Method for preparing magnetic sensitive microstructure unit by femtosecond laser non-mask method

A femtosecond laser and magnetically sensitive technology, which is applied in the manufacture of microstructure devices, microstructure technology, microstructure devices, etc., can solve the problem of long production cycle, difficult micro-nanoscale processing, unsuitable for single-piece, small-batch production and Problems such as the trial production of new products, to achieve the effect of short pulse duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: Prepare the magnetically sensitive microstructure unit according to the following steps

[0015] Step 1: Deposit a buffer layer Cr with a thickness of 5nm and a ferromagnetic layer CoPt with a thickness of 40nm on the cleaned single crystal silicon substrate by using high-vacuum magnetron sputtering equipment to obtain a magnetic recording film; wherein, the growth conditions of the magnetic layer For: back vacuum 5×10 -6 Pa; sputtering pressure 0.3Pa; sputtering power 10W; argon flow rate 20sccm; substrate temperature 100°C;

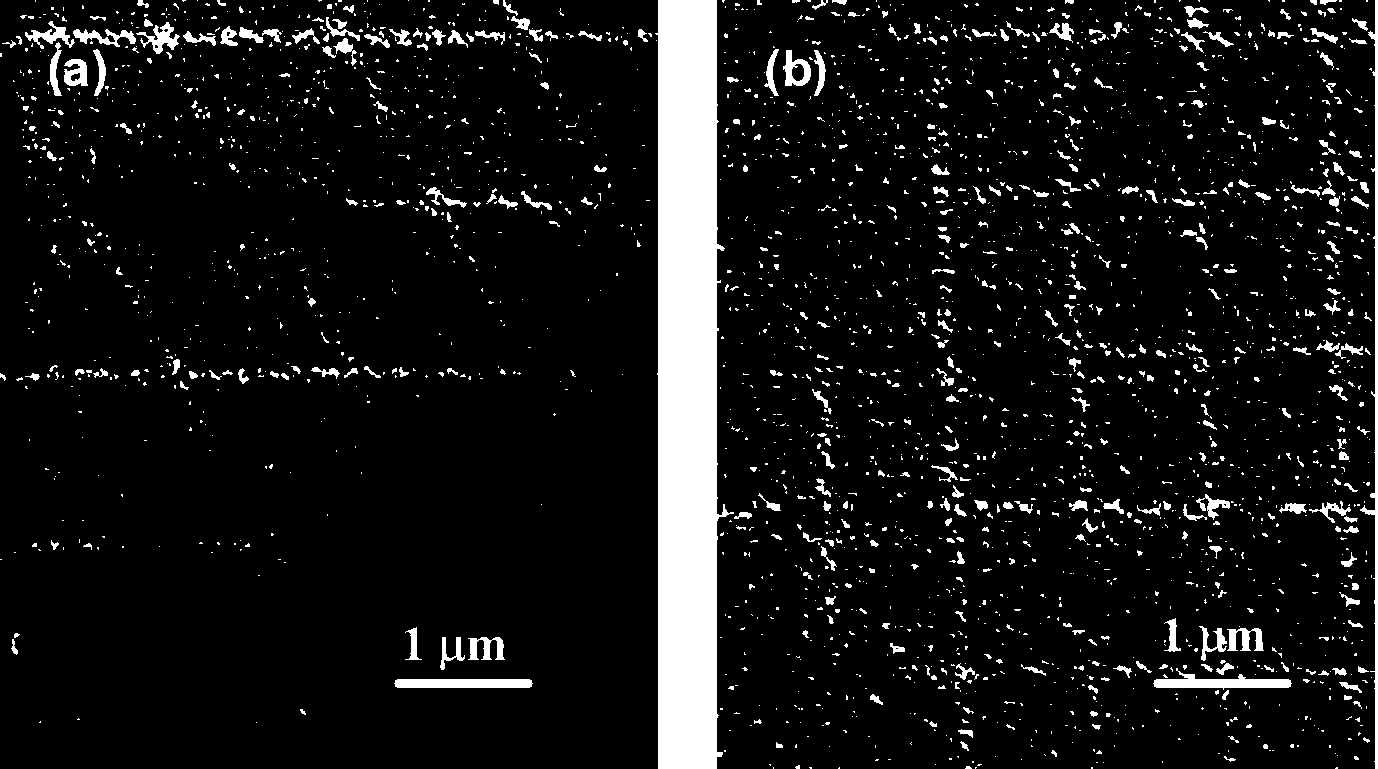

[0016] Step 2. Use femtosecond laser as light source to irradiate the magnetic thin film. After the irradiation is completed, a triangular magnetically sensitive microstructure unit is obtained; wherein, the parameters of the femtosecond laser are: single pulse energy 5 μJ; pulse width 90fs ; Wavelength 800nm; Pulse frequency 50Hz; Among them, an induced magnetic field of 500Oe is applied along the direction perpendicular to the su...

Embodiment 2

[0017] Example 2: Prepare the magnetically sensitive microstructure unit according to the following steps

[0018] Step 1, using high vacuum magnetron sputtering equipment to deposit a magnetic layer Tb-Dy-Fe with a thickness of 500nm and a protective layer Ta with a thickness of 5nm on the cleaned glass substrate to obtain a giant magnetostrictive film; The growth condition of the layer is: background vacuum 5×10 -6 Pa; sputtering pressure 0.5Pa; sputtering power 120W; argon flow 20sccm; substrate temperature 300°C;

[0019] Step 2. Use femtosecond laser as light source without applying an induced magnetic field to irradiate the magnetic thin film. After the irradiation is completed, a magnetically sensitive microstructure unit with a unit shape of a rectangle is obtained; wherein, the parameters of the femtosecond laser are: single pulse energy 50 μJ The pulse width is 100fs; the wavelength is 800nm; the pulse frequency is 100Hz; the moving track of the sample stage is pr...

Embodiment 3

[0020] Example 3: Prepare the magnetically sensitive microstructure unit according to the following steps

[0021] Step 1, utilize high-vacuum magnetron sputtering equipment to deposit a buffer layer Ta with a thickness of 5nm, a CoFe ferromagnetic layer with a thickness of 5nm, an IrMn antiferromagnetic layer with a thickness of 12nm, and a thickness of 12nm on the cleaned single crystal silicon substrate. A protective layer Ta of 8nm was obtained to obtain a ferromagnetic / antiferromagnetic double-layer film; wherein, the growth condition of the magnetic layer was: background vacuum 5×10 -6 Pa; sputtering pressure 0.3Pa; sputtering power 30W; argon flow 20sccm; substrate temperature at room temperature;

[0022] Step 2. Use femtosecond laser as light source to irradiate the magnetic thin film. After the irradiation is completed, a magnetically sensitive microstructure unit whose unit shape is a regular hexagon is obtained; wherein, the parameters of the femtosecond laser ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com