqueous solution is Bi (NO 3 ) 3 , Fe(NO 3 ) 3 9H 2 O and Co(NO 3 ) 2 9H 2 3.5 times of the total substance amount of metal ion in O; the mass of water in citric acid aqueous solution is Bi(NO 3 ) 3 , Fe(NO 3 ) 3 9H 2 O and Co(N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com