Polycrystalline diamond compacts, method of fabricating same, and various applications

A polycrystalline diamond, composite sheet technology, applied in the manufacture of tools, shafts and bearings, earth-moving drilling, etc., can solve problems such as PDC failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

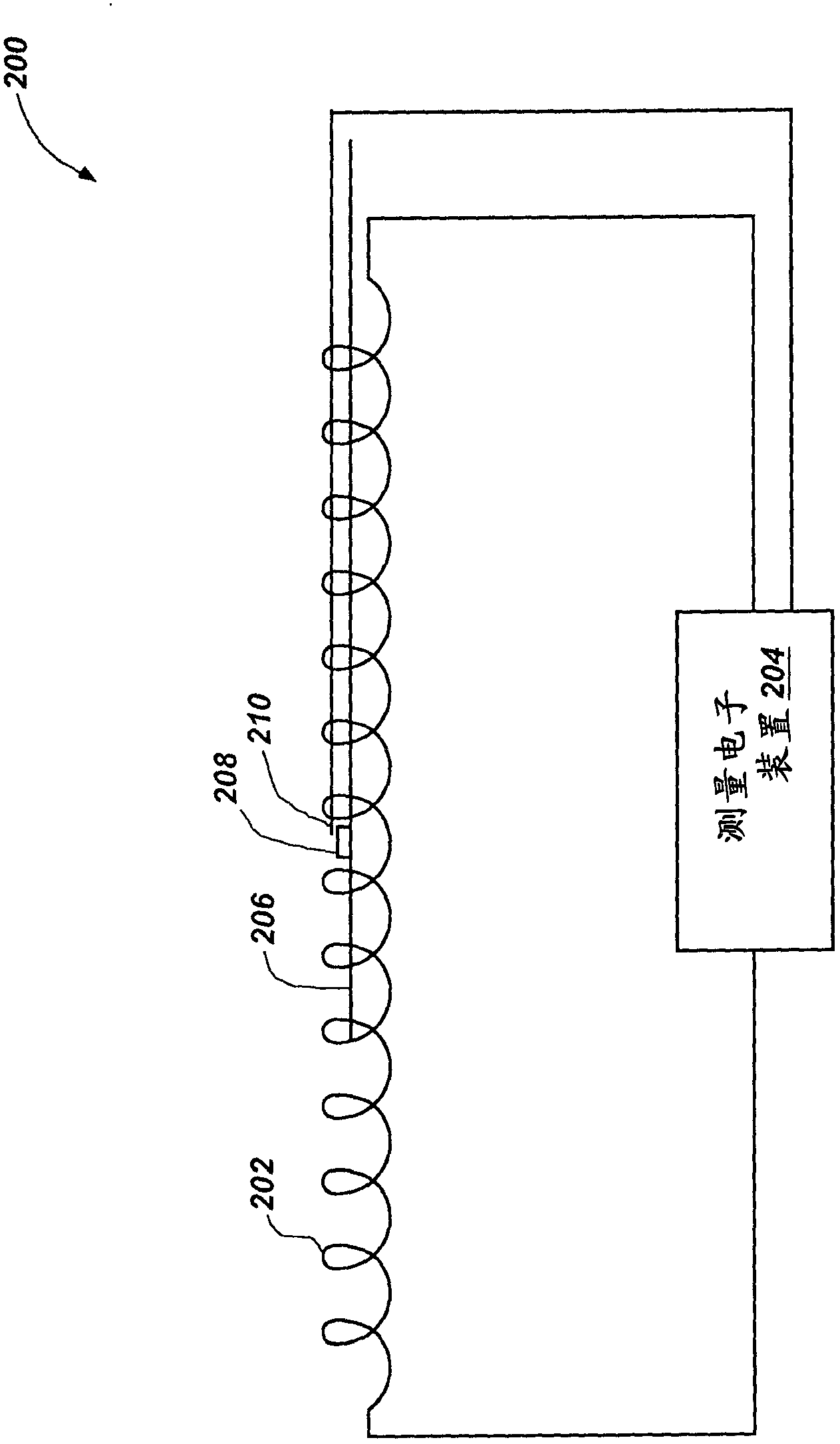

[0032] Embodiments of the invention relate to PCDs exhibiting enhanced diamond-to-diamond bonding. The inventors currently believe that the rate of diamond nucleation and growth increases as the sintering pressure used during the HPHT process used to make such PCD moves further away from the graphite-diamond equilibrium line into the diamond stable region. This increased diamond nucleation and growth between diamond particles (for a given diamond particle formulation) can lead to the formation of PCD exhibiting one or more of the following properties: relatively low metal solvent catalyst content, high coercive force, lower specific magnetic saturation, or lower specific magnetic permeability (ie, the ratio of specific magnetic saturation to coercive force), compared to PCD formed at lower sintering pressures. Embodiments also relate to PDCs having PCD tables containing such PCDs, methods of making such PCDs and PDCs, and such PCDs and PDCs in rotary drill bits, bearing device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com